Patents

Literature

132 results about "Cell factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Cell Factory is a biotechnology company focused on development, clinical translation and commercialization of immunotherapeutic drug candidates based on Exosomes, a disruptive and novel technology known as Extracellular Vesicles promising to be the future nanomedicines.

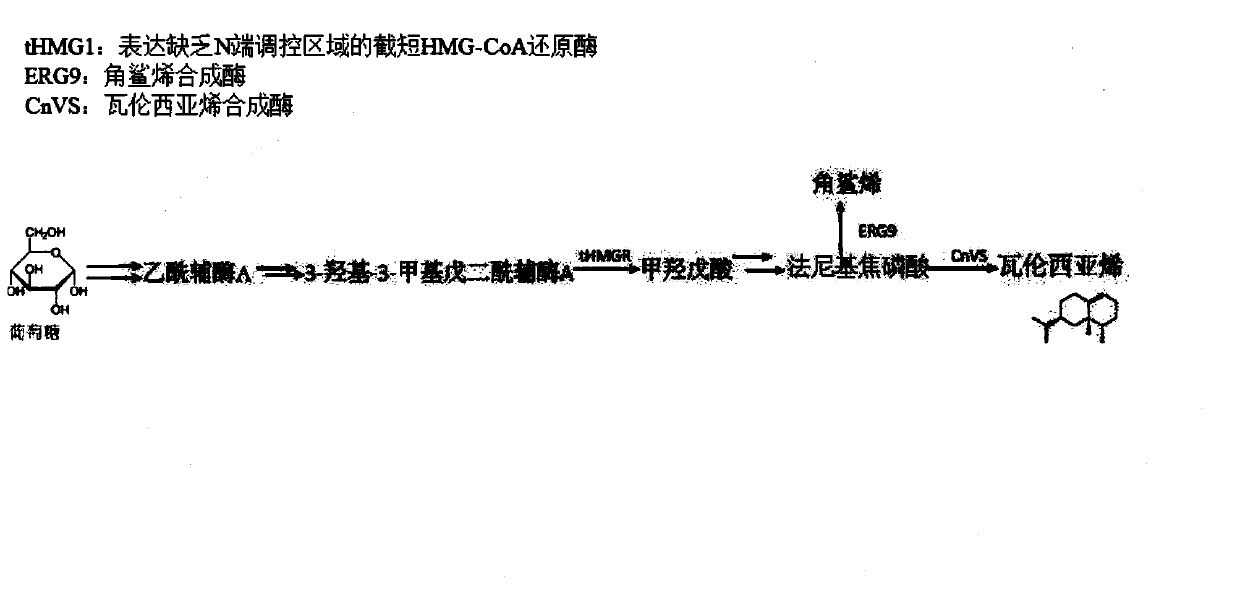

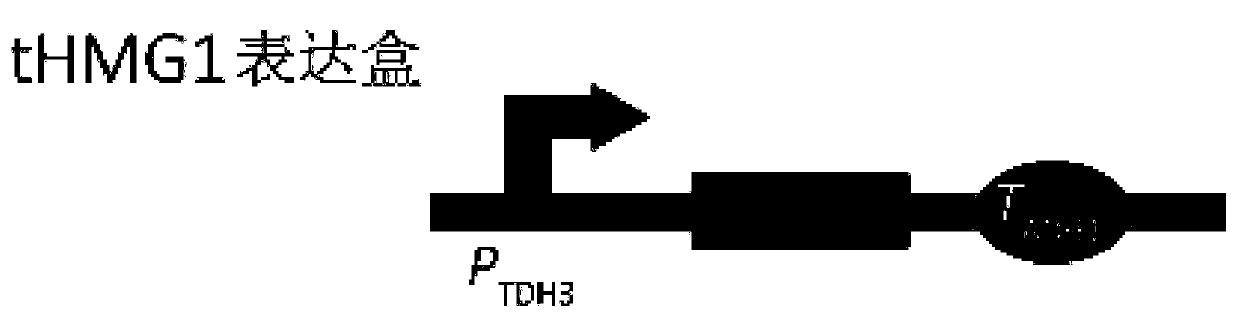

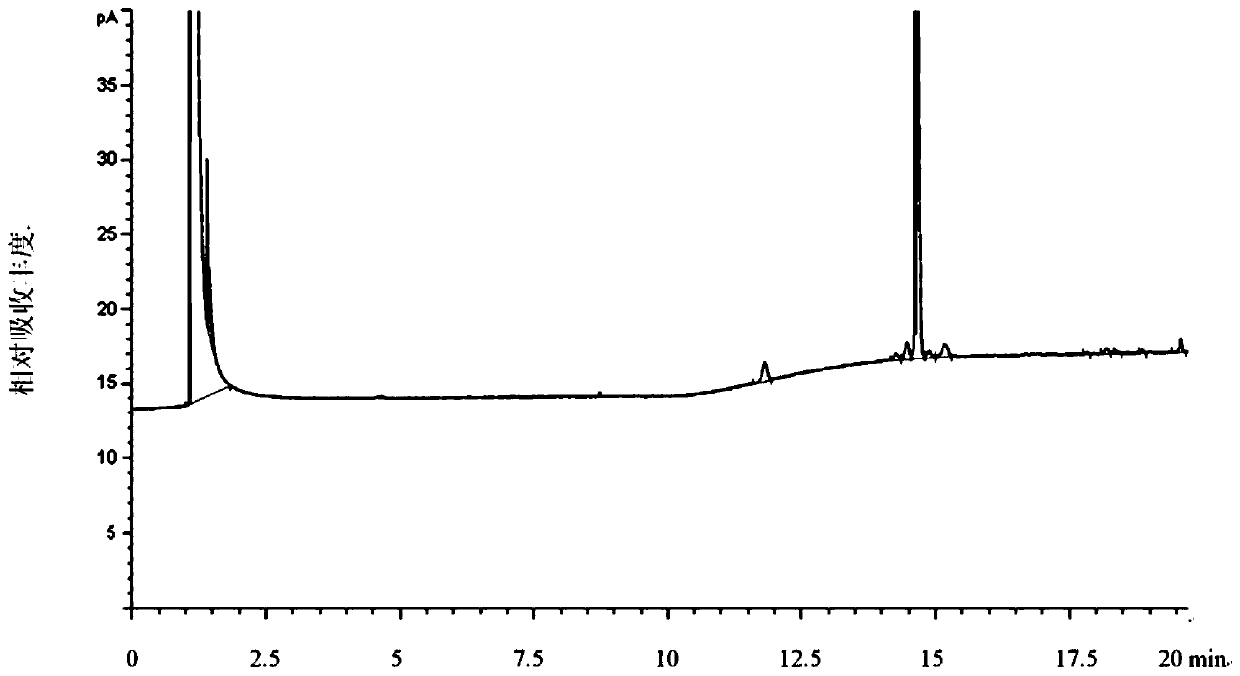

Brewer's yeast engineering bacterium for producing valencene and construction method and application of brewer's yeast engineering bacterim

ActiveCN110117551AEfficient productionIncrease production capacityFungiTransferasesBiotechnologyHMG-CoA reductase

The invention discloses a brewer's yeast engineering bacterium for producing valencene and a construction method and application of the brewer's yeast engineering bacterium. Overall inhibiting factorgenes in a yeast genome are subjected to knockout, a squalene synthetase gene is subjected to down reduction of expression, valencene synthetase is expressed, HMG-CoA reductase is overexpressed, the promoter of the valencene synthetase is optimized, and therefore the valencene is obtained. The key gene in the metabolic pathway is overexpressed through a free vector, the metabolic flux of the valencene in the synthetic route is increased, and the yeast cell factory is optimized; in combination with the suitability research of the promoter of the valencene synthetase, the brewer's yeast engineering bacterium obtained through culture optimization achieves efficient production of the valencene, and the dry cell weight yield of the valencene can reach 124.40 mg / g; the brewer's yeast engineeringbacterium has a wide industrial application prospect and positive economic and social development significance.

