Patents

Literature

77results about How to "Realize automation and intelligence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monitoring alarm strategy collocation method and device and monitoring alarm method and device

ActiveCN104572391ARealize automation and intelligenceImprove accuracyHardware monitoringCollocation methodReal-time computing

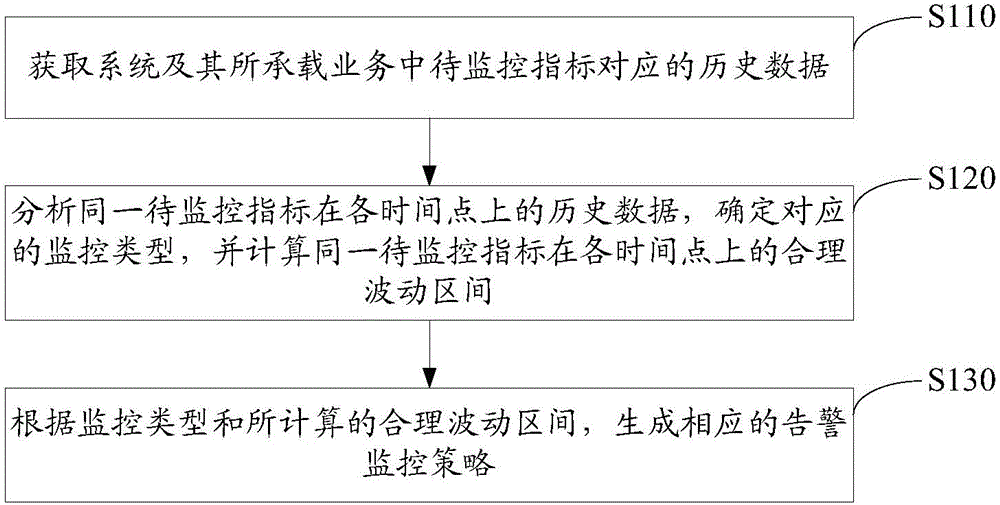

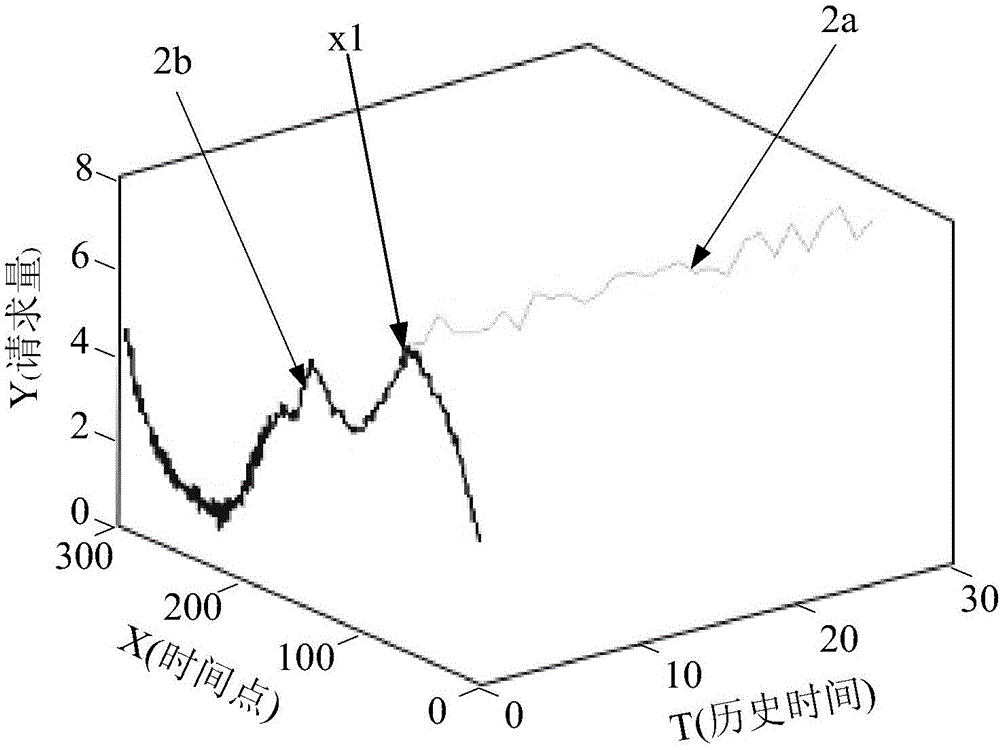

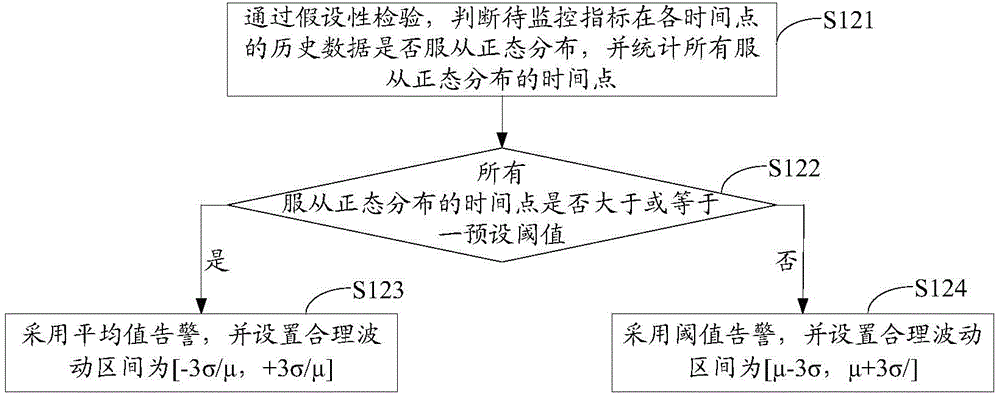

The invention discloses a monitoring alarm strategy collocation method. The monitoring alarm strategy collocation method includes steps of acquiring historical data of the system and the system's indicators to be monitored in bearer services; analyzing the historical data of the same indicator to be monitored in each time moment, determining corresponding monitoring types and calculating a reasonable fluctuation range of the same indicator to be monitored in each time moment; generating corresponding alarm monitoring strategies according to the monitoring types and the calculated reasonable fluctuation range. The invention further discloses a monitoring alarm strategy collocation device and the monitoring alarm method and device adopting the monitoring alarm strategy collocation. By the monitoring alarm strategy collocation method, automation and intelligentization of monitoring alarm strategy collocation are realized and monitoring accuracy is improved.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

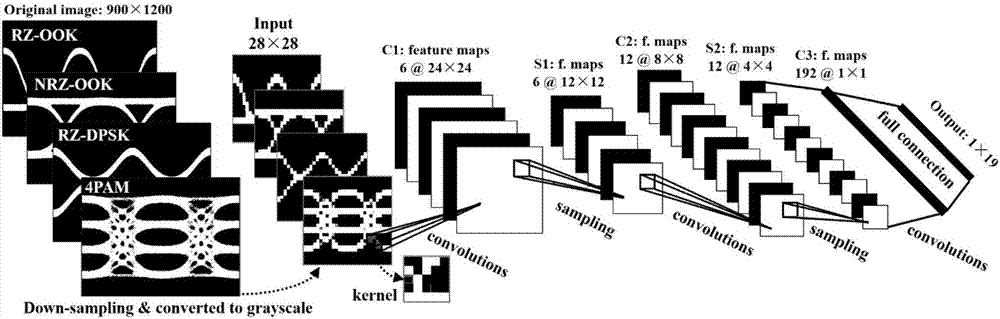

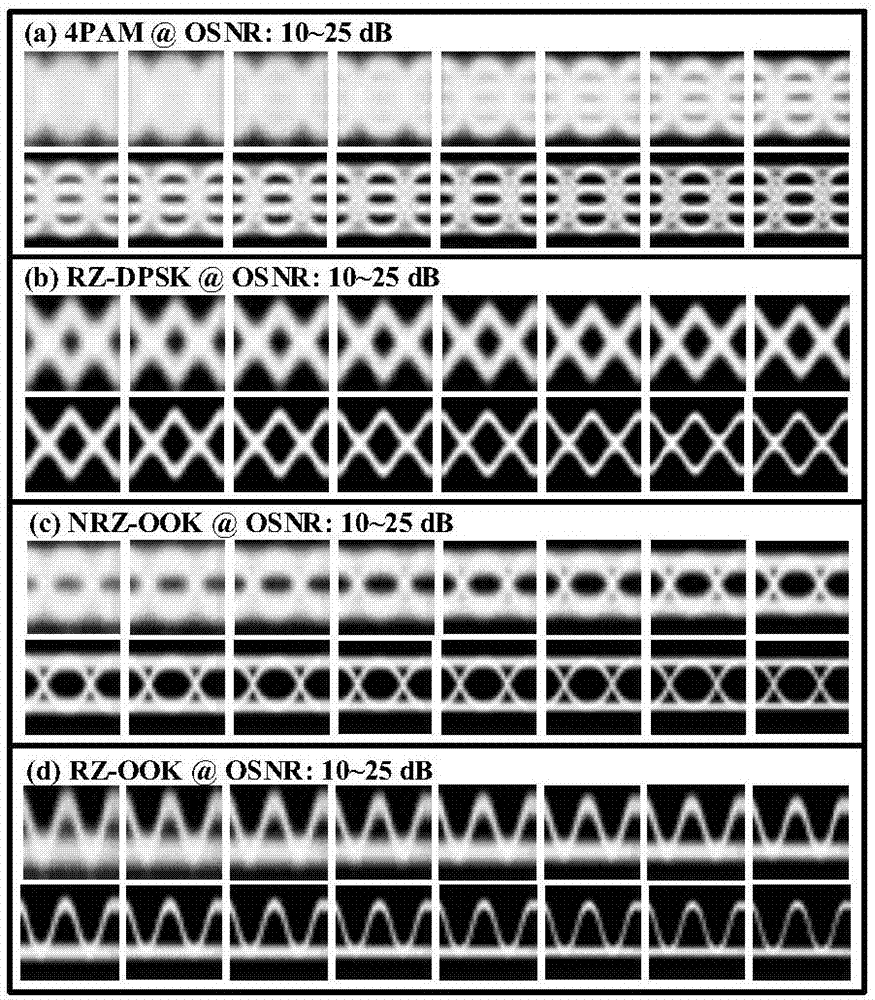

Intelligent eye diagram analysis method by use of deep learning based on convolutional neural network

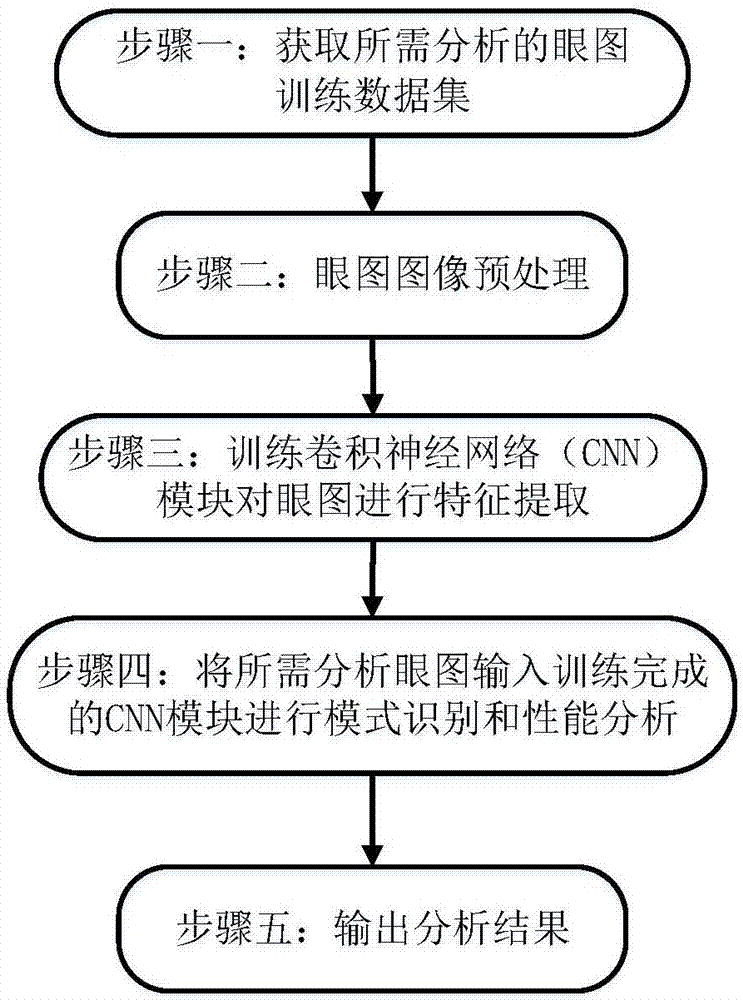

ActiveCN107342810ARealize automation and intelligenceAddressing the downsides of analyticsCharacter and pattern recognitionElectromagnetic transmissionOptical communicationSimulation software

The invention discloses an intelligent eye diagram analysis method by use of deep learning based on a convolutional neural network (CNN), which relates to the technical field of optical communication. A CNN module is built and trained to analyze the performance of an eye diagram. The method includes the following steps: acquiring an eye diagram training data set; preprocessing an eye diagram; training the CCN module, and extracting features; inputting the preprocessed eye diagram needing analysis into the trained CNN module for mode identification and performance analysis; and outputting the analysis result. By applying the deep learning technology based on the convolutional neural network to eye diagram analysis, the problem that original data cannot be processed directly without manual intervention in the traditional eye diagram performance analysis is solved. By using the CNN, intelligent and automatic analysis of the original image information of an eye diagram is realized. The CNN module can be embedded into a test instrument as an eye diagram software processing module of an oscilloscope or as an eye diagram analysis module of simulation software to carry out intelligent signal analysis and performance monitoring.

Owner:BEIJING UNIV OF POSTS & TELECOMM

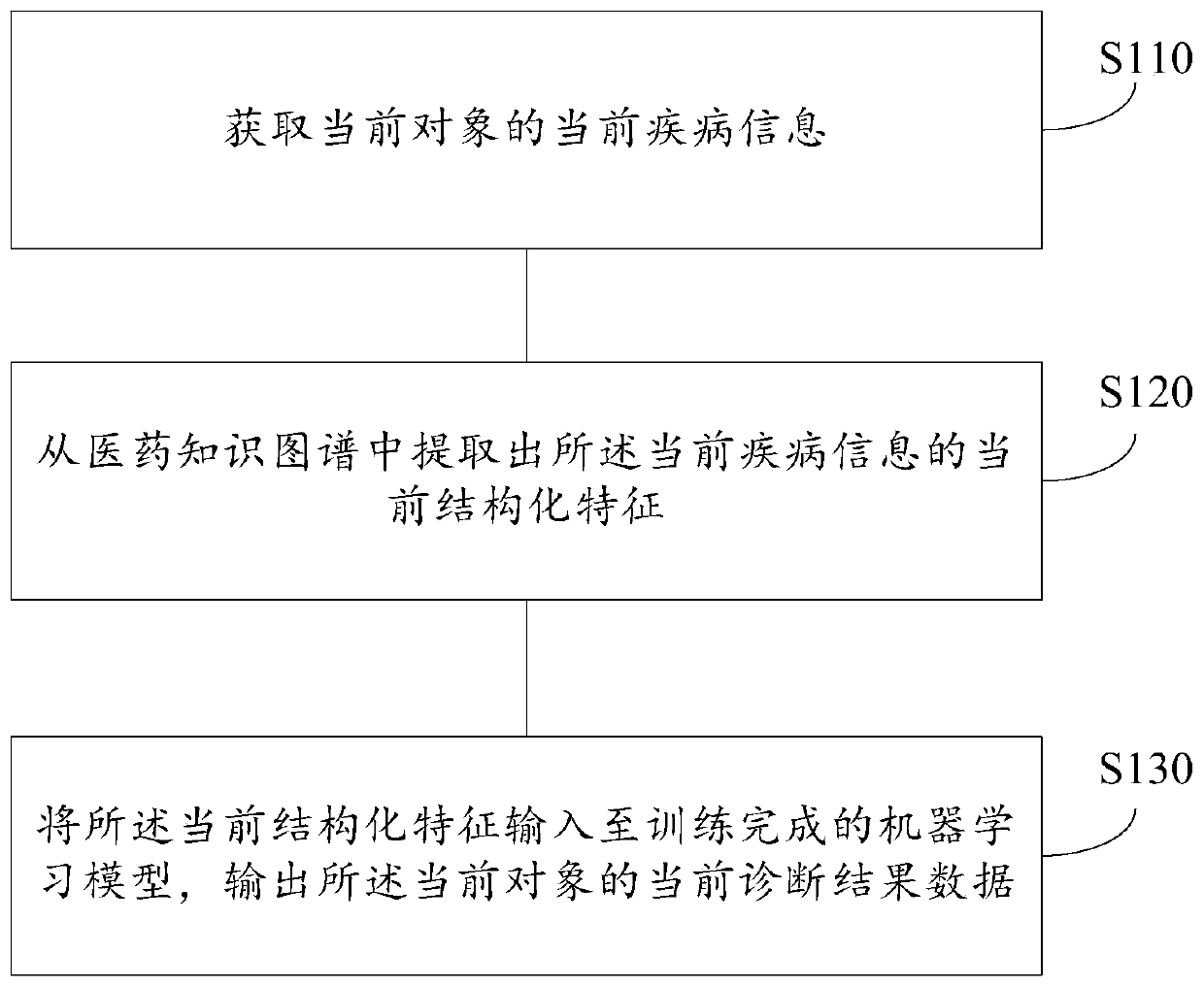

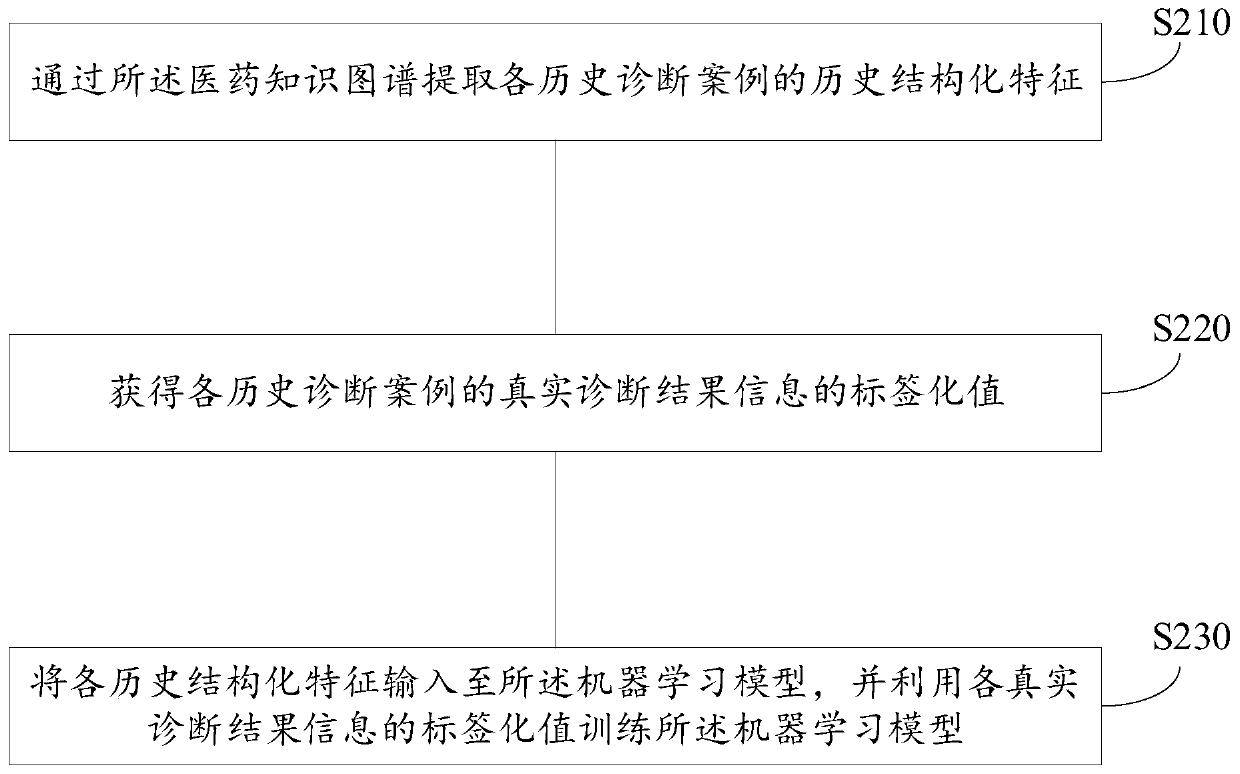

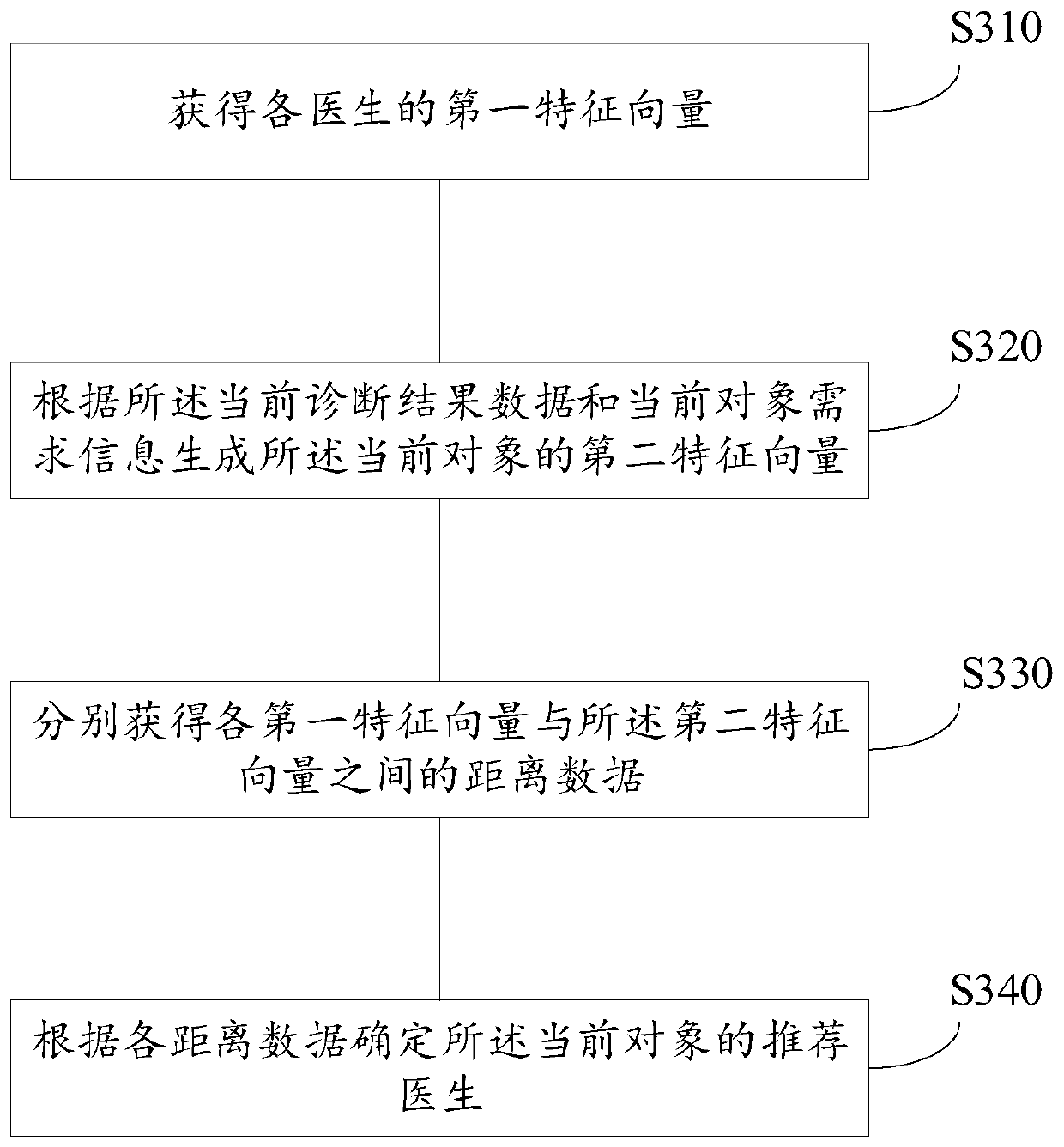

Data processing method and device, medium and electronic equipment

InactiveCN110335676ARealize automation and intelligenceImprove accuracy and diagnostic efficiencyMedical communicationMedical data miningMachine learningDisease

