High-voltage multifunctional two-position three-way solenoid valve

A two-position three-way, electromagnetic valve technology, applied in high-pressure air supply or oil supply systems of weapons, aviation, aerospace fields, can solve the problems of high machining and assembly precision, difficult debugging and maintenance of electromagnetic valves, etc., to achieve flow Smooth passage, high sealing pressure, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

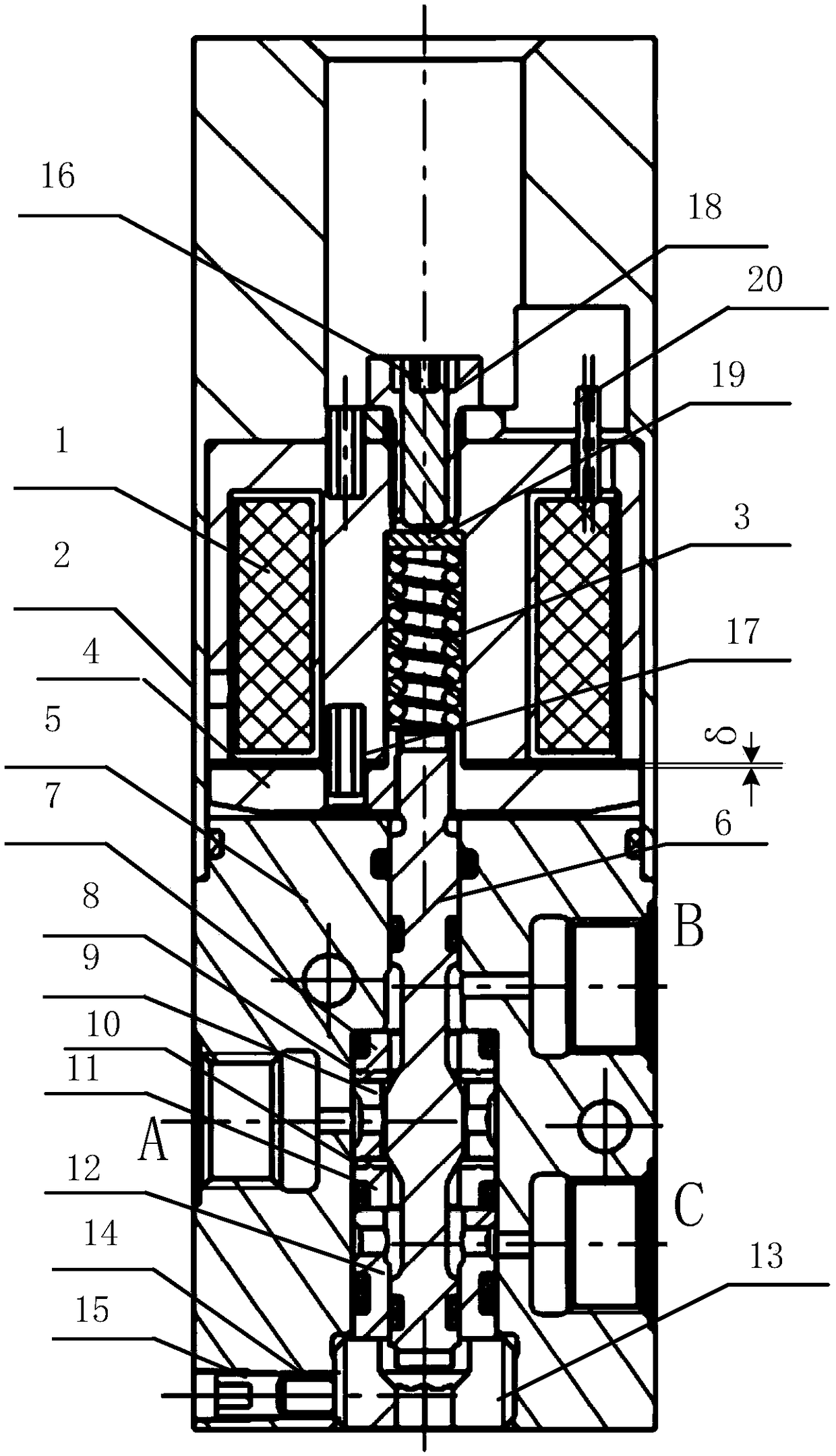

