Secondary ejection mechanism for complex plastic product structure

A product structure and secondary ejection technology, applied in the field of injection molds, can solve the problems of high space occupation rate, high maintenance cost, complex design structure and movement process, etc., to achieve low space occupation rate, low maintenance cost, working principle Clear and understandable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

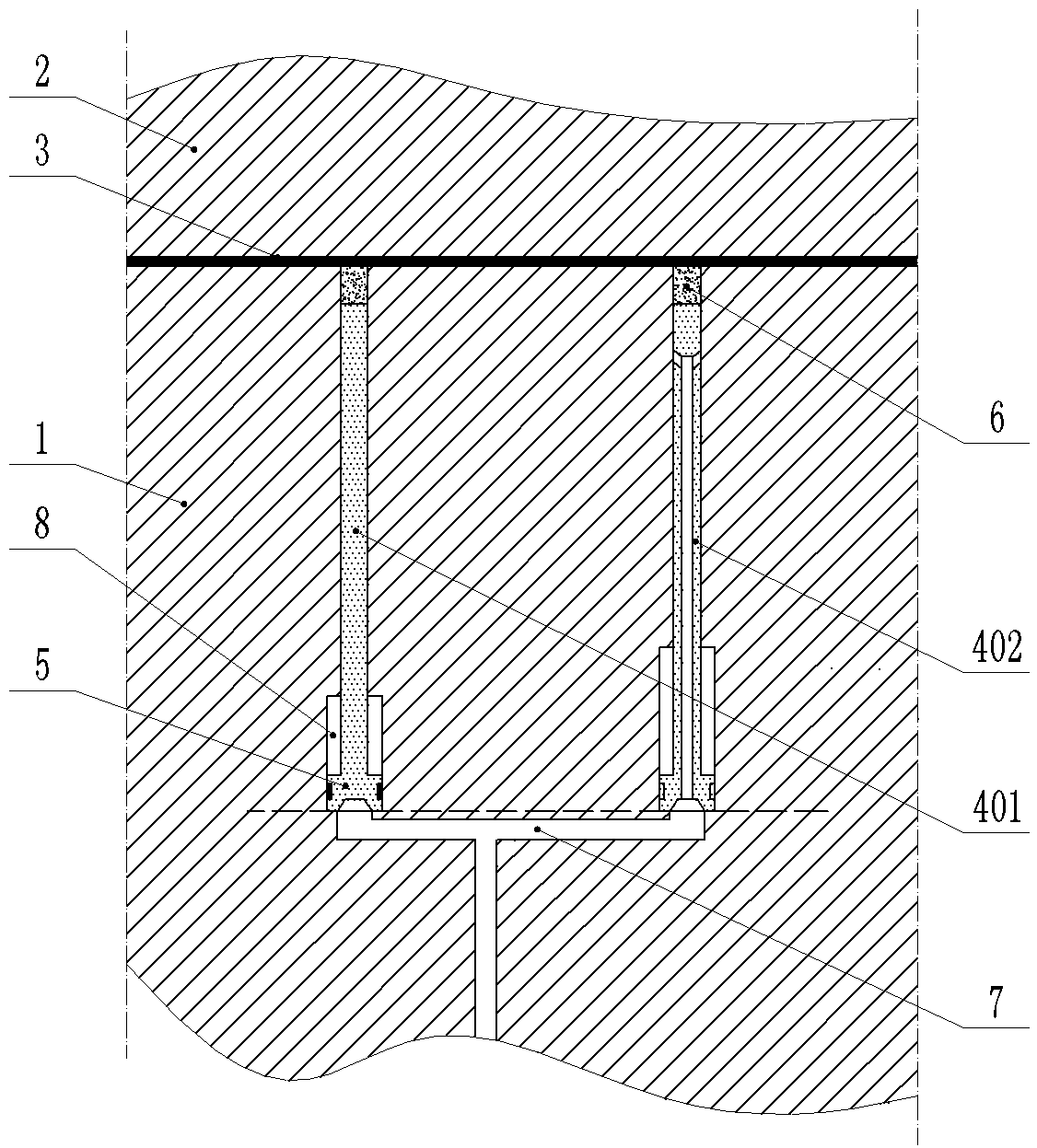

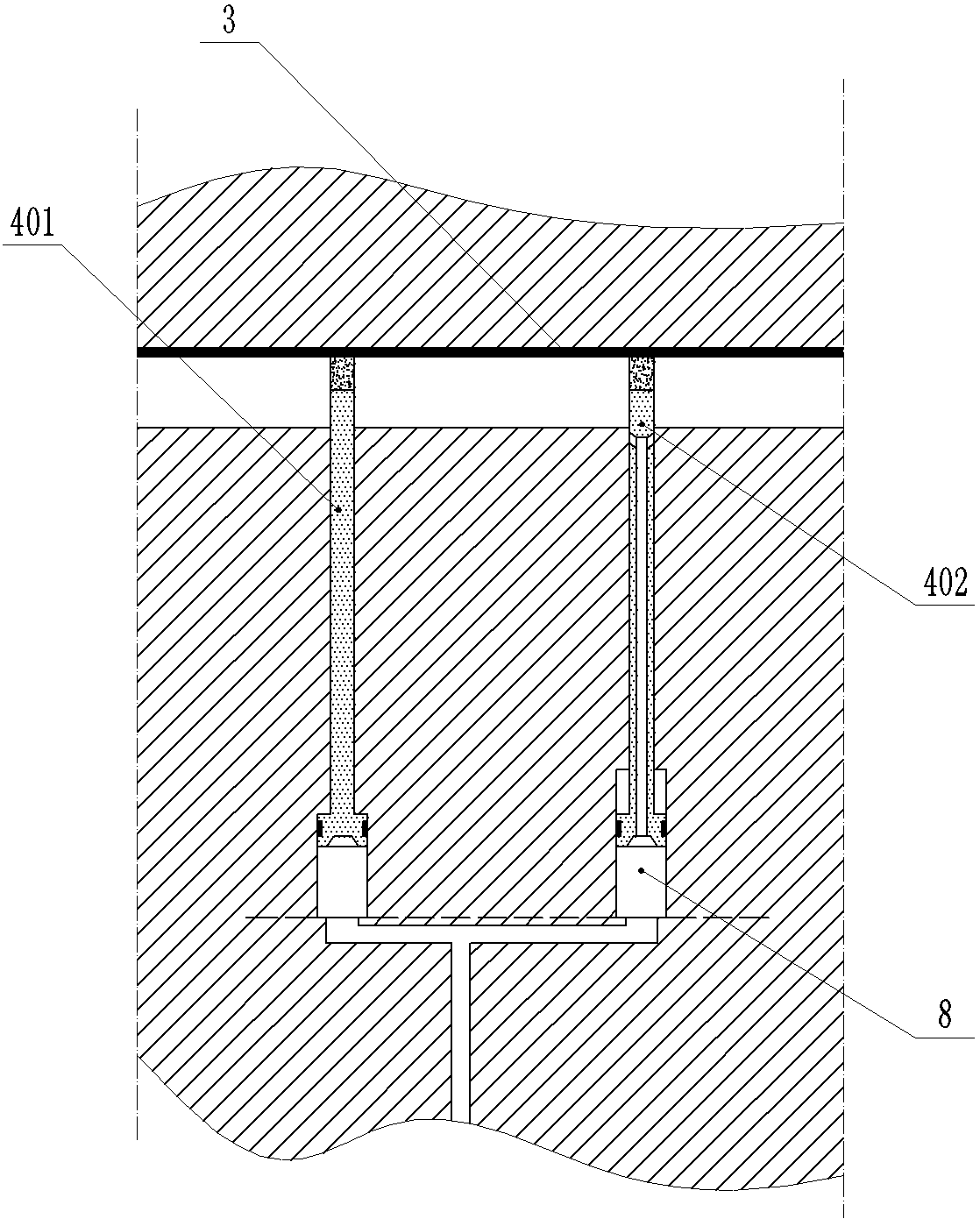