Owner:TAIKANG LIFE INSURANCE CO LTD

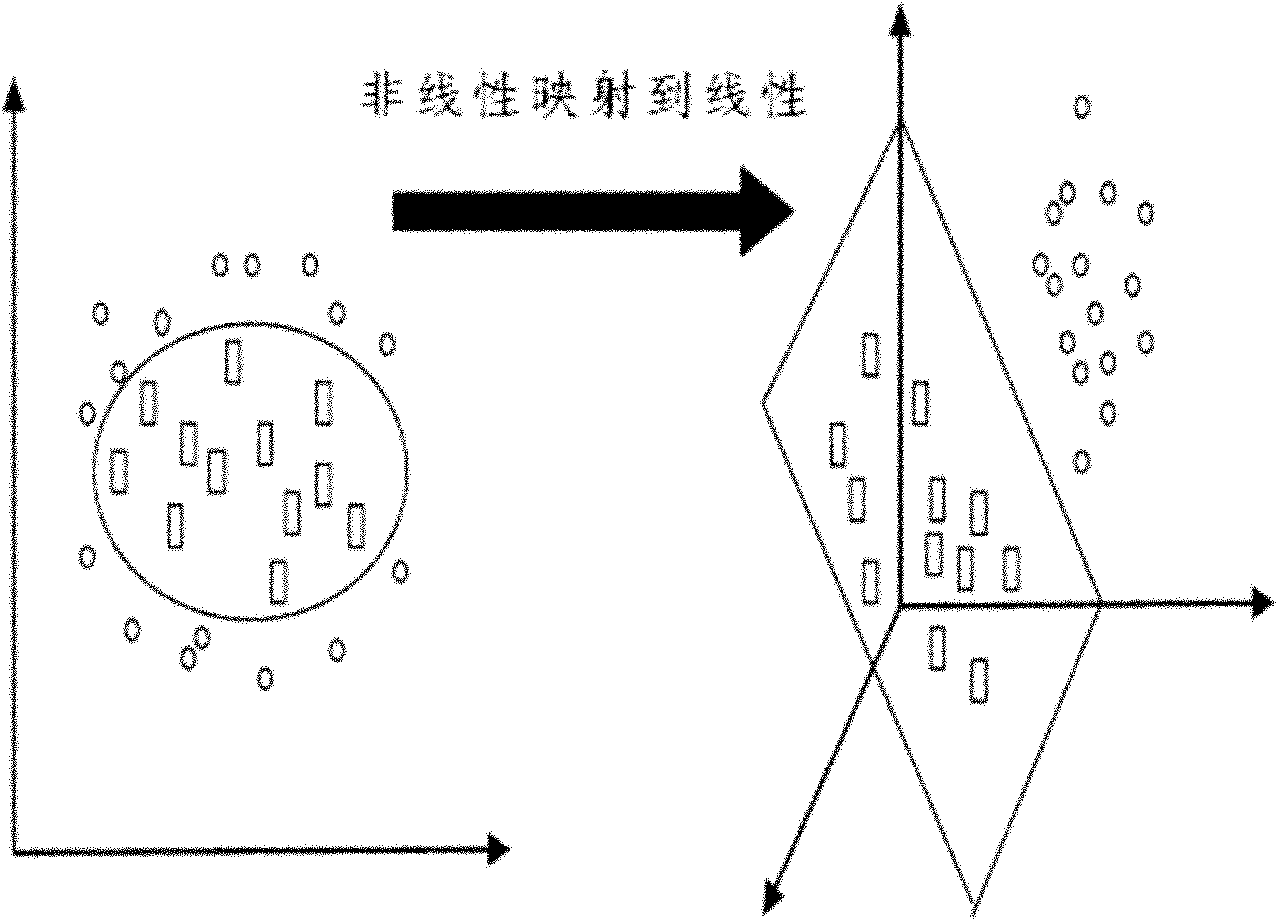

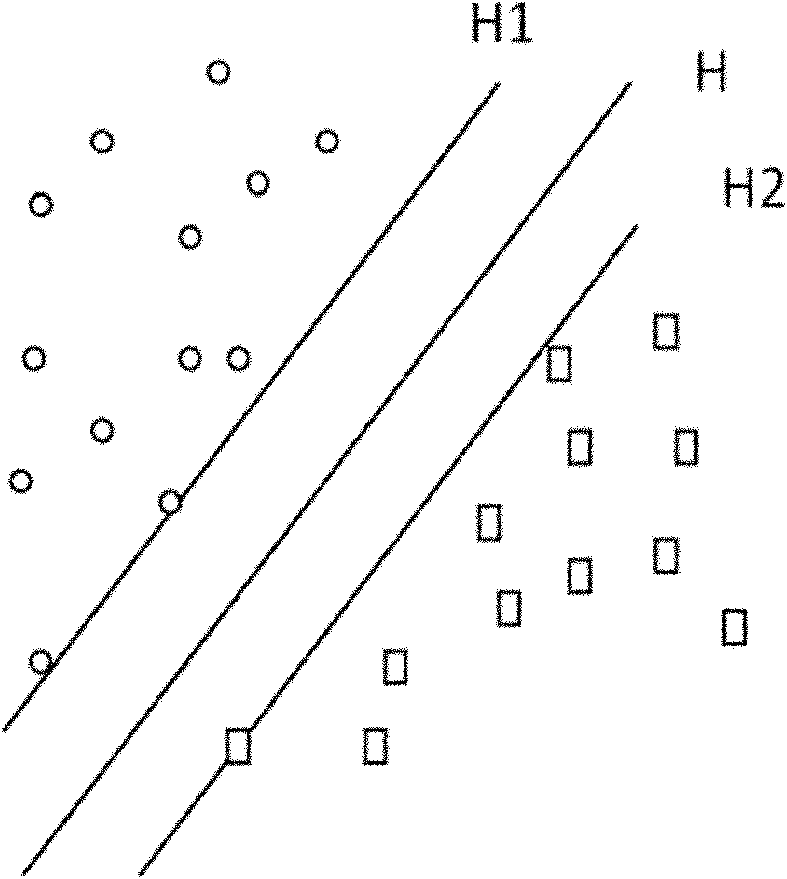

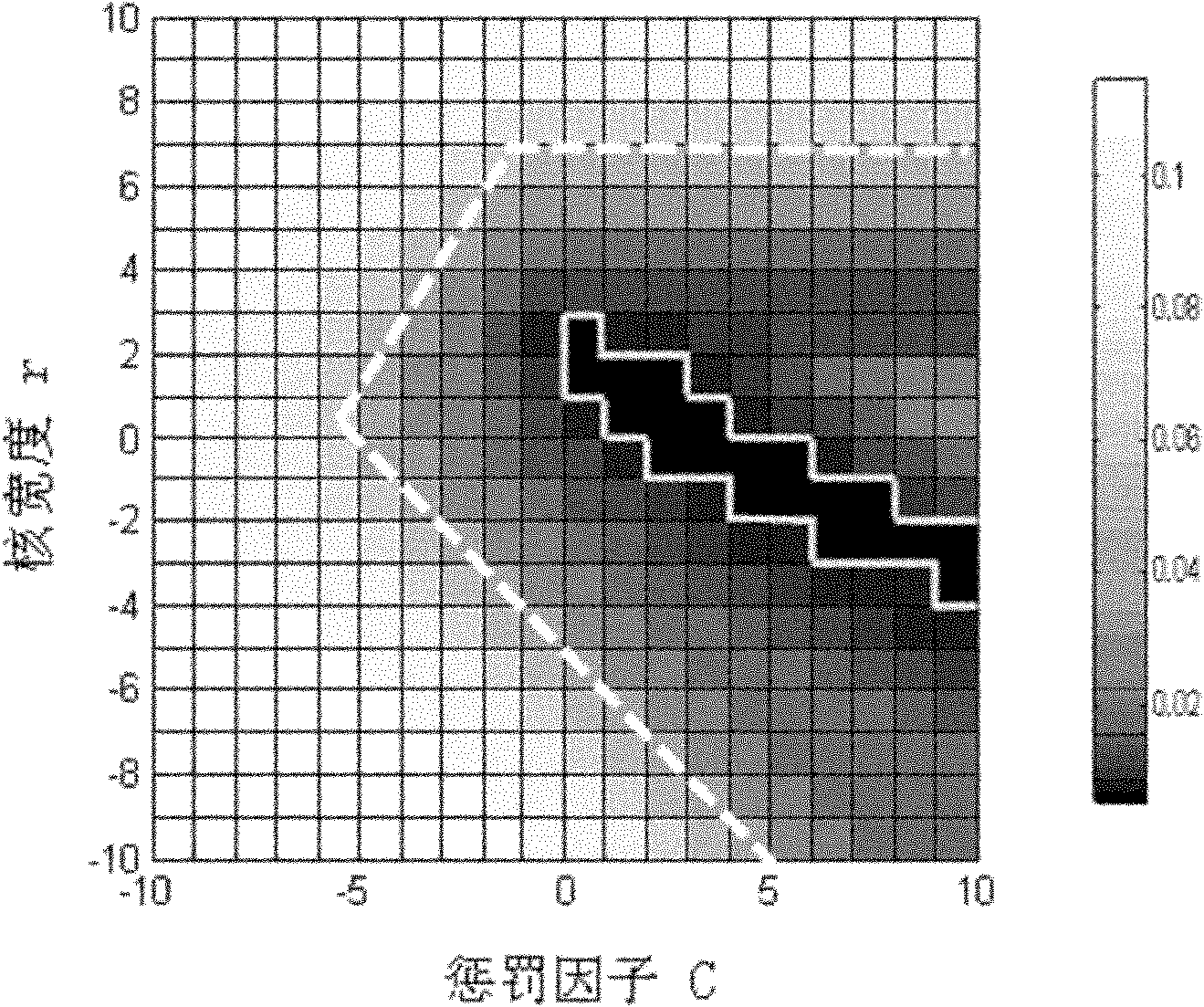

Support vector machine-based parameter-adaptive motion prediction method

InactiveCN102024180ARealize automation and intelligenceImprove calculation accuracyInference methodsLogarithmic spaceSupport vector regression machine

The invention discloses a support vector machine (SVM)-based parameter-adaptive motion prediction method, which comprises the following steps of: (1) converting sample data into a standard prediction training dynamic sequence data format of an SVM, normalizing data extremums and adding a decimal omega to each normalized extremum; (2) performing three-pixel-width linear searching by utilizing a minimum mean square error principle in grids of a logarithmic space coordinate system, finding an optimal parameter combination out and obtaining an optimal prediction model; and (3) sampling flutter data in real time, sampling k flutter displacements and performing SVM real-time prediction by using the optimal prediction model obtained by the step (2) to obtain the flutter displacement. The supportvector machine-based parameter-adaptive motion prediction method provided by the invention ensures high computing accuracy and high computing efficiency, can be used in various fields of SVM-based regression fitting and prediction, avoid the complexity of conventional manual parameter adjustment and simultaneously meet requirements on accuracy and efficiency, and well realizes automation and intellectualization.

Owner:ZHEJIANG UNIV

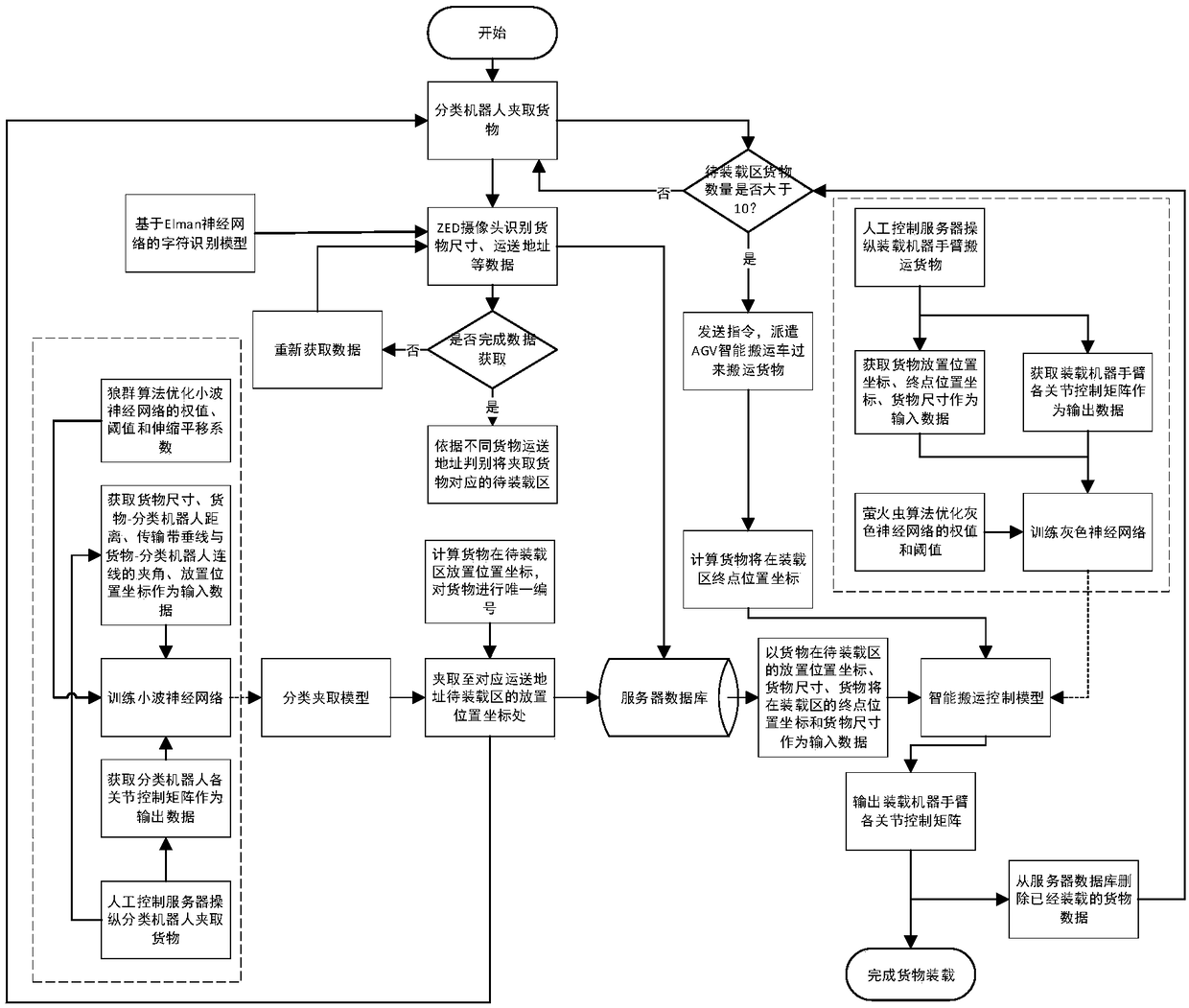

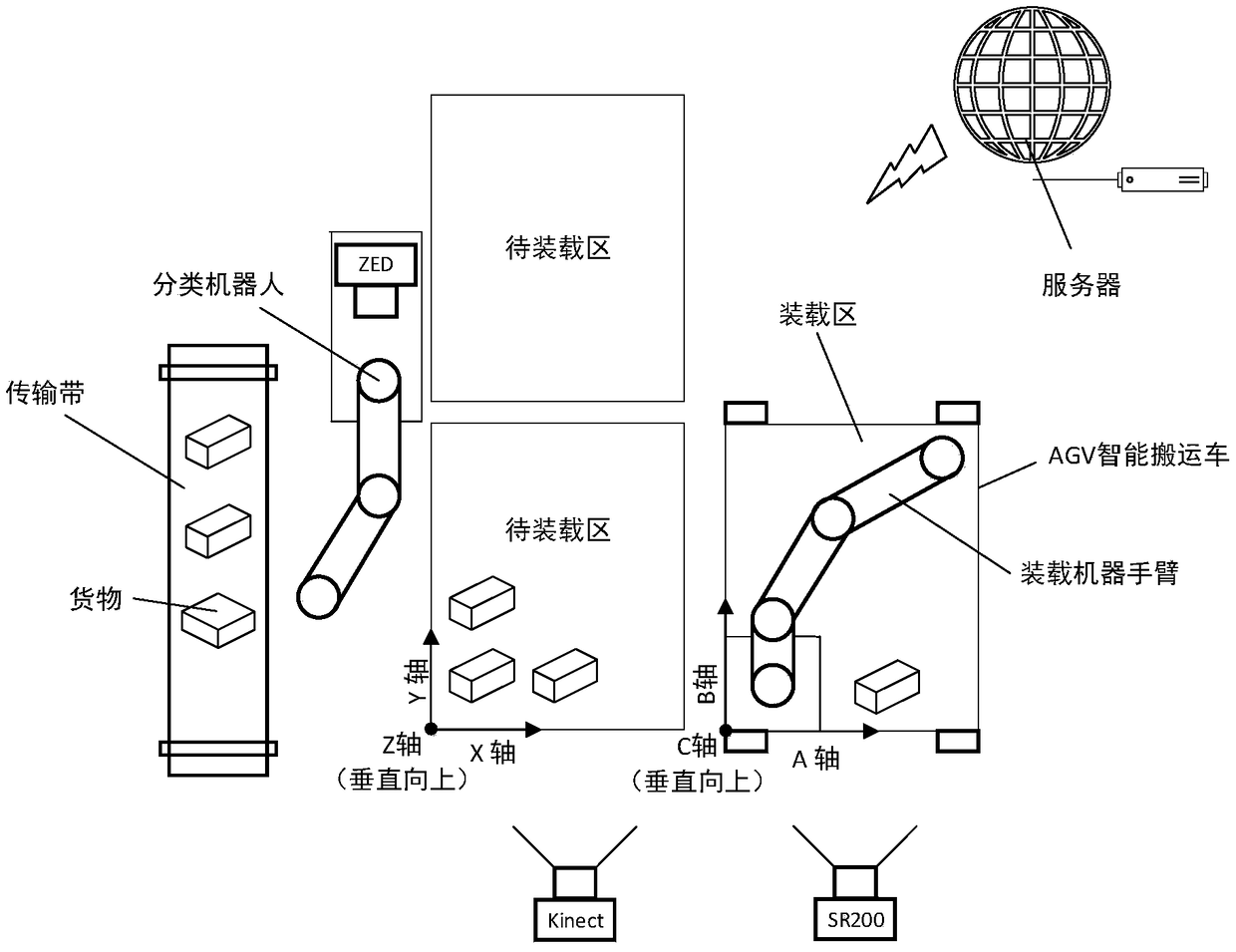

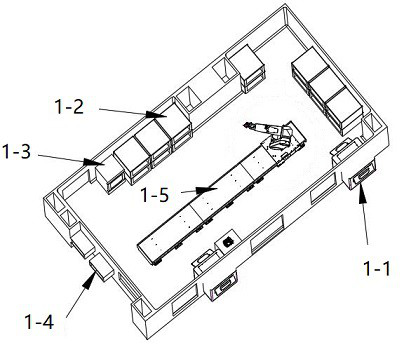

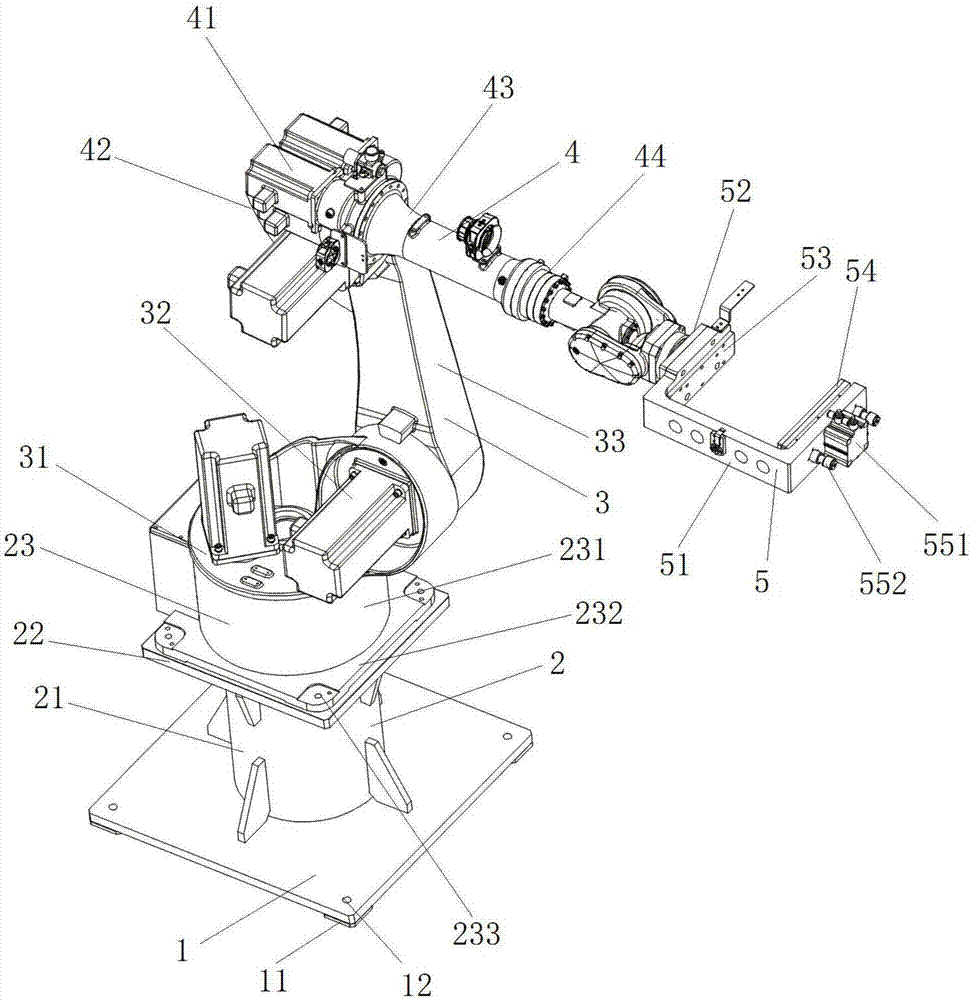

Loading method and device of intelligent logistics environment robot

ActiveCN108942946ASimple structureEasy to operateProgramme-controlled manipulatorMachine visionLogistics management

The invention discloses a loading method and device of an intelligent logistics environment robot. The method comprises the following steps that firstly, cargo information is acquired in real time; secondly, the coordinates of the placement positions of cargoes in to-be-loaded areas corresponding to conveying addresses are calculated; thirdly, a classification robot is utilized for clamping the cargoes to the corresponding to-be-loaded areas used for temporary storage from a conveying belt; fourthly, the coordinates of the final positions of the cargoes in loading areas of an AGV intelligent carrier; and fifthly, the cargoes are carried to the loading areas of the AGV intelligent carrier according to a control matrix obtained by an intelligent carrying control model. The cargo sizes, the cargo conveying addresses, the cargo position coordinates and other information are automatically acquired by combining machine vision, the classification robot and the intelligent carrier are utilizedfor automatically and intelligently classifying and loading the cargoes by setting up a neural network model, the loading error rate is greatly reduced, and the loading efficiency is improved.

Owner:CENT SOUTH UNIV

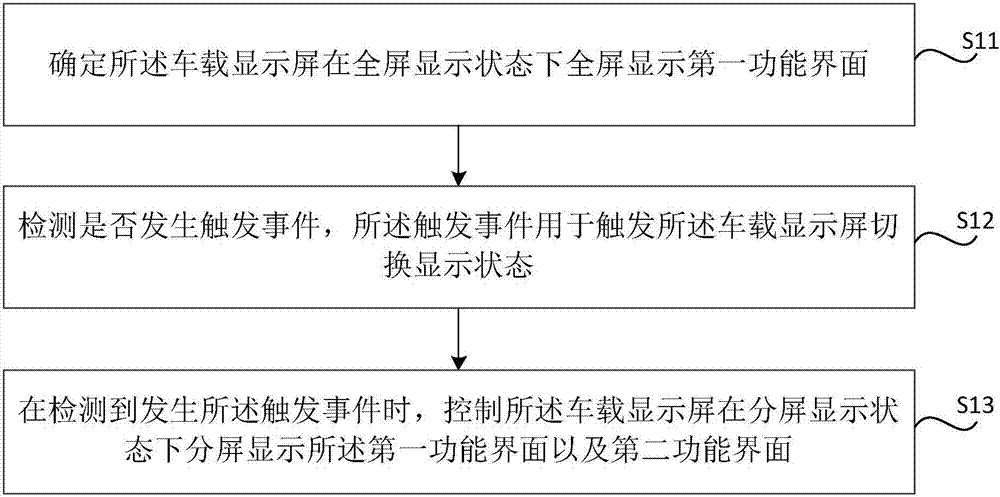

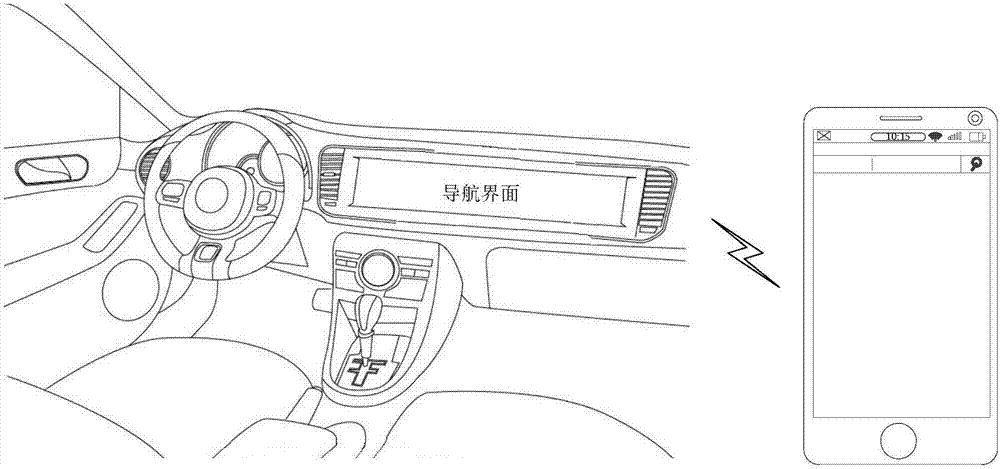

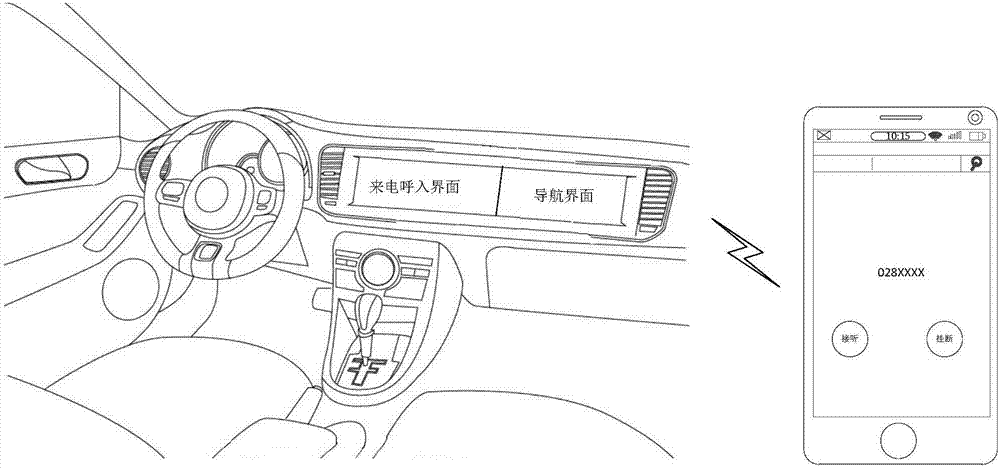

Method and device for controlling vehicle-mounted display screen and vehicle

InactiveCN107487274ARealize automation and intelligenceSimplify user operationsVehicle componentsReal-time computingAutomation

