Quantitative container

A container and quantitative cavity technology, applied in the field of liquid containers, can solve the problems of inconvenient carrying, volatile, troublesome, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

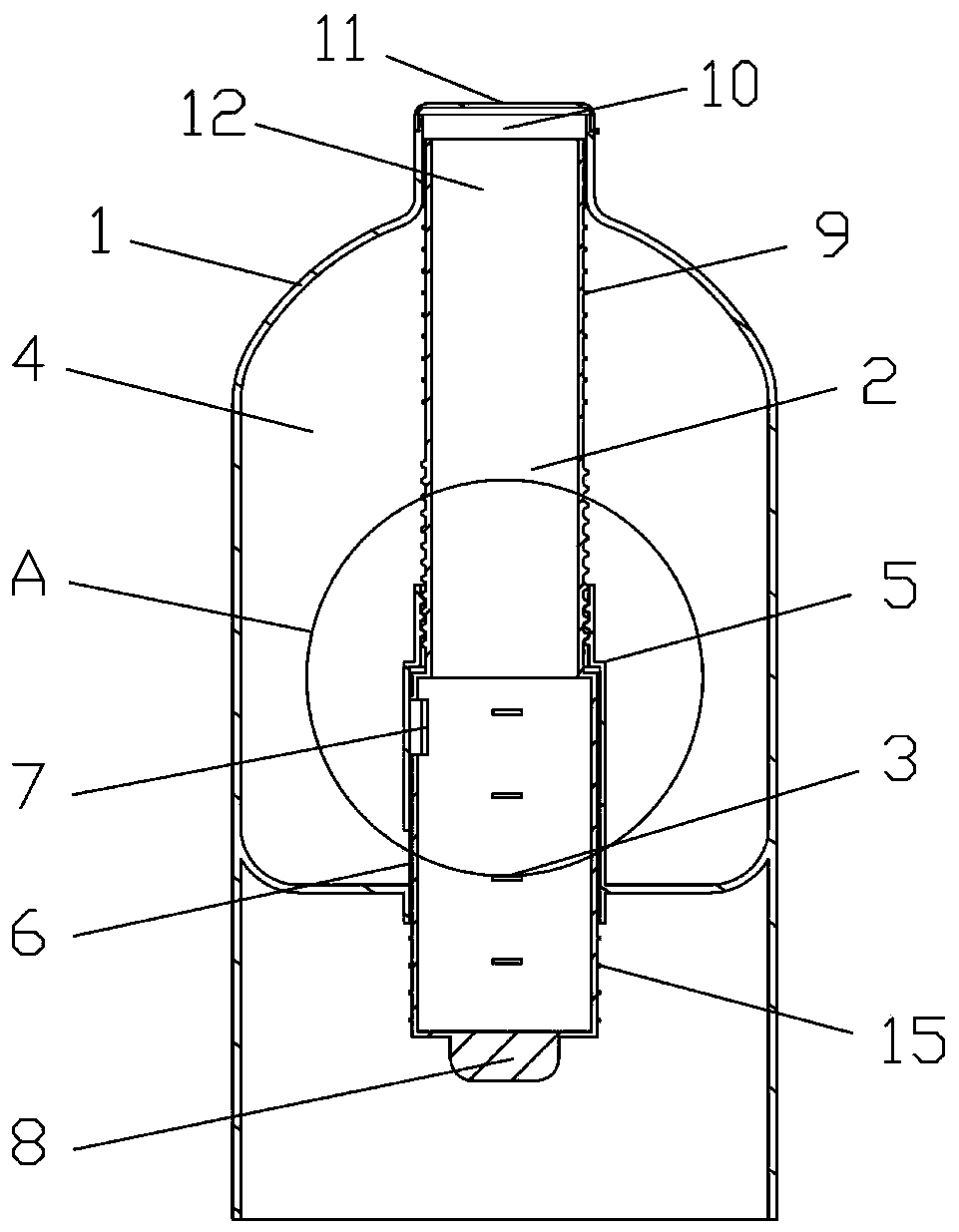

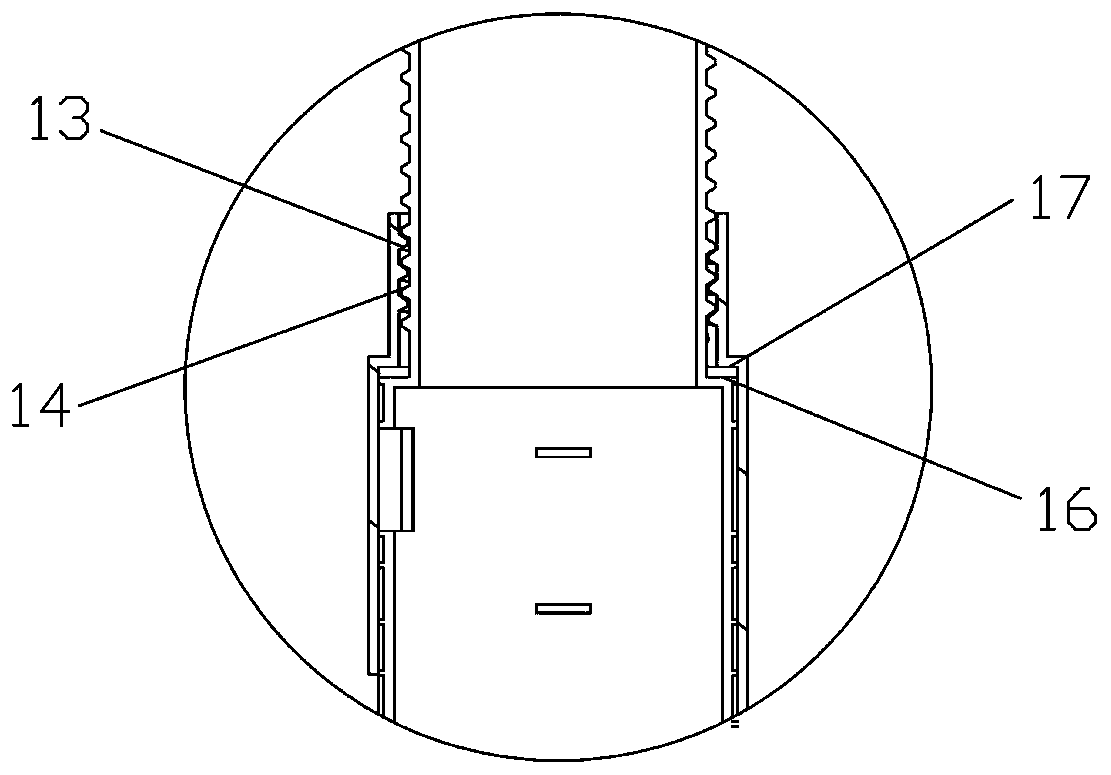

[0029] like Figure 1 to Figure 4 As shown, a quantitative container of the present invention includes a container 1 and a quantitative chamber 2, the container 1 is provided with a liquid storage chamber 4 and a guide post 5, the quantitative chamber 2 is rotatably arranged in the guide post 5, and the guide post 5 There is a liquid outlet 6 of the liquid storage chamber on the top, and a capacity scale line 3 and a liquid inlet 7 of the quantitative chamber are arranged on the quantitative chamber 2. The connection between the liquid inlet 7 of the quantitative chamber and the liquid outlet 6 of the liquid storage chamber is controlled by rotating the quantitative chamber 2. Corresponding connectivity and dislocation closure between them. The above constitutes the basic structure of the present invention.

[0030] The present invention adopts such a structural setting. When in use, by rotating the quantitative chamber 2 to control the liquid inlet 7 of the quantitative cham...