Owner:SOUTH CHINA UNIV OF TECH

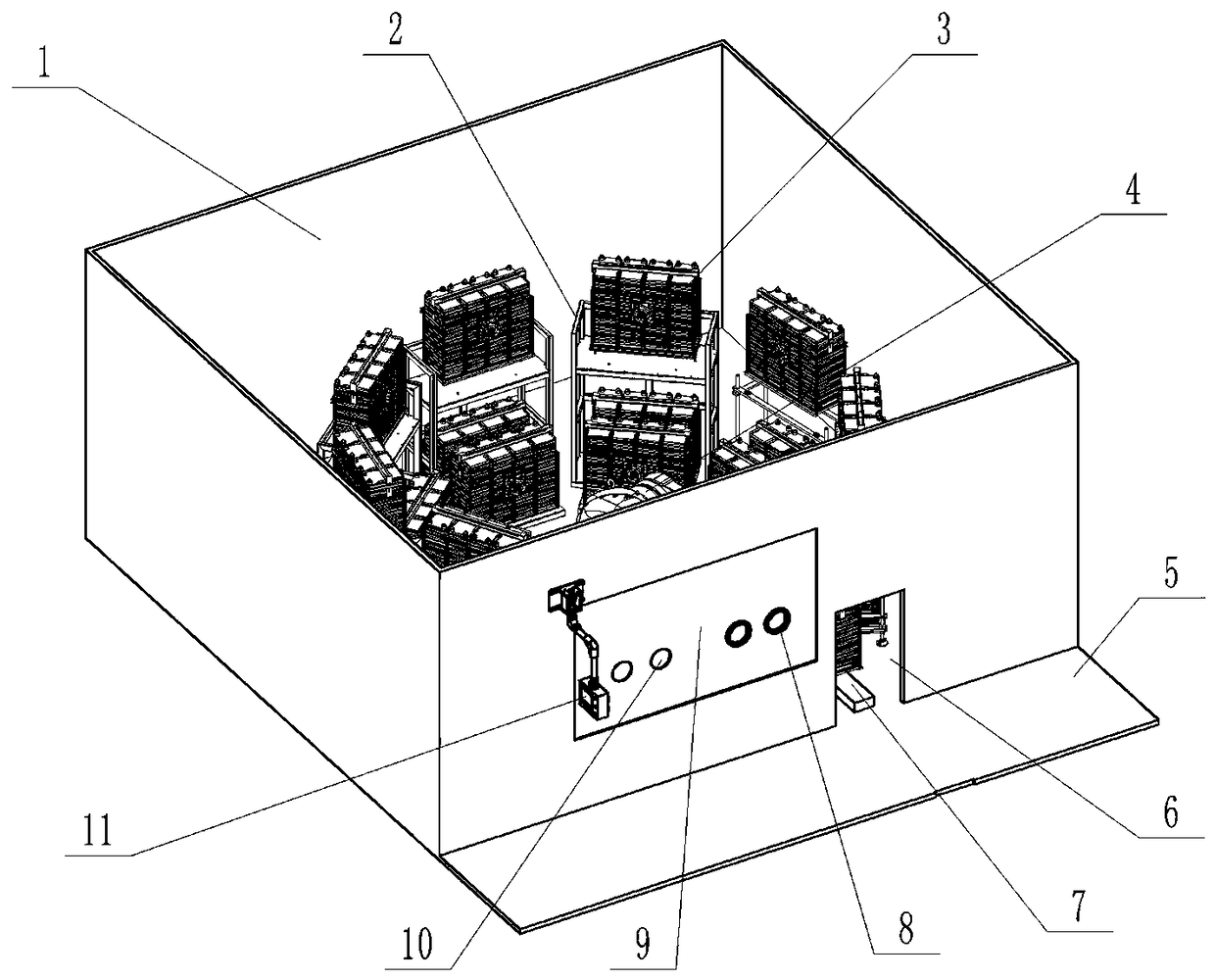

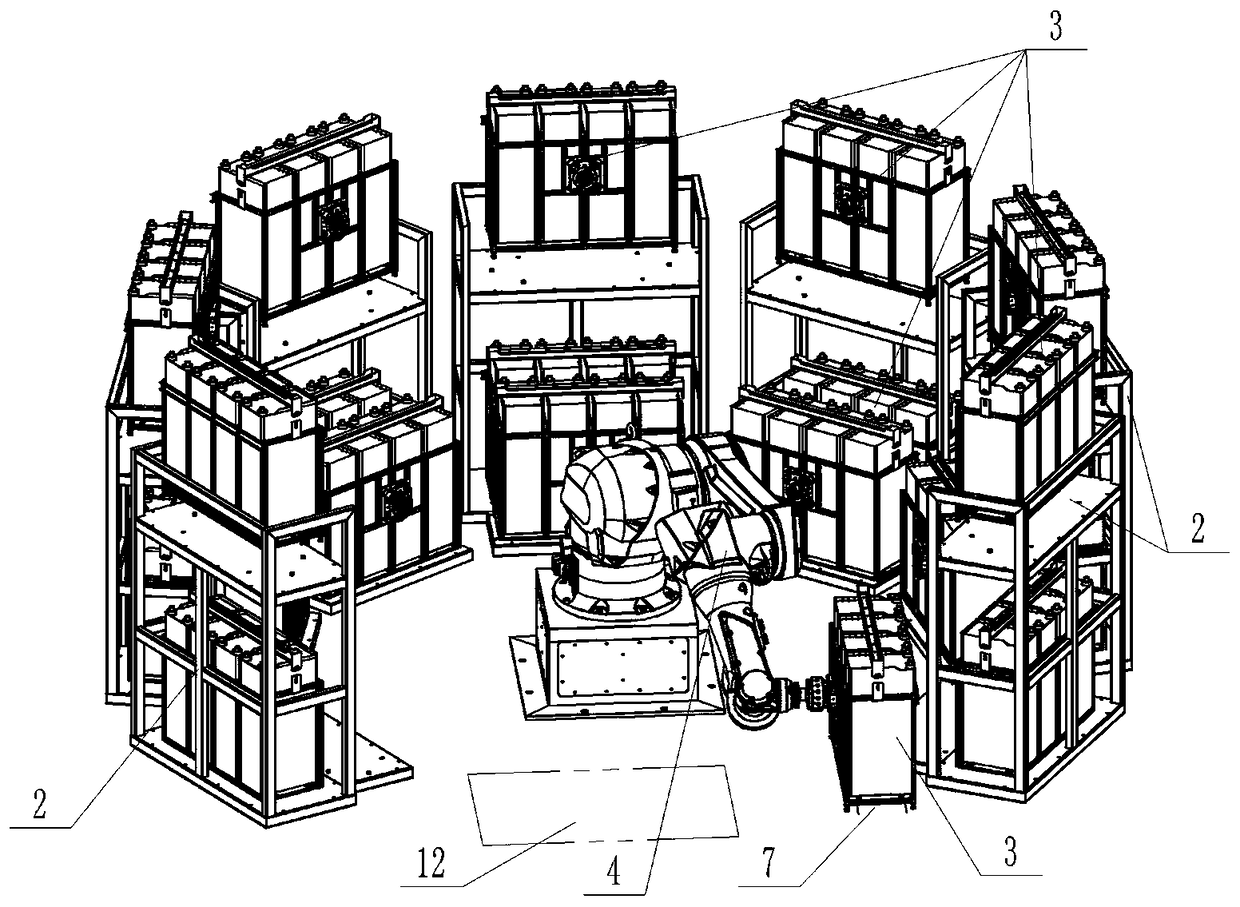

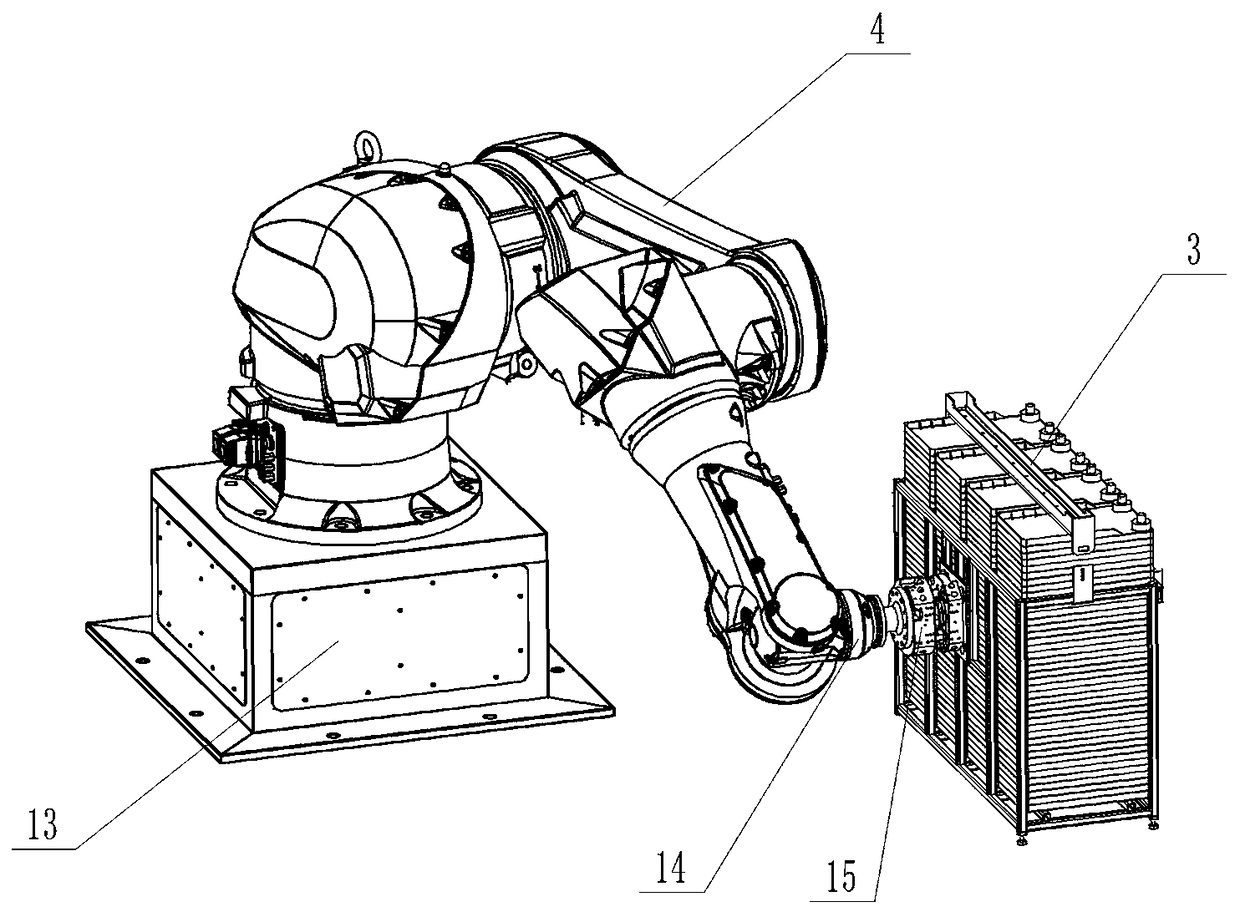

Method for applying multi-axis robot to cell factories to prepare biological products

ActiveCN109251861AStrong process controllabilityReduce in quantityBioreactor/fermenter combinationsBiological substance pretreatmentsCell factoryEngineering

The invention discloses a method for applying a multi-axis robot to cell factories to prepare biological products. The problems that in the prior art, a large amount of manual operation is needed, theconstant temperature room environment is difficult to control, thus the adverse effect on growing and amplification of cultures is caused, and the production cost is high are solved. A plurality of sets of culturing frames, arm operating openings and pipeline connecting openings cooperate with the multi-axis robot to achieve operations such as grabbing, moving, overturning and waggling of specialstructure cell factory frames to replace operating processes adopting manpower and other fixed equipment, wherein the culturing frames are sequentially arranged in a fan shape in a constant temperature room, and the arm operating openings and the pipeline connecting openings are formed in an observation window between the constant temperature room and an operation room. According to the method, the cell factories are intensively cultured and operated, operation does not need manual pushing and does not need to leave the constant temperature room, thus the culturing environment is easy to control, changing of the culture temperature is small, modular efficient production is facilitated, the product consistency is good, the pollution rate is low, and the overall operating cost can be saved.