The invention relates to a method and device for controlling a vehicle-mounted display screen and a vehicle. With adoption of the method for controlling the vehicle-mounted display screen, the vehicle-mounted display screen is triggered by triggering events to switch the displaying states, when occurrence of the triggering events is detected, the vehicle-mounted display screen is controlled to be switched to split-screen displaying, automation and intelligence of split-screen displaying are achieved, user operation is simplified, and user experience is improved.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

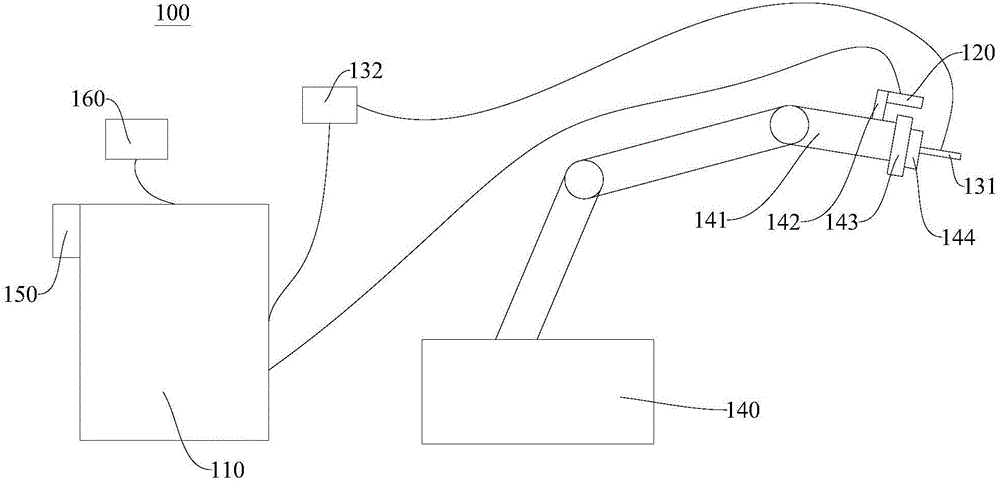

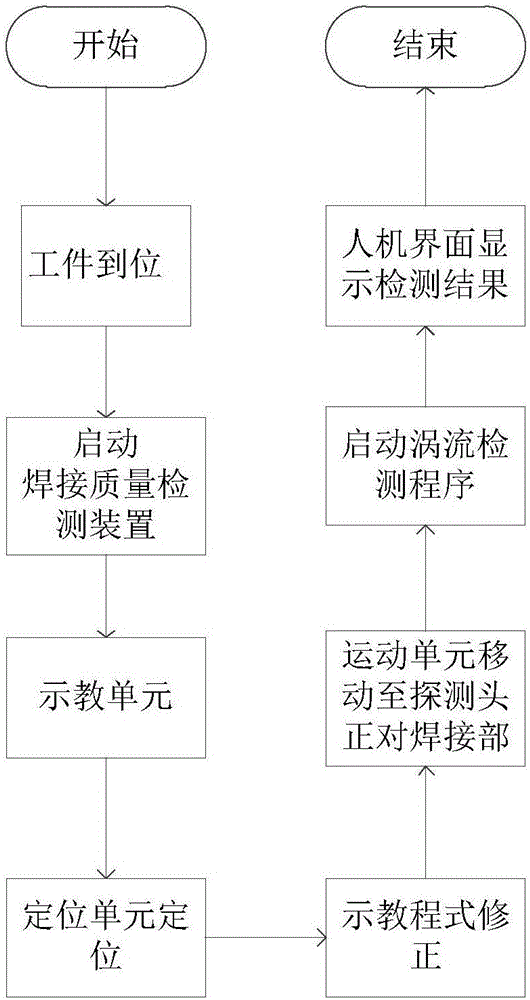

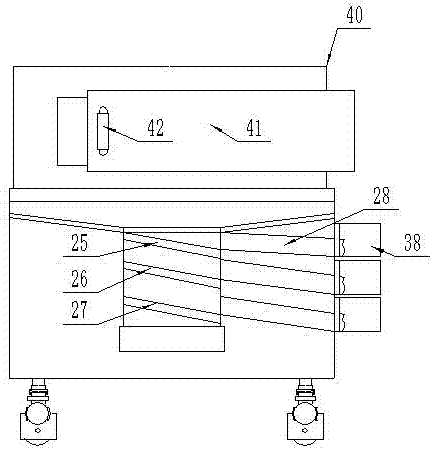

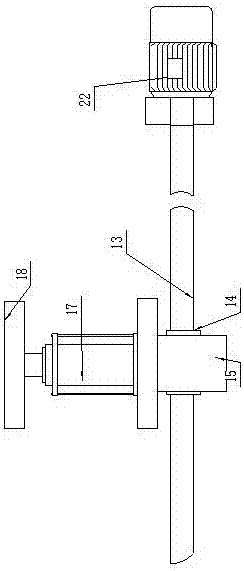

Welding quality detection device

InactiveCN106383166ARealize automation and intelligenceReduce labor intensityMaterial magnetic variablesEngineeringAutomation

The invention discloses a welding quality detection device. The welding quality detection device comprises a control unit, a positioning unit, a detection unit and a moving unit, wherein the positioning unit is connected with the control unit, and is used for transmitting positional information of a welding part to the control unit; the detection unit is used for detecting the welding information of the welding part; the positioning unit and the detection unit are arranged on the moving unit, and the moving unit is connected with the control unit so as to enable the detection unit to move to a detection position of the welding part according to the positional information, wherein the control unit is set to judge the welding quality of the welding part according to the positional information and the welding information. According to the welding quality detection device disclosed by the invention, automation and intellectualization of welding quality detection can be realized, the labor intensity is reduced, the detection efficiency is high, the influence of human factors is reduced, the stability and precision of detection are greatly promoted, and the detection cost is low.

Owner:BAIC MOTOR CORP LTD

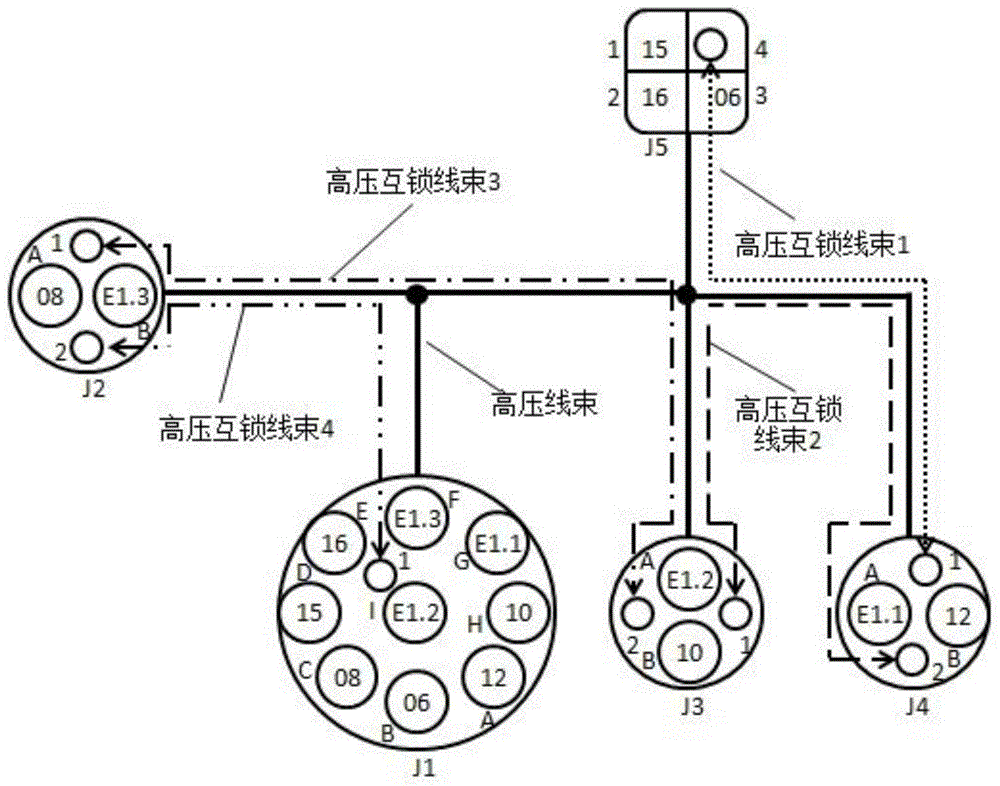

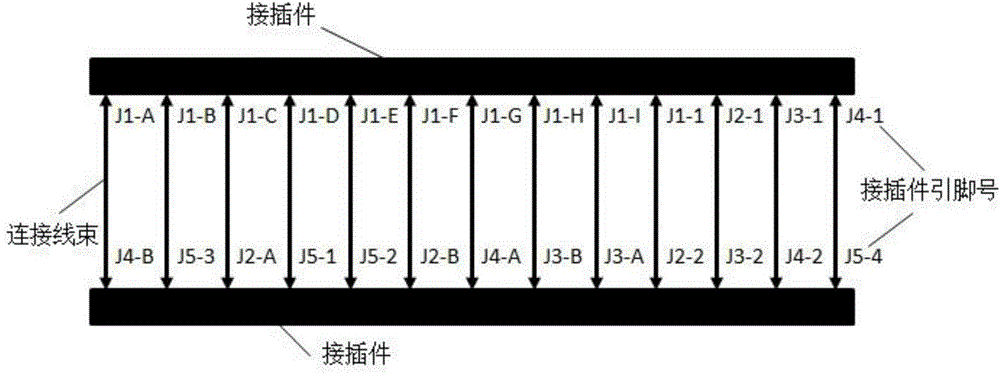

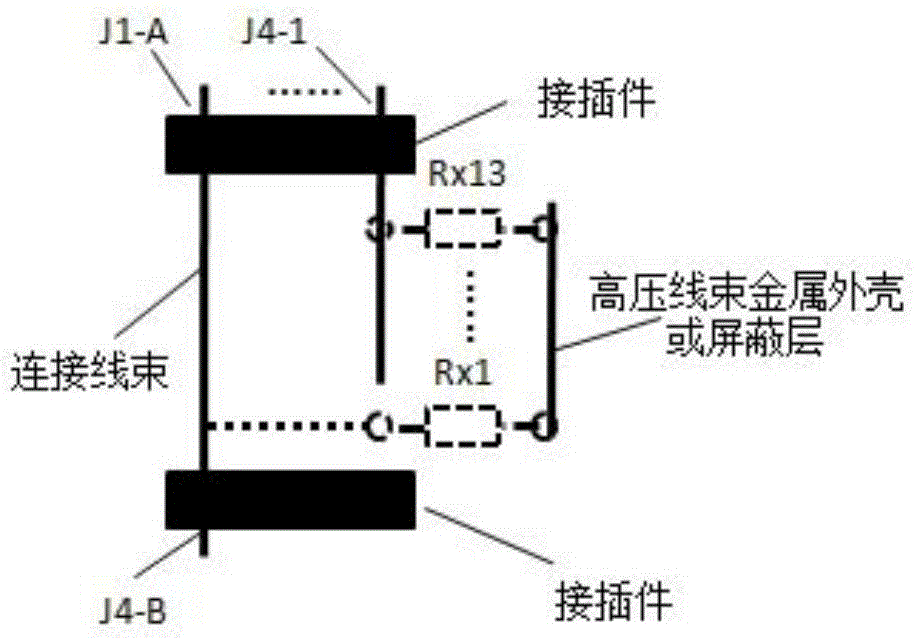

Device and method for detecting insulating property of high-voltage ancillary equipment of electromobile

InactiveCN104569751ARealize automation and intelligenceReduce workloadResistance/reactance/impedenceTesting circuitsInsulation resistanceQuality control

The embodiment of the invention provides a device and a method for detecting the insulating property of high-voltage ancillary equipment of an electromobile. The device comprises a high-voltage power supply, a relay switch matrix circuit, an adapter wire harness, a programmable logic device, an acquisition circuit and a single-chip microcomputer, wherein the single-chip microcomputer sends a control command to the programmable logic device according to the detected high-voltage grade, and the programmable logic device closes corresponding relay switches; the relay switch matrix circuit transmits high-voltage current output by the high-voltage power supply to the adapter wire harness through the closed relay switch; the adapter wire harness transmits high-voltage current to gating connector terminals; the acquisition circuit is connected with the electric conduction parts of all connector terminals of a high-voltage wire harness, and transmits the acquired voltage value to the single-chip microcomputer, and the single-chip microcomputer calculates the insulating resistance value according to the voltage value. According to the invention, the single-chip microcomputer and the programmable logic device are adopted for control, so that automatic and intelligent testing of the insulating resistance is realized, and accordingly, the workload of quality control personnel is reduced.

Owner:BEIJING ELECTRIC VEHICLE

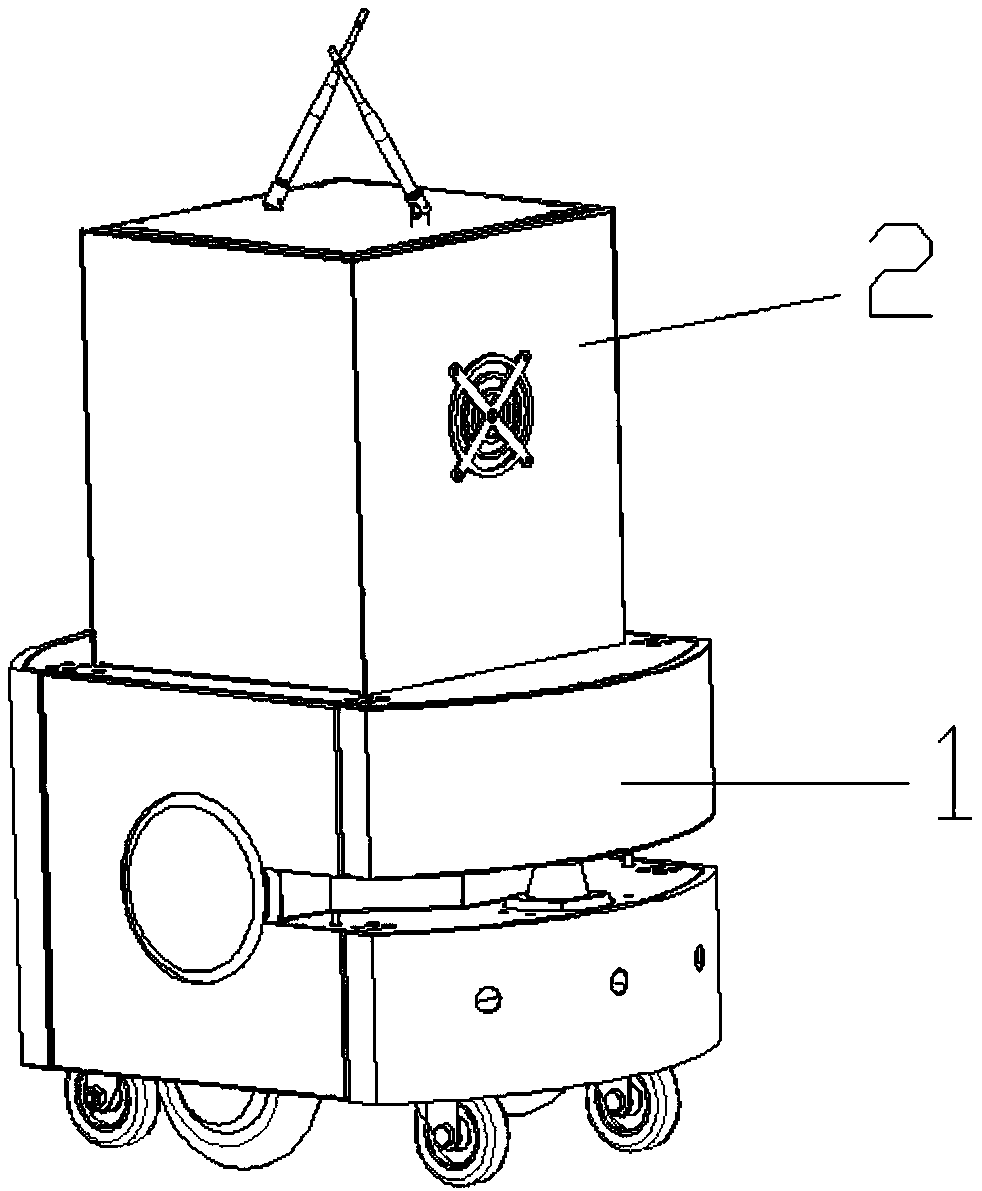

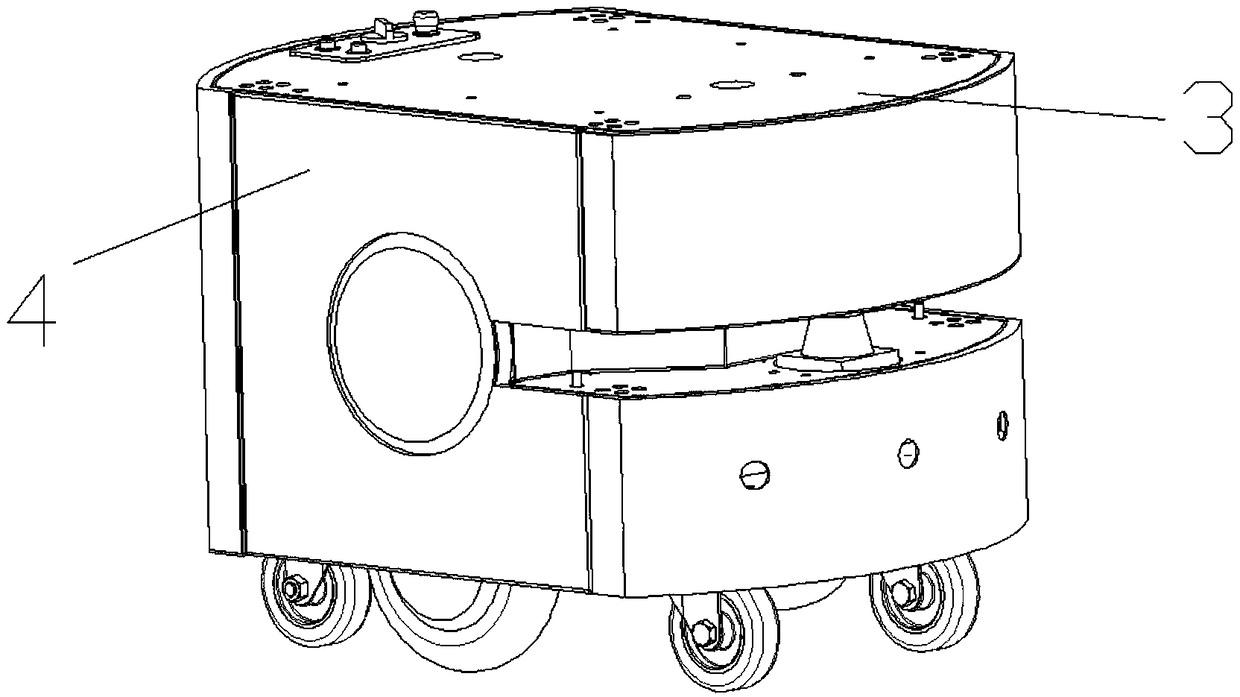

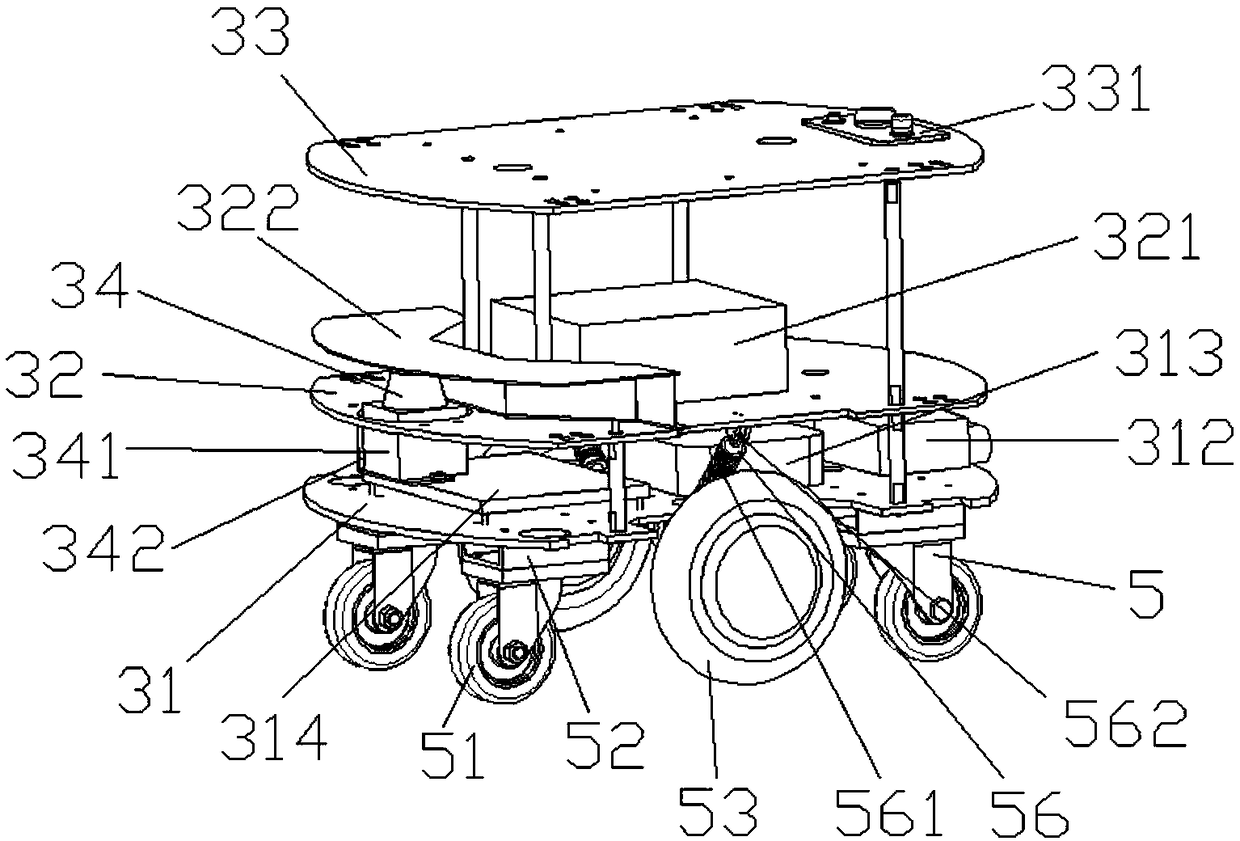

Indoor itinerant wheel-type mobile disinfection robot

PendingCN109316612AImprove disinfection effectRealize automation and intelligenceLavatory sanitoryChemicalsControllabilityInteractive control

The invention discloses an indoor itinerant wheel-type mobile disinfection robot. The indoor itinerant wheel-type mobile disinfection robot comprises a mobile platform module and a box body module. Byarranging an ultraviolet generation apparatus of the mobile platform module and an ozone generation apparatus of the box body module, three disinfection ways are provided for the disinfection robot,so that the disinfection effect can be significantly improved; by arranging a sensing and control assembly carried by the indoor itinerant wheel-type mobile disinfection robot, the autonomous disinfection can be realized or the disinfection robot can perform disinfection by virtue of human-machine interactive control; the automation and intelligence degrees are high, and the human-machine interaction is high. The indoor itinerant wheel-type mobile disinfection robot provided by the invention has the characteristics of good disinfection effect, high automation and intelligence degrees and highhuman-machine interaction controllability.

Owner:华南智能机器人创新研究院

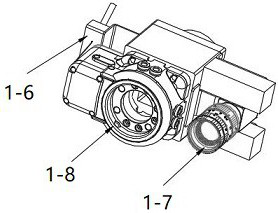

Fully-automatic kiwi fruit picking end effector

InactiveCN103404307ARealize automation and intelligenceAvoid labor-intensivePicking devicesTorsion springKiwi fruit

The invention relates to a fully-automatic kiwi fruit picking end effector. The fully-automatic kiwi fruit picking end effector comprises a holding device, a shearing device, a detecting device and a machine case housing. The holding device comprises a horizontal type speed reducer driving motor, lifting mechanism belt pulleys, a lifting mechanism speed reducer assembly, a screw, a lifting nut, connecting rods and picking fingers and is used for driving the picking fingers to move back and forth and holding and separating kiwi fruit; the shearing device comprises a vertical type speed reducer driving motor, winding mechanism belt pulleys, a winding mechanism speed reducer assembly, winders, torsion springs, electromagnets and blades and is used for cutting the carpopodium of the kiwi fruit; the detecting device comprises a picking pressure sensor, a limit pressure sensor and a revolution sensor and is used for detecting information of all positions during a kiwi fruit picking process and providing control information for a controller. The fully-automatic kiwi fruit picking end effector is easy to control, reliable in operation, achieves automated and intelligentized kiwi fruit picking, saves manpower, increases operation efficiency and reduces labor costs.

