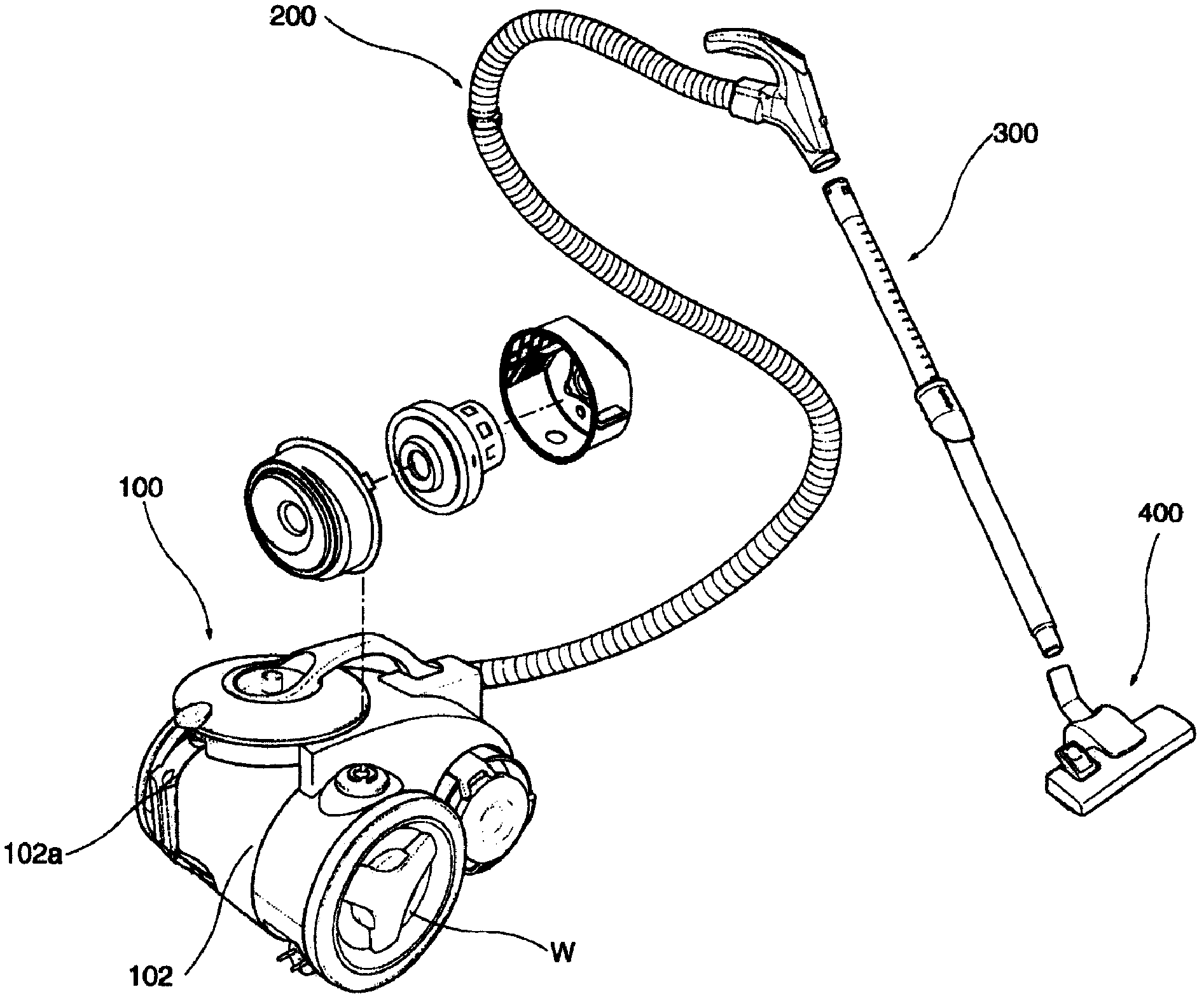

Motor casing with spiral airflow chamber

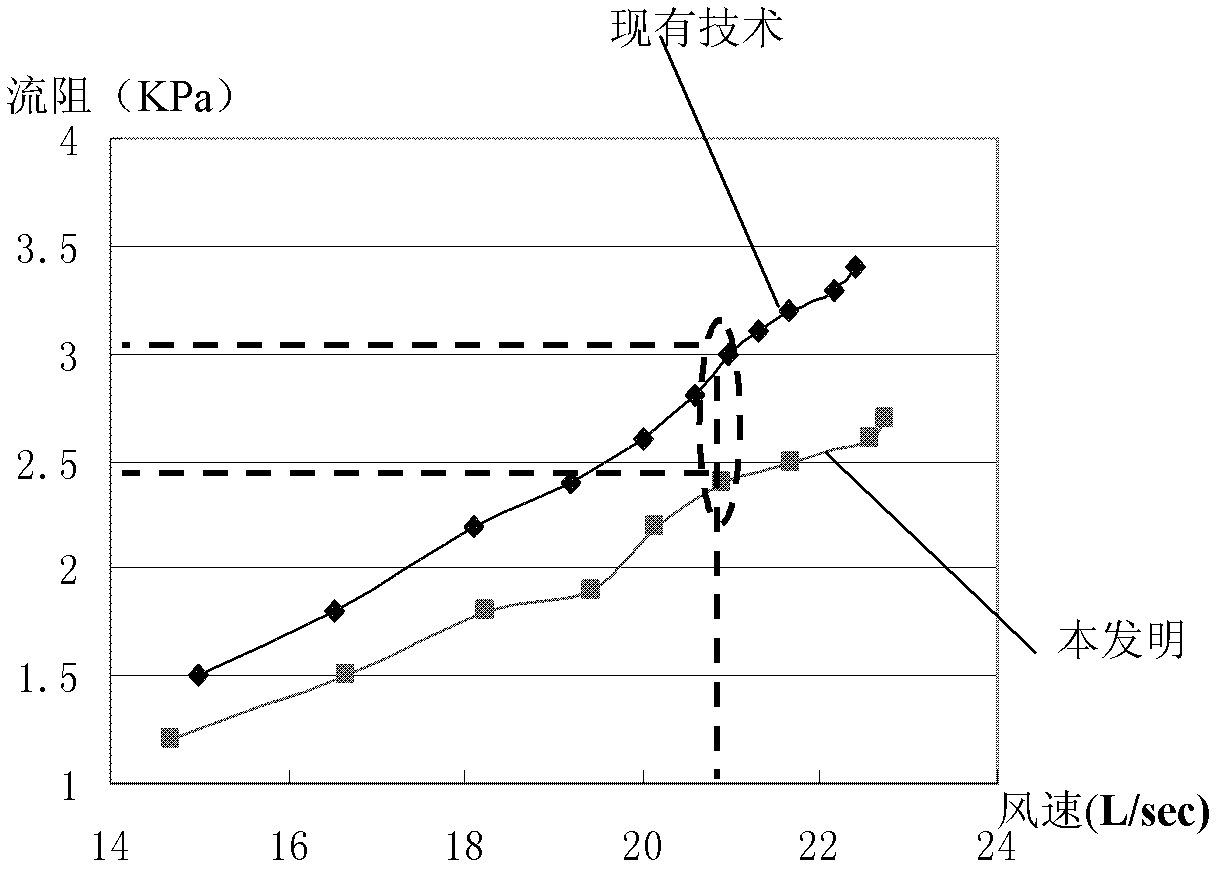

A technology of spiral airflow and motor casing, applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of loud noise, user discomfort, poor effect, etc., to reduce noise and extend the flow path , the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