Owner:LIAONING CHENGDA BIOTECH

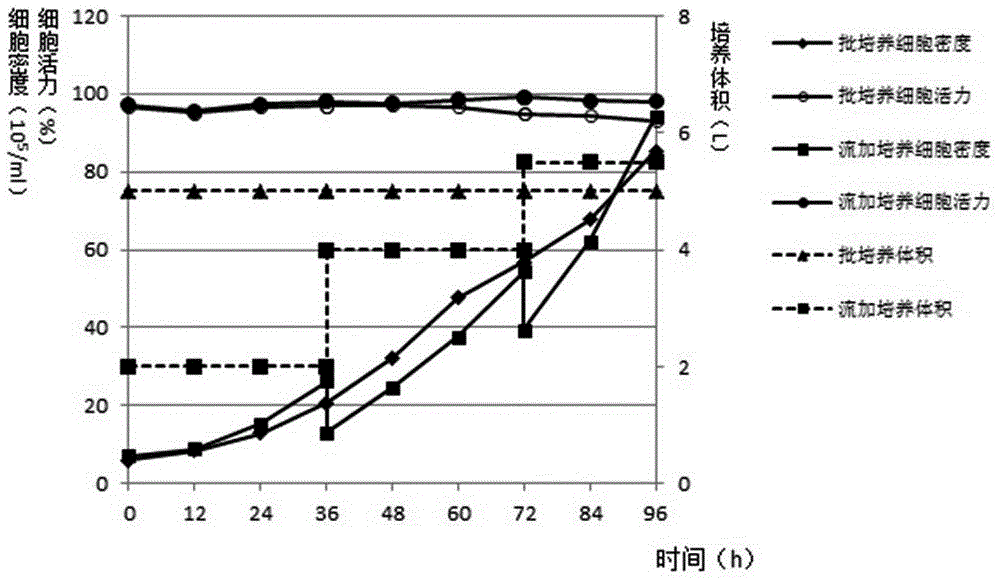

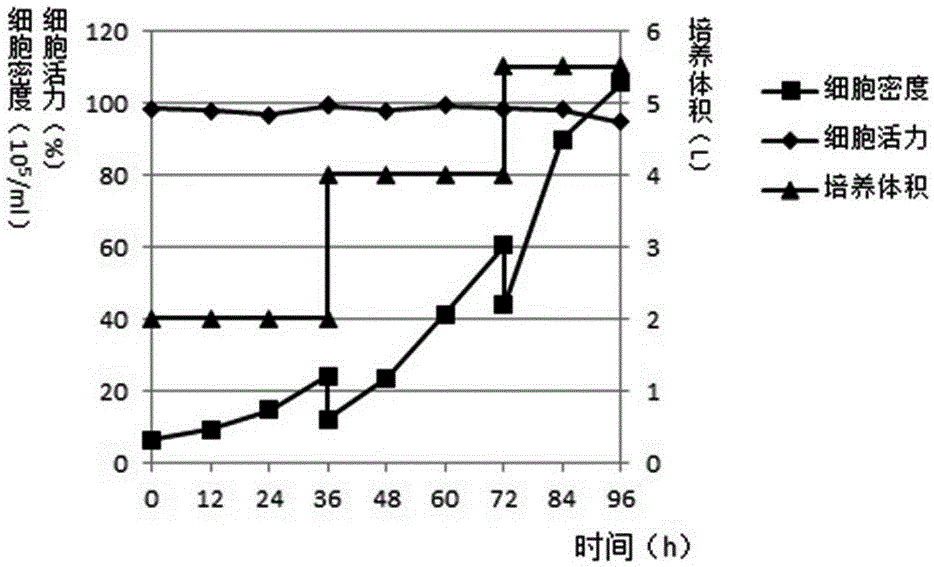

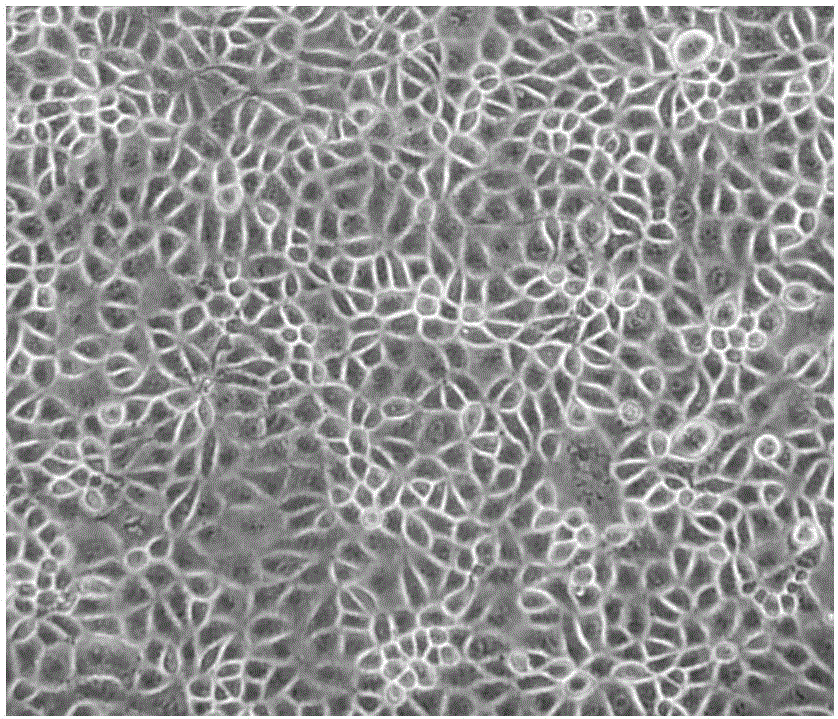

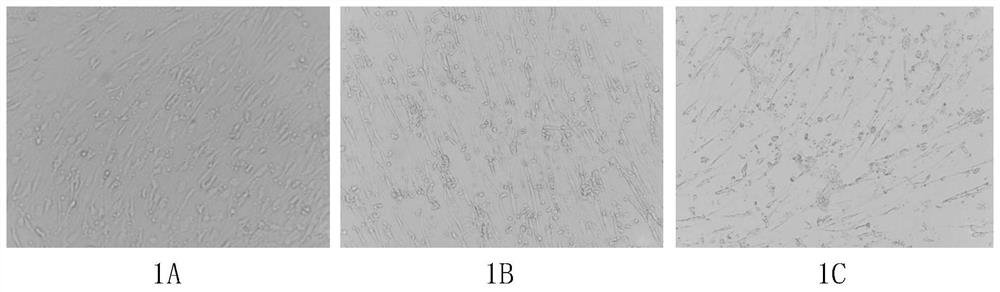