Embodiment 2

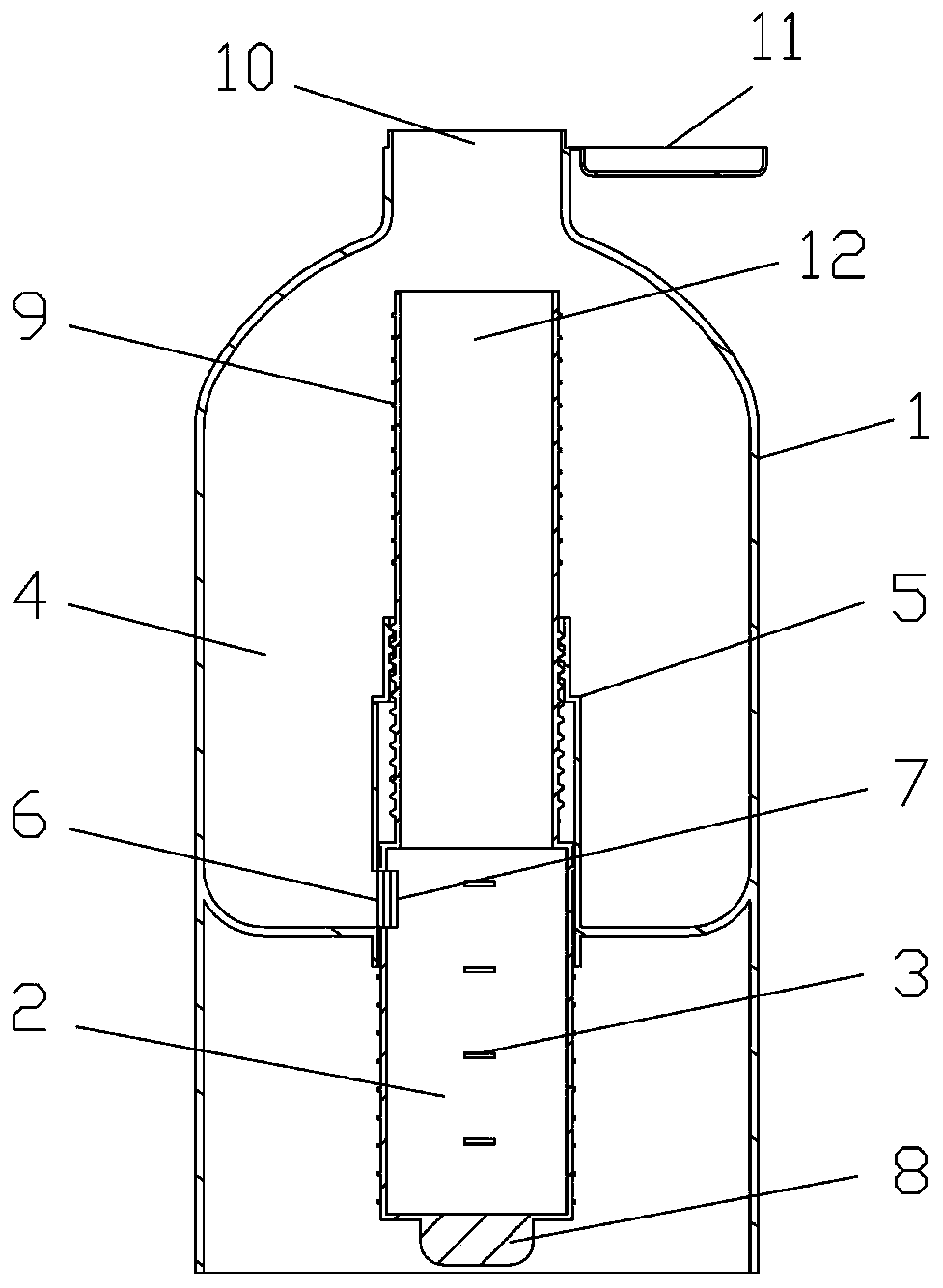

[0044] like Figure 5 to Figure 7 As shown, the difference between the second embodiment and the first embodiment is that the cover body 11 and the quantitative chamber 2 described in the second embodiment have an integrated structure, and the cover body 11 is threadedly connected to the liquid inlet 10 of the liquid storage chamber of the container 1 Above, the liquid outlet 12 of the quantitative chamber is set on both sides of the top of the quantitative chamber 2 . The rest of the structures are the same as those in Embodiment 1, and will not be described repeatedly.

Embodiment 3

[0046] like Figure 8 As shown, the third embodiment differs from the second embodiment in that the cover body 11 described in the third embodiment is set separately from the quantitative chamber 2 . The rest of the structures are the same as those in Embodiment 2, and will not be described repeatedly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com