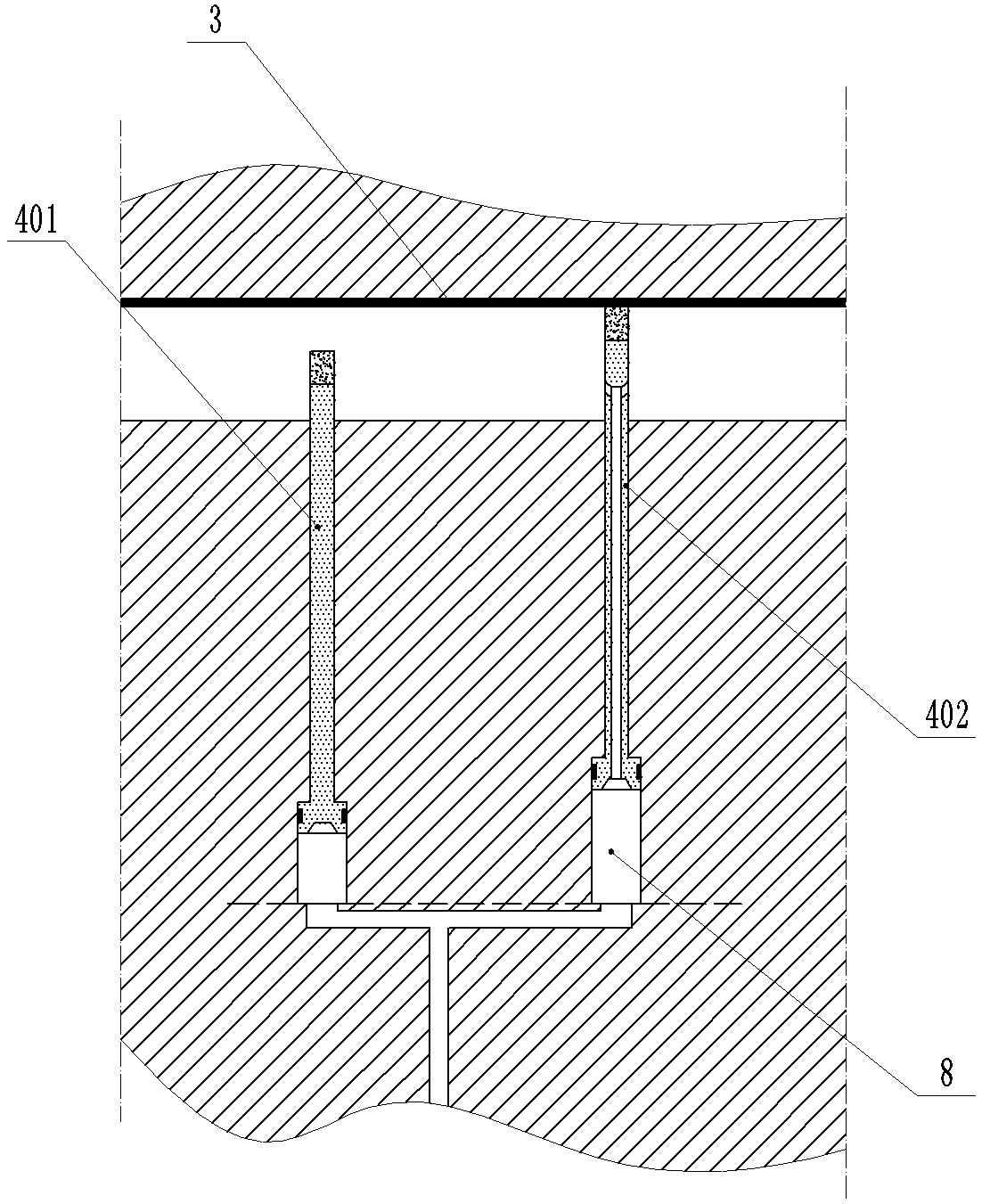

[0021] Such as figure 1 As shown, the embodiment of the present invention includes a female formwork 2 and a male formwork 1, the female formwork 2 and the male formwork 1 are closed and matched up and down, and separated and closed up and down driven by a cylinder. The male template 1 is provided with several thimble mechanisms, and the ejector mechanism is used to separate the product 3 from the male template 1 . The thimble mechanism includes a top hole arranged on the male template 1 and a thimble fitted in the top hole. The top hole includes a sliding hole connecting the upper end surface of the male template 1 and a piston hole 8 arranged at the lower end of the sliding hole. The thimble includes a sliding fit in the sliding hole. The push rod in the hole and the piston 5 fixed on the lower end of the push rod, the piston 5 is slidingly fitted in the piston hole 8, that is, the piston 5 slides in the piston hole 8 during work, and the push rod slides in the slide hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com