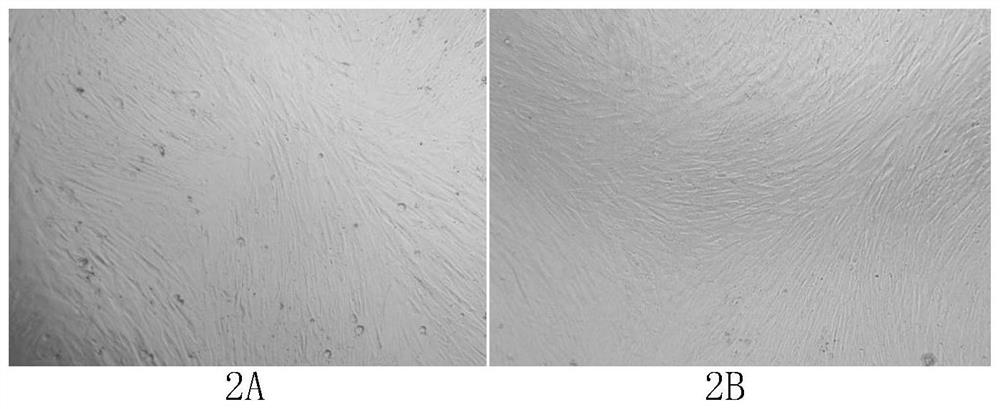

Domestication method of full suspension culture type Marc-145 cell line

ActiveCN105950544AReduce investmentConform to energy savingCulture processCell culture active agentsSerum freeMicrobiology

