Butterfly valve

A butterfly valve and valve body technology, applied in the field of butterfly valves, can solve the problems of seat ring deterioration, failure to achieve sealing, failure to promote sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

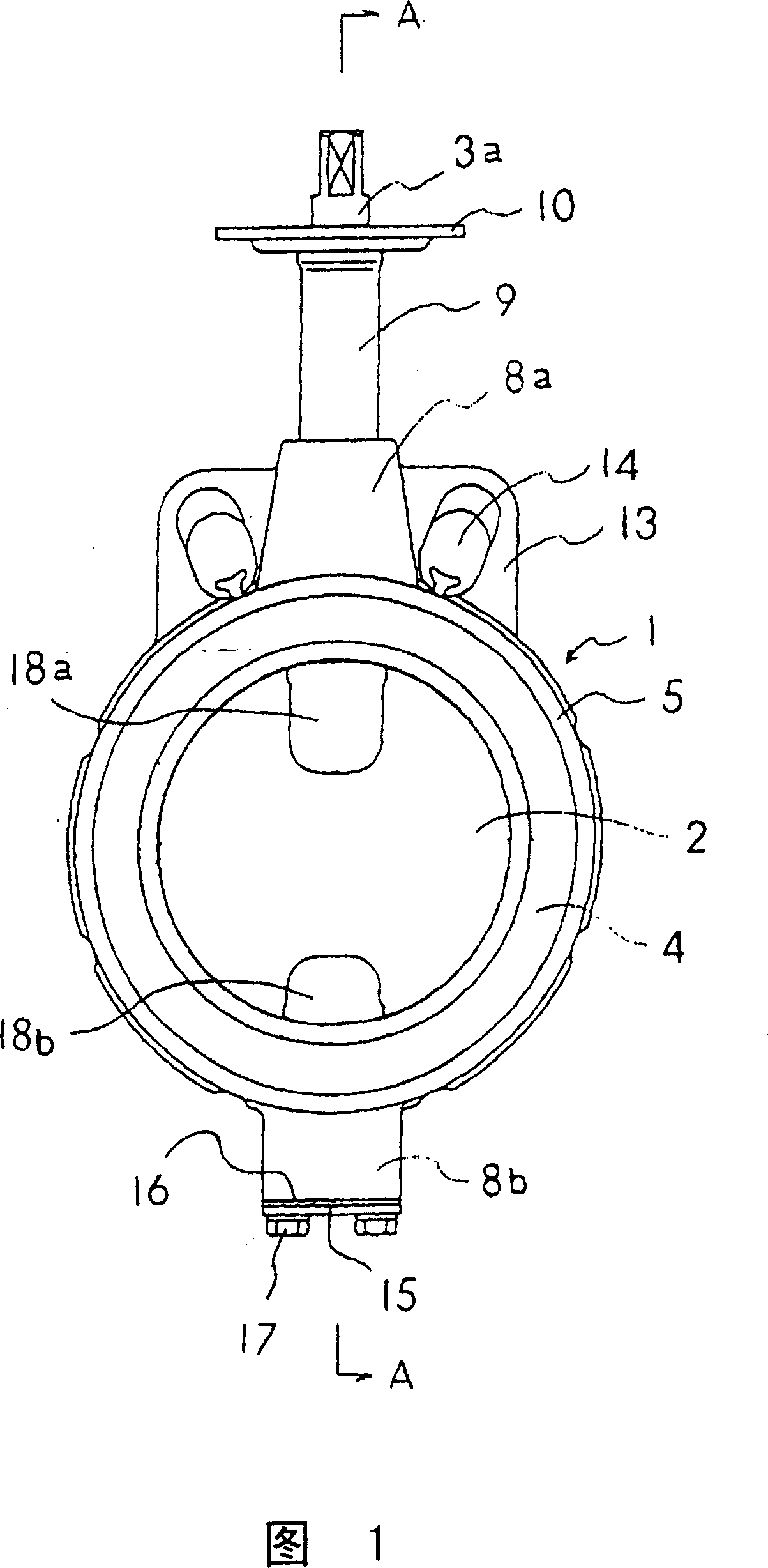

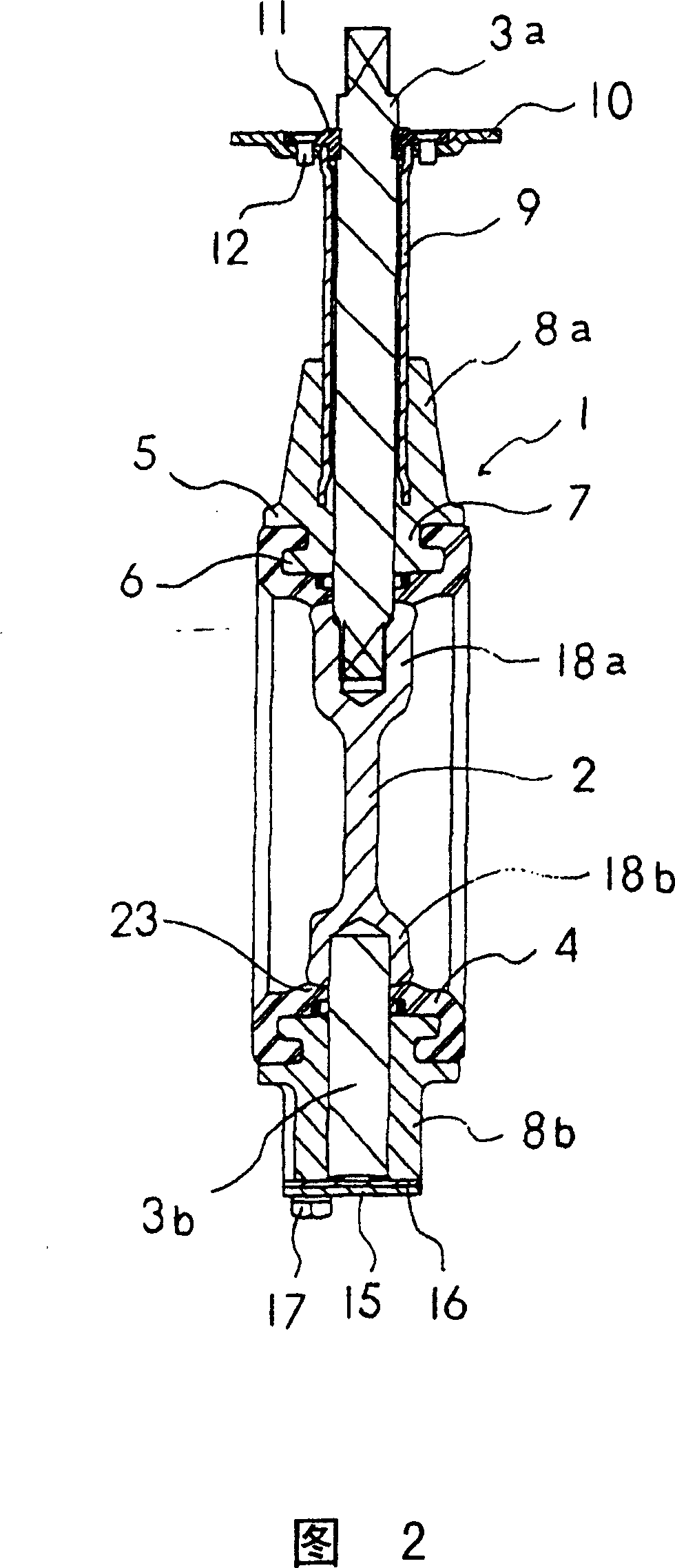

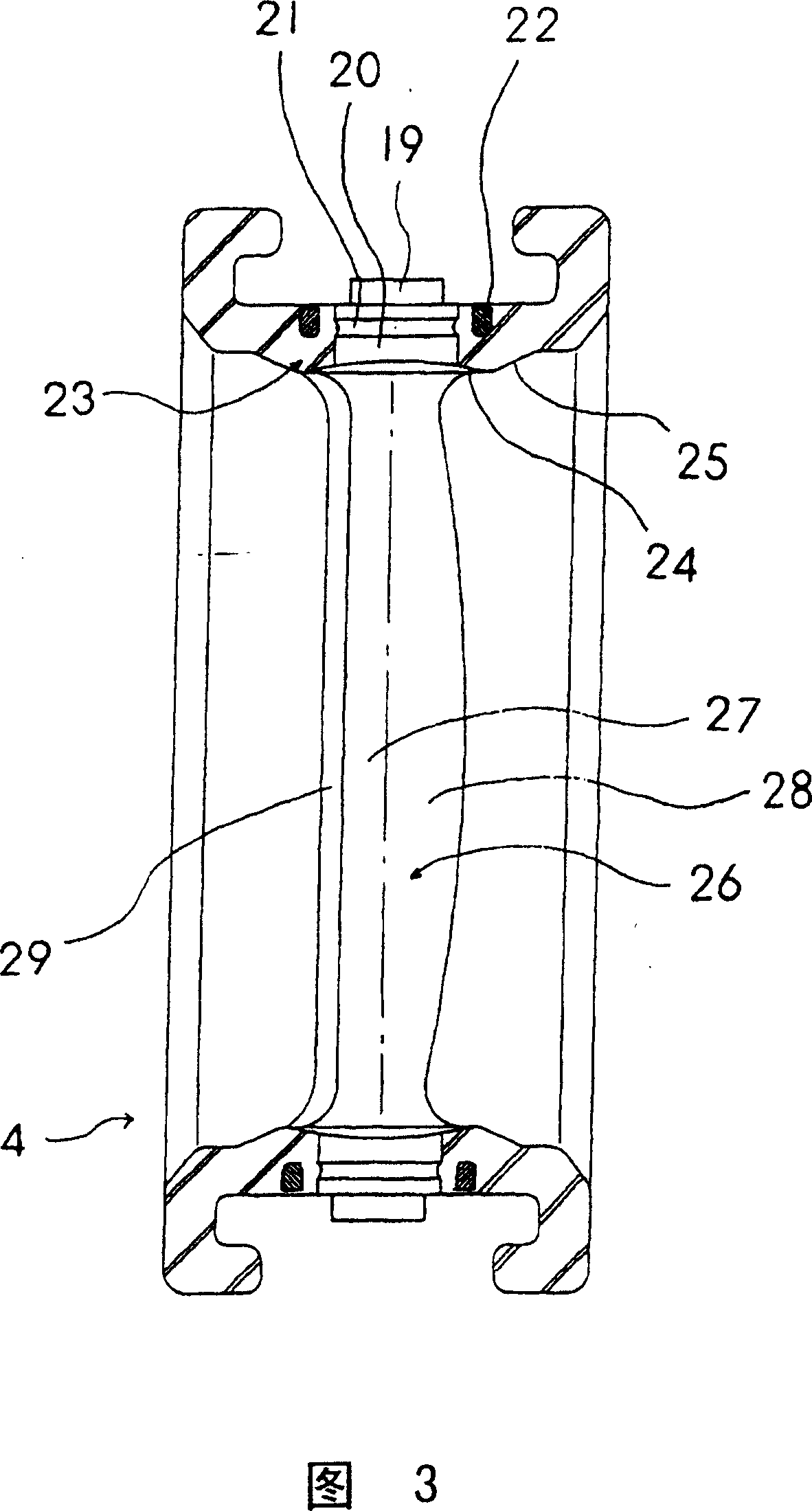

[0028] The embodiment of the butterfly valve of the present invention will be described below with the accompanying drawings. Fig. 1 is a front view of the butterfly valve of the present invention, Fig. 2 is a sectional view along the line A-A of Fig. 1, Fig. 3 is a sectional view of the seat ring along the direction of the valve axis, and Fig. 4 is a sectional view of the seat ring along the direction perpendicular to the valve axis.

[0029] The butterfly valve is set at the connecting part of the pipe that can flow in it, and performs on-off control and flow adjustment of the flow path. It has: an annular valve box 1, which is clamped by two pipes along its axial direction (flow path direction); A substantially disc-shaped valve body 2 installed inside the valve box 1; the valve body 2 is freely rotatably supported around the valve shaft 3 (the axis passing through the center of the valve box 1 in a direction perpendicular to the direction of the flow path). The valve rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com