Cam bending mechanism

A technology of bending mechanism and cam, which is applied in the field of automatic assembly, can solve the problems of waste of cost and space, heavy workload of assembly personnel, and low efficiency, so as to ensure assembly accuracy and stability, realize automation and intelligence, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0025] The invention provides a cam bending mechanism, which is widely used for terminal cutting and welding in the field of automatic assembly, can realize high-quality and high-efficiency assembly of products, and has the advantages of improving production efficiency and reducing production cost.

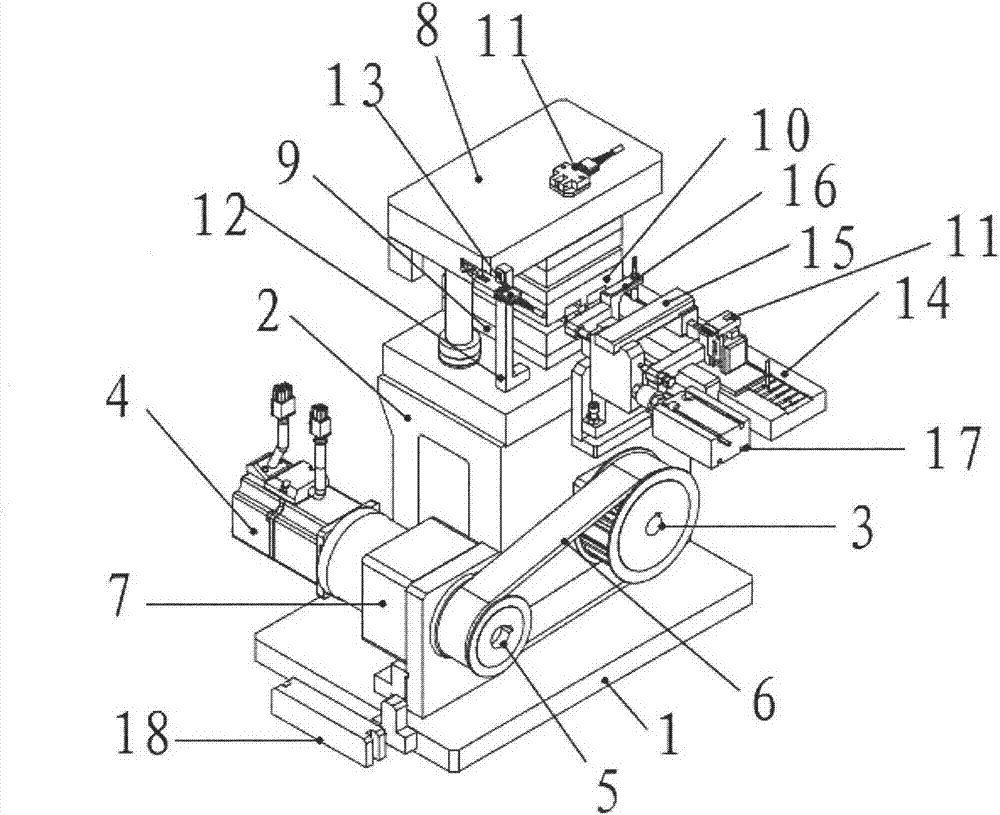

[0026] Such as figure 1 As shown, a cam bending mechanism is used in the processing and assembly process of terminals, including a base plate 1, a cam box 2 is installed above the base plate 1, and a cam is provided inside and outside the cam box 2, and the two cams cooperate with each other. synchronous rotation;

[0027] The outer cam 3 is connected to and driven by a driving device;

[0028] The inner cam (not shown in the figure) is upwardly connected with a cutting and bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com