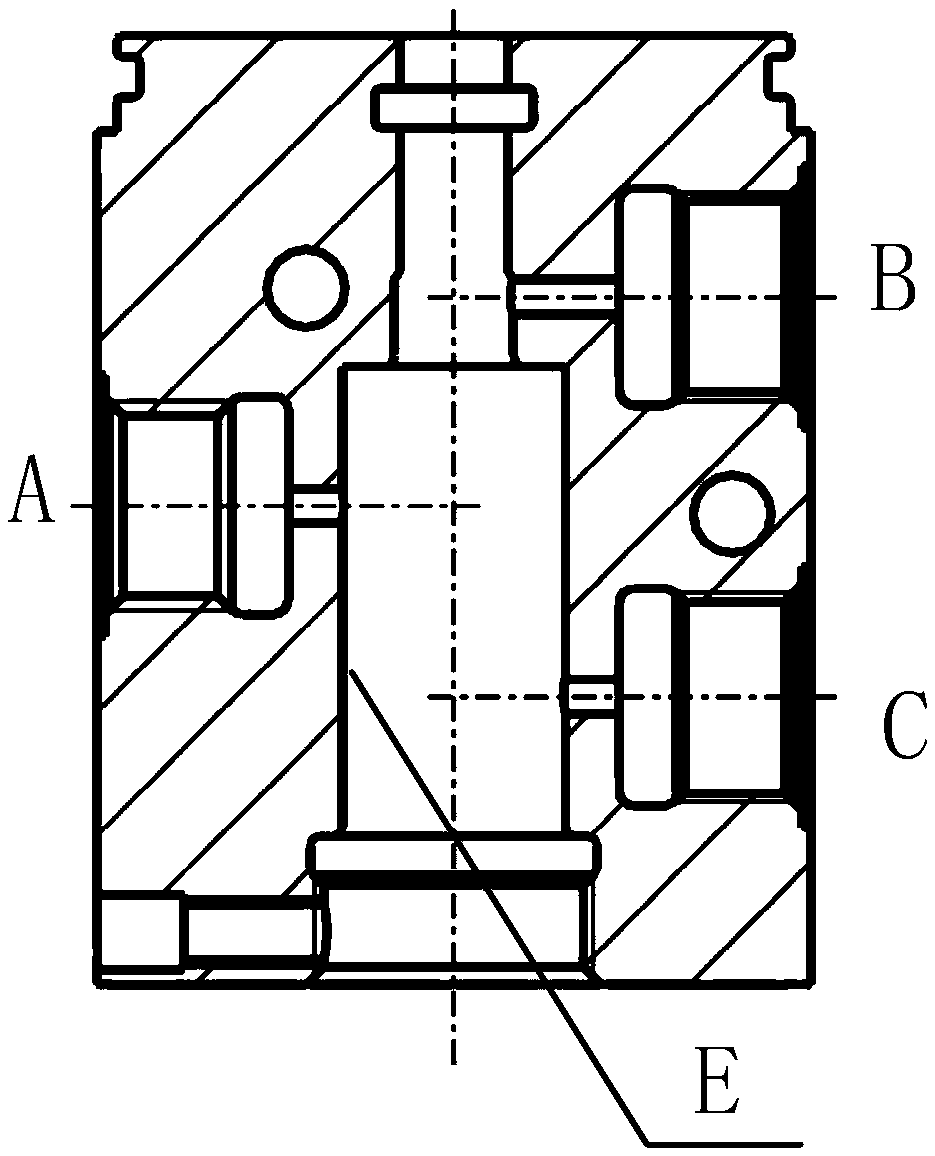

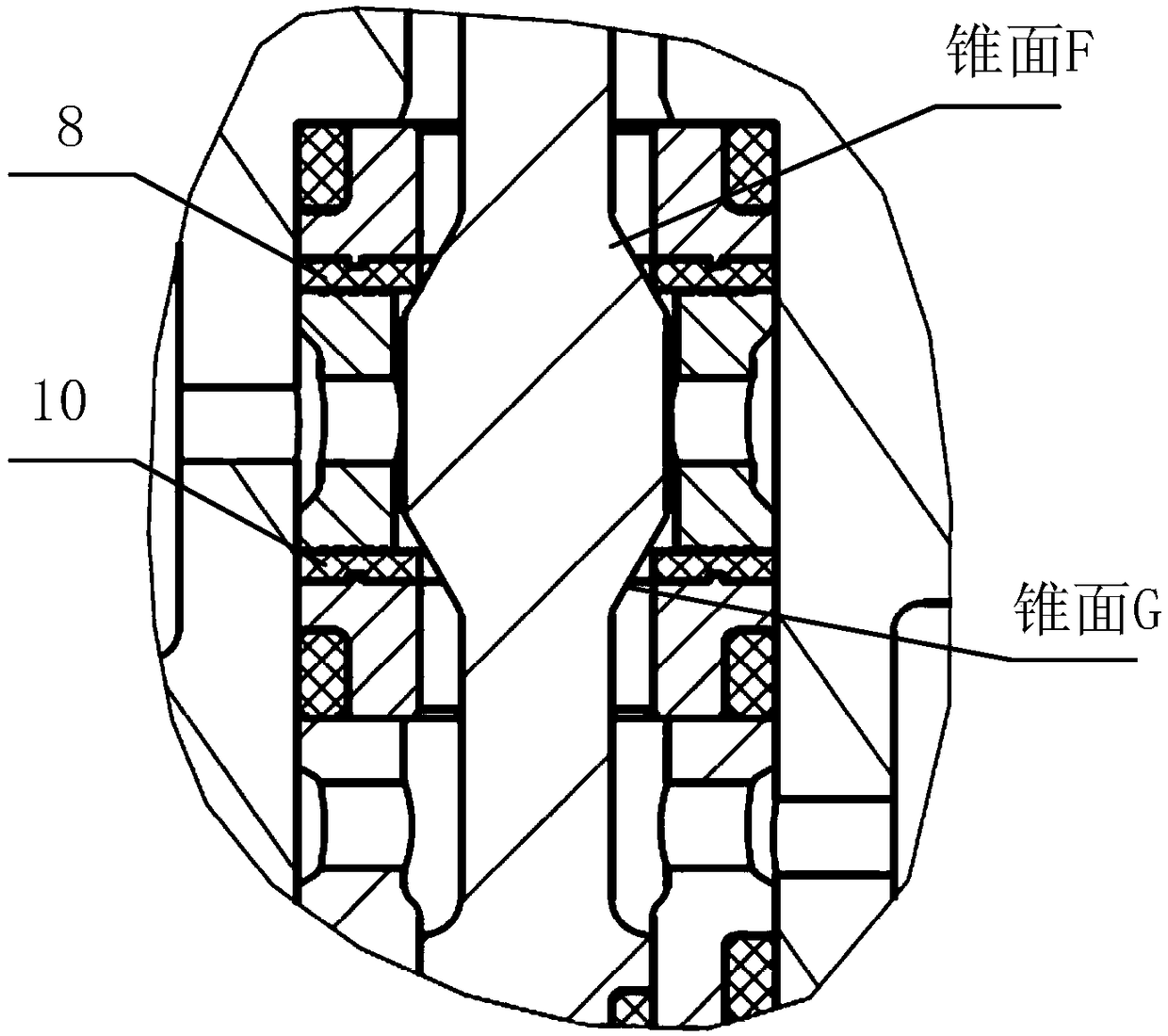

[0033] Such as Figure 1-9 Shown is the structural diagram of the high-voltage, high-reliability, multi-functional two-position three-way solenoid valve of the present invention. It can be seen from the figure that the high-pressure, high-reliability multi-function two-position three-way solenoid valve includes an electromagnet 1, an electromagnet housing 2, a return spring 3, and an armature. 4. Valve body 5, valve stem 6, upper valve seat 7, upper valve port gasket 8, middle valve sleeve 9, lower valve port gasket 10, lower valve seat 11, bottom valve sleeve 12, nut 13, anti-loosening rod 14. Jacking screw 15, adjusting screw 16, positioning pin 17, electromagnet locking bolt 18, spring adjusting pad 19, wire 20.

[0034] Among them, the electromagnet 1 is placed in the electromagnet housing 2 and fixed by the electromagnet locking bolt 18. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com