Engine piston capable of automatically changing compression ratio

A compression ratio, engine technology, applied in the direction of engine components, machines/engines, pistons, etc., can solve the problems of inability to automatically change, difficult to control, no mass production, etc., to reduce production costs, improve thermal efficiency, and improve load thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

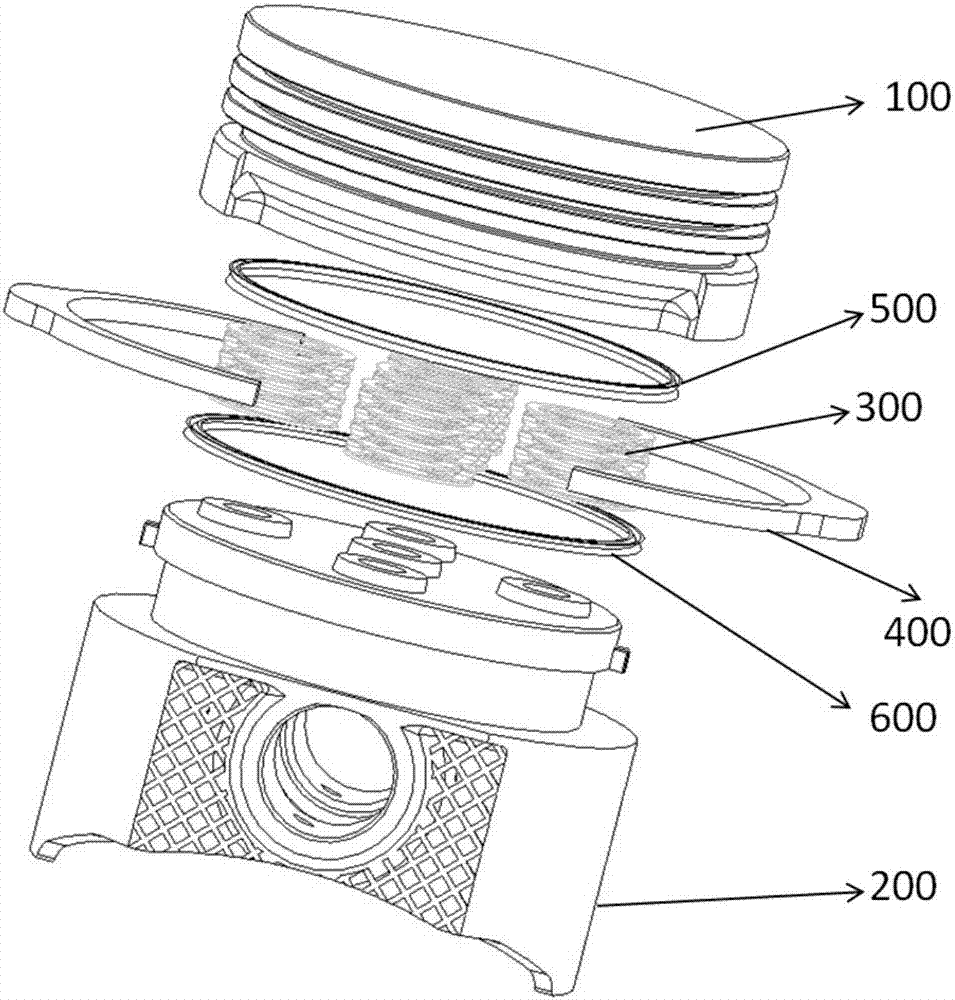

[0028] Such as figure 1 The engine piston shown is designed as two relatively slidable upper and lower parts: a piston head 100 and a piston skirt 200. And between the piston top 100 and the piston skirt 200, 5 compression springs 300 are evenly distributed around the circumference and the center of the circle (the number can be adjusted according to specific conditions) and the limit stop 400 is welded. Between the piston skirt 200 and the stop piece 400, and between the stop piece 400 and the piston head 100, an upper damping component 500 and a lower damping component 600 are respectively provided.

