Equipment state evaluation method, device and system and storage medium

A technology of equipment status and equipment, applied in data processing applications, prediction, calculation, etc., can solve problems such as lack of objectivity and inaccurate evaluation results, achieve automation and intelligence, solve misjudgment, accurate evaluation and monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

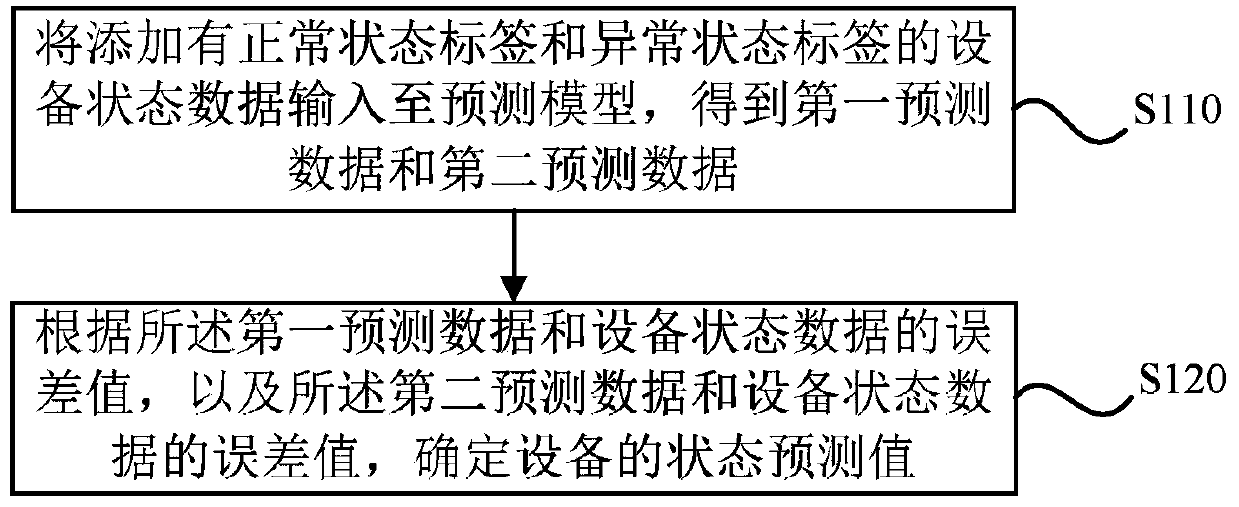

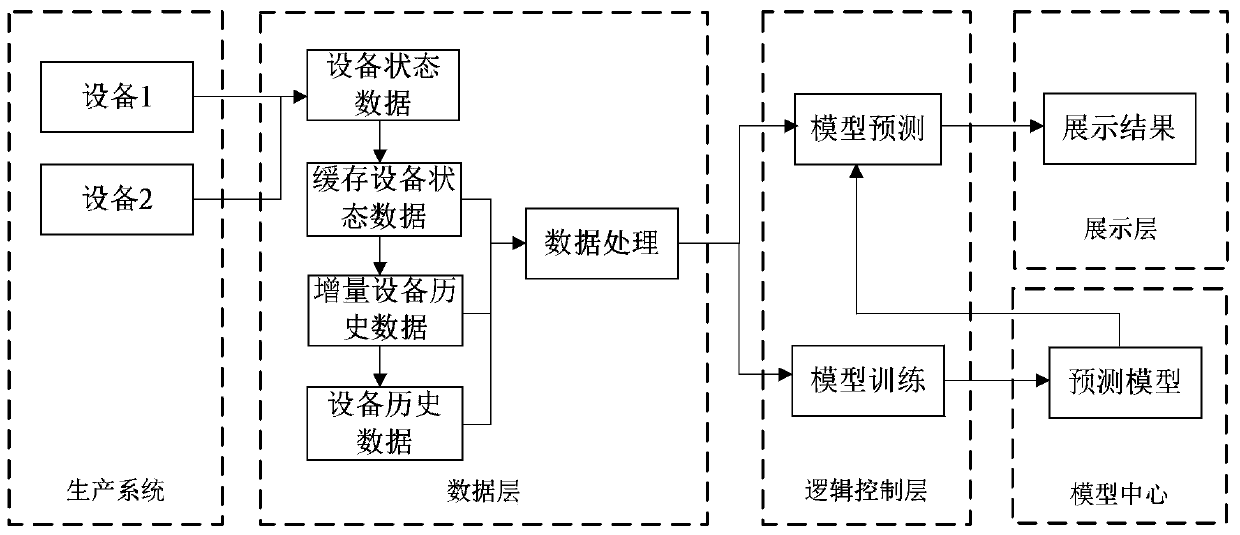

[0025] figure 1 It is a flow chart of a method for assessing equipment status in Embodiment 1 of the present invention. The equipment status evaluation method provided in this embodiment is applicable to the situation of monitoring and evaluating the status of the equipment, and the method can be specifically executed by an equipment status evaluation device, which can be implemented by software and / or hardware, and the device Can be integrated in the system. see figure 1 , the method of the embodiment of the present invention specifically includes:

[0026] S110. Input the equipment state data added with the normal state label and the abnormal state label into the prediction model to obtain the first prediction data and the second prediction data.

[0027] Wherein, there is at least one device to be evaluated, and the status of one device may be monitored and evaluated, or the status of a system composed of multiple devices may be monitored and evaluated. The normal state...

