Full-automatic cell production line

A fully automatic, production line technology, applied in tissue cell/virus culture devices, biochemical instruments, biomass post-processing, etc., can solve problems such as unstable operation, long continuous manual work time, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

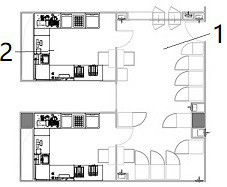

[0113] combined with figure 1 , a fully automatic cell production line, including culture area 1 (in order to save costs, its environment is set to a B-level environment at least) and an operation area 2 (in order to biosafety, its environment is set to an A-level environment). The culture area 1 is used for cell culture and cold storage; the operation area 2 is used for operations such as liquid exchange, centrifugation and freezing during cell culture. In this application, robot arms are used in the culture area 1 and the operation area 2 to realize the full automation of cell culture.

[0114] In order to better illustrate the technical solution of the present application, the following will be described in conjunction with specific examples:

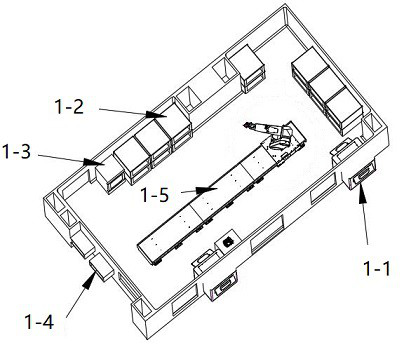

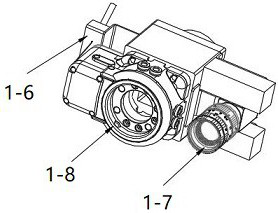

[0115] attached Figure 2-3 About the training area

[0116] Such as figure 2 As shown, the cultivation area includes a B-level platform body, and the B-level platform body includes a cultivation area 1-2, a cold storage area 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com