The invention provides a domestication method of a full suspension culture type Marc-145 cell line. The domestication method comprises the following steps: (1) cultivating adherent-culture Marc-145 cells; (2) domesticating a low-serum adherent-culture Marc-145 cell line; (3) domesticating low-serum full suspension culture type Marc-145 cells; and (4) domesticating serum-free full suspension culture type Marc-145 cells. With the application of the cell domestication method disclosed by the invention, the Marc-145 cells of suspension culture can be obtained; the cells are adaptive to low-serum and serum-free full suspension culture; the density of the cells, when subjected to serum-free culture in a 7.5L reactor, can reach 8*10<6> / ml, and at least 4.4*10<10> cells can be obtained, equal to the number of cells obtained from 80-90 15L roller bottles or 18-20 40-layer cell plants; and the domestication method disclosed by the invention is significant in effect.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Production and freeze-drying method and application for supernate of culture solution of mesenchymal stem cell

InactiveCN104946585ALow costSave spaceCosmetic preparationsToilet preparationsCell factoryUmbilical cord tissue

The invention relates to a production and freeze-drying method and application for supernate of a culture solution of a mesenchymal stem cell. a culture solution supernate freeze drying agent can be used with skin care products simultaneously after being dissolved again, the function of improving a skin is achieved, the production method adopts umbilical cord tissues of a healthy person as raw materials, the umbilical cord tissues are digested through collagenase and cultured outside the body, amplification and trypsin digestive passage are conducted, an NuncTM cell factory system with ten layers or four layers is utilized to replace a traditional cell culture bottle finally, the cost is greatly reduced, needed space is reduced, a large number of mesenchymal stem cells are obtained in shorter culture time, low concentration fetal bovine serum (3%FBS) is reserved in cell culture media to make the condition of the cells healthier compared with that of the cells without serum, the quality of culture supernatant fluid is guaranteed, the culture supernatant fluid can be stored under room temperature after vacuum freeze drying is conducted on the culture supernatant fluid directly, and activity of various growth factors of the culture supernatant fluid is maintained.

Owner:MILTENYI TIANJIN BIOLOGICAL SCI & TECH

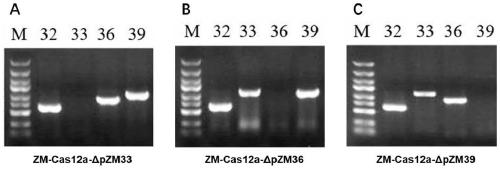

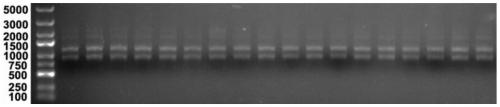

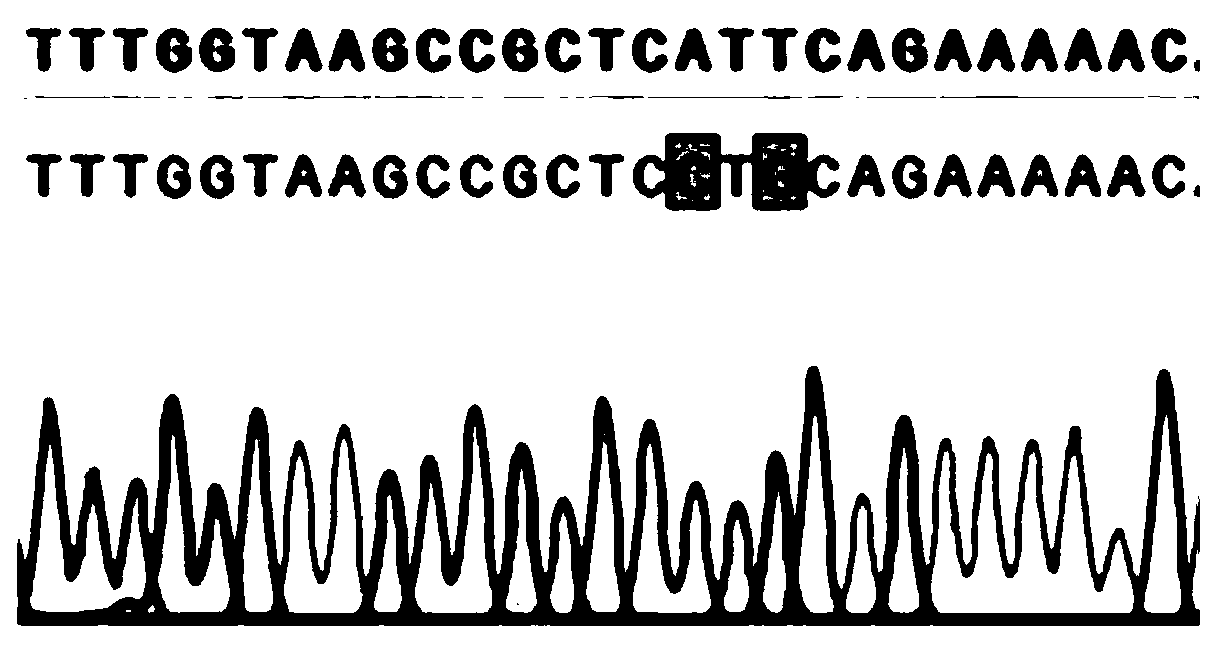

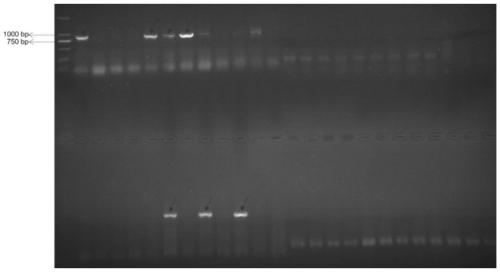

Zymomonas mobilis genome editing method based on CRISPR-Cas12a system and application of method

