Open-centre valve block with two pump connections and associated auxiliary sliders on the main sliders

A technology for auxiliary sliders and main sliders, which is applied to servo motor components, fluid pressure actuators, earth movers/shovels, etc., can solve the problem that the unloading valve is not opened quickly enough, and achieves low cost and low cost. Avoid the formation of shrinkage cavity, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

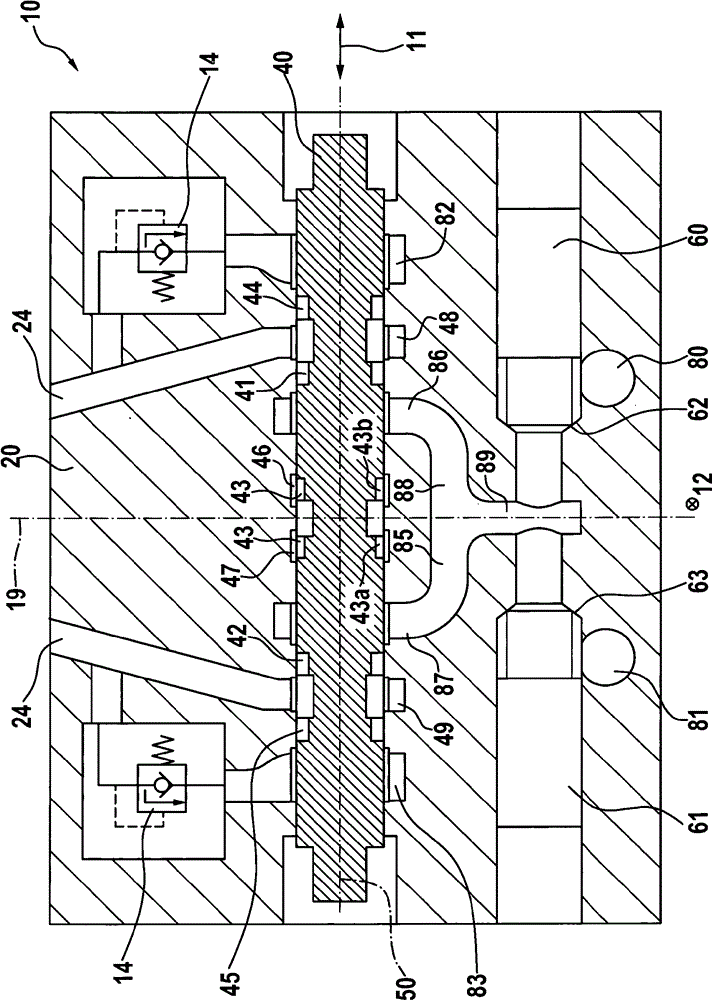

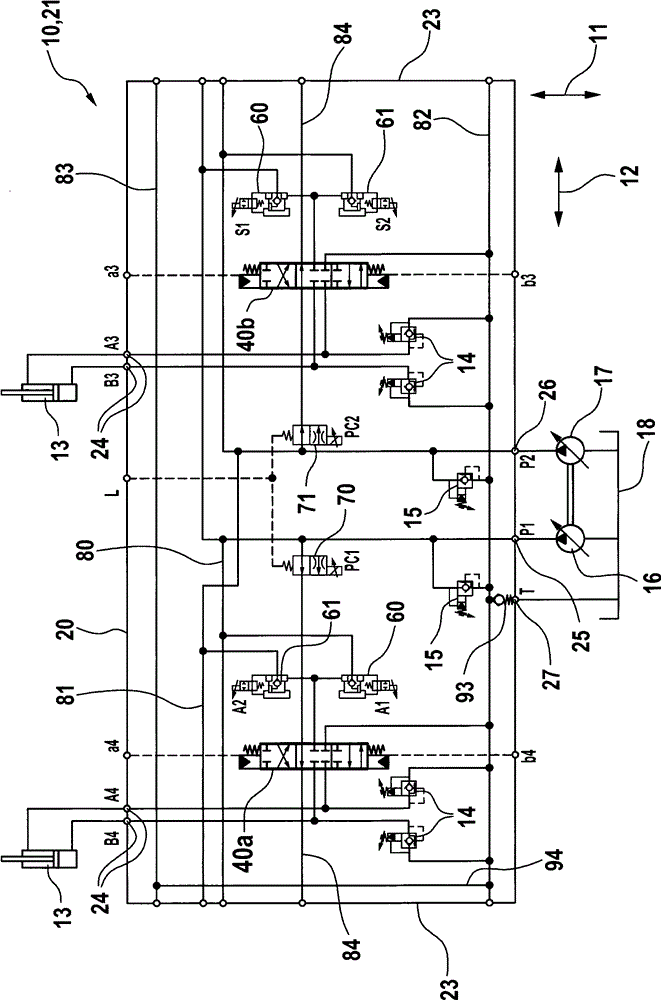

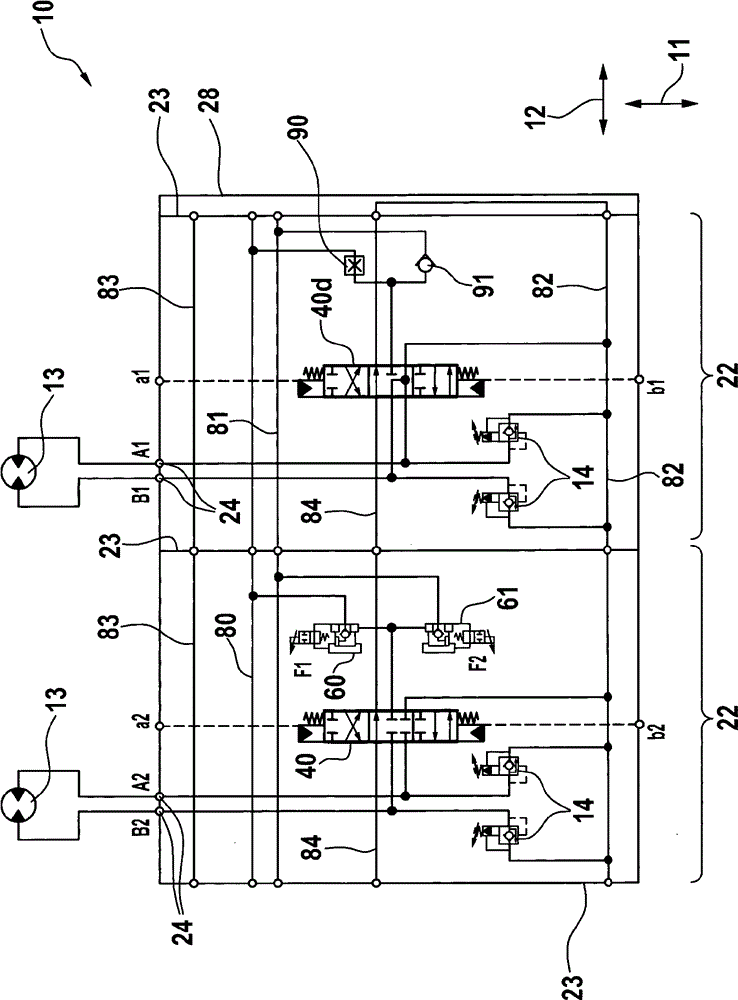

[0027] figure 1 A wiring diagram of the valve block 10 in the region of the base body 21 of the housing 20 is shown. The base body 21 is produced in one piece from cast iron in a casting method with a lost core. The basic body has two opposite, flat contact surfaces 23, the reference of the housing 20 figure 2 with 3 The described sub-body is added to the contact surface. The parallel contact surfaces 23 are oriented perpendicular to the longitudinal direction 12 .

[0028] The base body 21 has a first and a second pump connection 25 ; 26 and a tank connection 7 . A first and a second pump 16; 17 are connected to the pump connection 25; 26, the first and the second pump each having an adjustable displacement volume. The pump 16 ; 17 draws pressurized fluid, in particular hydraulic oil, from the tank 18 , wherein the pressurized fluid flows back into the tank 18 via the tank connection 27 .

[0029] The displacement volume of the pumps 16 : 17 can be adjusted hydraulical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com