Heat exchanger with brushing function and convenient-to-replace cleaning ball

A technology that facilitates replacement and heat exchangers, and is applied in the directions of cleaning heat transfer devices, flushing, and non-rotating equipment cleaning, etc. Thermal efficiency and other issues, to achieve the effect of easy replacement, avoid loss, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

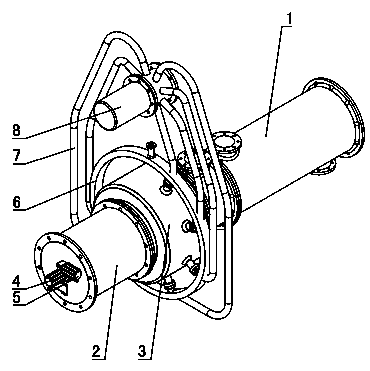

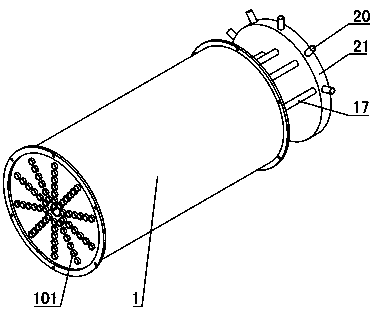

[0041] like Figure 1~5 As shown: the heat exchanger 1 is a cylindrical shape with both ends closed, the heat exchanger 1 is arranged horizontally, and a plurality of heat exchange tubes 101 are arranged at intervals in the heat exchanger 1, and both ends of the heat exchange tubes 101 extend out for heat exchange At the corresponding end of the heat exchanger 1, the heat exchange tube 101 is arranged parallel to the axis of the heat exchanger 1, and a plurality of fins are arranged at intervals along the axial direction in the heat exchanger 1, and the fins are semicircular, and the heat exchange tube 101 passes through The fins are fixedly connected to the heat exchanger 1, which not only facilitates the installation of the heat exchange tube 101, but also increases the heat exchange area and improves the heat exchange efficiency. Both ends of the heat exchanger 1 are coaxially provided with flanges.

[0042] A water inlet tube is coaxially installed on the left end of the ...

Embodiment 2

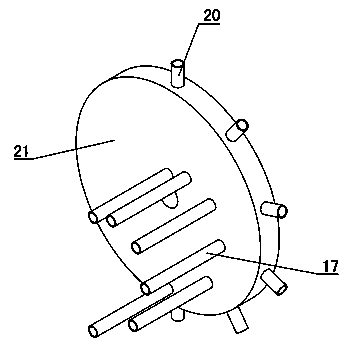

[0051] like Figure 7 As shown, the difference between Embodiment 2 and Embodiment 1 is that: one end of the water inlet cylinder is provided with a flushing bin 16 and a pushing mechanism, there are multiple flushing bins 16 spliced into a ring coaxial with the heat exchanger 1, and each flushing bin 16 A plurality of flushing pipes 17 are arranged on the side close to the heat exchanger 1, and the flushing pipes 17 correspond to the heat exchange tubes 101 one by one and are arranged coaxially with the corresponding heat exchange pipes 101. The mechanism is connected with the flushing chamber 16 one by one and pushes it to translate, so that the flushing pipe 17 on the flushing chamber 16 communicates with the water inlet end of the corresponding heat exchange tube 101; the pushing mechanism includes a feed motor 4, a conversion motor 5, a shift fork 19 and Screw 11, the screw 11 is coaxially arranged with the heat exchanger 1, the shift fork 19 is provided with a nut 1901...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com