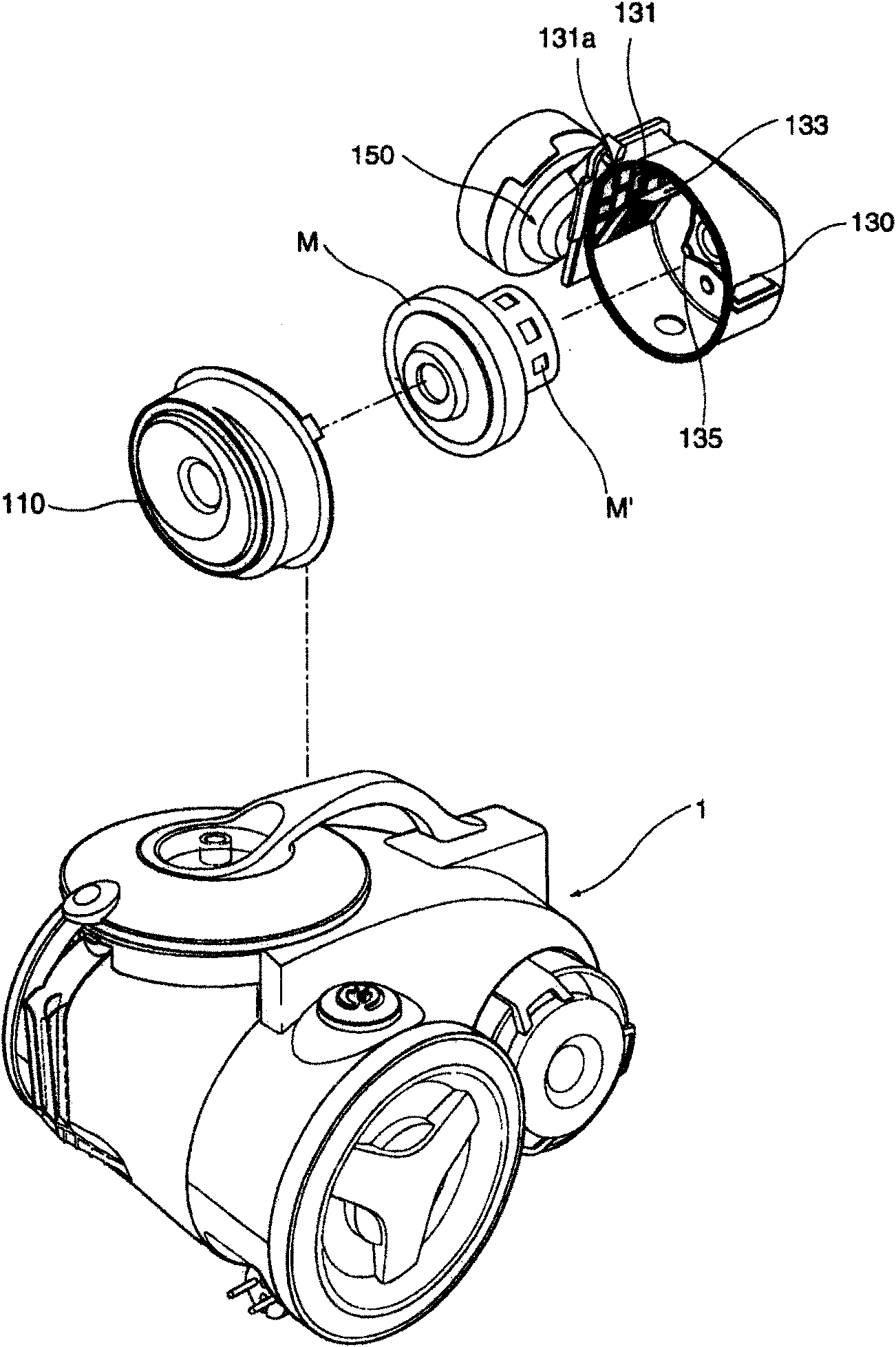

[0029] The present invention will be further described in detail below in combination with specific embodiments.

[0030] Such as Figure 4-2 with Figure 4-4 As shown, the present invention has a motor casing with a spiral air flow chamber, including a cavity, an air inlet 11 and an air outlet 12, the air inlet 11 is located at the bottom of the cavity, and the air outlet 12 is located at the bottom of the cavity side of the body; Figure 4-5 As shown, a partition is provided in the cavity, and the partition is formed by alternately connecting flat plates and curved panels, and the curved panel is a curved panel that is substantially equidistant from the outer wall of the cavity, such as Figure 4-5As shown, the curved plate is a circular arc plate, and alternately arranged and connected expansion chambers 20 and contraction chambers 10 are formed between the partition plate and the outer wall of the cavity, and are aligned with the air outlet 12 A grid-shaped air port is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com