ActiveCN110358767ASimple and fast operationIncrease positive rateBacteriaStable introduction of DNAHeterologousCompetent cell

The invention belongs to the technical field of gene editing, and particularly relates to a Zymomonas mobilis genome editing method based on a CRISPR-Cas12a system and application of the method. The method for editing a Zymomonas mobilis genome is established on the basis of the CRISPR-Cas12a system with Zymomonas mobilis (ZM4) as the modulus strain, the oriented editing of the genome is realized,a gene editing tool is provided for developing the rational design of an allogenic metabolic pathway and cell factory for producing biomass fuel and biological materials in the strain, and the development in metabolic engineering and related research fields is promoted. The method is technically characterized by including the steps of establishing an inducible expression Cas12a recombinant strainand an editing plasmid containing an artificial CRISPA expression unit, designing guiding RNA, connecting the guiding RNA to the editing plasmid after annealing the primer sequence of the guiding RNA, and shifting a target plasmid into a competent cell for expression editing.

Owner:武汉睿嘉康生物科技有限公司

Genetically engineered bacterium for producing fucosyllactose and production method

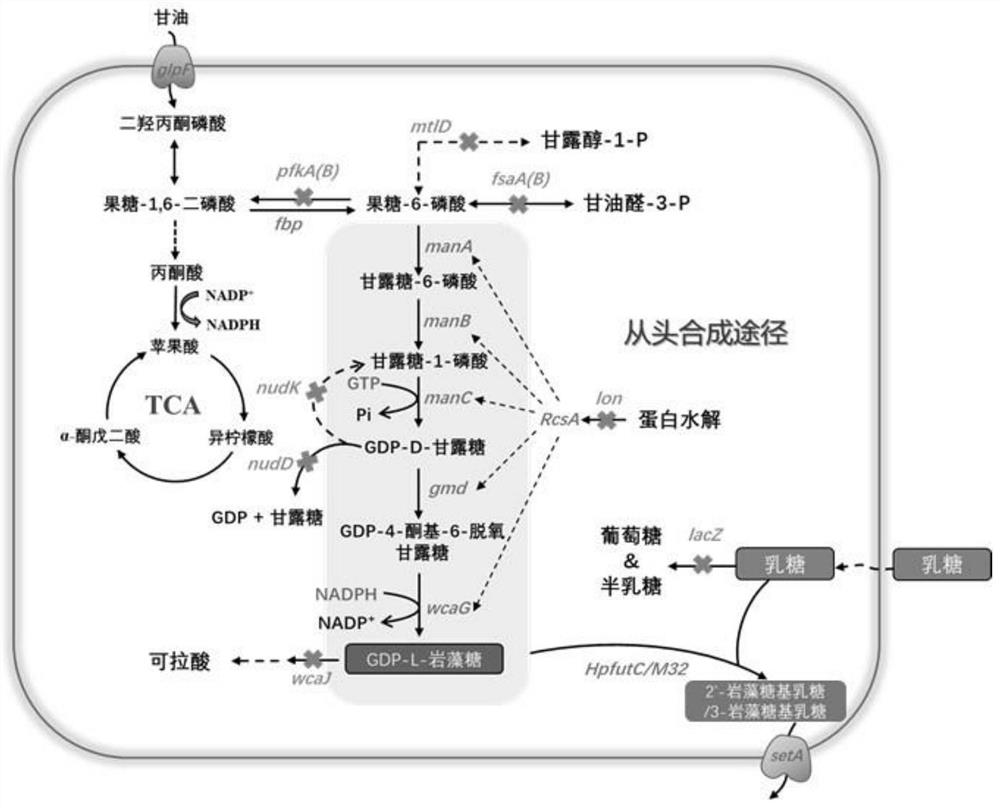

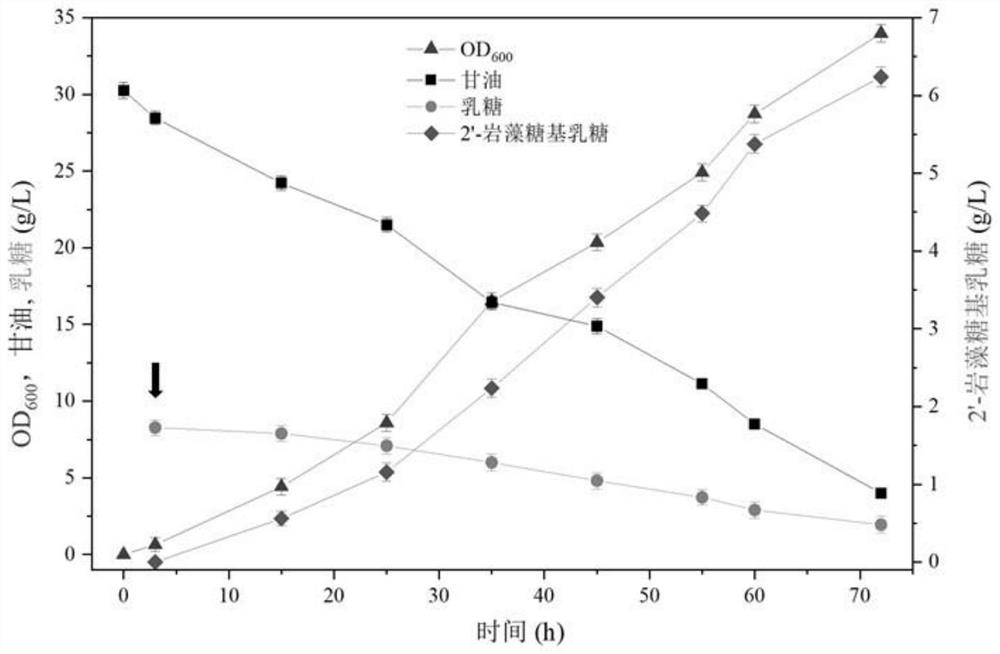

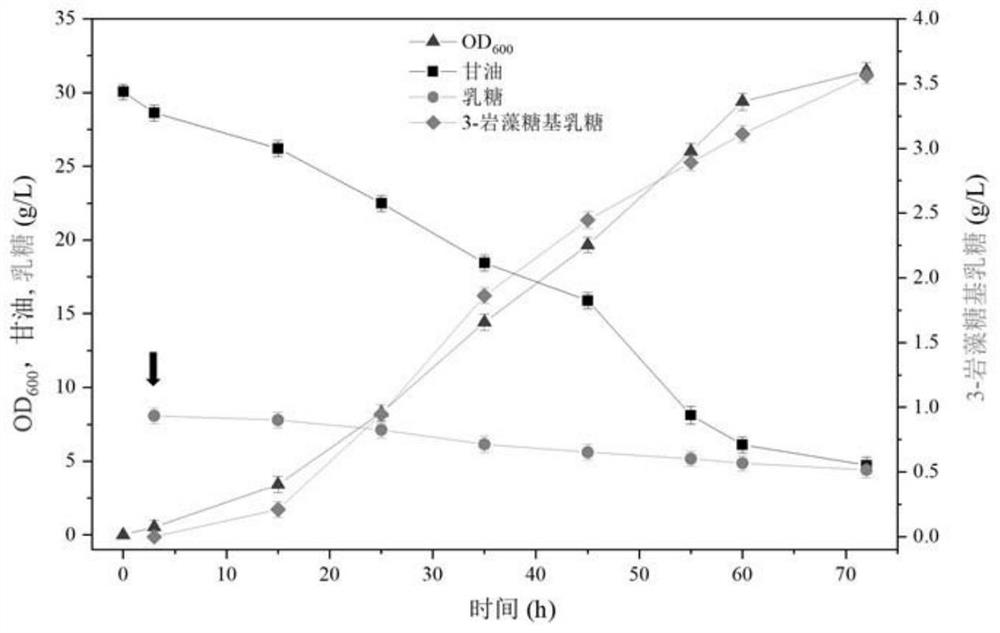

PendingCN114480240AGrow fastImprove expression levelBacteriaMicroorganism based processesBiotechnologyCell factory