Embodiment 2

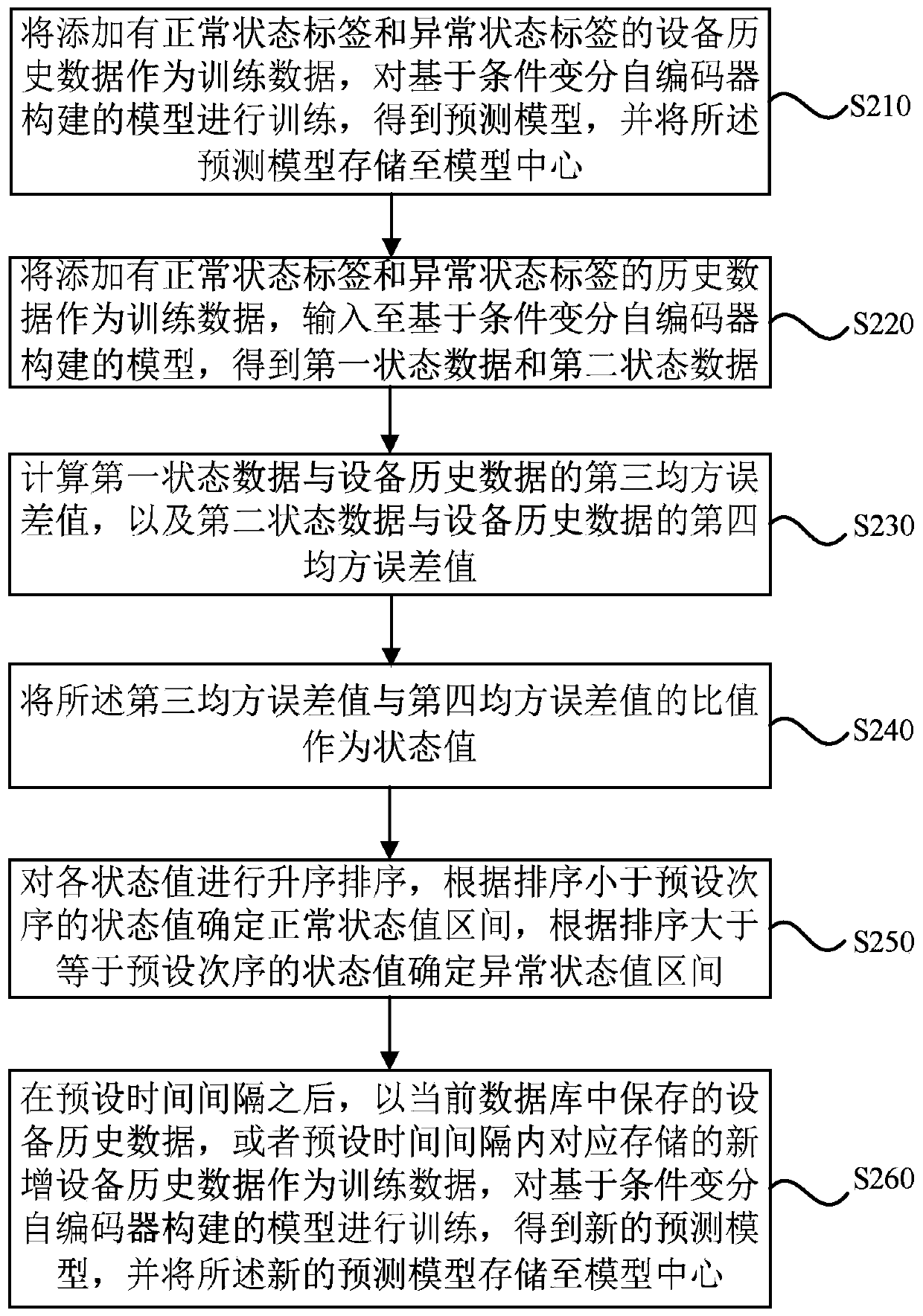

[0039] image 3 It is a flow chart of a method for assessing equipment status in Embodiment 2 of the present invention. This embodiment is optimized on the basis of the foregoing embodiments, and the training process of the prediction model is introduced in detail. For details not described in detail in this embodiment, refer to the above-mentioned embodiment. see image 3 , the equipment status assessment method provided in this embodiment may include:

[0040] S210. Using the equipment historical data with normal state labels and abnormal state labels as training data, train the model constructed based on the conditional variational autoencoder to obtain a prediction model, and store the prediction model in the model center.

[0041] Specifically, before the prediction model is used to predict the device status data, the prediction model needs to be trained. First, obtain the historical equipment data stored in the database. Since it is impossible to know whether the cor...

Embodiment 3

[0053] Figure 4 It is a schematic structural diagram of an equipment status evaluation device provided by Embodiment 3 of the present invention. The device is suitable for monitoring and evaluating the state of the equipment, the device can be realized by software and / or hardware, and the device can be integrated in the system. see Figure 4 , the device specifically includes:

[0054] A forecasting module 310, configured to input the equipment status data added with normal status tags and abnormal status tags to the forecasting model to obtain first forecast data and second forecast data;

[0055] The state prediction value determination module 320 is configured to determine the state prediction value of the device according to the error value between the first prediction data and the device state data, and the error value between the second prediction data and the device state data.

[0056] Optionally, the state prediction value determination module 320 includes:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com