Packaging film printing mechanism

A printing mechanism and packaging film technology, applied in printing presses, rotary presses, printing, etc., can solve the problems of dirty workers, clumsy operation, pollute the environment, etc., and achieve the effect of preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

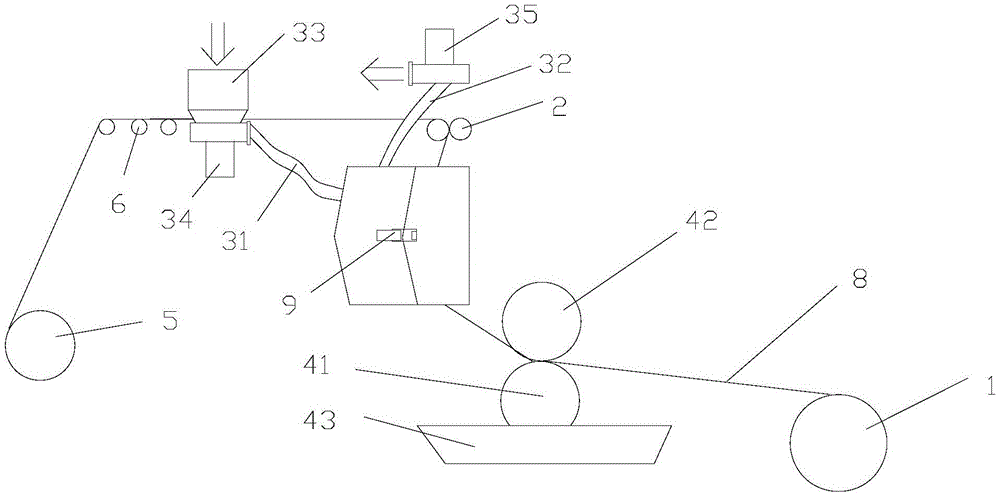

[0031] Such as figure 1 As shown, this embodiment discloses a packaging film printing mechanism, which includes a packaging film feeding roller 1, a printing mechanism, a packaging film printing and drying device, a traction pair roller 2 and a winding roller 5 according to the process flow from front to back.

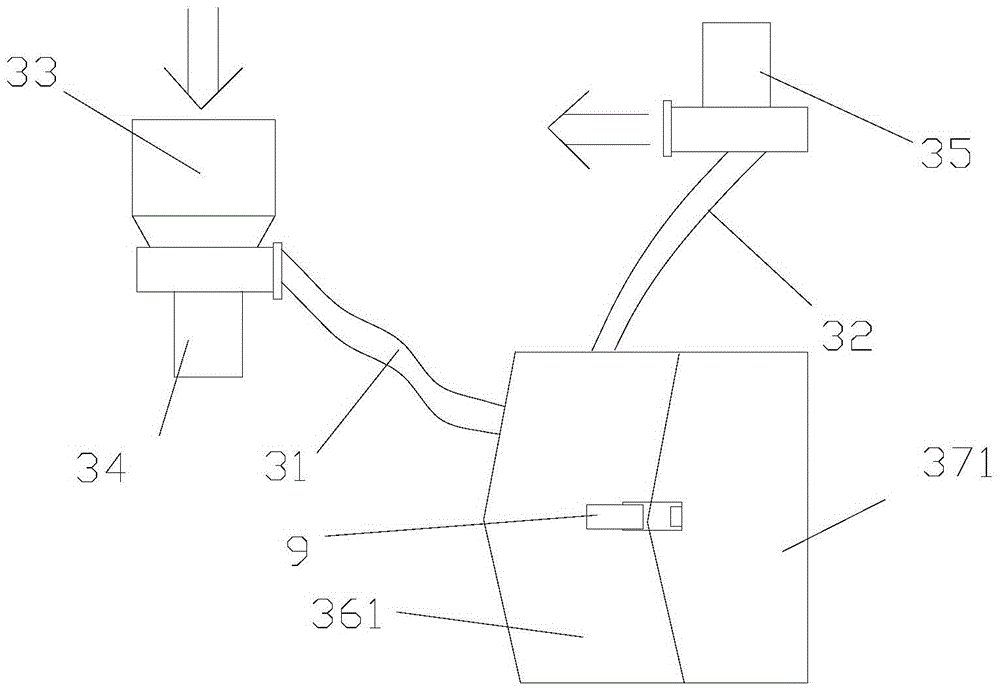

[0032] The packaging film printing and drying device includes an air inlet pipe 31, an air outlet pipe 32, and a drying main device. The drying main device includes a heating device and a packaging film 8 conveying device.

[0033] The heating device dries the ink on the surface of the packaging film 8 conveyed by the packaging film conveying device. Both the air inlet pipe 31 and the air outlet pipe 32 are in communication with the heating device.

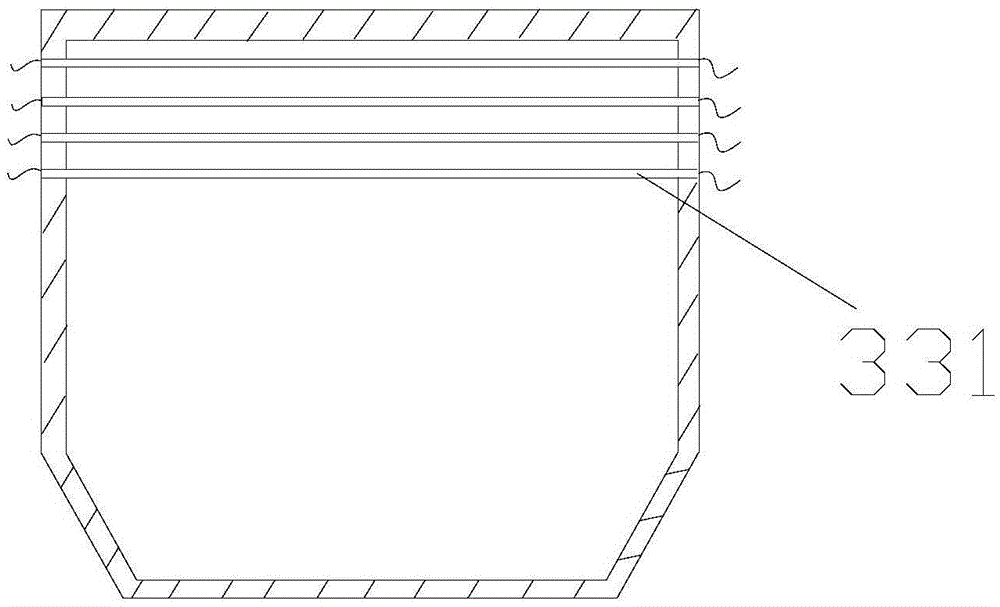

[0034] The drying device also includes a heating box 33 . The top of the heating box 33 is provided with an air inlet (not shown in the figure), the heating box 33 communicates with the air inlet pipe 31 through the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com