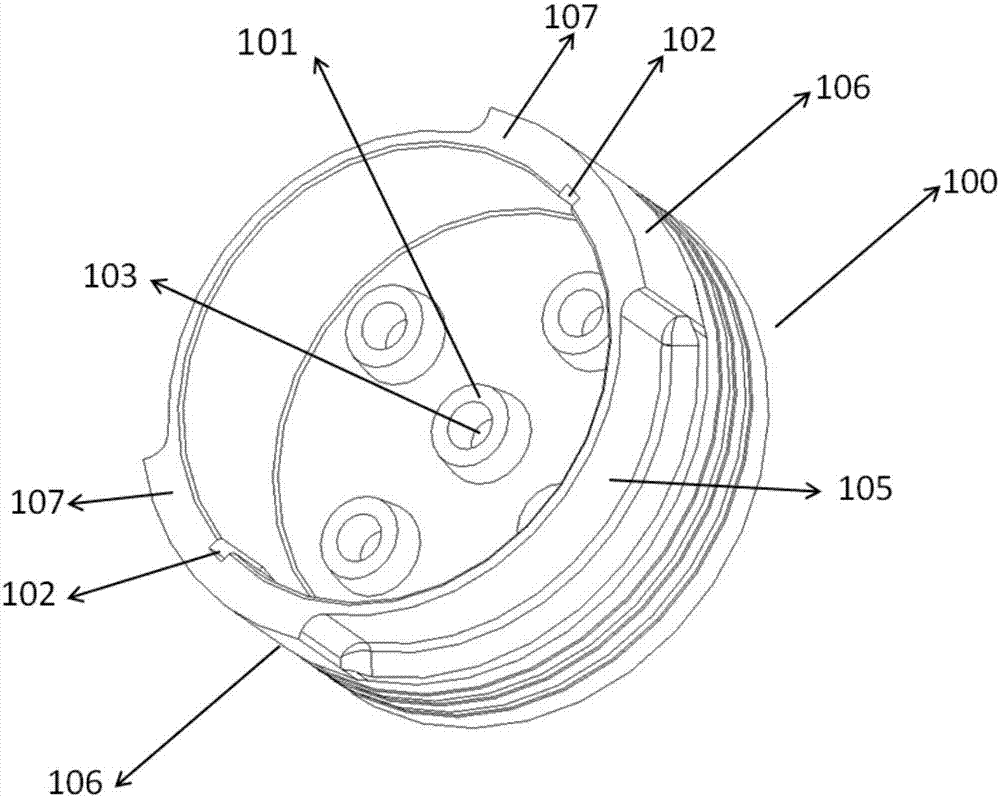

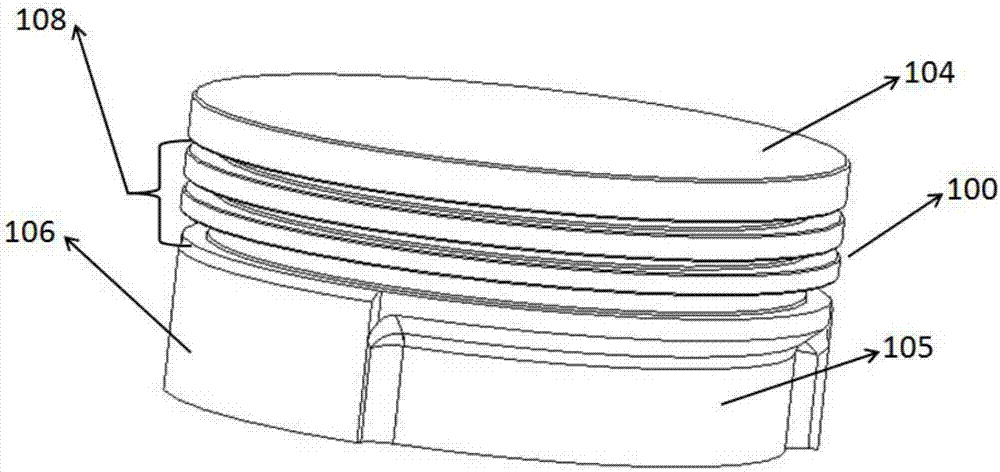

[0029] Such as figure 2 , 3 As shown, the piston head 100 includes five bosses 101 for installing the compression spring 300, which can prevent the compression spring 300 from radial displacement. The boss 101 is dug with small holes 103 to reduce the weight of the piston head 100. The boss 101 The structure is large at the bottom and small at the top for easy installation of sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com