Owner:NORTHWEST A & F UNIV

Full-automatic cell production line

ActiveCN113073052ARealize automatic liquid additionRealize automatic liquid changeBioreactor/fermenter combinationsBiological substance pretreatmentsProduction lineRobotic arm

The invention belongs to the technical field of biology, and relates to a full-automatic cell production line. The full-automatic cell production line comprises a culture zone and an operation area,; the culture zone comprises a B-level platform body, and the B-level platform body comprises a culture area, a refrigeration area and a robot provided with a motion track; the motion track of the robot is linearly arranged; the culture area, the refrigeration area and a manual delivery window are all arranged around the track and are all located in an operation area of the robot; a liquid storage table, a cell factory liquid changing device and a centrifugal bottle liquid changing device are integrated in the operation area; a transfer window is adopted between the culture area and the operation area to transfer materials; and the transfer window is provided with a transfer rotating disc and a transfer rotating disc driving mechanism, and the transfer rotating disc is provided with a zero position for the robot in the culture zone to pick and place the materials and a working position for a robotic arm in the operation area to pick and place the materials. The full-automatic cell production line is mainly used for full-automatic cell batch production.

Owner:HELP STEM CELL INNOVATIONS CO LTD

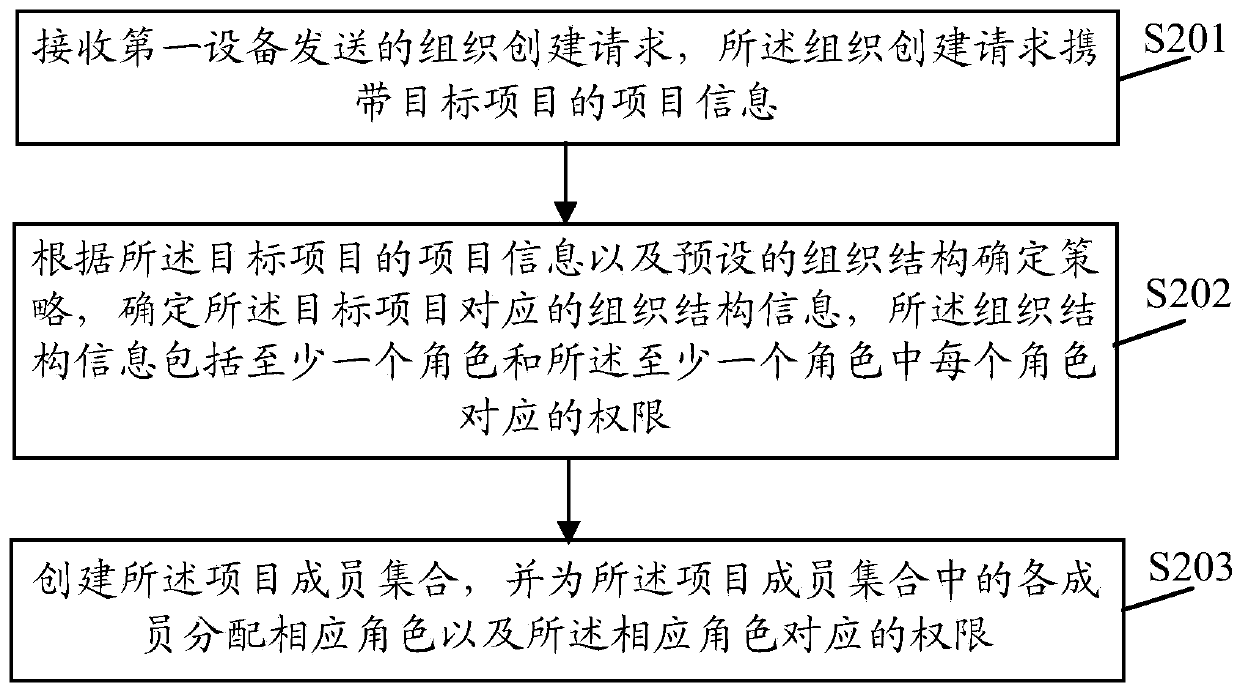

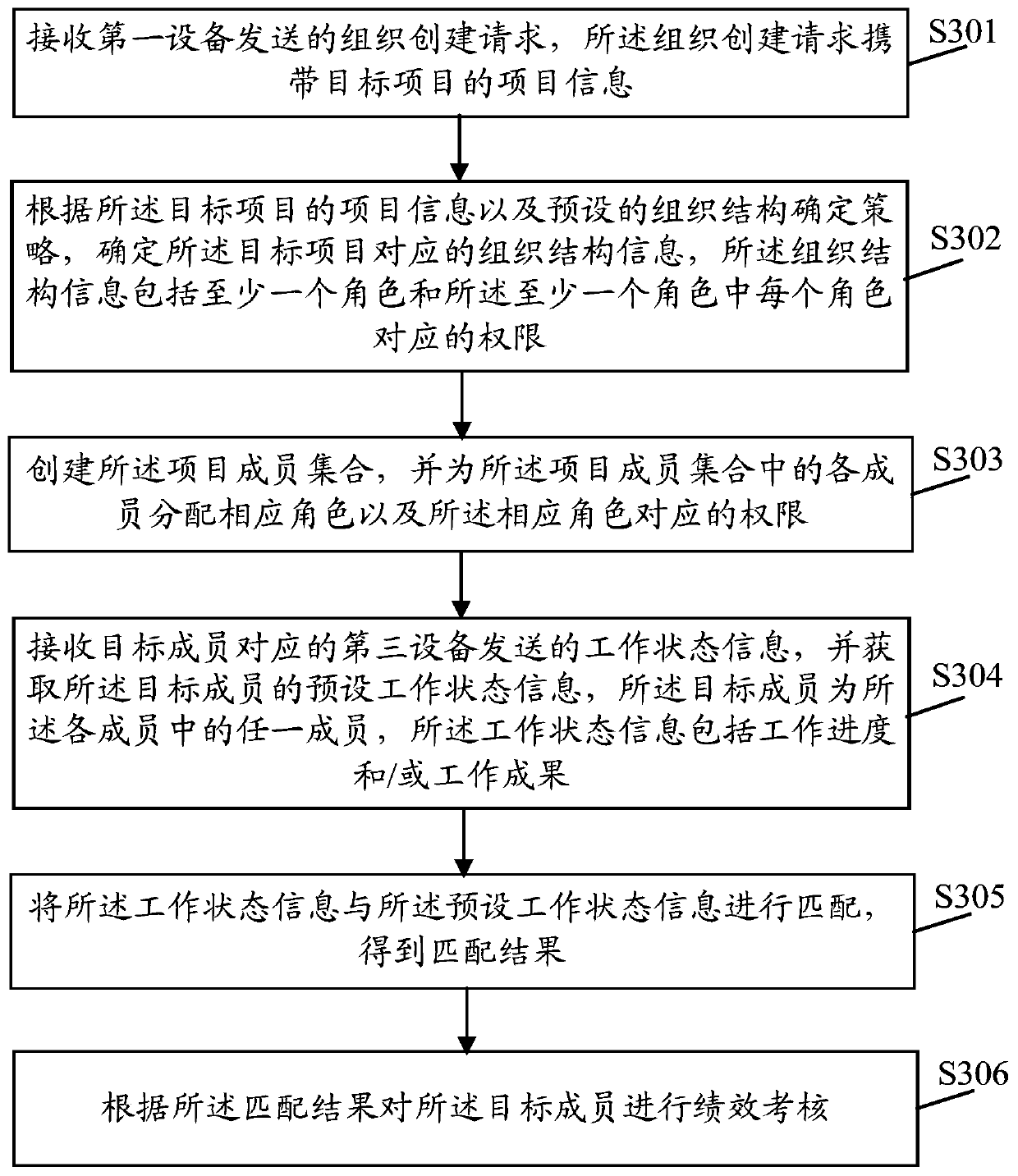

Project management method and device, electronic equipment and storage medium

PendingCN110223040ARealize automation and intelligenceImprove management efficiencyOffice automationProject managementComputer science

The embodiment of the invention provides a project management method and device, electronic equipment and a storage medium, and the method comprises the steps: receiving an organization creation request sent by first equipment, the organization creation request carrying project information of a target project; wherein the organization creating request is used for requesting to create a project member set for executing the target project; according to the project information of the target project and a preset organization structure determining strategy, organization structure information corresponding to the target project is determined, and the organization structure information comprises at least one role and a permission corresponding to each role in the at least one role; and creating the project member set, and allocating a corresponding role and a permission corresponding to the corresponding role to each member in the project member set. By the adoption of the method and device,the automatic intelligent process of project member set creation and role and authority distribution can be achieved, and then project management efficiency is improved.

Owner:LAUNCH TECH CO LTD

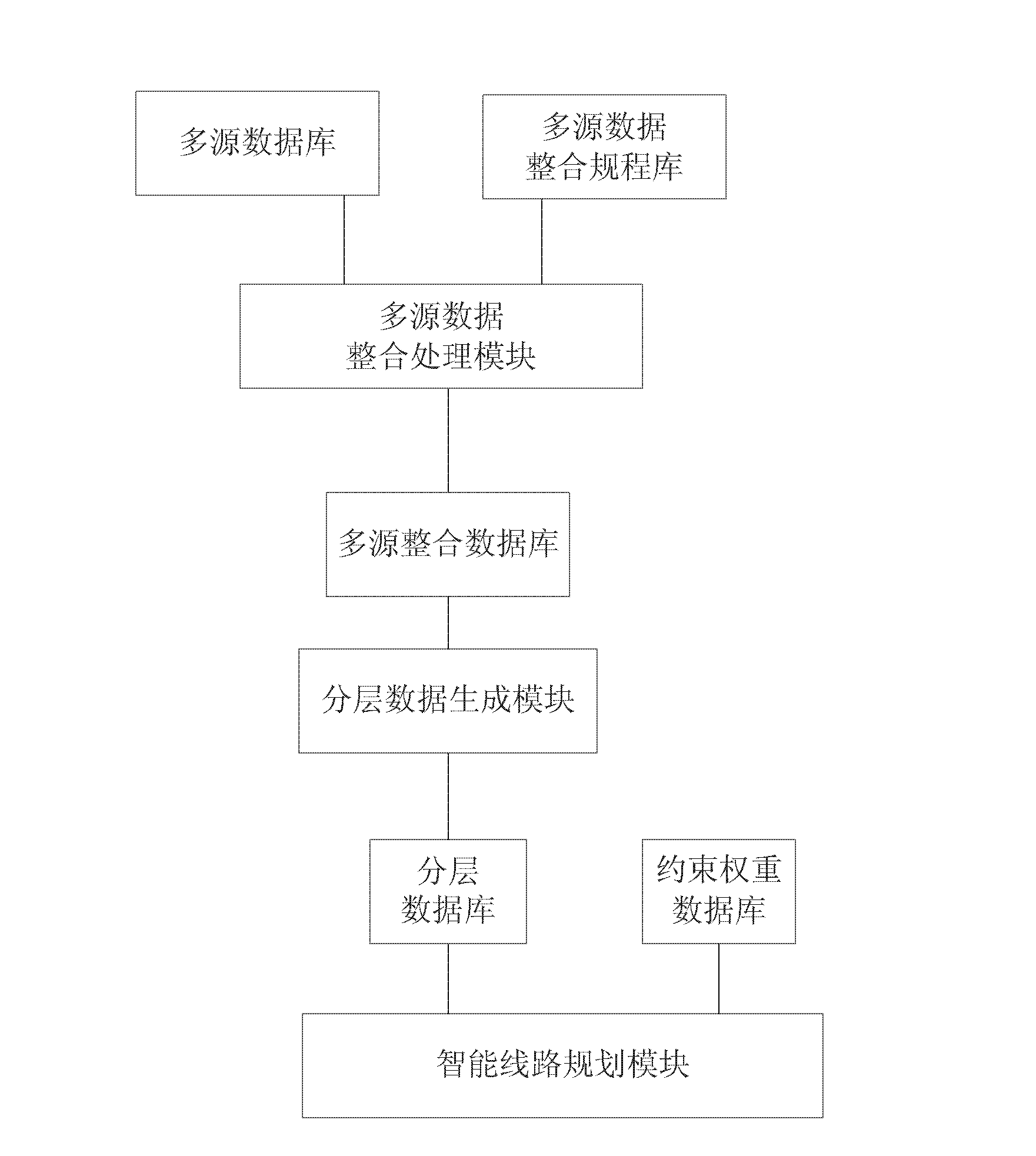

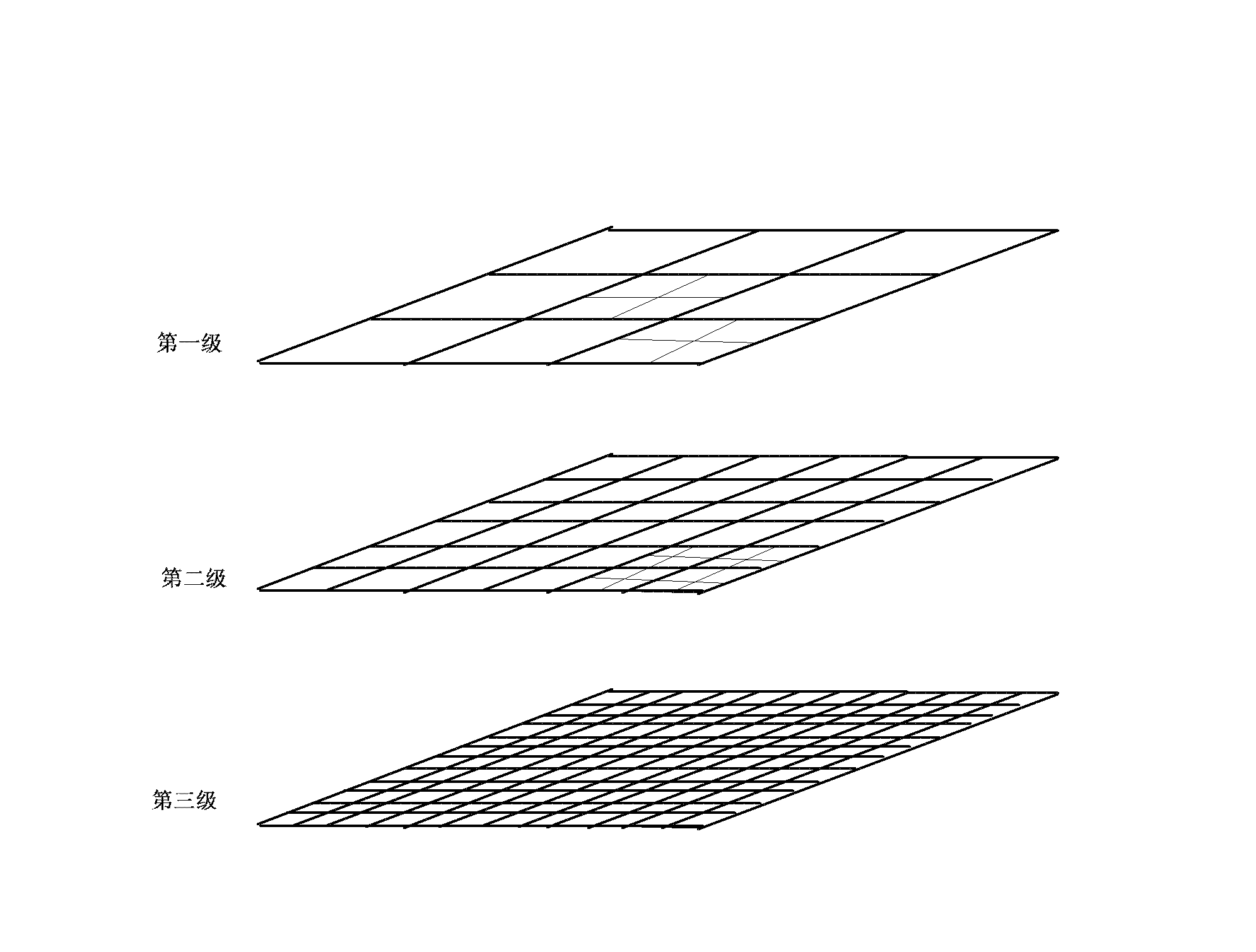

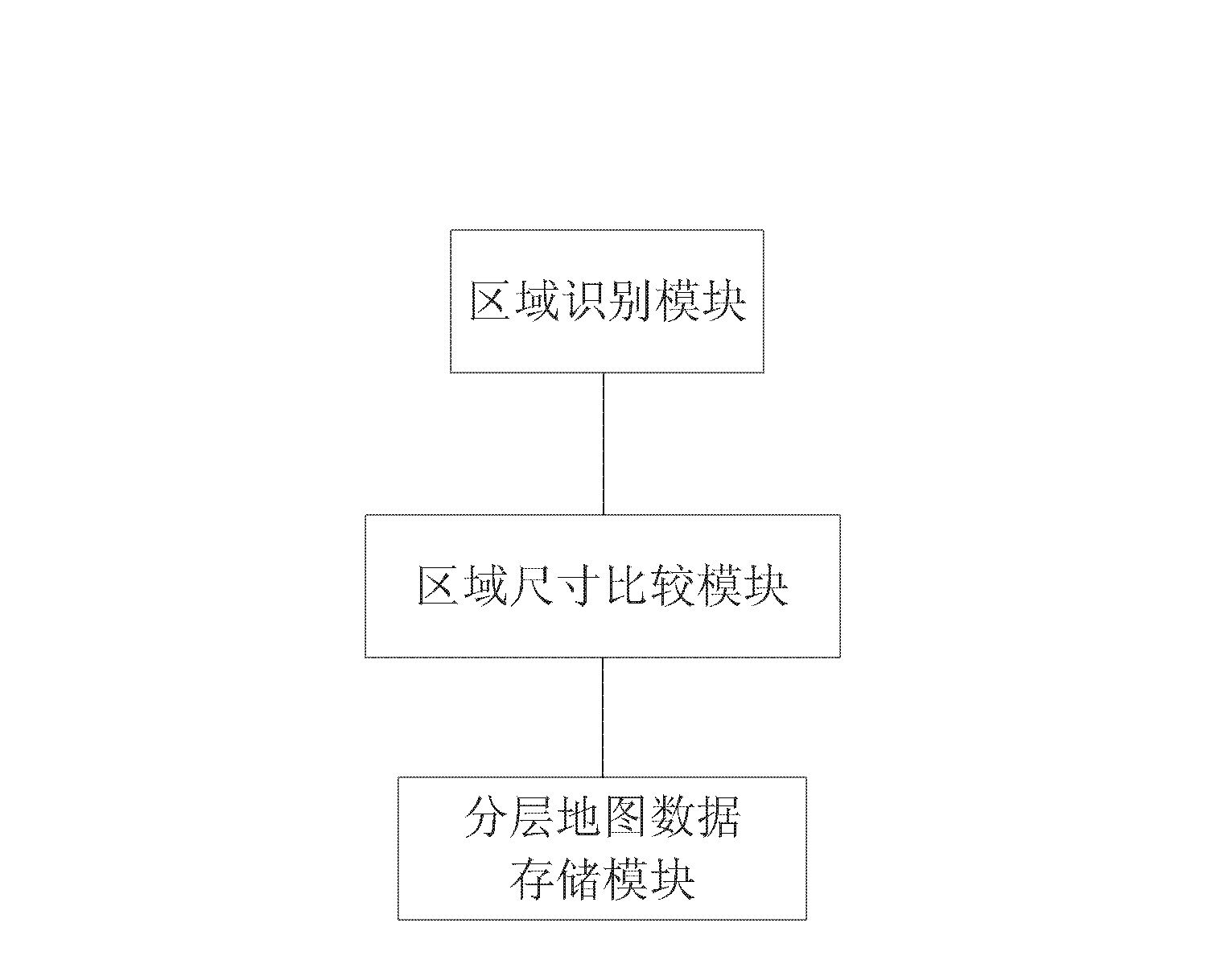

Intelligent line selecting system and method for power transmission line

InactiveCN102509165ARealize automation and intelligenceRealize line selection technologyData processing applicationsSpecial data processing applicationsComputer scienceLine planning

The invention provides an intelligent line selecting system and method for power transmission line. The system comprises a multisource integrated data base, a hierarchical data generating module, a hierarchical data base, a constraint weight data base and an intelligent line planning module. The technical scheme includes that multisource data of all aspects are integrated to form hierarchical map data according to area dimensions divided according to attributes, each area is planned and screened based on the constraint weight value of the area to form a power transmission line scheme, and automatic and intelligent power transmission line selecting technique is realized. During power transmission line selecting, the areas in the hierarchical map is screened sequentially from top to bottom, so that the map of the area for line selecting can be simplified quickly, operating quantity during the intelligent processing is reduced greatly, and line selecting efficiency is improved.

Owner:NORTH CHINA GRID +1

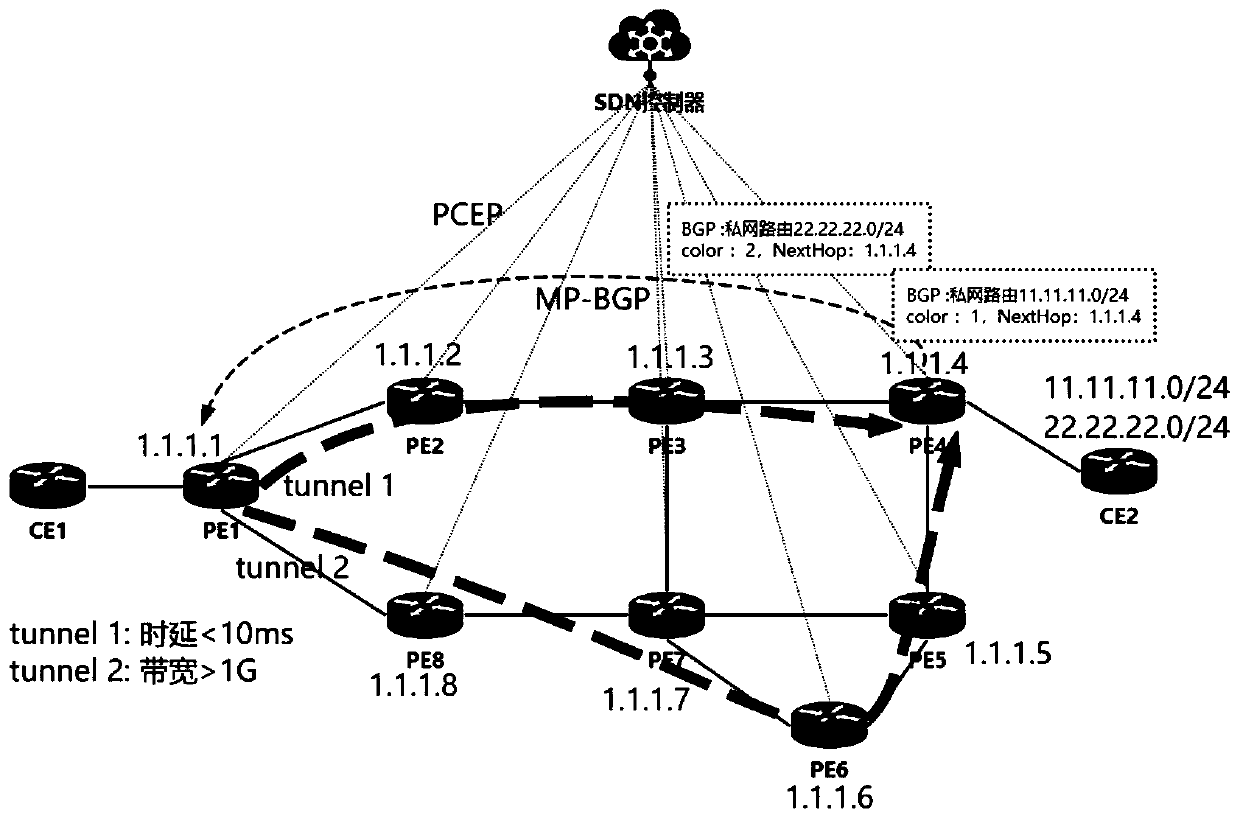

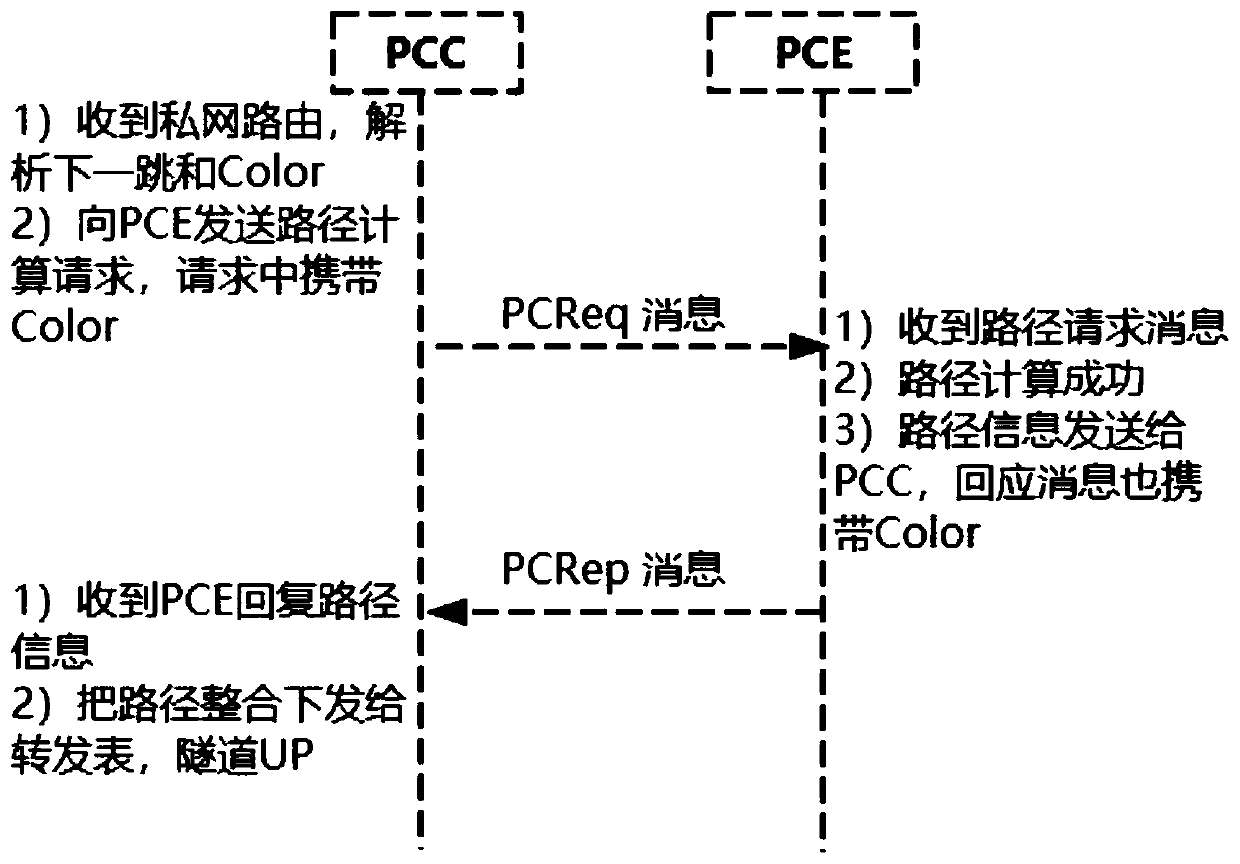

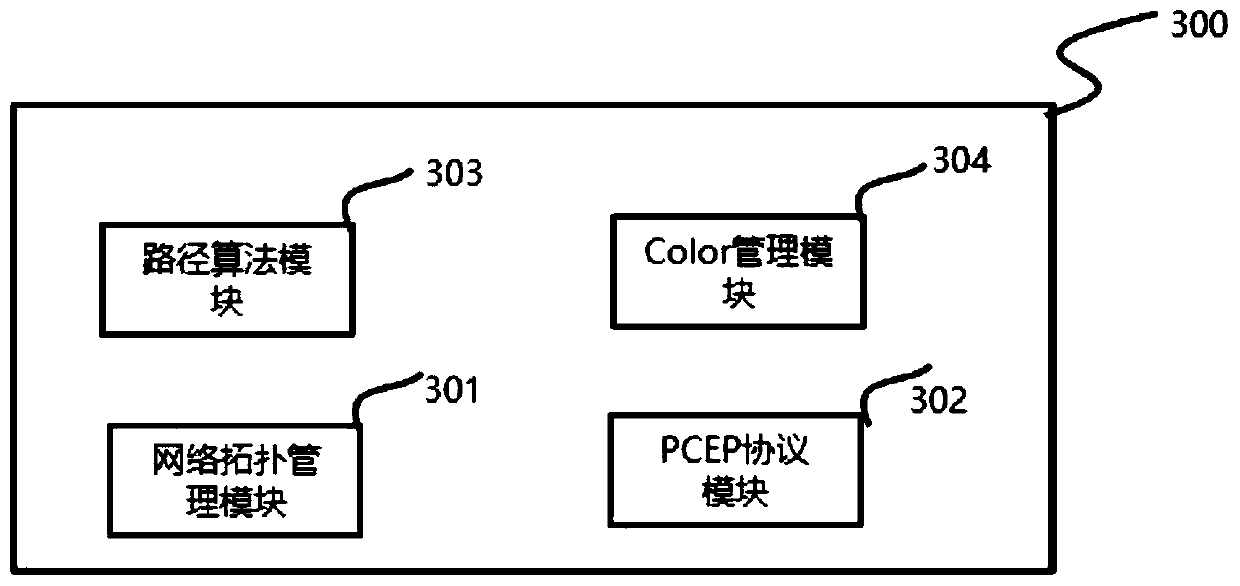

Method and system for expanding PCEP protocol to automatically create tunnel in SDN scene

