Ignition plug with pre-chamber and device for flushing pre-chamber

A technology of ignition plug and pre-combustion chamber, which is applied in the field of ignition plug to avoid overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

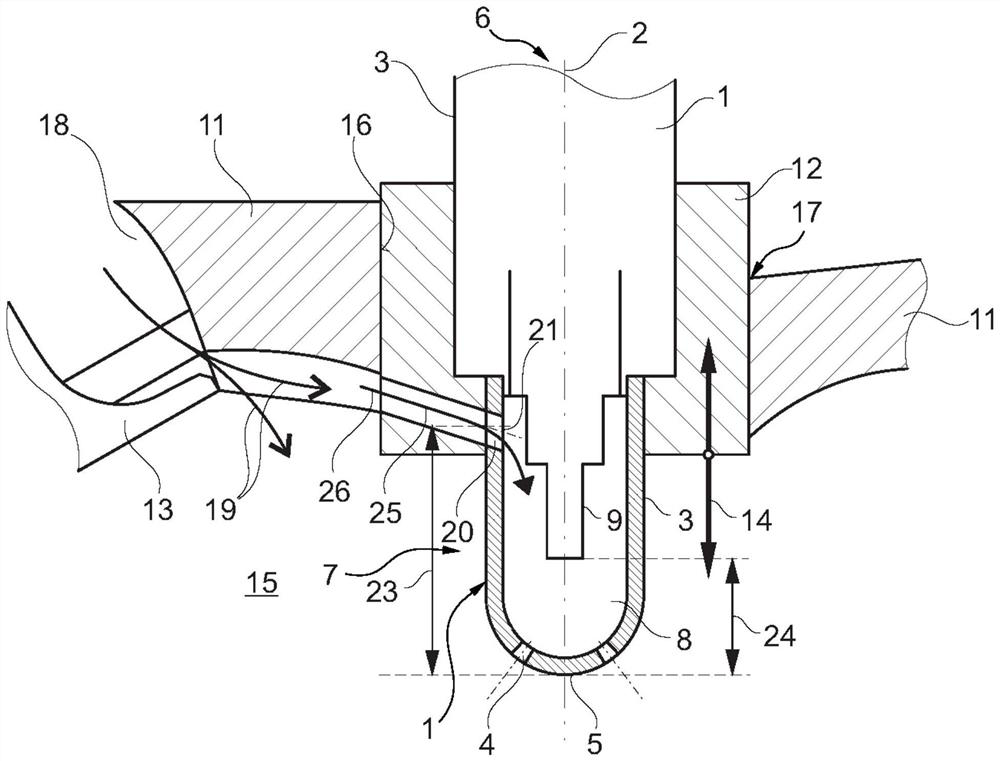

[0028] figure 1 A detail of a cylinder head 11 according to the invention with a glow plug 1 according to the invention is shown schematically in partial section. The cylinder head 11 comprises an opening 17 in which the ignition plug 1 is arranged and a further opening 18 with an inlet valve 13 . The opening 17 has an inner surface 16 .

[0029] Glow plug 1 has a longitudinal axis 2 . Glow plug 1 also has an outer wall 3 . The glow plug further comprises, in the longitudinal direction 2 , a combustion chamber-side end 5 and a combustion chamber-opposite end 6 , which in figure 1 is not explicitly shown. The outer wall 3 includes a combustion chamber-side region 7 which is configured to be arranged in the combustion chamber 15 or to protrude into the combustion chamber 15 .

[0030] A prechamber 8 is arranged at the combustion chamber-side end 5 . At least one ignition electrode 9 is arranged in the pre-chamber 8 . Furthermore, the pre-chamber 8 comprises at least one c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com