Prestressed wire tendon equipment

A technology of prestressed steel wire and equipment, which is applied in the direction of bridge construction, erection/assembly of bridges, structural elements, etc., can solve the problems such as the inability of prestressed steel wire to be braided into bundles, and the easy dispersal of prestressed steel wire bundles, so as to prevent the device from rusting. , improve quality, prevent rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

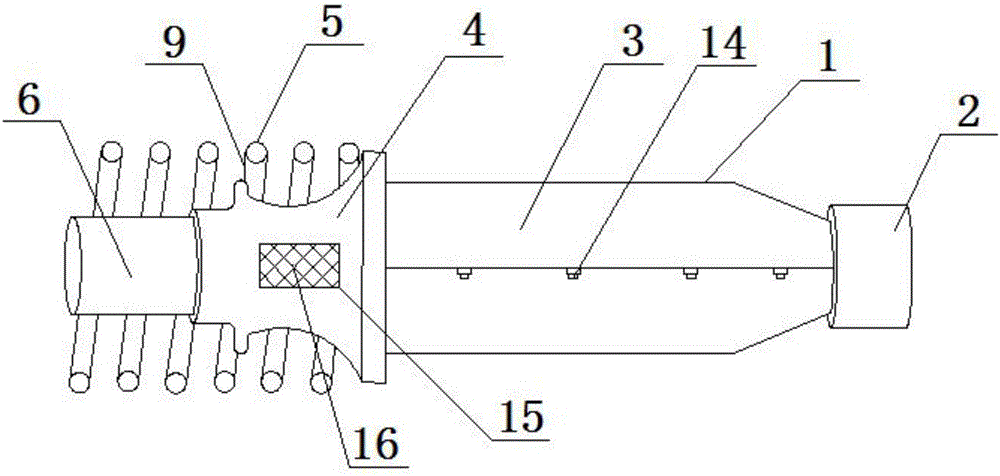

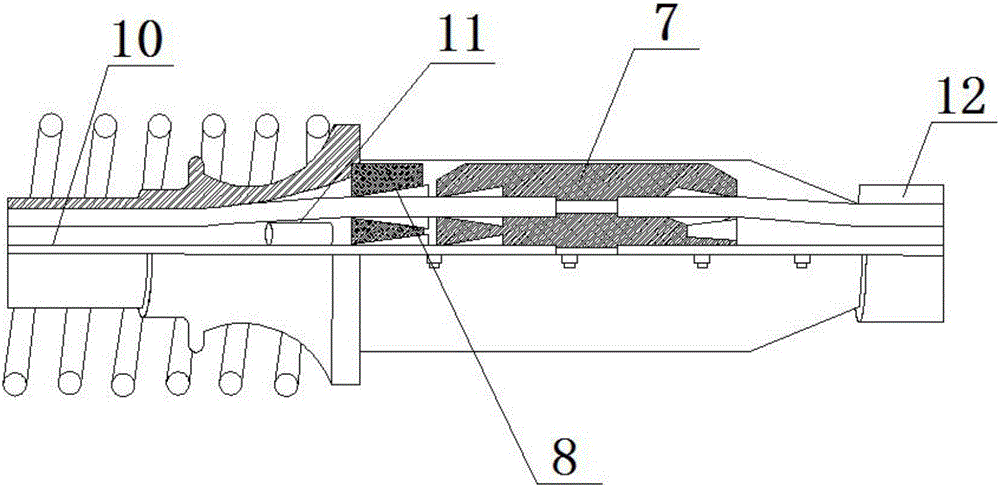

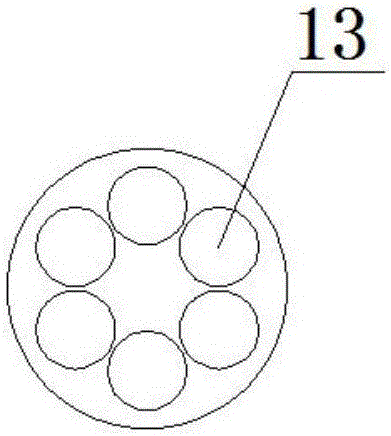

[0018] refer to figure 1 , figure 2 and image 3 , a prestressed steel wire bundle equipment, including a protective shell 1, a restraint device 2, a working device 3, an anchor pad device 4, a screw device 5, and a bellows 6, the surface of the prestressed steel wire bundle equipment is provided with a protective shell 1, the The right end of the protective shell 1 is provided with a restraint device 2, the left end of the restraint device 2 is connected to the working device 3, the left end of the working device 3 is connected to the anchor pad device 4, and the left side of the anchor pad device 4 is provided with a bellows 6, The upper and lower sides of the anchor pad device 4 are connected with screw devices 5, the working device 3 is provided with a connecting body 7, the left side of the connecting body 7 is provided with a working anchor plate 8, and the screw device 5 is provided with a screw Rib 9, steel wire tubes 10 are arranged in the prestressed steel wire bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com