ActiveCN111245644ASimplify network deploymentRealize automation and intelligenceNetworks interconnectionComplex networkPathPing

The invention provides a method and a system for expanding a PCEP protocol to automatically create a tunnel in an SDN scene. In SDN scenarios, SR-TE is automatically created based on a service routingdestination, different forwarding paths are created based on a cooler of a private network route, an SDN controller is adopted to calculate a forwarding path meeting the service requirements for theSR-TE tunnel. According to the method, the problems of complex configuration and network adjustment in the backbone network at present can be effectively solved, the service requirements can be automatically matched through the automatically created SR-TE tunnel and the intelligent path algorithm, the service application drives the network deployment, and the network deployment is simplified.

Owner:PURPLE MOUNTAIN LAB

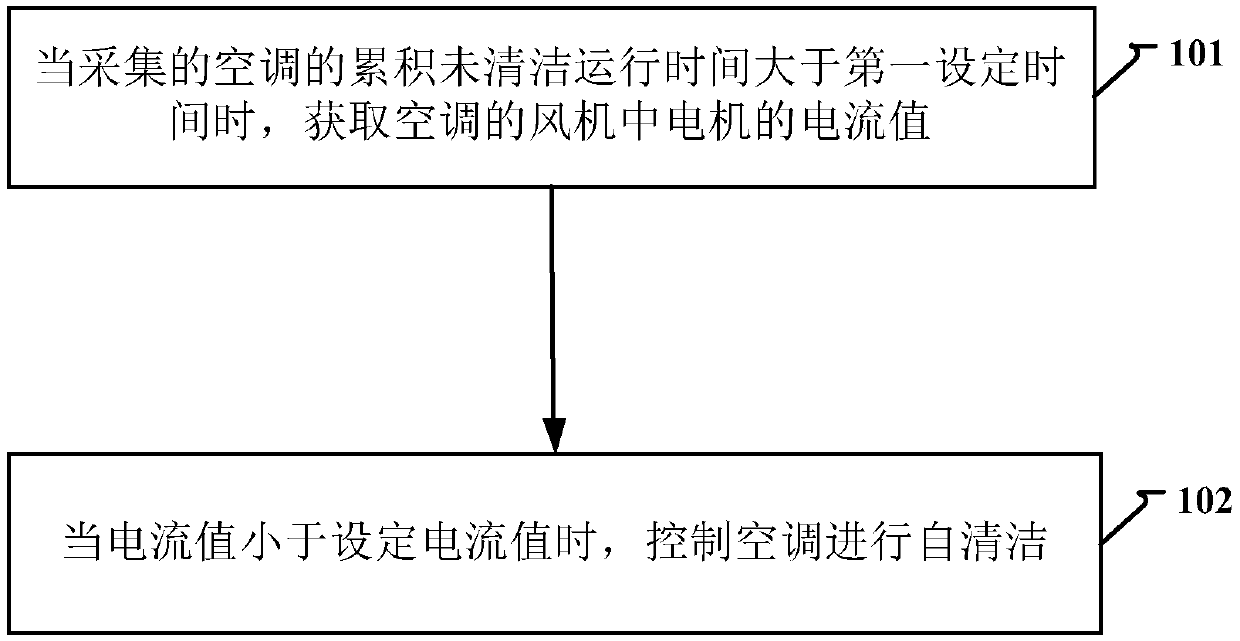

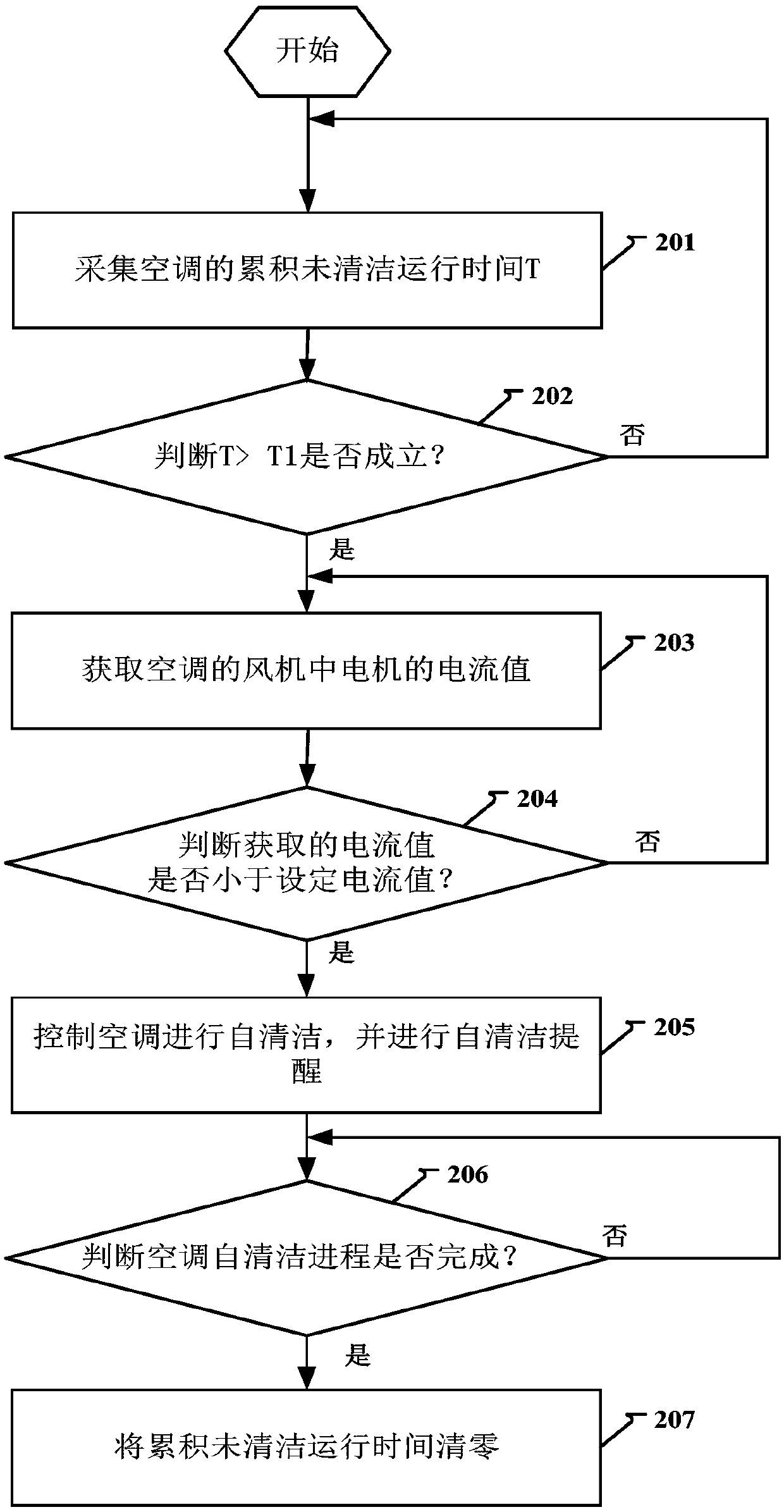

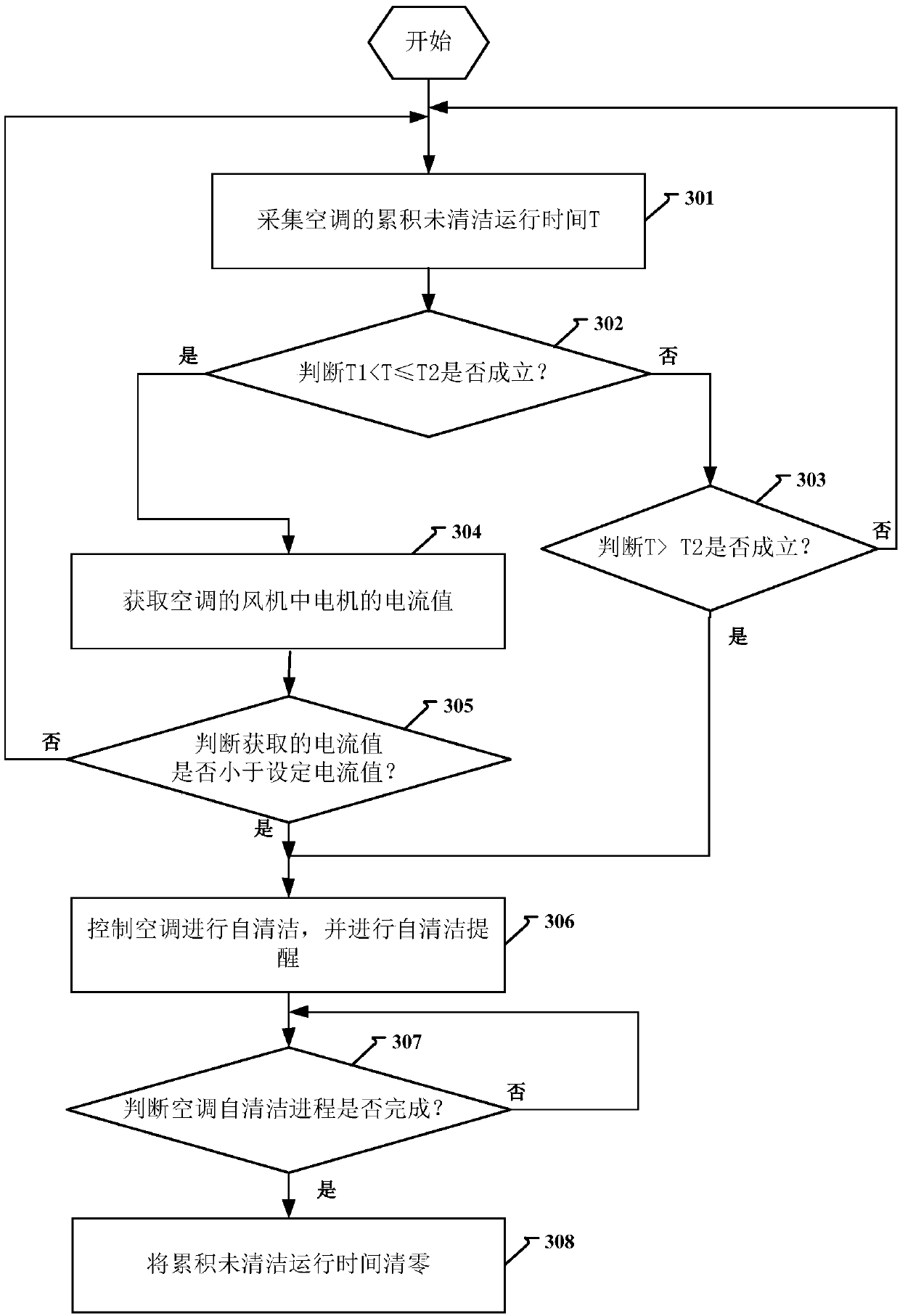

Method and device for cleaning control of air conditioner and computer storage medium

ActiveCN110454925ARealize automation and intelligenceGuaranteed efficacyMechanical apparatusEvaporatorSetting time

The invention discloses a method and device for cleaning control of an air conditioner and a computer storage medium, and belongs to the technical field of air conditioners. The method comprises the steps that when the collected accumulated non-cleaning running time of the air conditioner is larger than first set time, the current value of a motor in a fan of the air conditioner is acquired; and when the current value is smaller than the set current value, the air conditioner is controlled to achieve self cleaning. Thus, automation and intelligentization of the self-cleaning function of the air conditioner are achieved, the probability that a user forgets to trigger the self-cleaning function, and consequently filth blockage of an evaporator of an indoor unit is caused is reduced, then theeffect of the air conditioner is guaranteed, and user experience is further improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

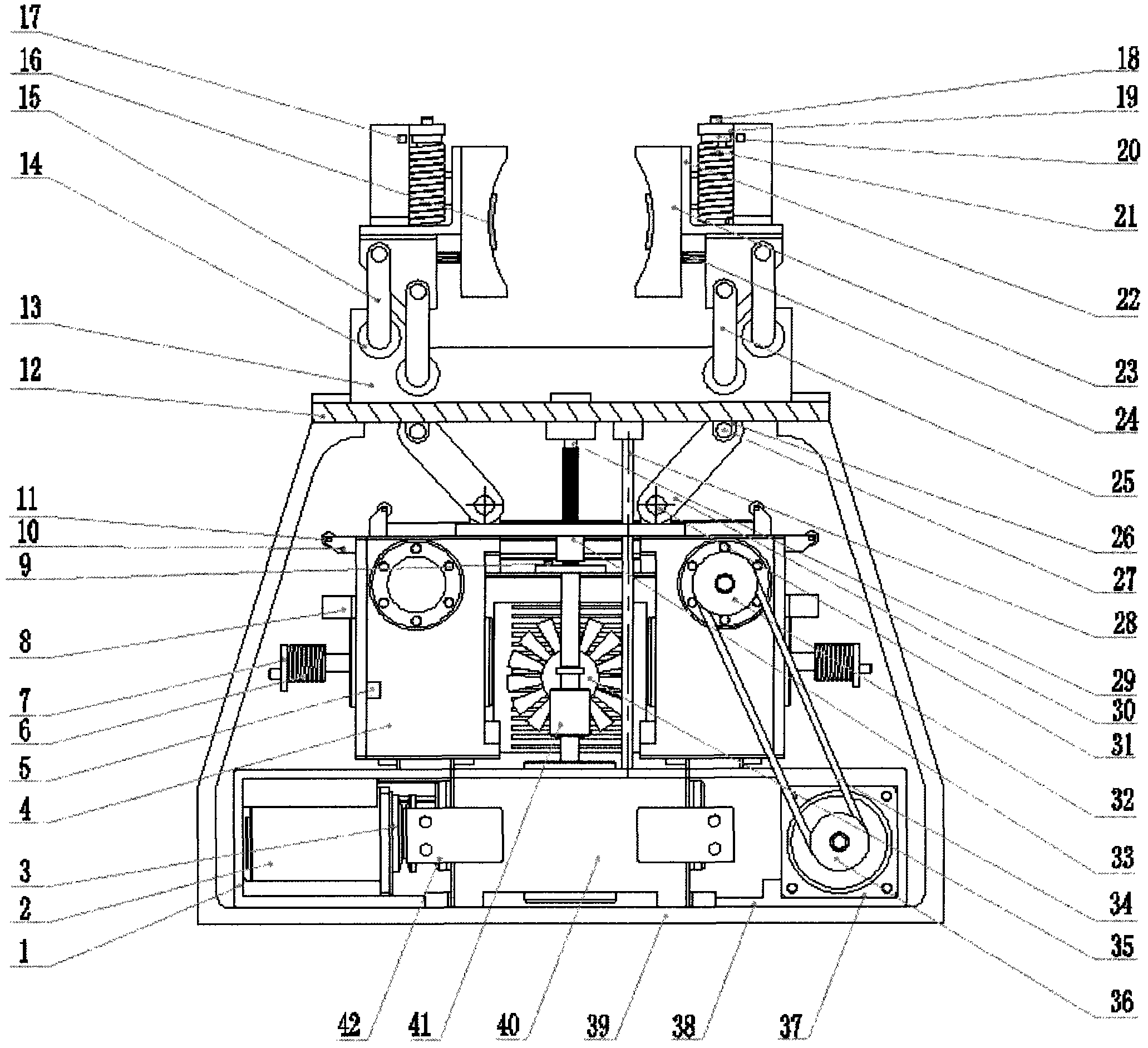

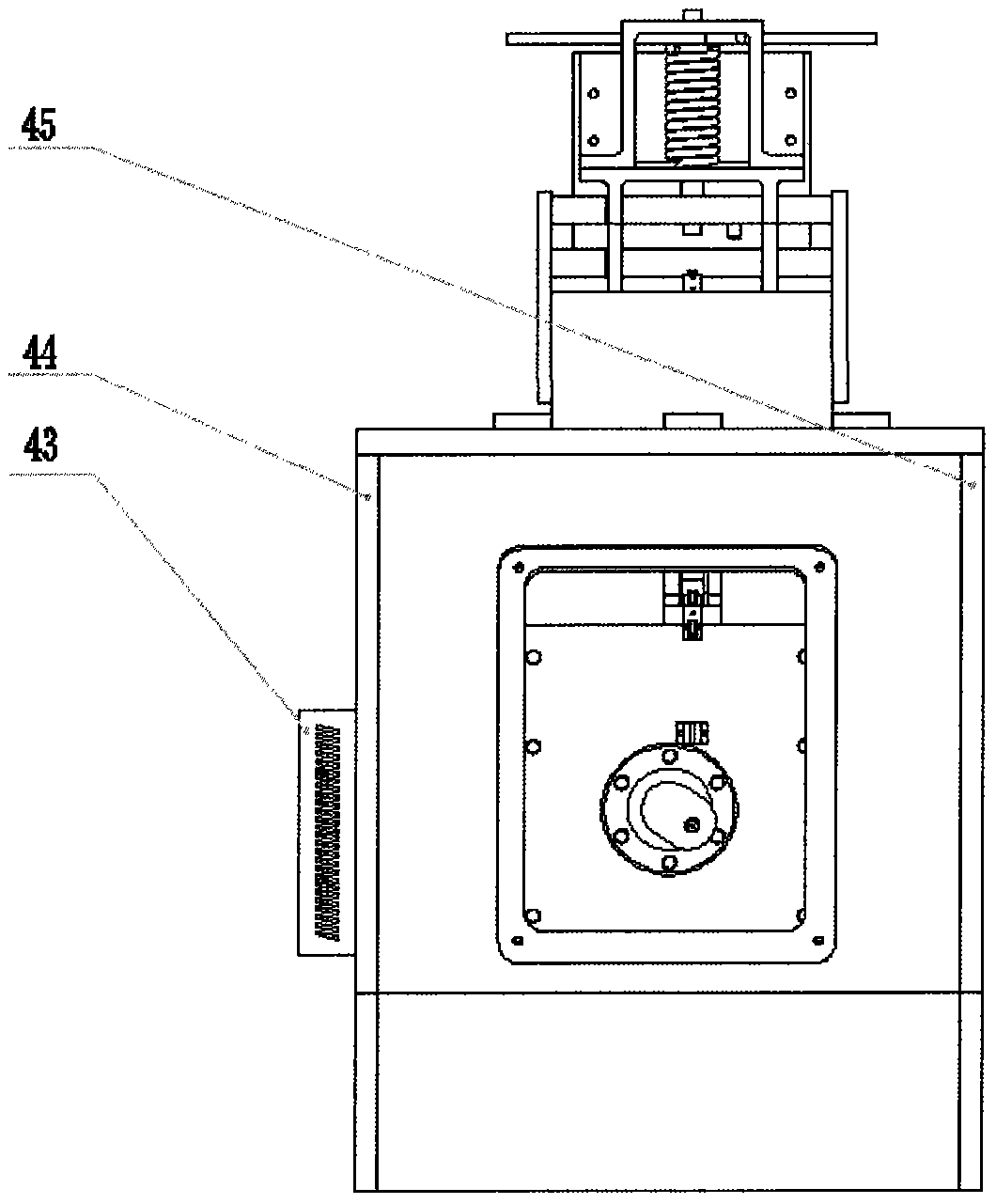

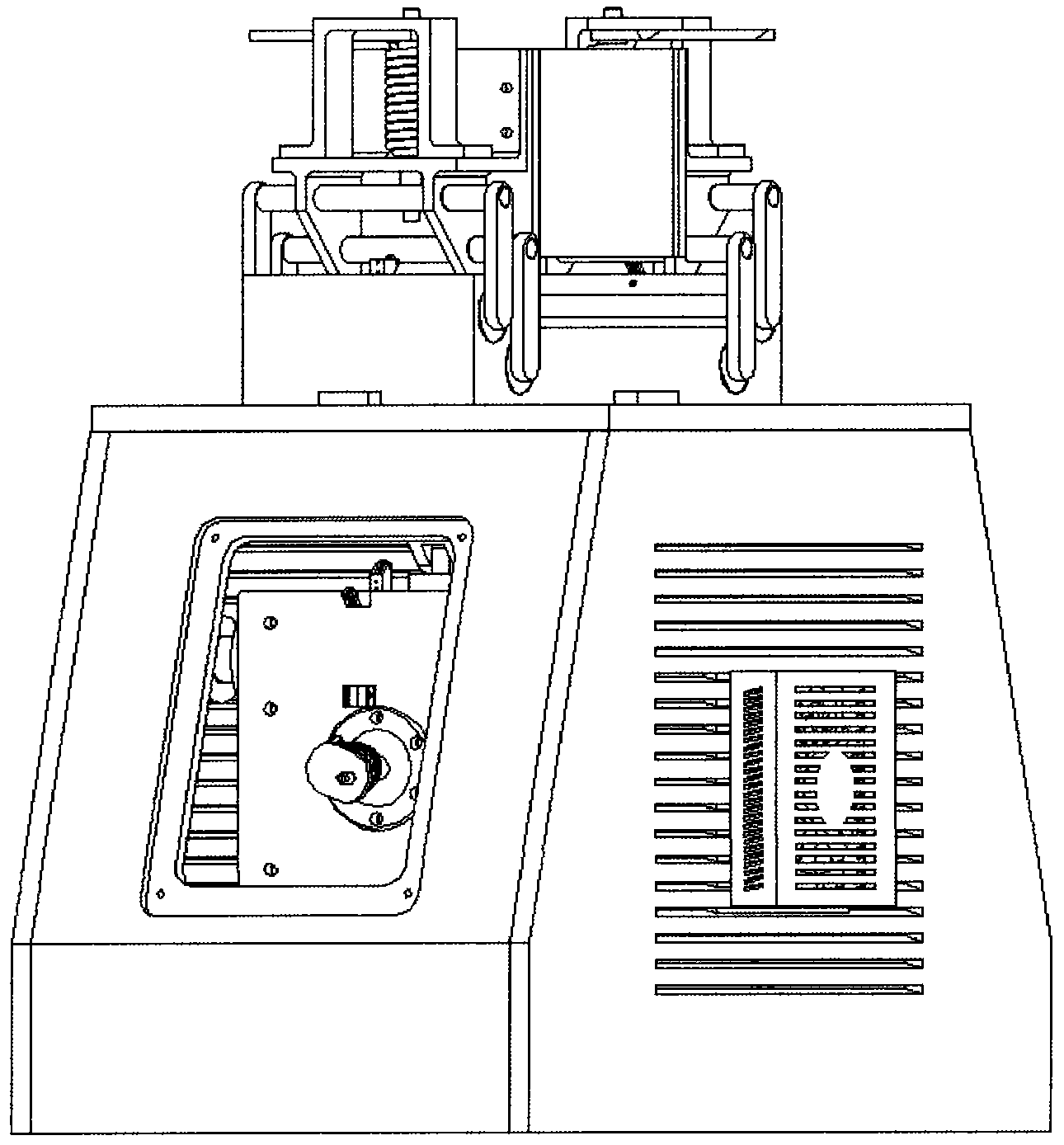

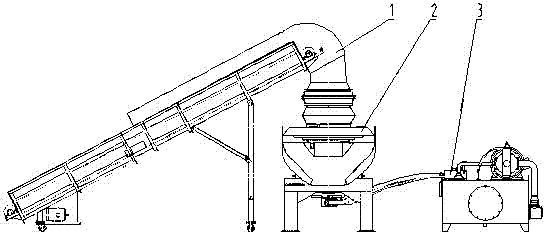

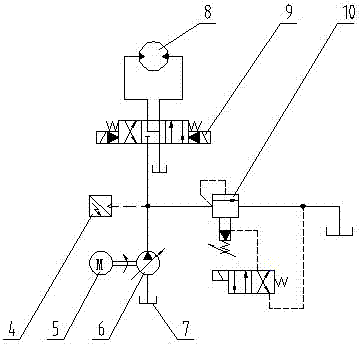

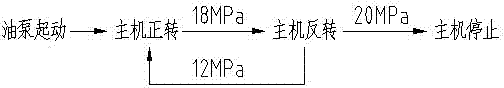

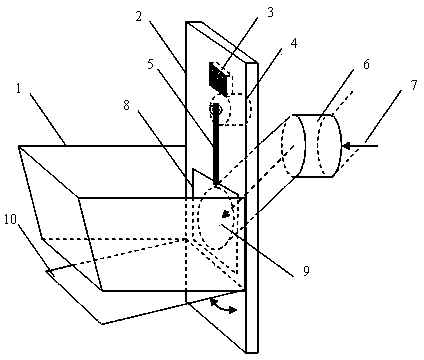

Intelligent RDF environment former

InactiveCN103753849ARealize automation and intelligenceImprove work efficiencyShaping pressFuel tankVariable-frequency oscillator

The invention provides an intelligent RDF environment former which comprises a feeding device, a forming mainframe, a hydraulic system (3) and an electric control system. The feeding device comprises a feeding rack and a variable frequency motor, the forming mainframe comprises a spindle, a rack, a forming module and the like, the hydraulic system comprises a hydraulic motor, an electrohydraulic reversing valve, an overflow valve, a pressure transmitter, a motor, a constant-power variable pump, an oil tank and an oil pipe, and the electric control system comprises a PLC (programmable logic controller) and a frequency changer. Electric signals of pressure of the hydraulic system are monitored by the PLC through the pressure transmitter in real time, the spindle of the forming mainframe is controlled to rotate forwards and backwards or stop, and running of the variable frequency motor of the feeding device is controlled. Pressure signals reflecting load size are utilized to control related actions like automatic backward rotating, automatic forward rotating and stopping of the mainframe and enable feeding speed to be constantly matched with working speed of the mainframe, so that automation and intelligentization of equipment production can be realized.

