Simple secondary ejecting mechanism

A secondary ejection and simple technology, applied in the field of simple secondary ejection mechanism, can solve the problems of affecting the quality of plastic products, easily damaged plastic products, single structure, etc., achieve simple structure, uniform force, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

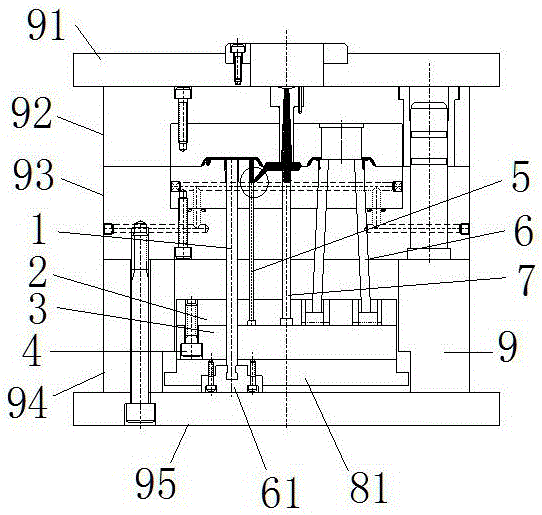

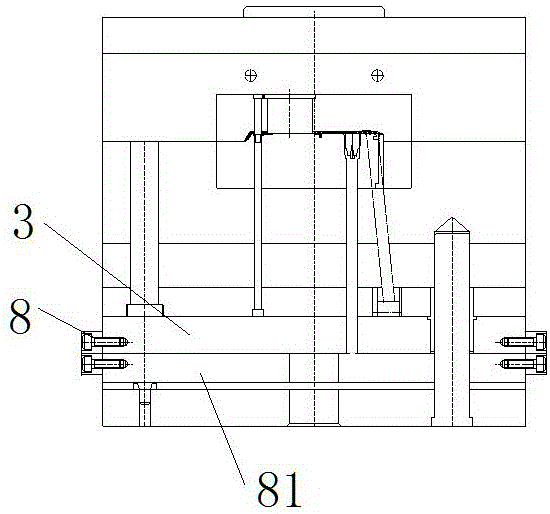

[0015] A simple secondary ejection mechanism, including a top plate 91, an upper formwork 92, a lower formwork 93, a backing plate 94 and a bottom plate 95 distributed from top to bottom, and a gate is vertically opened in the middle of the top plate 91 and the upper formwork 92, A cavity insert and a core insert are installed between the upper template 92 and the lower template 93, and the upper middle position of the bottom plate 95 is installed with a thimble bottom plate 81, a thimble push plate 3 and a thimble panel 2 from bottom to top, and the thimble bottom plate 81 is vertically installed with a primary ejector rod 1 that pushes into the upper formwork 92, and on the thimble panel 2 is vertically installed with a secondary ejector rod 5, a material pulling rod 7 and an inclined ejector rod 6 that are pushed into the lower template 93. The rod 7 is installed in the middle position between the secondary ejector rod 5 and the inclined ejector rod 6 .

[0016] In the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com