Cathode for free-form-surface-cavity electrochemical machining

A cathode and curved surface technology, which is used in machining electrodes, electric machining equipment, electrode manufacturing, etc., can solve problems such as short circuits and incomplete flow fields, and achieve the effect of preventing poor flow fields, eliminating dead water areas, and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

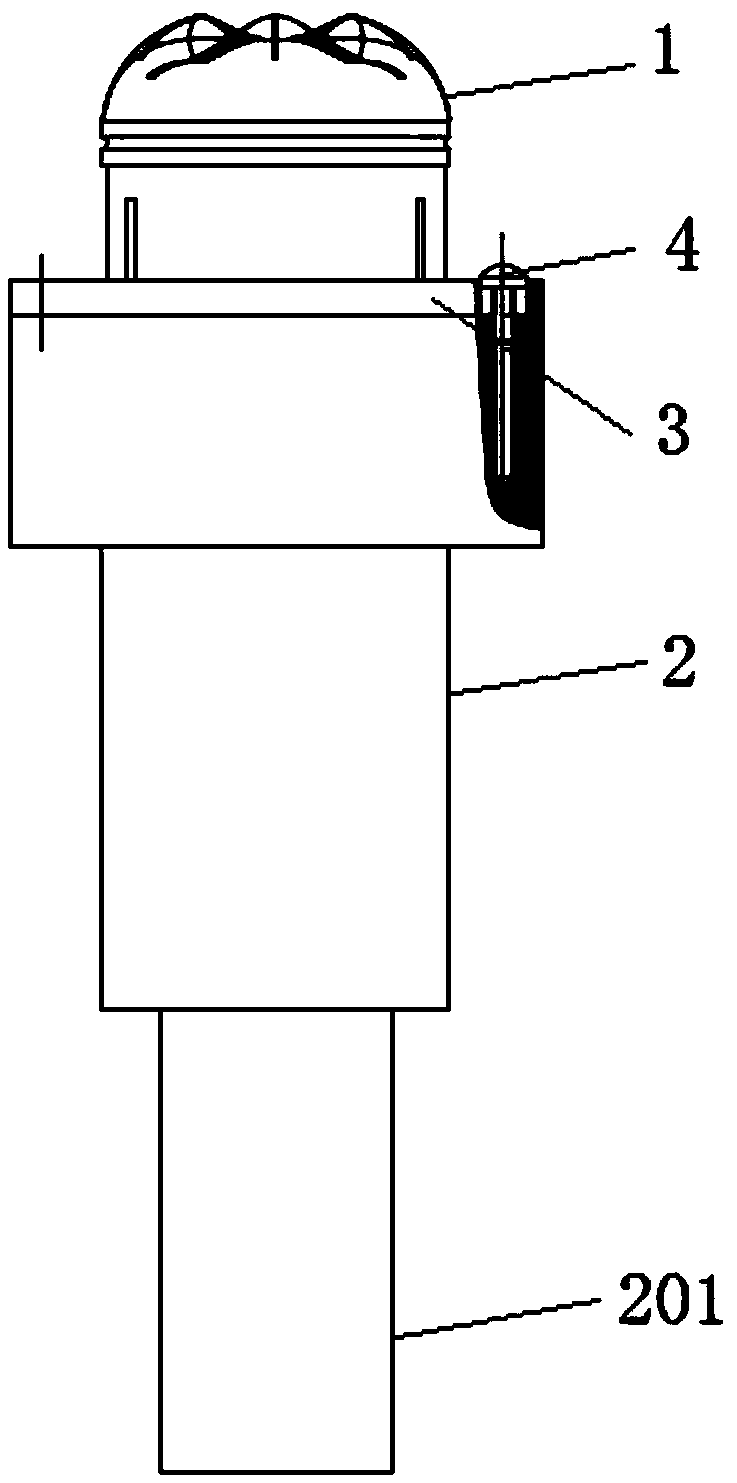

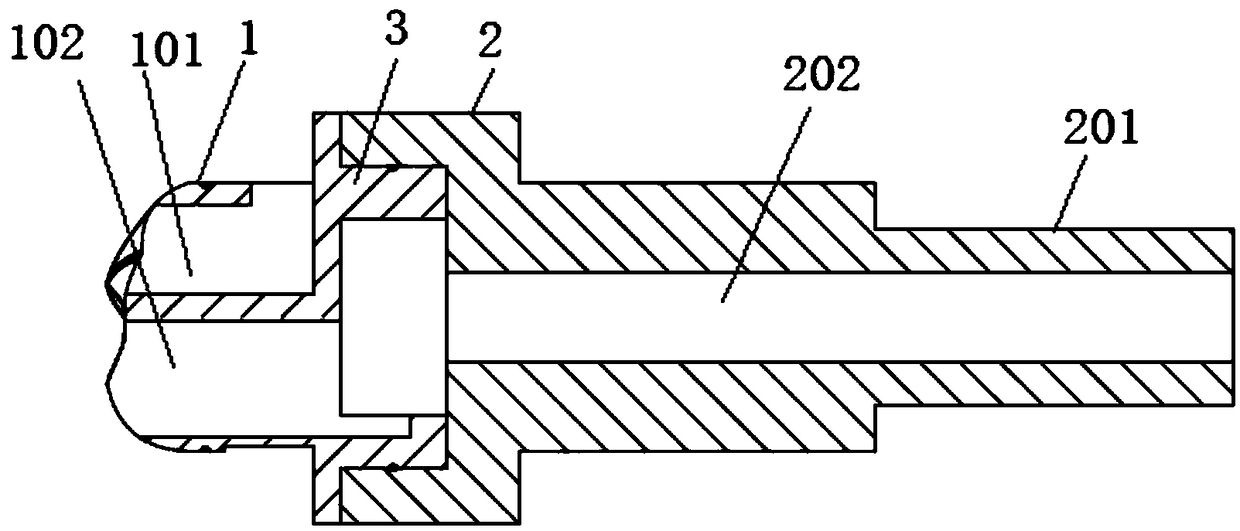

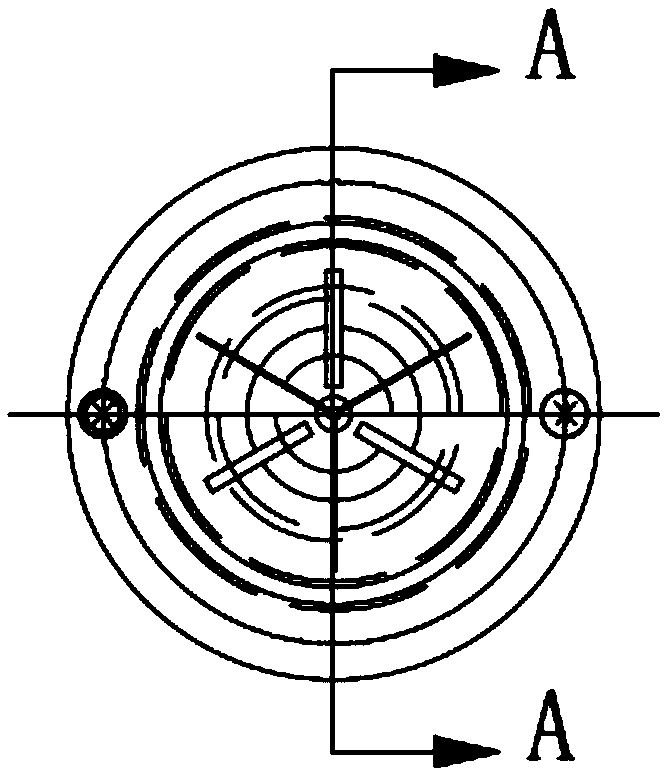

[0029] This embodiment provides a Figure 1-3 The shown cathode for electrolytic machining of a free-form surface cavity includes a cathode body 2 and a cathode head 1 . The structure of the cathode head 1 is as Figure 4-6 Shown, the structure of cathode body 2 is as Figure 7 shown. The cathode body 2 is provided with an electrolyte inflow channel 202, and the cathode head 1 is provided with a liquid inflow channel 102 and a liquid outflow channel 101, and one end of the liquid inflow channel 102 is connected to the electrolyte inflow channel 202 The other end leads to the workpiece 4, one end of the liquid outflow channel 101 leads to the workpiece 4, and the other end leads out from the side of the cathode head 1 above the workpiece 4. The liquid inflow channel 102 and the liquid outflow channel 101 can be arranged in parallel.

[0030] The present invention has no special limitation on the specific structure of the liquid outflow channel 101, preferably as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com