Multi-lifter ejection device

A technology of ejecting device and inclined roof, applied in the field of mold ejecting device, can solve problems such as damage to product 2, easy sticking of product 2 to the inclined roof 3, easy compression molding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

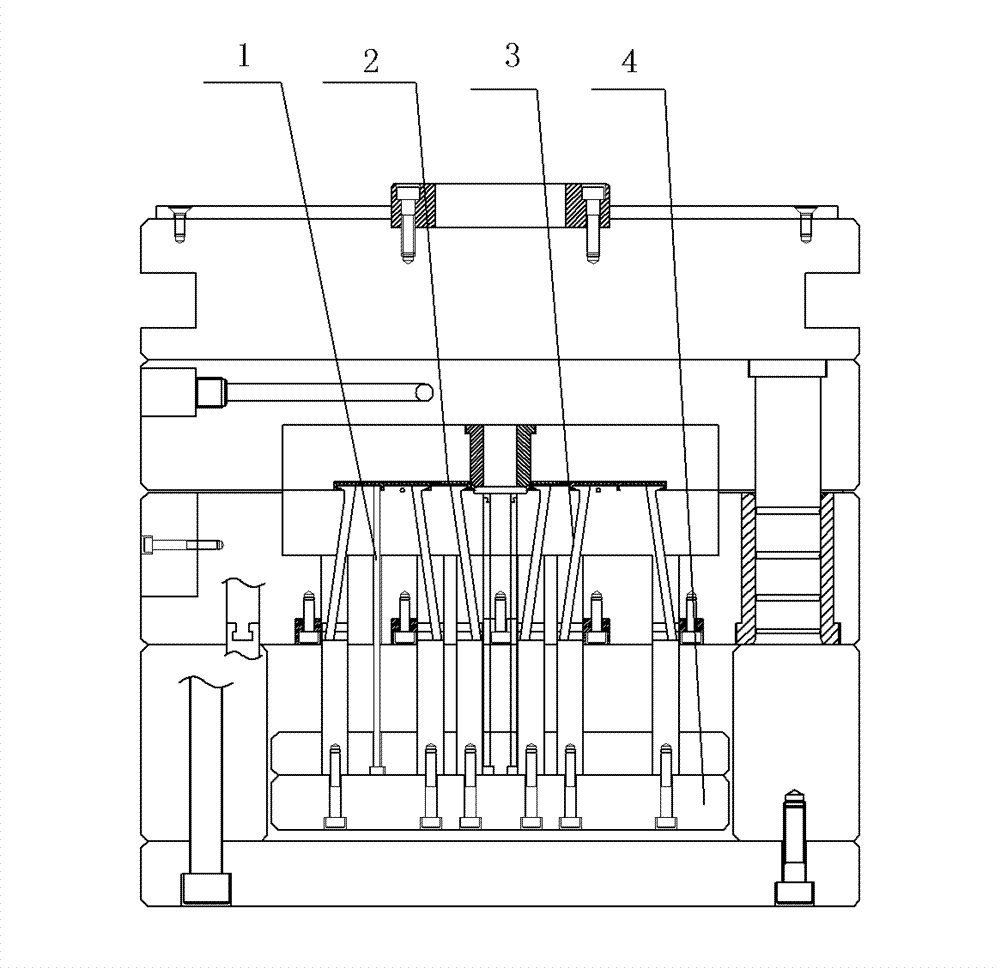

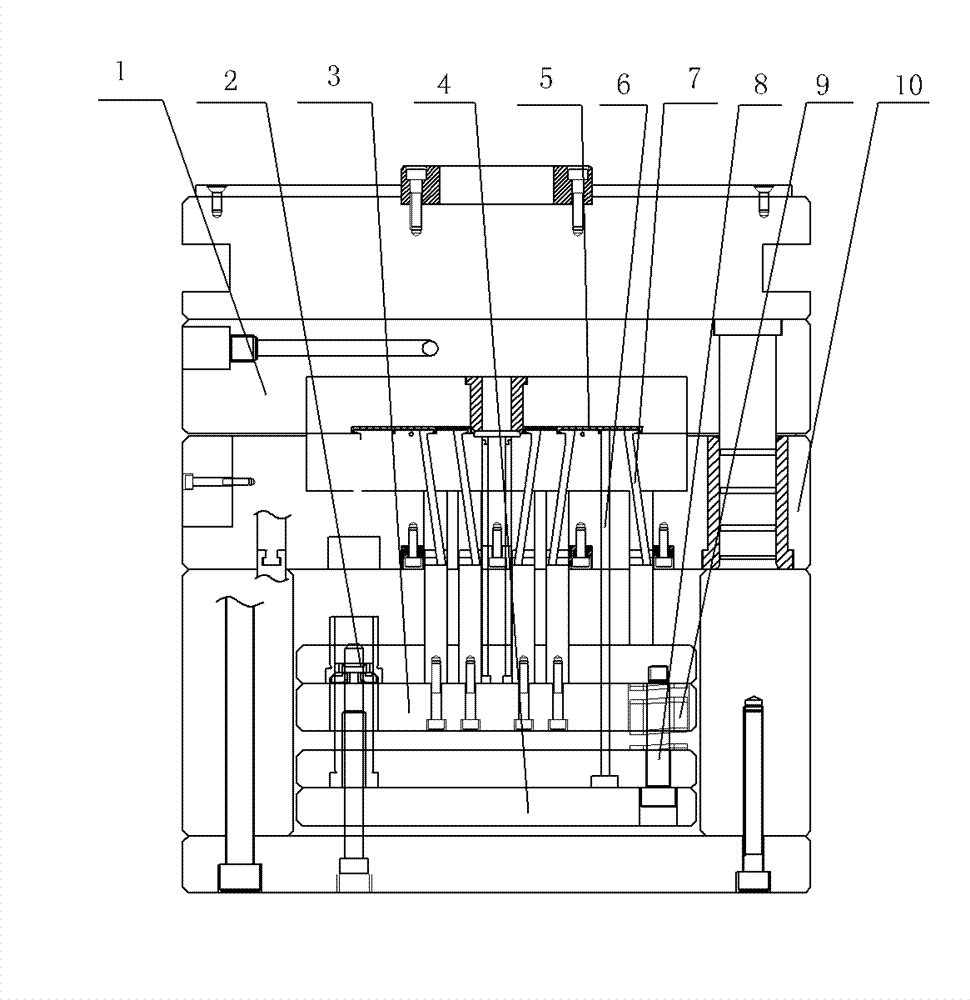

[0008] See figure 2 , the ejector device of the present invention, which includes an upper mold 1, a lower mold 10, an inclined ejector 7, an ejector pin 6, an upper ejector plate 3 and a lower ejector plate 4, and an end between the upper ejector plate 3 and the lower ejector plate 4 The push plate early return device 2 is used for flexible connection, and the other end is connected with spring 9 and bolt 8. When the mold is opened, the lower ejector plate 4 is ejected, and the lower ejector plate 4 is ejected twice through the push plate early return device 2 to realize The ejector pin 6 and the inclined ejector 7 are ejected at the same time, then the inclined ejector 7 stops, the ejector pin 6 continues to eject, and the product 5 is ejected, so that the product 5 will not stick to the inclined ejector 7, and the bolt 8 guides and The pressure of the spring 9 makes the lower ejector plate 4 reset accurately, which prevents the product from being molded when the inclined e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com