Scanning type circuit board welding spot pseudo soldering automatic detection system and detection method

An automatic detection and detection method technology, applied in the direction of material defect testing, etc., can solve problems such as danger and solder joint failure, and achieve the effects of simple operation, convenient repair and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

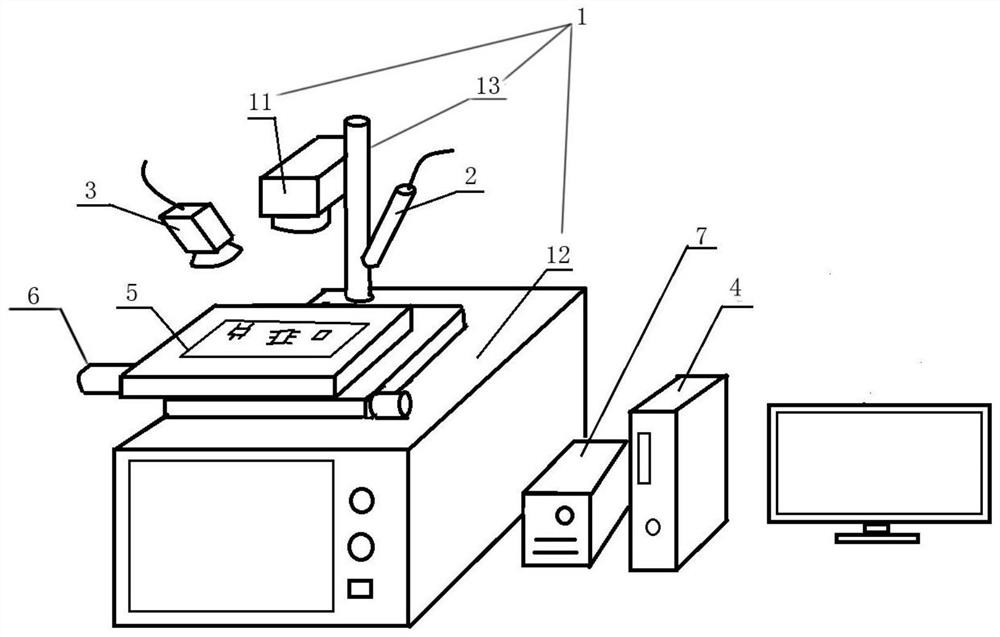

[0055] A scanning type circuit board solder joint virtual welding automatic detection system includes a galvanometer scanning laser 1, a digital optical microscope 2, an infrared thermal imager 3 and a computer 4, and the galvanometer scanning laser 1 includes a laser head 11 and a system Platform 12, the laser head 11 is fixed directly above the system platform 12 by a support rod 13 and is electrically connected with the system platform 12, and the infrared thermal imager 3 and the digital optical microscope 2 are respectively located on both sides of the laser head 11, so The field of view of the infrared thermal imager 3 and the digital optical microscope 2 overlaps and is positioned at the scanning range of the laser head 11 on the circuit board 5 to be tested, and the signal output end of the infrared thermal imager 3 is electrically connected to the signal input end of the computer 4 , the image signal output end of the digital optical microscope 2 is electrically connec...

specific Embodiment approach 2

[0059] The detection method of the scanning circuit board solder joint virtual welding automatic detection system described in the specific embodiment 1 includes the following steps:

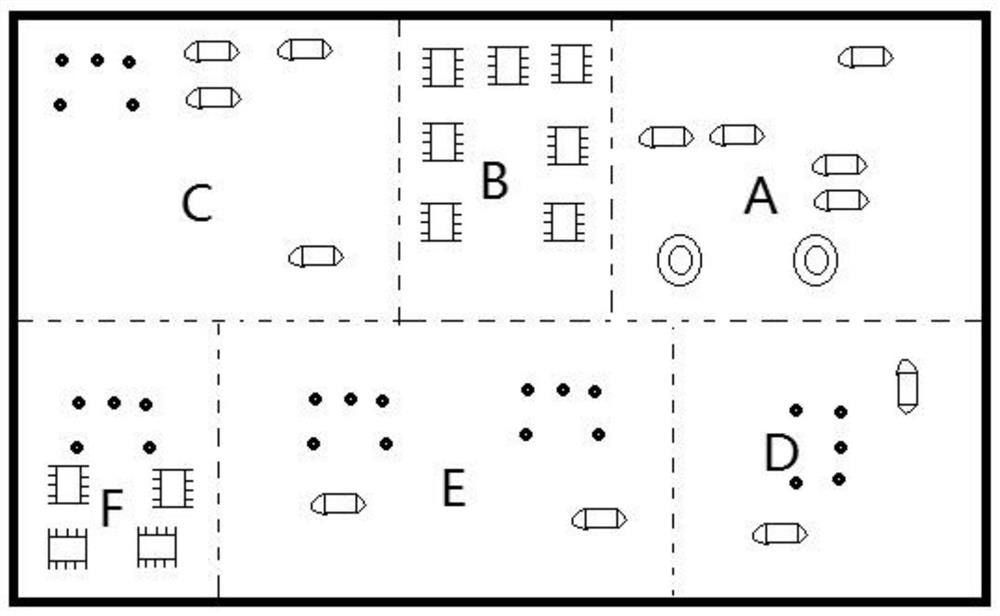

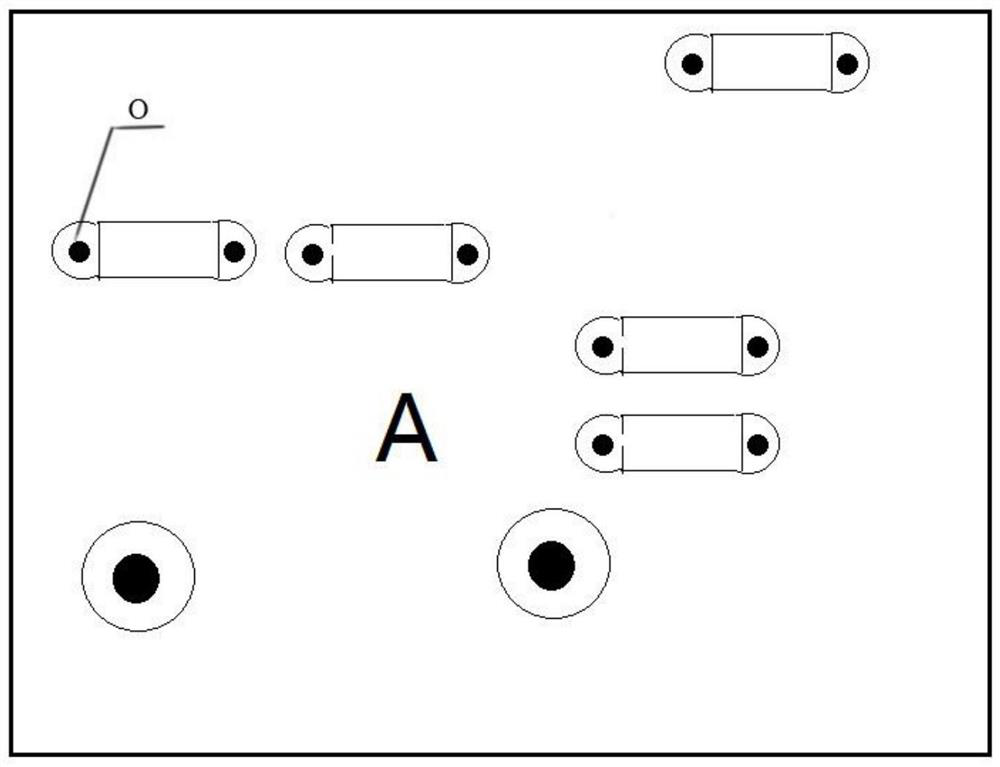

[0060] Step 1. Set and save the detection area solder spot scanning template in the system platform 12 of the galvanometer scanning laser 1;

[0061] Step 2, setting and saving the detection laser parameters in the system platform 12 of the galvanometer scanning laser 1;

[0062] Step 3: Set the temperature measurement template of the temperature measurement area for each solder joint in the detection area in the infrared thermal imager 3 and save it;

[0063] Step 4. Set and save the temperature measurement threshold for each solder joint in the detection area in the infrared thermal imager 3;

[0064] Step 5: Fix the circuit board 5 to be tested on the system platform 12 and below the laser head 11, fix it with a positioning fixture, start the vibrating mirror scanning laser 1, and the emitte...

specific Embodiment approach 3

[0073] The detection method of the scanning circuit board solder joint virtual welding automatic detection system described in the specific embodiment 1 includes the following steps:

[0074] Step 1, setting a scanning template for solder joints in the detection area in the system platform 12 of the galvanometer scanning laser 1;

[0075] Step 2, setting detection laser parameters in the system platform 12 of the galvanometer type scanning laser 1;

[0076] Step 3. Set the temperature measurement area for each solder joint in the detection area in the infrared thermal imager 3 and save the temperature measurement template;

[0077] Step 4. Set the temperature measurement threshold for each solder joint in the detection area in the infrared thermal imager 3;

[0078] Step 5: Fix the circuit board 5 to be tested on the system platform 12 and below the laser head 11, fix it with a positioning fixture, start the vibrating mirror scanning laser 1, and the emitted laser automatical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com