Pump body manufacturing technology

A manufacturing process and pump body technology, which is applied in the field of pump body manufacturing, can solve the problems of reduced pump efficiency, poor pump performance, and reduced operating efficiency, and achieve the effects of alleviating corrosion speed, increasing service life, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

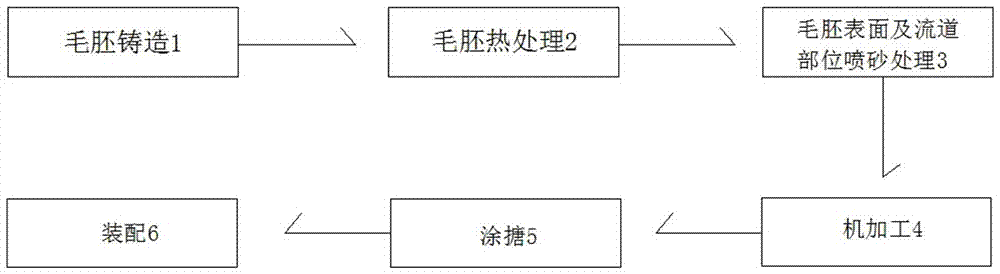

[0010] see figure 1 As shown, the specific embodiment of the present invention is composed of process steps 1 blank casting, 2 blank heat treatment, 3 sandblasting treatment on the surface of the blank and the flow channel, 4 machining, 5 enamelling, and 6 assembly. The process steps 3 The sandblasting treatment of the surface of the blank and the flow channel requires the use of corrosion-resistant and wear-resistant coatings, which are ceramic particle coatings. Through the above process steps, the strength and toughness of the flow-passing parts of the pump body are greatly improved, making the flow-passing parts of the pump body more corrosion-resistant and wear-resistant, and at the same time, the service life of the pump body is improved, the production cost is saved, and the production efficiency is improved.

[0011] Further, the specific plan for the sandblasting treatment of the surface of the blank and the flow channel in the process step 3 is as follows: the base p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com