Intelligent RDF environment former

A forming machine and intelligent technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of reducing transmission efficiency, equipment debugging, overloading, etc., to achieve automation and intelligence, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing for further explanation:

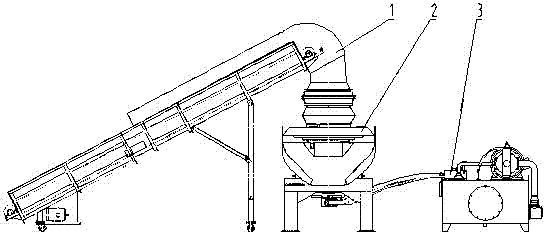

[0036] like figure 1 As shown, the intelligent RDF ring die forming machine described in the present invention adopts electromechanical-hydraulic integration technology. It is mainly composed of feeding device 1, forming host 2, hydraulic system 3 and electrical control system.

[0037] The feeding device 1 is composed of a feeding frame, a conveyor belt, a driving roller, a driven roller, a discharge hopper, a variable frequency motor and a reducer, and the speed of the variable frequency motor is controlled by a frequency converter.

[0038] The forming main machine 2 is mainly composed of a feed hopper, a module fixing plate, a forming module, an extrusion wheel, a material copying device, a main shaft, a frame, etc. The main shaft is directly driven by a hydraulic motor, and the hydraulic system 3 controls the torque and torque of the hydraulic motor. Rotating speed.

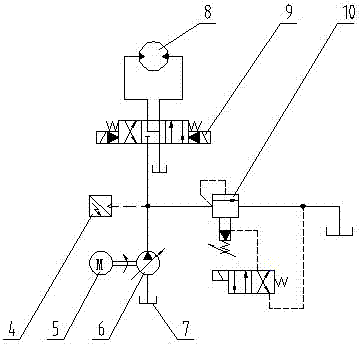

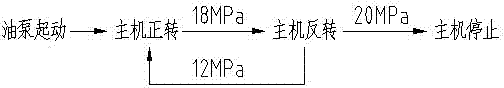

[0039] like fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com