Lift car energy-saving device

An energy-saving equipment and car technology, applied in lifts, elevators in buildings, transportation and packaging, etc., can solve problems such as energy waste, poor air quality, and poor air replacement effects, and achieve convenient use and power saving , the effect of saving energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

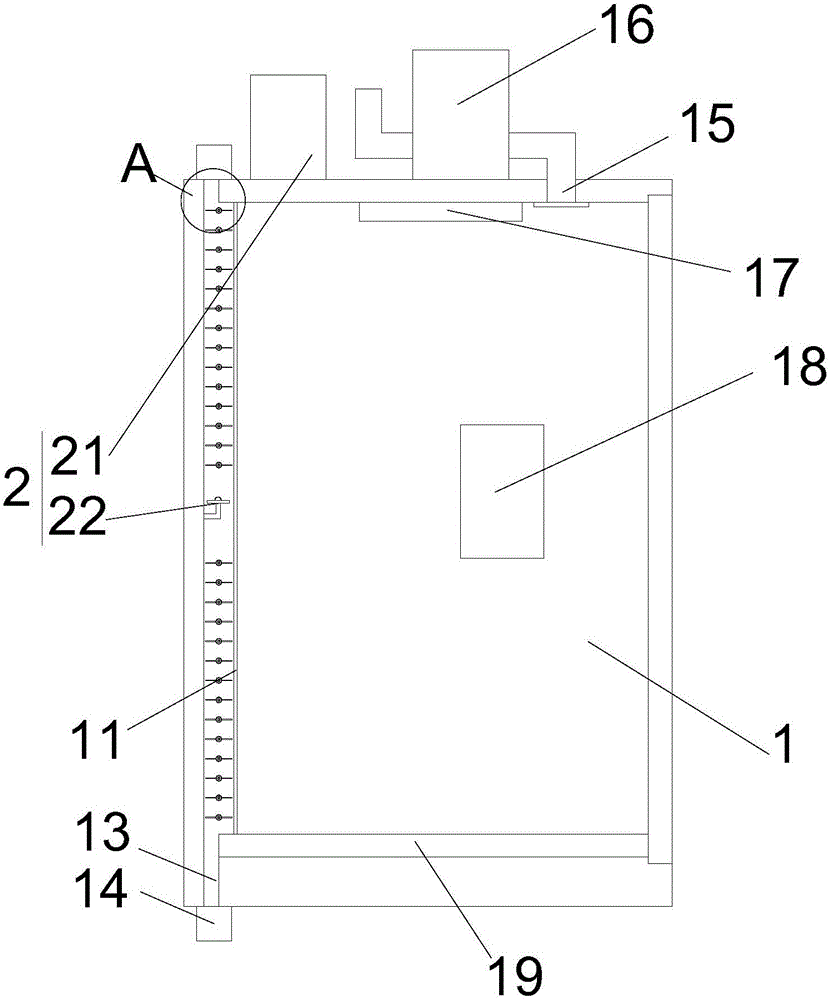

[0017] refer to figure 1 with figure 2 As shown, a car energy-saving device proposed by the present invention includes a car 1 and a control mechanism 2;

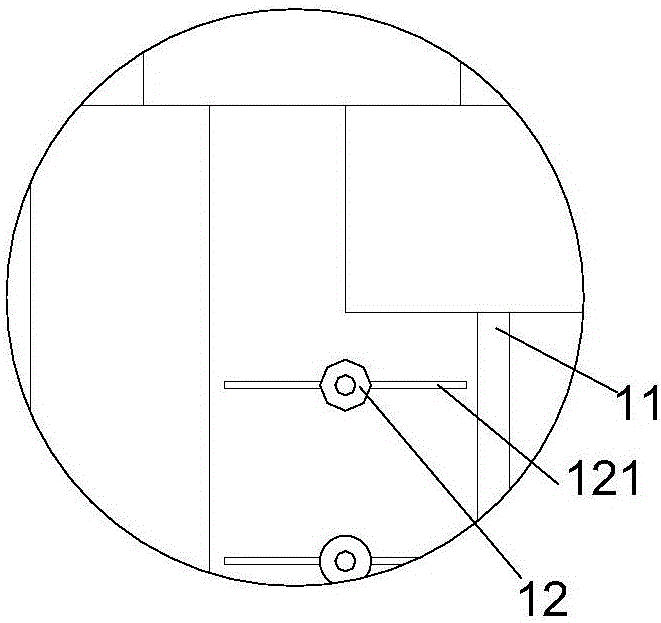

[0018] A net plate 11 is installed in the car 1, and the net plate 11 is parallel to the car wall on the side of the car door of the car 1, and a plurality of Rotating shaft 12, the rotating shaft 12 is parallel to the length direction of the screen plate 11 and distributed along the height direction of the screen plate 11, the two ends of the rotating shaft 12 are respectively rotatably installed on the two adjacent car walls of the car door of the car 1; The car floor of car 1 and the car top of car 1 are provided with ventilation holes 13, and the ventilation holes 13 are located on the side of the rotating shaft 12 away from the screen plate 11. An air filter device 14 is installed on the car 1 corresponding to the position of the ventilation holes 13. Windshields 121 are installed on the opposite sides on the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com