Owner:EGUARD NEW ENERGY AUTOMOBILE CO LTD

Multifunctional animal feeding trough

InactiveCN103371108ARealize automation and intelligenceAnimal feeding devicesContact modeEngineering

Provided is a multifunctional animal feeding trough. A non-contact magnetic card reader is installed above a back plate of the feeding trough and can collect electronic information in a magnetic card hung on the ear or the neck of an animal in the aspects of growth, propagation, nutrition and the like of the animal in a non-contact mode. A round feeding hole is formed under the back plate, the rear portion of the feeding hole is connected with a forage supply pipe, a gate is arranged on the feeding hole, the non-contact magnetic card reader collects individual electronic information of the magnetic card of the animal and analyzes the information to open and close the gate, forage is provided for the animal according to requirements, and food consumption of the animal is controlled. A base plate of the multifunctional animal feeding trough can be manually opened and closed, and a breeder can conveniently clear forage residues and clean the feeding trough.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

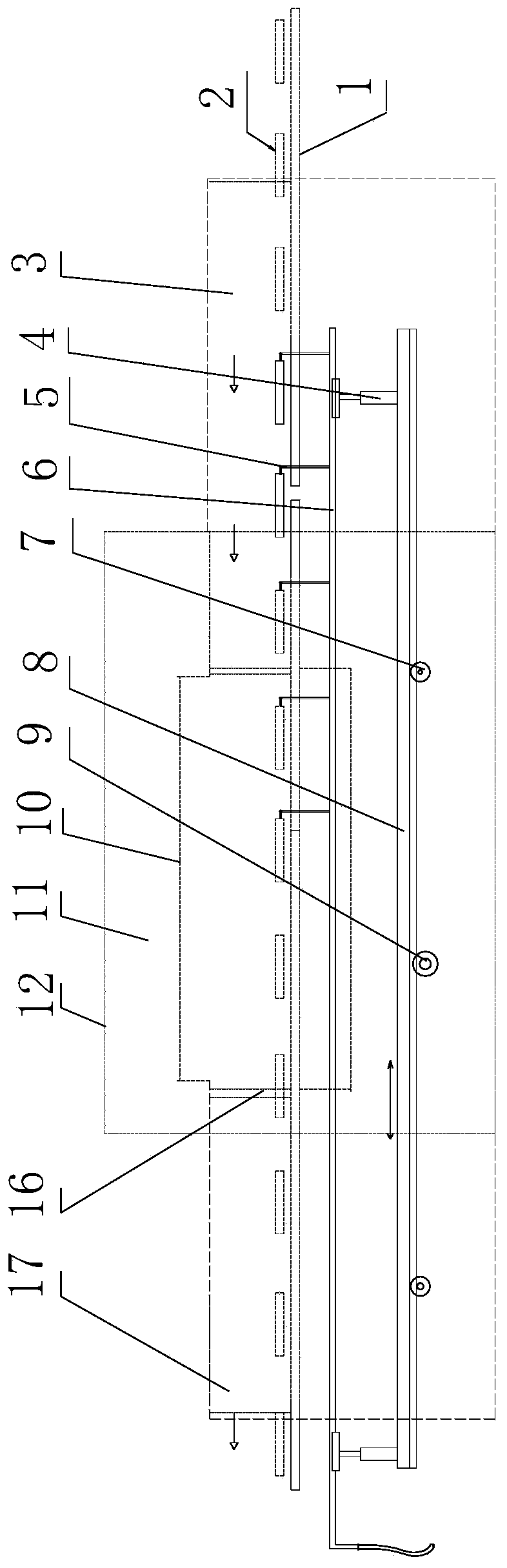

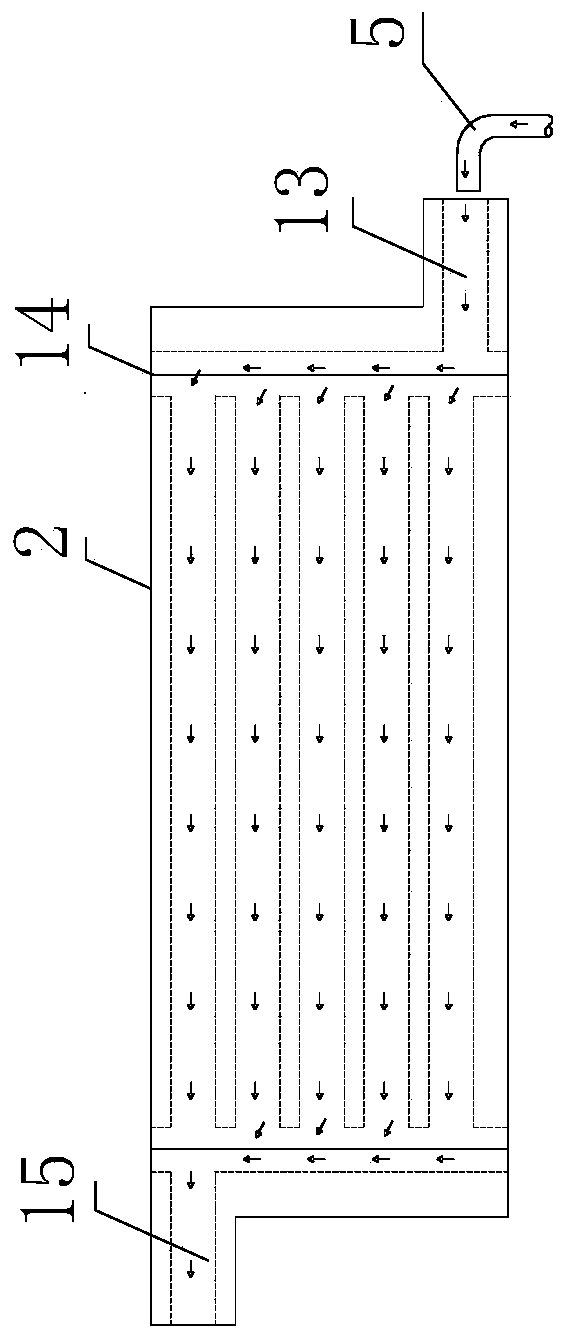

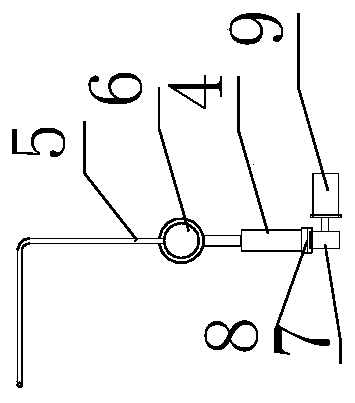

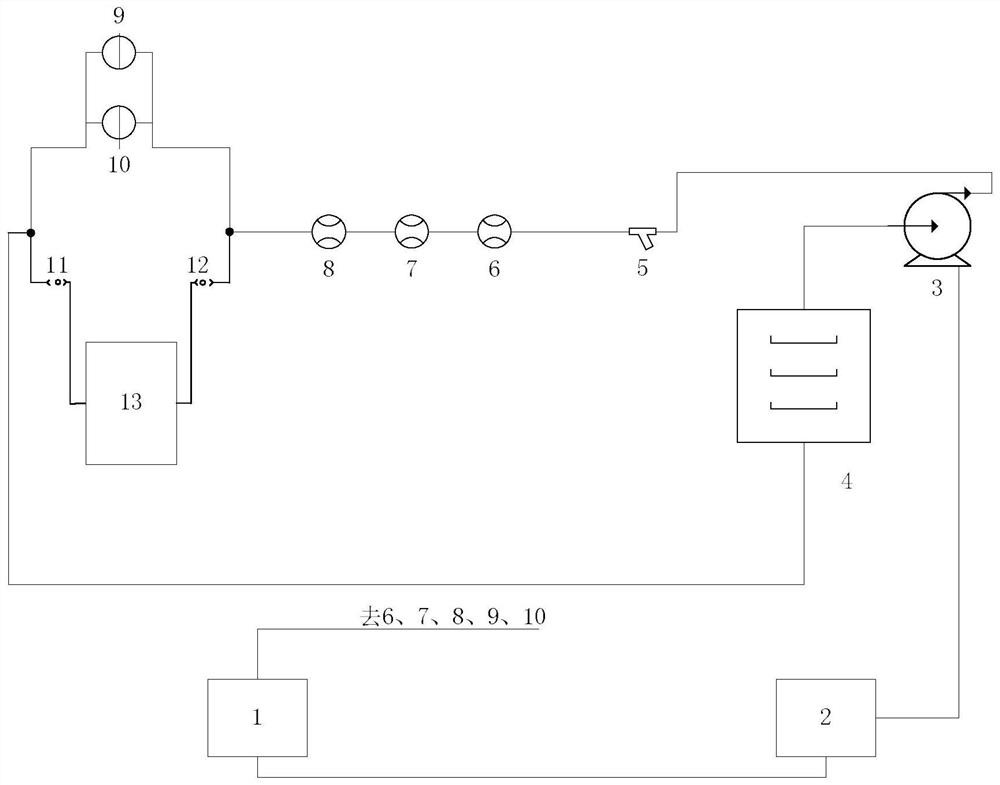

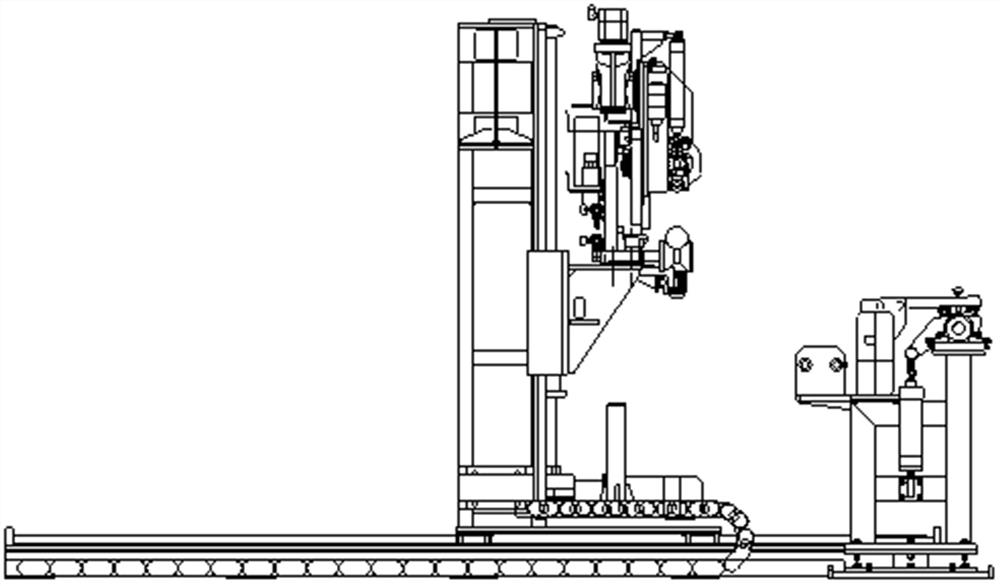

Brazing device and process for interior of cooling plate sealing cavity under inert gas shielding environment

PendingCN110948074ARealize automation and intelligenceReduce labor intensitySoldering auxillary devicesHeat conservationChain conveyor

The invention provides a brazing device and process for the interior of a cooling plate sealing cavity under an inert gas shielding environment. The device structurally comprises a drying preheatmentfurnace, a brazing furnace, a cooling furnace, a chain conveyor and an automatic nitrogen charging and oxygen removal mechanism, wherein the drying preheatment furnace and the cooling furnace are arranged at the two ends of the brazing furnace. A to-be-welded aluminum heat-dissipation cooling plate workpiece is clamped and fixed on the chain conveyor, the chain conveyor passes through the drying preheatment furnace, the brazing furnace and the cooling furnace, the inlet and outlet of the drying preheatment furnace, the brazing furnace and the cooling furnace are provided with a heat insulationcurtain, the automatic nitrogen charging and oxygen removal mechanism is arranged on the two side faces of the chain conveyor, and nitrogen blowing jet nozzles of the automatic nitrogen charging andoxygen removal mechanism automatically follow the aluminum heat-dissipation cooling plate workpiece to move, and are aligned with the cavity inside the aluminum heat-dissipation cooling plate workpiece. The brazing device and process are high in automation degree, greatly increase the rate of finished products, and have a high popularization value.

Owner:山东海力同创散热制冷技术开发有限公司

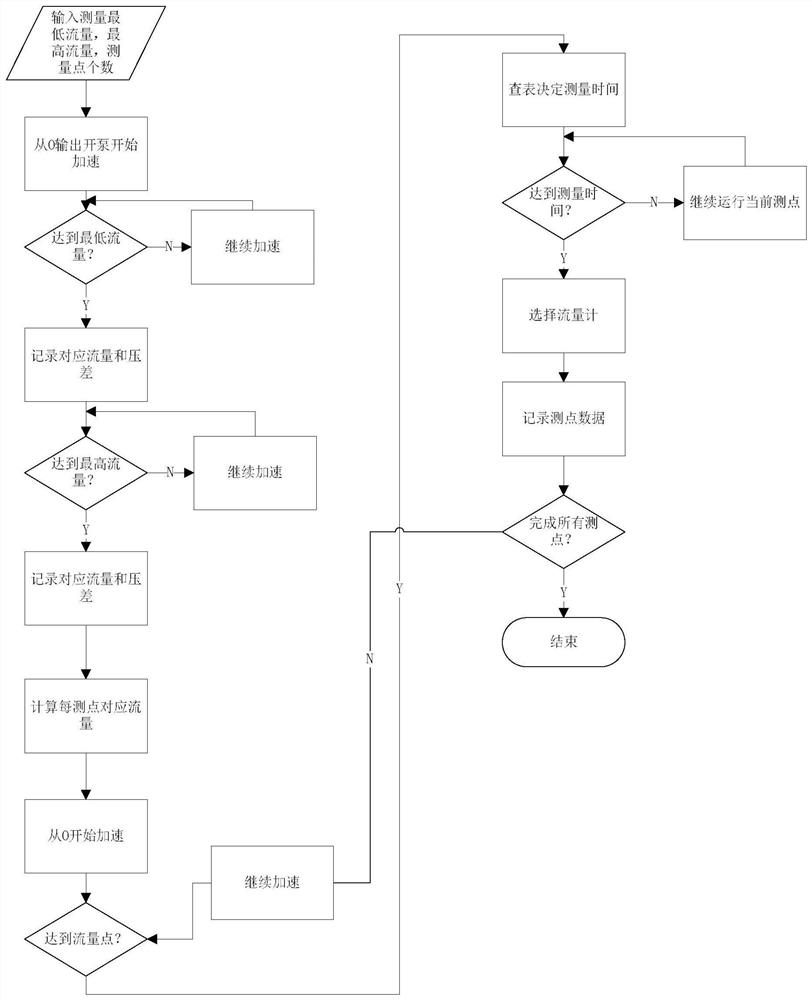

Automatic flow resistance control system for minimum flow

According to an automatic flow resistance control system for minimum flow, a small flow can be continuously measured in real time, and the measurement precision is high. According to the technical scheme, a positive displacement pump is communicated with a flow and flow resistance circulation loop formed by series flow pipes of a positive displacement flow meter, a differential pressure flow meter and an ultrasonic flow meter, and the flow and flow resistance circulation loop is connected with a PWM voltage converter through a single-chip microcomputer; and the single-chip microcomputer 1 realizes equal proportion conversion of a duty ratio PWM signal and a voltage signal through a PWM signal-to-analog signal module to form a direct current control voltage to drive a motor, the single-chip microcomputer selects a reading of a corresponding measuring range flow meter to directly drive a dual-mode PWM control circuit in a pump motor to adjust the rotating speed of the motor and a pump, the readings of the selected flow meter and the differential pressure sensor at the corresponding moment are collected at the tail of each time slice to form measuring points, then the measuring step length is automatically set according to the number of the input measuring points, and the measurement of the differential pressure and the flow in the measuring range is achieved.

Owner:10TH RES INST OF CETC

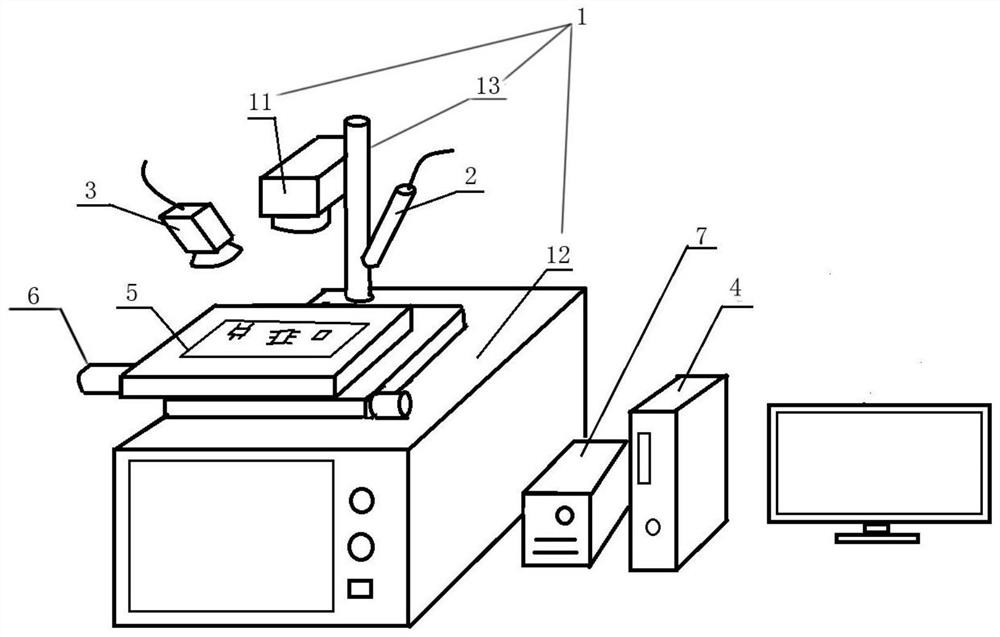

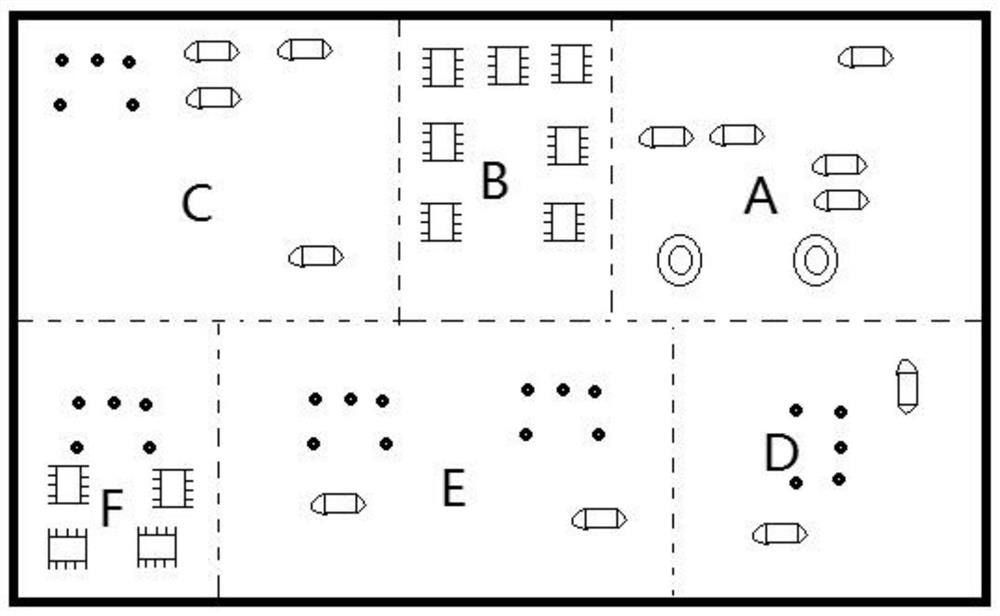

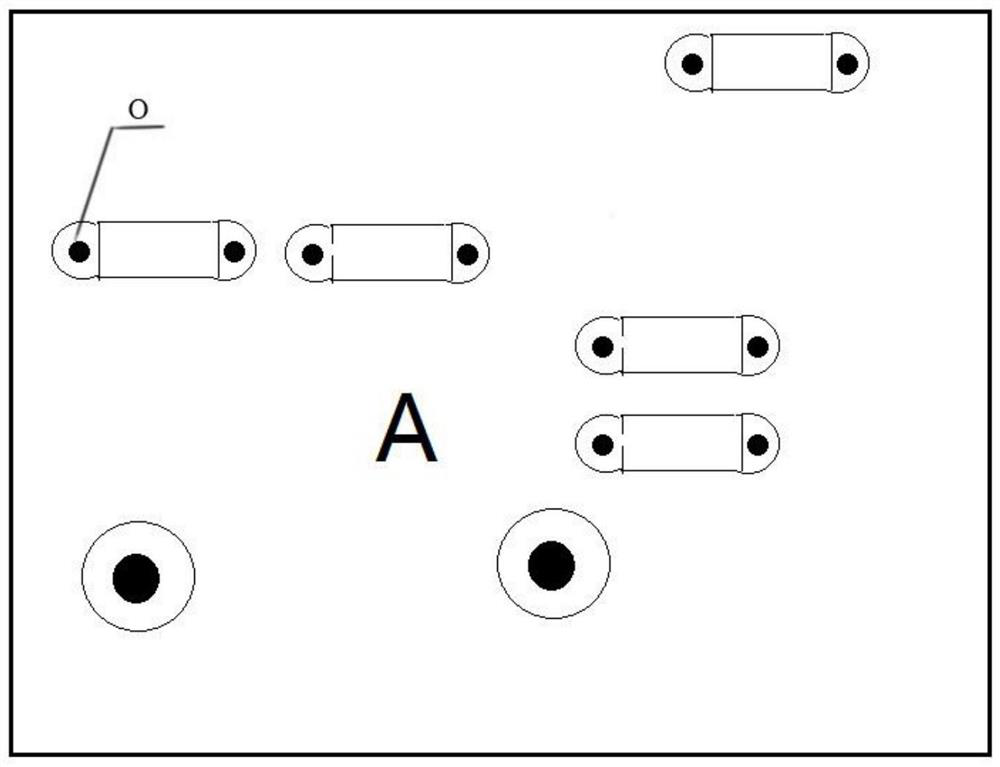

Scanning type circuit board welding spot pseudo soldering automatic detection system and detection method

ActiveCN111735850AReduce labor intensityRealize automation and intelligenceMaterial flaws investigationGalvanometerEngineering

The invention discloses a scanning type circuit board welding spot pseudo soldering automatic detection system and detection method. The invention belongs to the technical field of printed circuit board welding spot quality offline detection. The specific scheme is as follows: the scanning type circuit board welding spot pseudo soldering automatic detection system comprises a galvanometer type scanning laser, a digital optical microscope, a thermal infrared imager and a computer; the galvanometer type scanning laser comprises a laser head and a system platform, wherein the laser head is arranged above the system platform and is electrically connected with the system platform; the thermal infrared imager and the digital optical microscope are respectively positioned beside the laser head; the visual fields of the thermal infrared imager and the digital optical microscope are overlapped and positioned within the scanning range of the laser head on the circuit board to be tested; the thermal infrared imager is electrically connected with the computer; and the digital optical microscope is electrically connected with the computer or the system platform. According to the invention, theindustry traditional problem that pseudo soldering of circuit board welding spots is difficult to detect is solved in a breakthrough manner, and the system has the characteristics of simple operation,automation and intellectualization and wide market prospect.

