Liquid nitrogen level automatic control device in fusion diagnostic device

A liquid level automatic control, liquid nitrogen technology, applied in the direction of liquid level control, non-electric variable control, control/adjustment system, etc., can solve the problems of damage, liquid nitrogen waste, time-consuming and labor-intensive, etc., and achieve simple operation, friendly interface, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

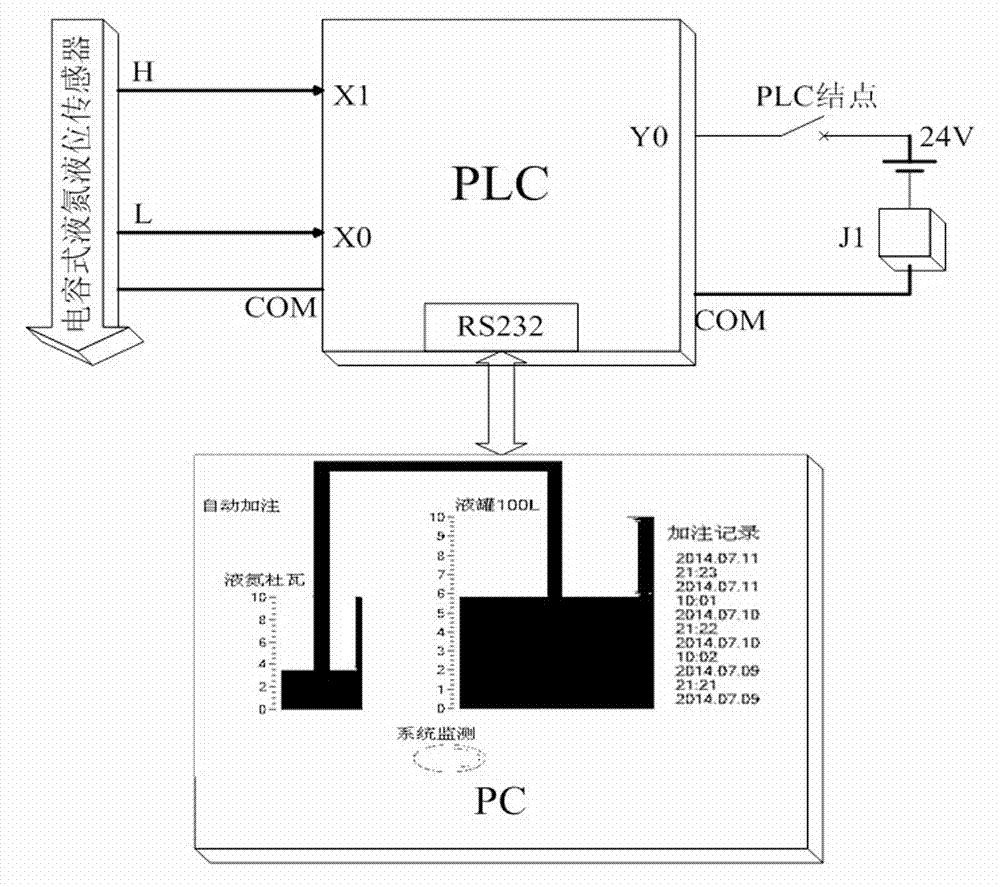

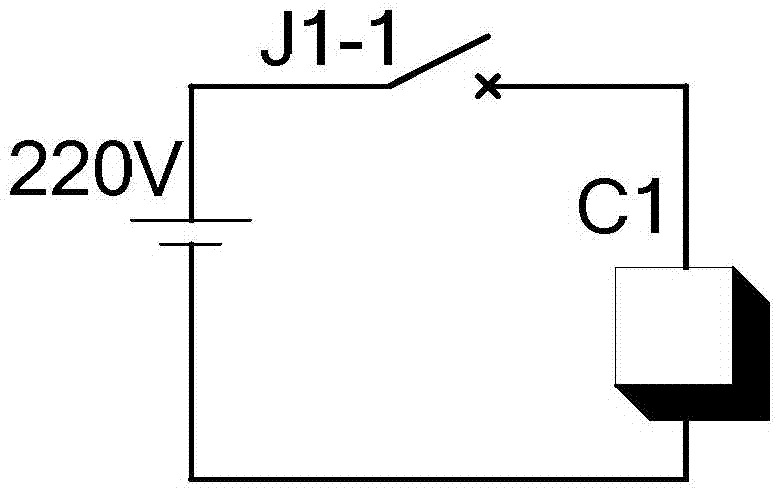

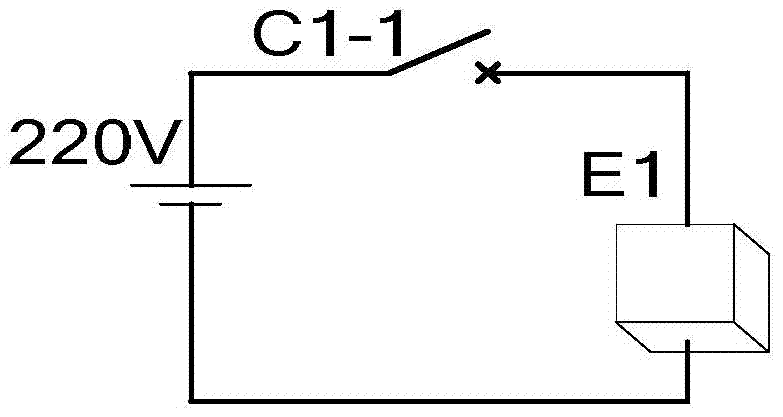

[0021] An automatic liquid nitrogen liquid level control device in a fusion device diagnostic system, the liquid nitrogen is placed in a Dewar bottle, and the automatic control device includes a main control device PLC, a capacitive liquid nitrogen in the Dewar bottle Liquid level sensor, small intermediate relay, AC contactor, low temperature solenoid valve, DC power supply, air switch, characterized in that: the main control device PLC is provided with two switching value input terminals X0 and X1 and one switching value output terminal Y0, the switch value input terminals XO and X1 are connected to the output terminal of the capacitive liquid nitrogen liquid level sensor, and the capacitive liquid nitrogen liquid level sensor is also connected to the input common terminal COM of the main control device PLC; the switch A PLC node, a DC power supply module, and a main coil of a small intermediate relay J1 are connected in series on the volume output terminal Y0, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com