Rapid glue dispenser

A glue dispenser and fast technology, applied in the field of glue dispensers, can solve the problems of difficult dispensing quantity, affecting the precise execution and adjustment of dispensing, and achieve the effect of preventing the amount of glue dispensed and improving the accuracy of dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

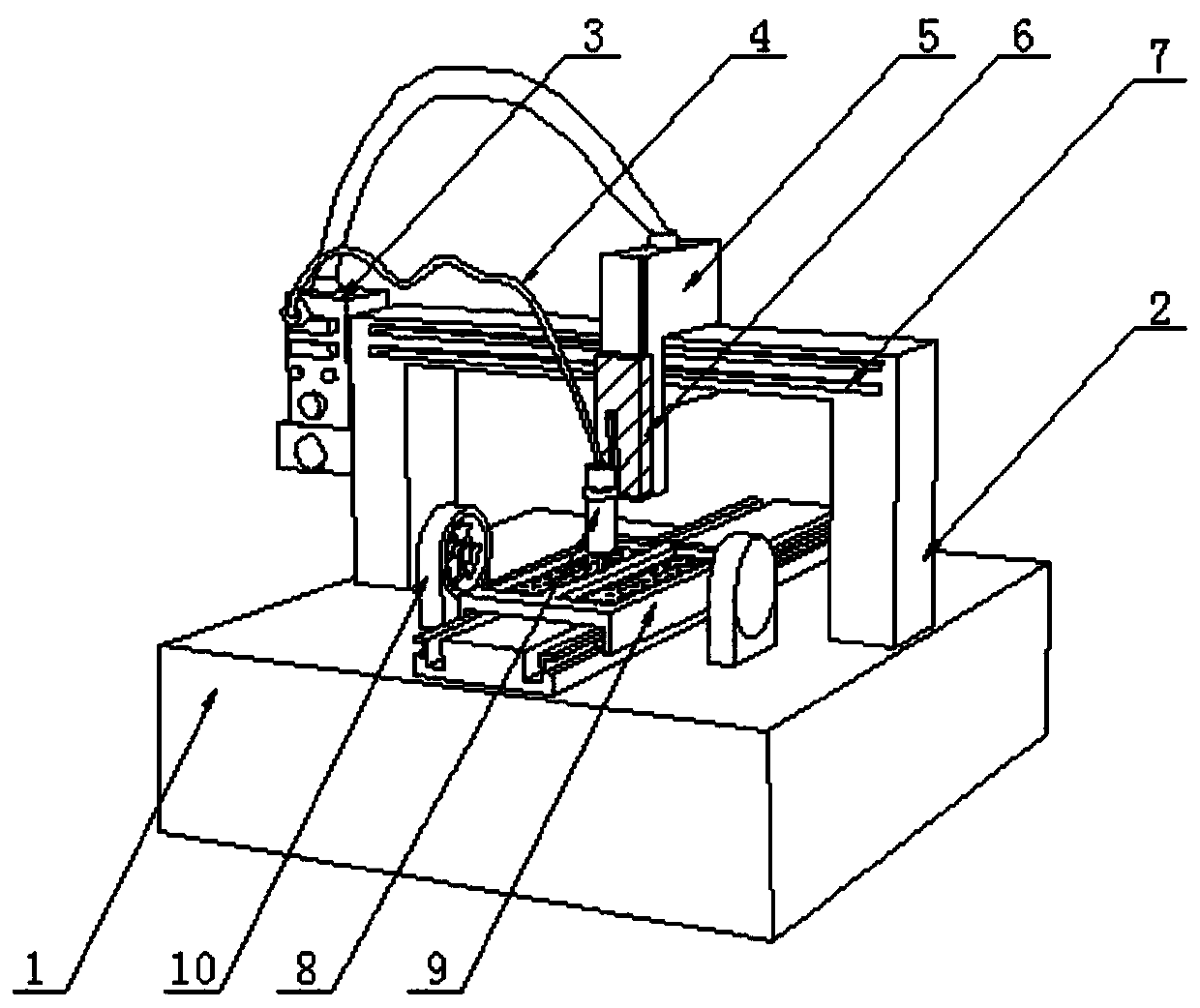

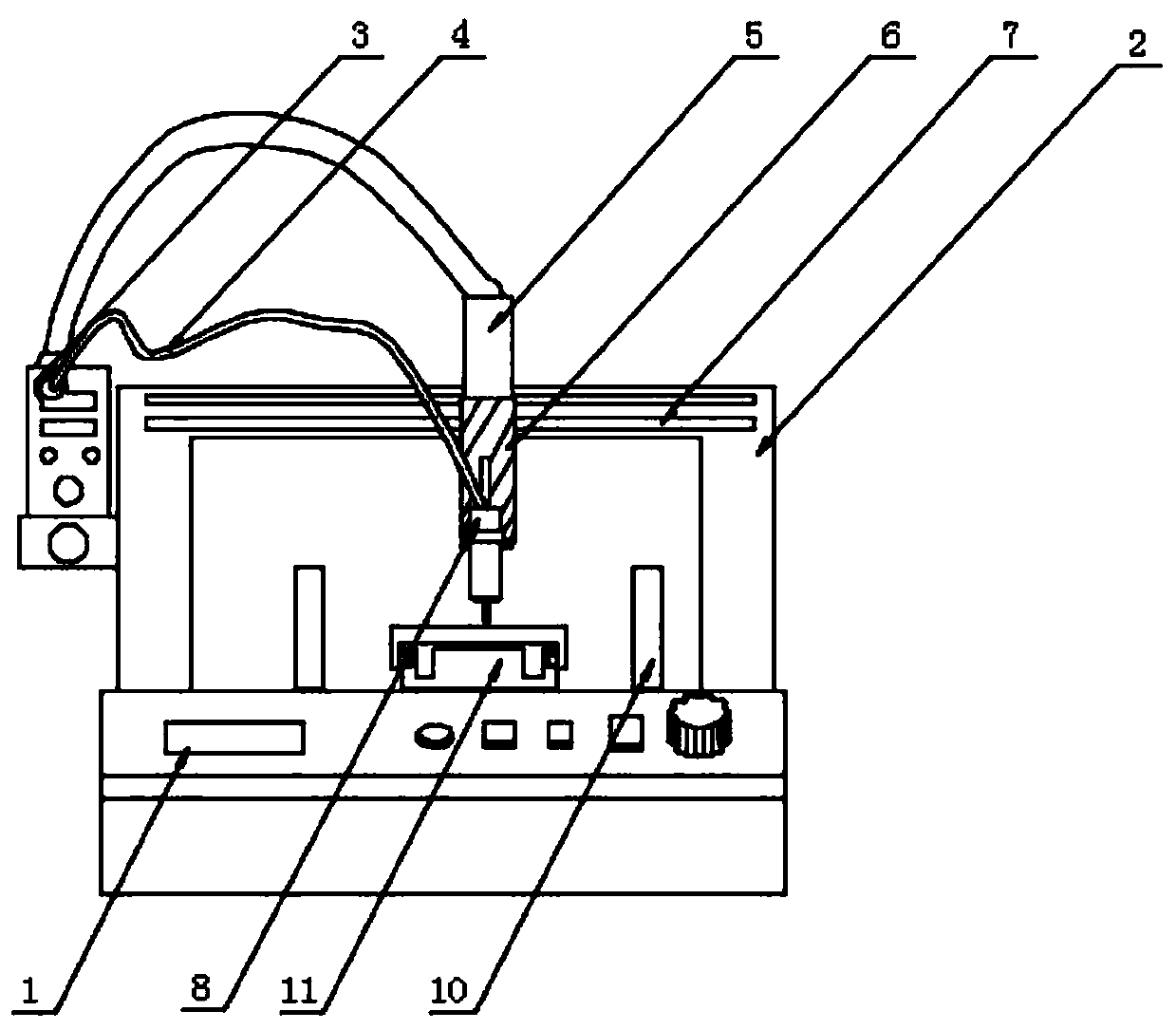

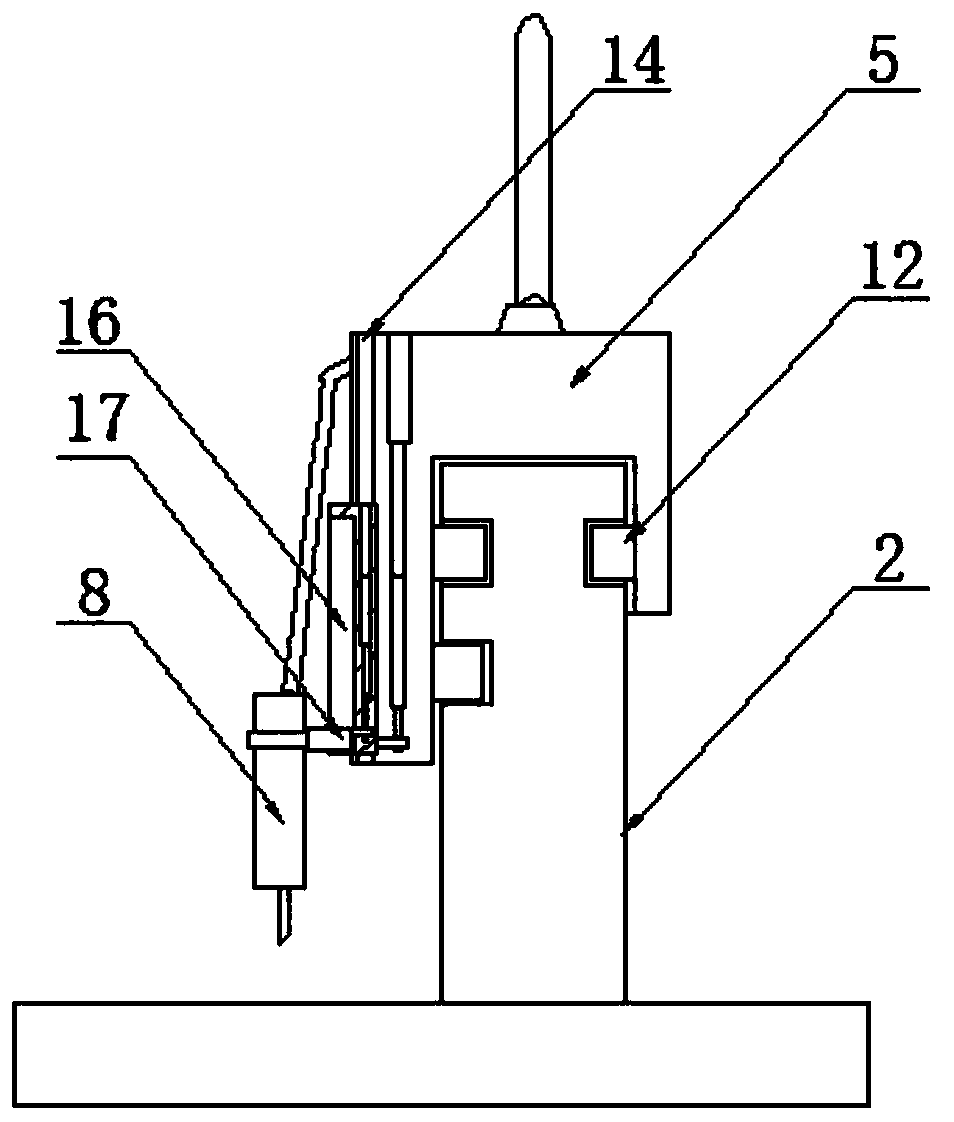

[0023] see Figure 1~6 , in the embodiment of the present invention, a kind of fast dispensing machine, comprises machine base 1, dispensing head two-dimensional moving mechanism, dispensing head 8, dispensing platform and dispensing platform moving mechanism, wherein, the upper connection of described base The two-dimensional movement mechanism of the dispensing head located above it is provided, the output end of the two-dimensional movement mechanism of the dispensing head is connected with the dispensing head 8, and the upper end surface of the base 1 is located at the dispensing head. The bottom of the head is provided with the dispensing platform, and the dispensing platform is driven and moved by the moving mechanism of the dispensing platform; it is characterized in that the dispensing head 8 includes an outer fixed cylinder 82, an inner dispensing head 86, an adjustment Sleeve 87, rubber-containing inner cylinder 813, wherein, the outer fixed cylinder 82 is coaxially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com