Owner:HARBIN INST OF TECH

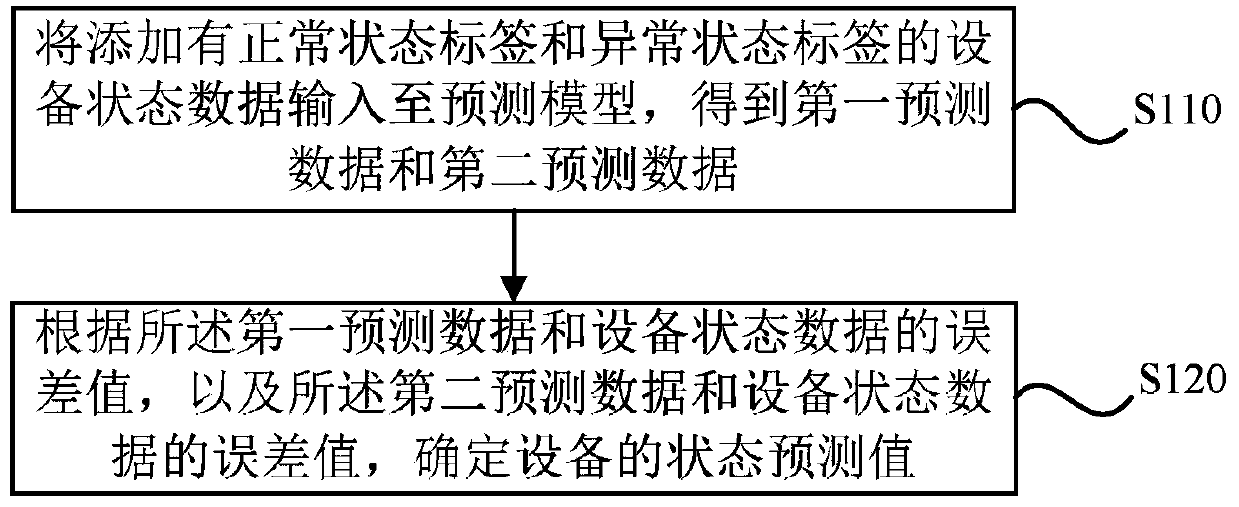

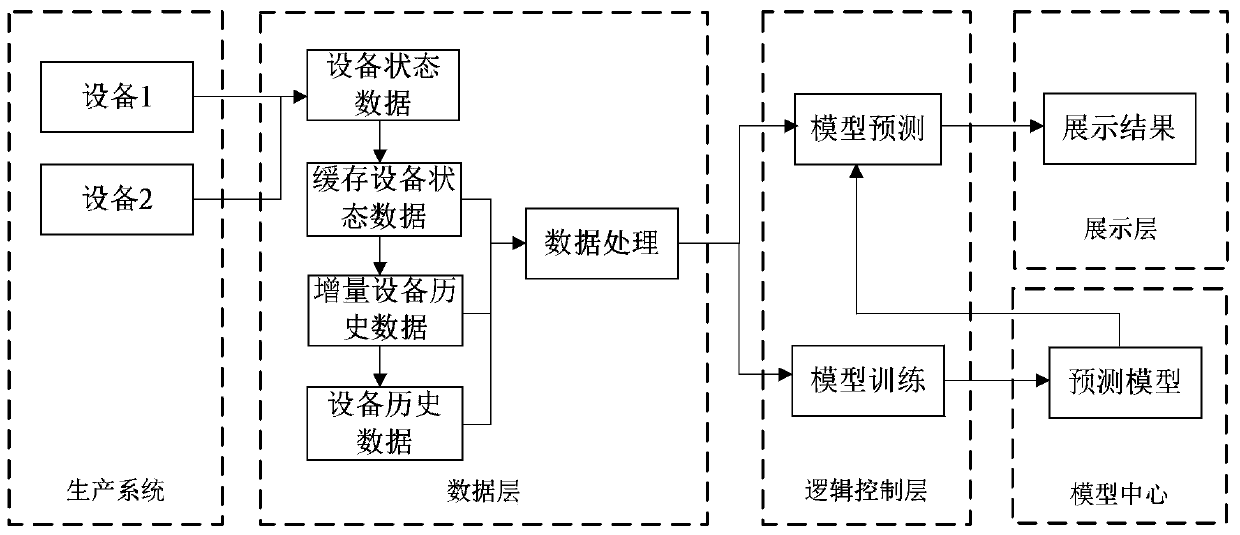

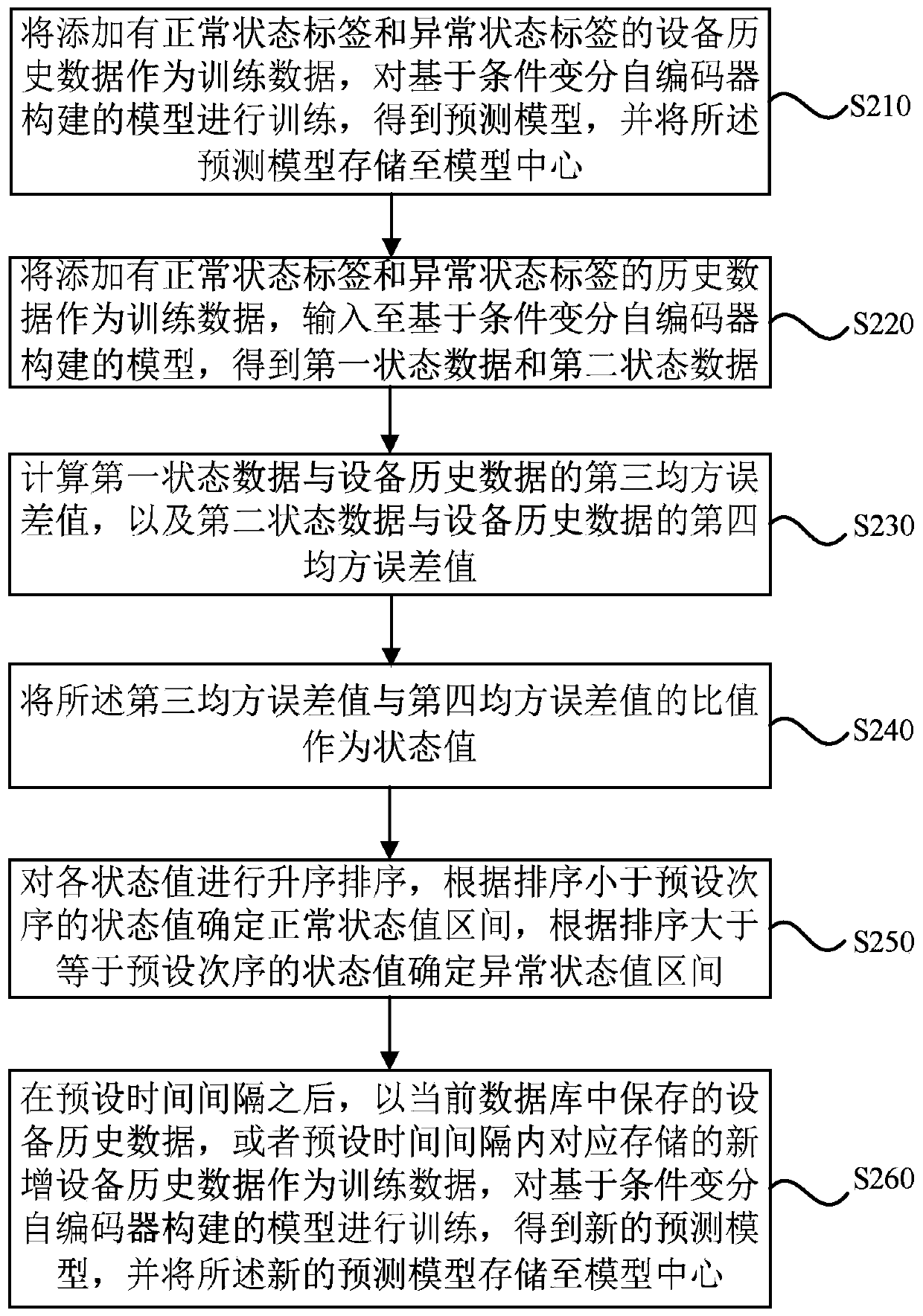

Equipment state evaluation method, device and system and storage medium

ActiveCN110059894ARealize automation and intelligenceAccurate monitoring and evaluationForecastingAssessment methodsState prediction

The embodiment of the invention discloses an equipment state evaluation method, device and system and a storage medium. The method comprises the following steps: inputting equipment state data added with a normal state label and an abnormal state label into a prediction model to obtain first prediction data and second prediction data; and determining a state prediction value of the equipment according to the error values of the first prediction data and the equipment state data and the error values of the second prediction data and the equipment state data. Through the technical scheme, manualparticipation is not needed for equipment state evaluation; according to the technical scheme, automation and intelligentization of equipment state evaluation are achieved, the accurate index value of the equipment can be obtained, in addition, under the condition that the performance of the equipment changes, the equipment state can be accurately evaluated and monitored through the technical scheme, and the problem that misjudgment is generated through experience rule evaluation is solved.

Owner:无锡雪浪数制科技有限公司

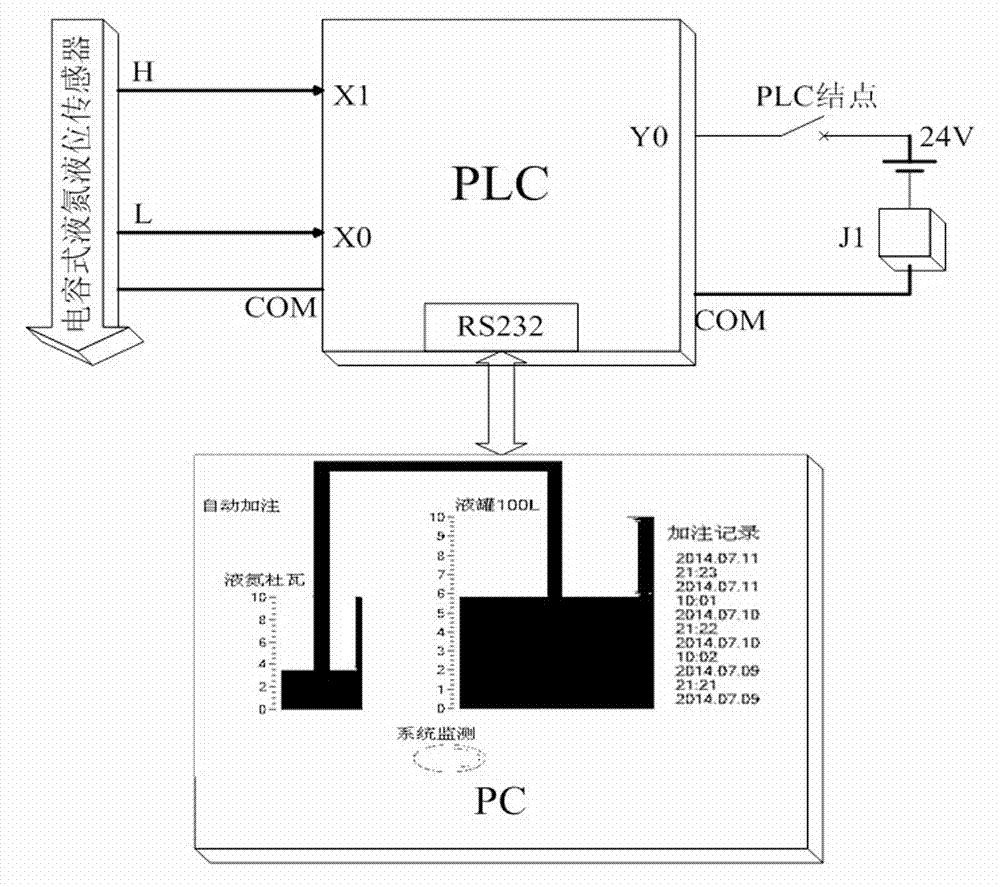

Liquid nitrogen level automatic control device in fusion diagnostic device

ActiveCN104331093ARealize automatic control functionImprove work efficiencyLevel controlAutomatic controlSolenoid valve

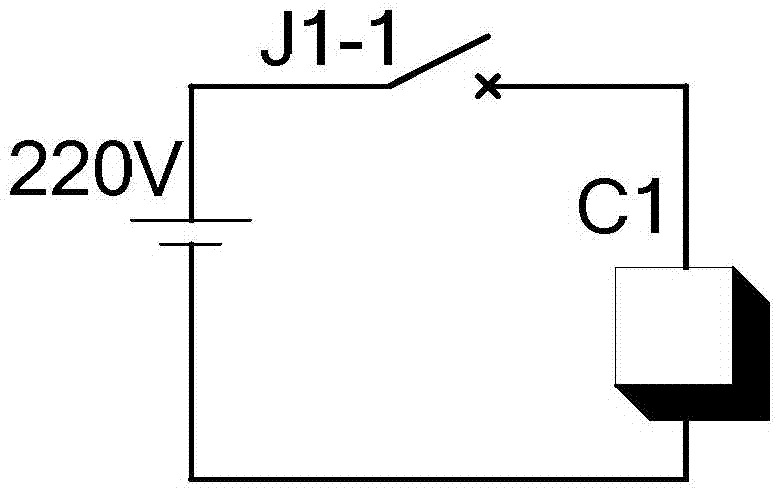

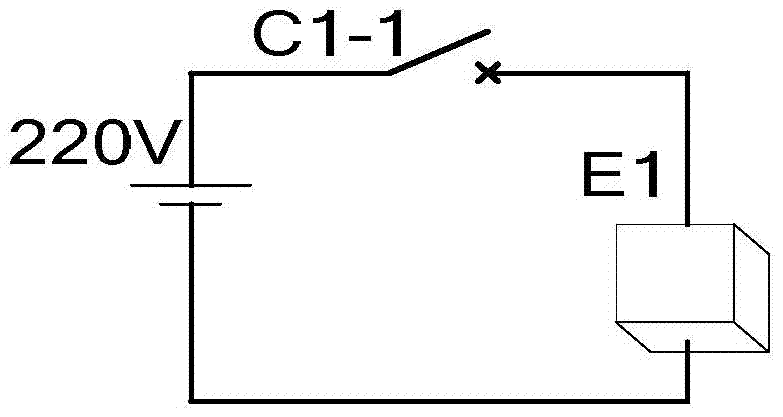

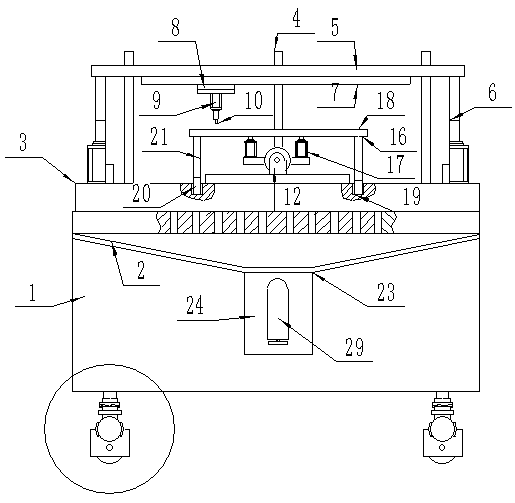

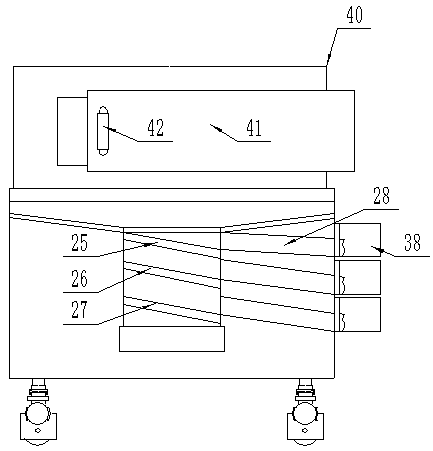

The invention discloses a liquid nitrogen level automatic control device in a fusion device diagnostic system. The device includes a main control device PLC, a capacitive liquid nitrogen level sensor in a Dewar flask, a small intermediate relay J1, an AC contactor C1, and a cryogenic solenoid valve E1. Two switching value input ends X0 and a switching value output end Y0 are arranged on the PLC. All of the X0 and the X1 are connected with output ends of the capacitive liquid nitrogen level sensor. A PLC node, a DC power supply module and a main coil of the J1 are sequentially serially connected with the Y0. An output normally-open node J1-1 of the J1 is serially connected with the main coil of the C1 and then serially connected with an AC constant-voltage source so that a loop is formed. An output normally-open node C1-1 of the C1 is serially connected with the E1 and then forms a loop with the AC constant-voltage source. The main control device PLC is also connected with an upper computer through a serial port communication cable. The liquid nitrogen level automatic control device is friendly in interface, simple to operate, and capable of saving and inquiring data at any time as to further analyze and solve problems.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Paper shredding and fragment recycling integrated equipment

InactiveCN108789641AEasy to recycleRealize automation and intelligenceSievingScreeningProcess engineeringWaste material

The invention discloses paper shredding and fragment recycling integrated equipment. The paper shredding and fragment recycling integrated equipment comprises a cutting base; the inside of the cuttingbase is of a hollow structure; the outside of the cutting base is of a rectangular mechanism; the cutting base is provided with a three-way cutting mechanism; a fragment recycling mechanism is arranged inside the cutting base; the upper surface of the cutting base is provided with a plurality of leaking holes; the top surface of the cutting base is a conical partition plate; and the bottom surface of the cutting base is provided with a height adjusting mechanism and a moving mechanism. The paper shredding and fragment recycling integrated equipment disclosed by the invention has the beneficial effects that the equipment can totally realize automation and intelligence after a PLC series is installed at an idle position for control, the manual work pressure is relatively low, meanwhile waste materials can be recycled more simply and conveniently, and cutting and finishing work of collecting the paper fragments are implemented perfectly.

Owner:叶永菲

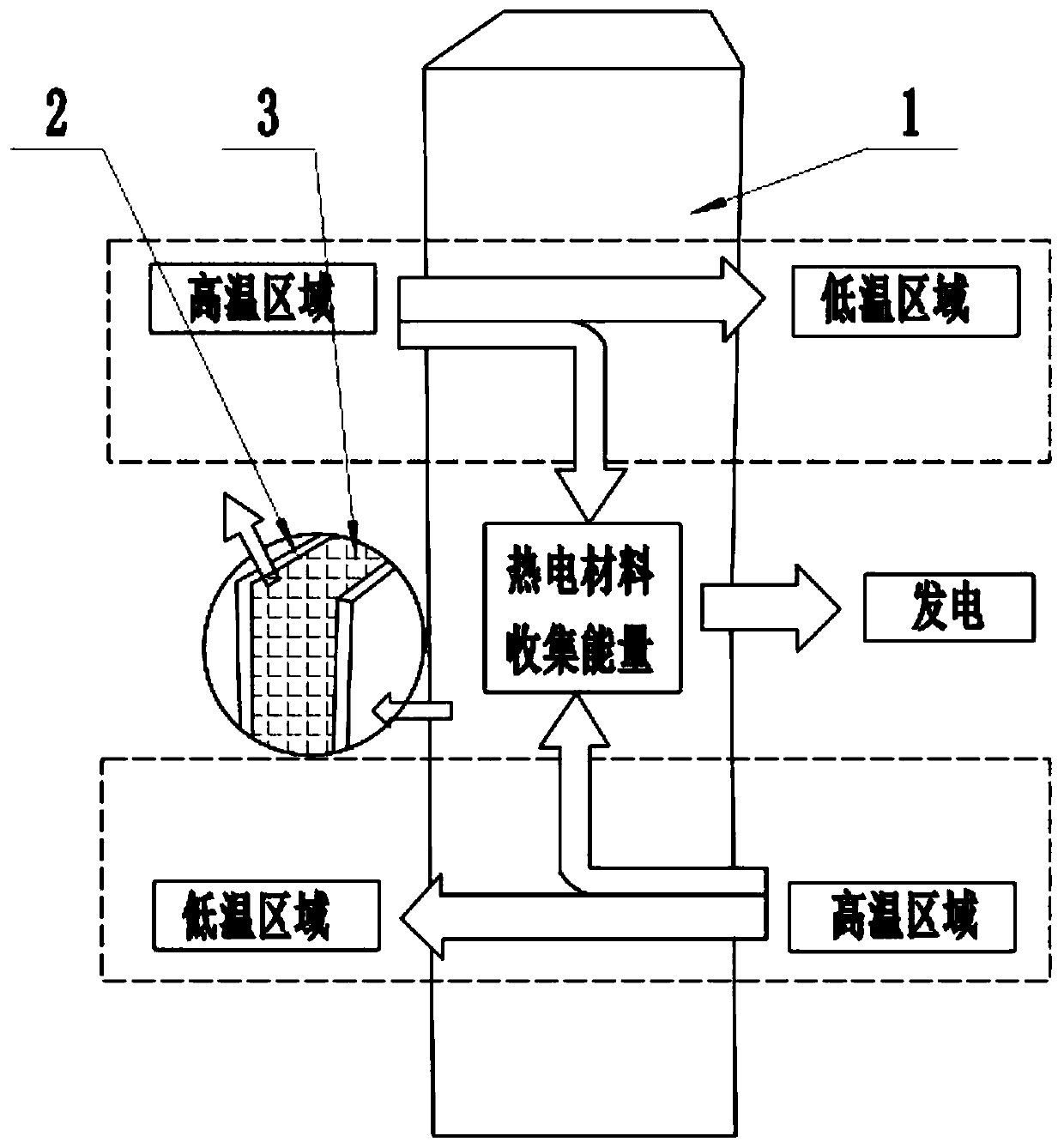

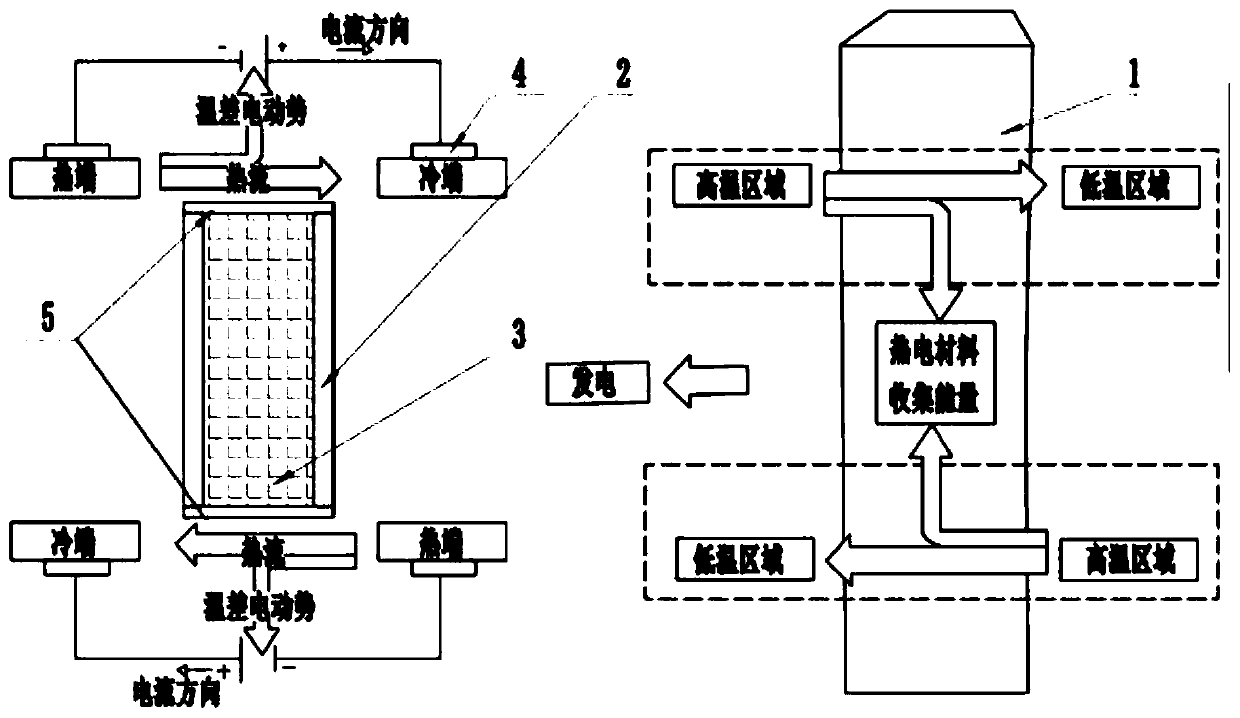

Building wall thermoelectric power generation system

PendingCN111082707AReduce consumptionRealize automation and intelligenceWallsGenerators/motorsElectrical conductorMechanical engineering

The invention discloses a building wall thermoelectric power generation system, and relates to the technical field of thermoelectric energy conversion. The system comprises a wall, a thermoelectric material layer is arranged in the wall, conductors are embedded into two sides of the wall, and the conductors at the two sides can be communicated through a wire; the thermoelectric material layer cancollect heat energy and convert the heat energy into electric energy and the like. The thermoelectric material layer is arranged in the wall body, when temperature difference exists inside and outsidethe wall body, heat passes through the thermoelectric material layer, part of the heat can be collected and converted into available electric energy, circulating energy is formed, energy consumptionis reduced, and an automatic intelligent building is achieved.

