Double-arc irregular shaped inner-cooling type efficient titanium alloy milling tool

A milling tool and double arc technology, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problem of high requirements for machine tools, achieve the effect of increasing the contact area, ensuring the rigidity and deflection resistance of the tool holder, and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

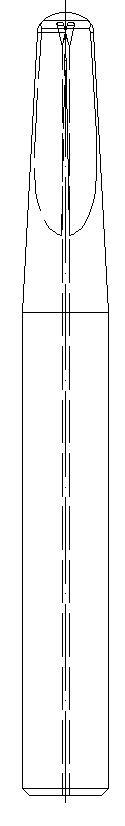

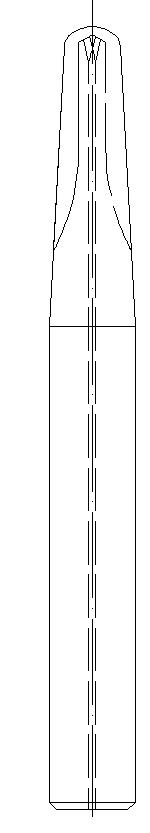

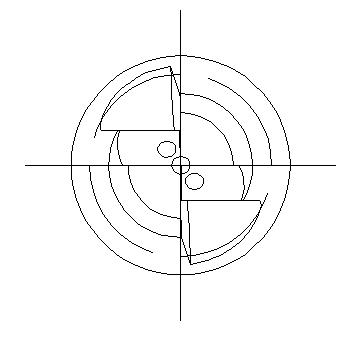

[0034] A double-arc special-shaped internal cooling titanium alloy high-efficiency milling tool, which consists of: a tool handle 1, the tool handle 1 transitions through a cone 2 to a double-arc-shaped milling head at the front end, and the tool handle One side of the head has a pair of chip pockets 6 with a rake angle structure, the center of the tool has a coolant channel 5, the outlet of the coolant channel is located at the end of the tool, and the tail of the tool has a negative Edge 7.

Embodiment 2

[0036] The above-mentioned double-arc special-shaped internal cooling titanium alloy high-efficiency milling tool, the double-arc milling head includes a small curvature ball head 4 at the end of the tool, and the gap between the small curvature ball head 4 and the cone 2 is It is a large curvature ball head 3.

Embodiment 3

[0038] For the above-mentioned dual-arc special-shaped internally cooled titanium alloy high-efficiency milling tool, the tool handle is cylindrical with a diameter of 10-14 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com