Owner:SHENZHEN UNIV

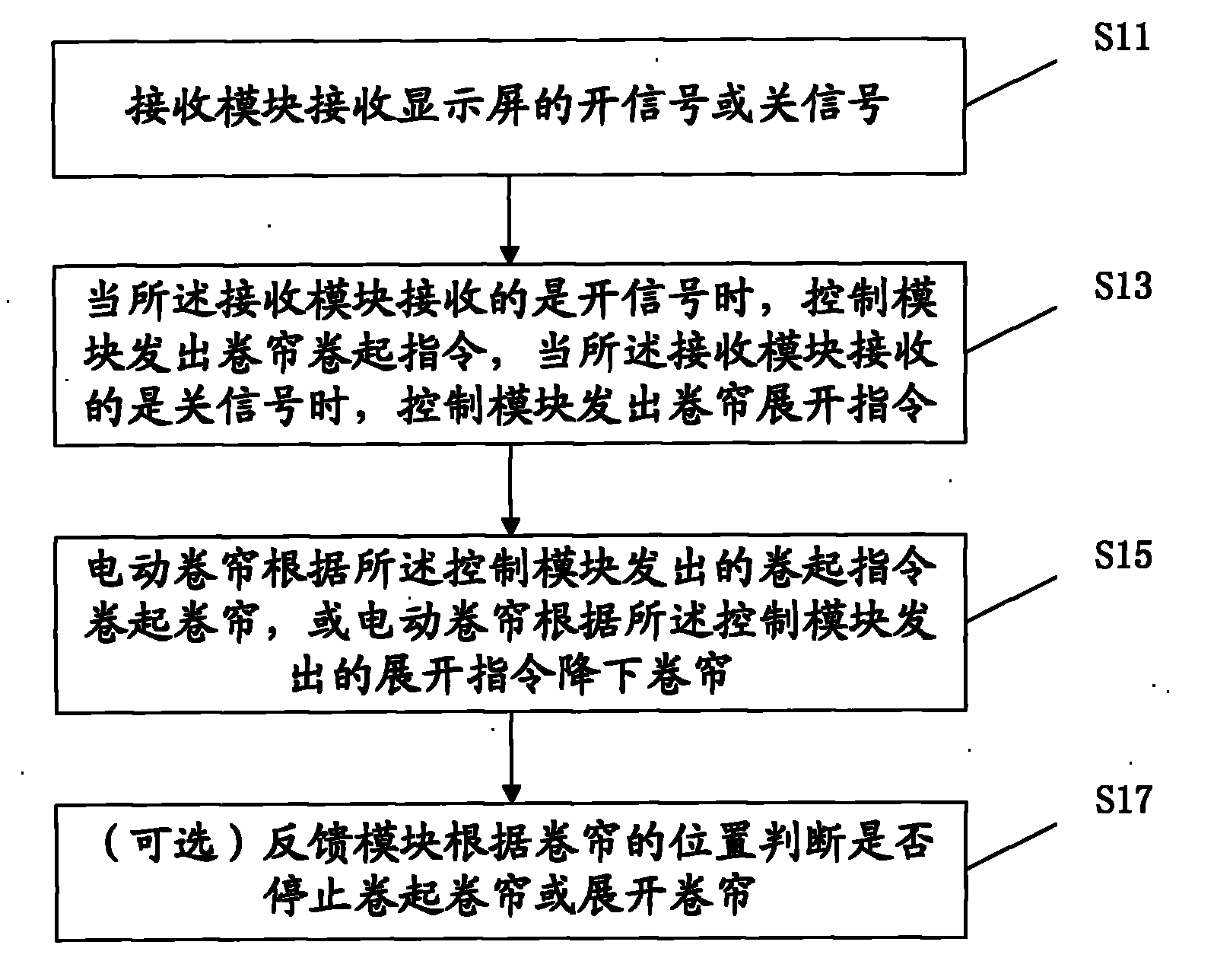

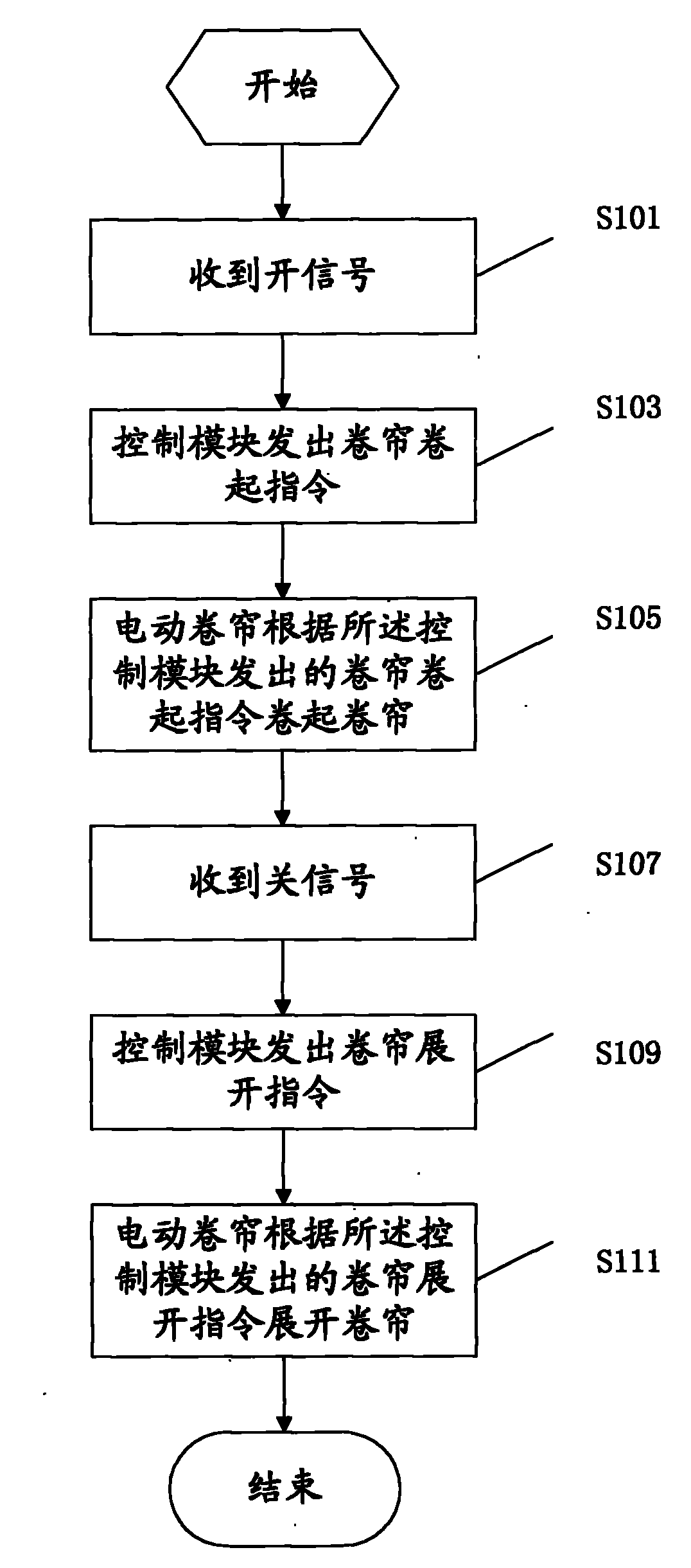

Method and device for controlling roller shutter for display screen

InactiveCN102041963ARealize automation and intelligenceHave an aesthetically pleasing effectDoor/window protective devicesCurtain accessoriesComputer moduleComputer engineering

The invention discloses a method for controlling a roller shutter. The method comprises the following steps: a receiving module receives an open signal or close signal of the display screen; when the receiving module receives the open signal, a control module sends a roller shutter rolling-up instruction; when the receiving module receives the close signal, the control module sends a roller shutter spreading instruction; an electric roller shutter rolls up the roller shutter according to the roller shutter rolling-up instruction sent by the control module so as to expose the display screen; or the electric roller shutter spreads the roller shutter according to the spreading instruction sent by the control module so as to cover the display screen. The invention also correspondingly discloses a device for controlling the roller shutter and a television using the same. By adopting the technology disclosed by the invention, automatic and intelligent dustproof functions of the roller shutter can be realized.

Owner:KONKA GROUP

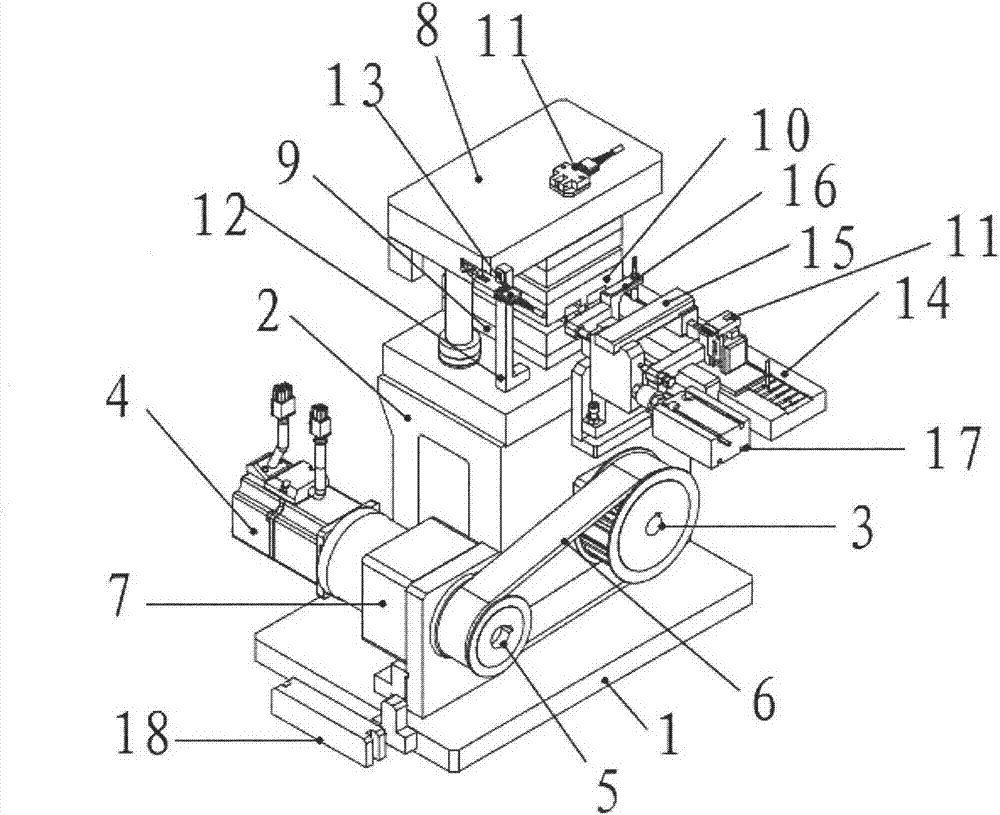

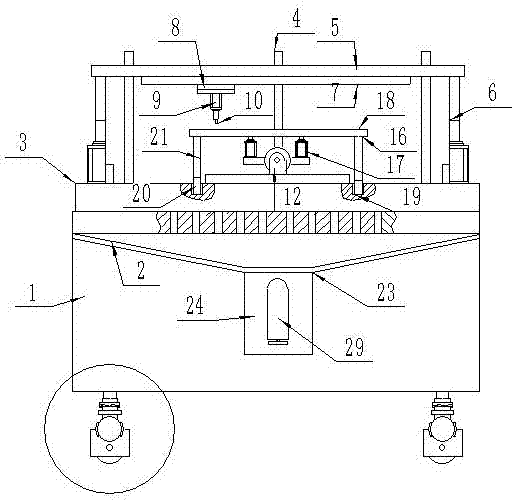

Cam bending mechanism

InactiveCN103500908ARealize automation and intelligenceIncrease productivityContact member manufacturingEngineeringCam

The invention provides a cam bending mechanism. The cam bending mechanism has the advantages that a cam is driven by a servo motor, further drives a mold to cut and bend a terminal and simultaneously is matched with a feeding device to realize automation and intelligentization of cutting and bending of the terminal, so that not only is the production efficiency improved greatly and is the production cost saved, but also the occupied area of equipment is reduced, and the assembling accuracy and the stability are ensured. Therefore, the cam bending mechanism is beneficial to long-term stable development of an enterprise.

Owner:KUNSHAN YIXIN RELIANCE PRECISION IND

Integrated device for covering paper cutting scraps

InactiveCN106853654AEasy to recycleRealize automation and intelligenceSievingScreeningWorking pressureEngineering

The invention discloses an integrated device for covering paper cutting scraps. The integrated device comprises a cutting seat, wherein the cutting seat is internally of a hollow structure and is externally a rectangular mechanism, a three-dimensional cutting mechanism is arranged on the cutting seat, a scraps recovering mechanism is arranged in the cutting seat, multiple leaking holes are formed in the upper surface of the cutting seat, the top surface of the cutting seat is a conical partition plate, and a height adjusting mechanism and a moving mechanism are arranged on the bottom surface of the cutting seat. The integrated device has the advantages that after a PLC series control is installed at a leisure position, the device can completely achieve automatic intelligence, a manual working pressure is smaller, meanwhile waste recovery is simpler and more convenient, and the finished work of paper scraps collection after cutting is completed perfectly.

Owner:ANHUI ZHONGYA PAPER

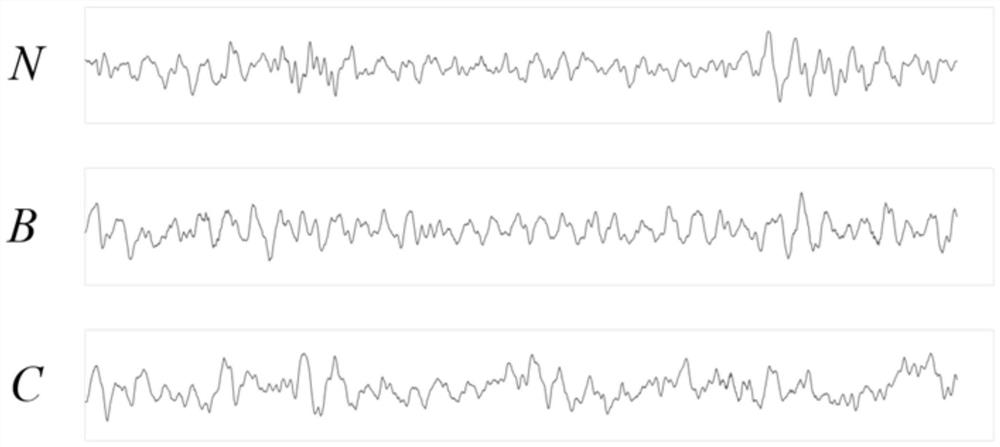

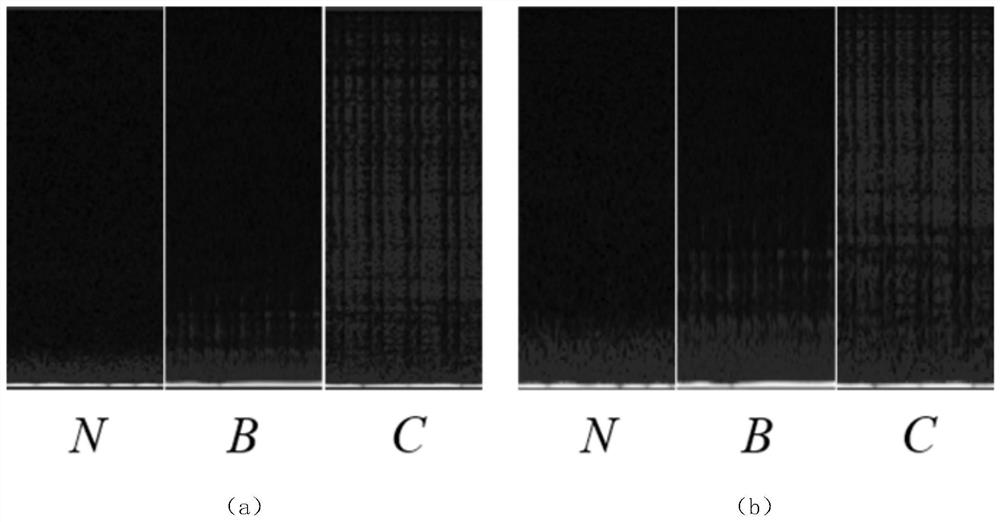

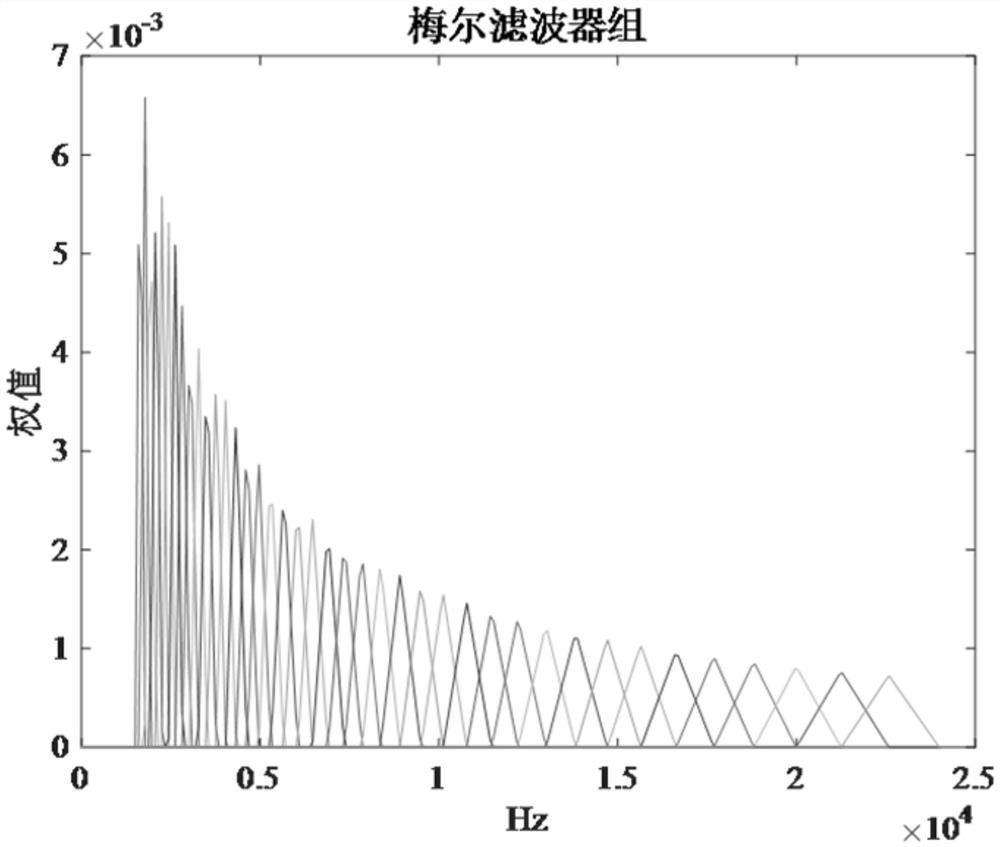

Air conditioner indoor unit abnormal sound detection method based on sound classification model

PendingCN113763986ARealize automation and intelligenceIncrease productivitySpeech analysisClassification resultEngineering

The invention relates to an air conditioner indoor unit abnormal sound detection method based on a sound classification model. The air conditioner indoor unit abnormal sound detection method comprises three parts of data preprocessing, Mel joint feature extraction and network classification. The method comprises the specific steps of collecting and slicing sound data of a to-be-detected air conditioner; extracting a Mel spectrum feature and a Mel cepstrum coefficient of each fragment, and forming a Mel joint feature by using the Mel spectrum feature and the Mel cepstrum coefficient; inputting the Mel joint features into a trained classification network for classification, wherein each segment corresponds to a classification result; and visualizing the result sequence, and meanwhile, giving an overall judgment result of the air conditioner quality. According to the method, the abnormal sound of the air conditioner can be quickly and accurately detected, and automation and intelligence of a quality inspection link are realized, so that the production efficiency is improved, and the production cost is reduced.

Owner:SHANDONG UNIV

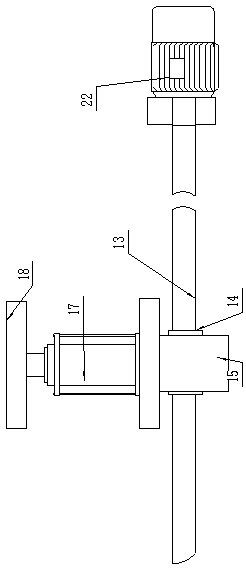

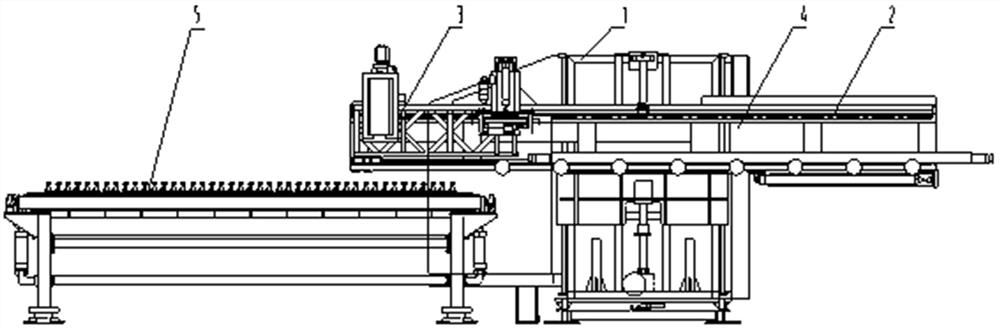

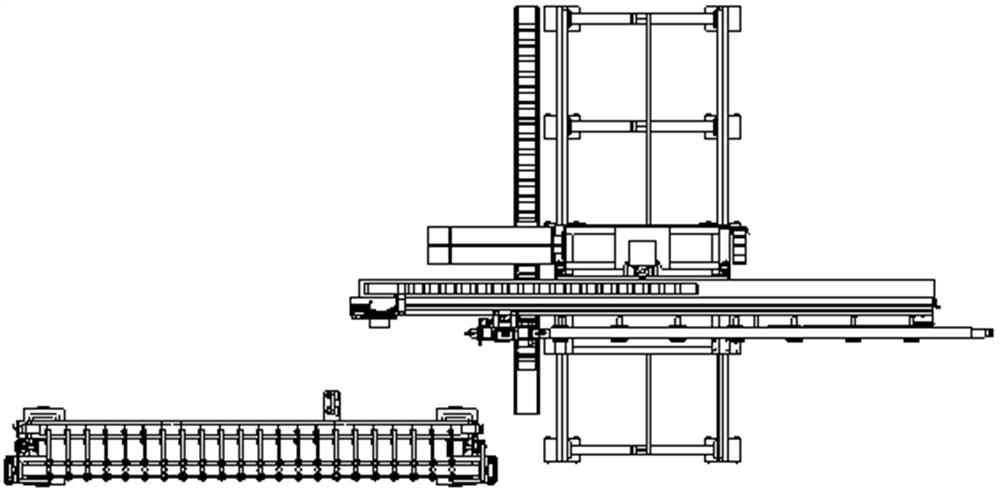

Automatic spindle mounting and pulling and paper tube sleeving mechanism

PendingCN111945414ARealize automation and intelligenceReduce manual labor intensitySevering textilesWebs handlingStructural engineeringMachine

An automatic spindle mounting and pulling and paper tube sleeving mechanism is characterized by comprising a vertical frame mechanism capable of moving forwards and backwards on a rail mechanism, a horizontal guide mechanism mounted on a vertical frame mechanism lifter, a clamping inflating and deflating device mounted on the horizontal guide mechanism and capable of moving leftwards and rightwards along the horizontal guide mechanism, an air channel control mechanism installed on the horizontal guide mechanism, and a paper tube sleeving positioning device located on one side of the vertical frame mechanism. The mechanism is suitable for the condition that the spindle can be mounted in a splitting machine from the side face and the relative position of a cloth roll can be fixed after splitting and roll unloading; by using the mechanism, operators can be reduced, the labor intensity of workers can be greatly reduced, and automatic spindle mounting and pulling and paper tube sleeving functions of the splitting machine are achieved.

Owner:CHTC HEAVY IND +1

Transporting manipulator in lithium cell production line

InactiveCN107088874ARealize automation and intelligenceImprove sintering efficiency and precisionProgramme-controlled manipulatorDrive motorManipulator

The invention discloses a handling manipulator in a lithium battery production line, which comprises a substrate, a base installed on the base, a first robot arm installed on the base, and a first robot arm installed on the first robot arm. Two mechanical arms, and a clamping assembly arranged on the second mechanical arm; the base is fixed with a support plate on the top of the base, and a rotating seat is installed on the support plate, and the first mechanical The arm includes a bearing plate fixedly installed on the rotating seat, a rotating motor is installed on the bearing plate, a rotating arm is connected to the output end of the rotating motor, and the second mechanical arm includes a rotating arm installed on the first rotating base. A driving motor on a mechanical arm, the driving motor is fixedly installed on the top of the rotating arm through a mounting base, a coupling is provided at the output end of the driving motor, and is connected to the transport shaft through the coupling, and the transporting One end of the shaft is fixedly connected with the drive motor, and one end of the transport shaft is fixedly installed with a clamping assembly.

Owner:浙江小宇科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com