The invention relates to a genetically engineered bacterium for producing fucosyllactose and a production method of the genetically engineered bacterium, and belongs to metabolic engineering and food fermentation technologies. According to the invention, a synthetic biological means is utilized, an escherichia coli cell factory of fucosyllactose is constructed based on a de novo synthetic route, bypass related genes lacZ, wcaJ, nudD, pfkA and lon in host cells are knocked out by adopting a CRISPR / Cas9 gene editing technology, and genes manB, manC, gmd and wcaG are assembled through a multi-plasmid expression system, so that the fucosyllactose is obtained. Constructing expression vectors with different copy numbers to increase the expression level of key genes; fucosyltransferase from different sources is screened, so that the activity of rate-limiting enzyme is improved. The constructed recombinant escherichia coli can be used for synthesizing 2 '-fucosyllactose and 3-fucosyllactose by utilizing glycerol, is stable in heredity and high in expression level, and has obvious industrial production potential.

Owner:JIANGNAN UNIV

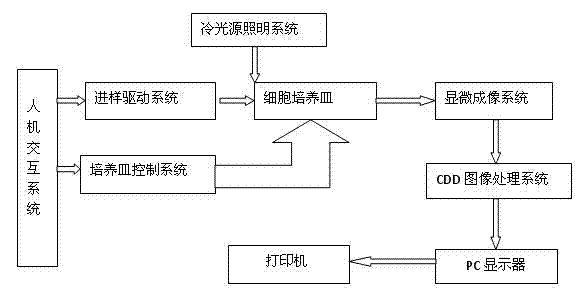

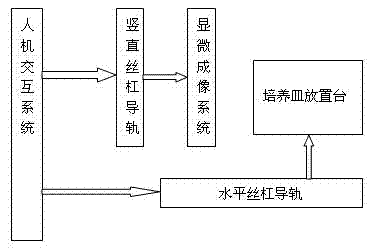

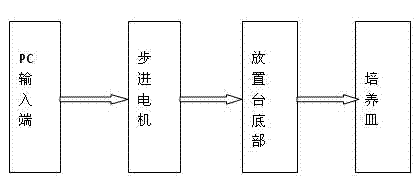

Cell microscopic observation monitor in cell factory

InactiveCN102827758ALow costSimple and fast operationBioreactor/fermenter combinationsBiological substance pretreatmentsCell factoryMicroscopic observation

The invention relates to a cell microscopic observation monitor in a cell factory, belonging to the technical field of bioengineering. The cell microscopic observation monitor is characterized in that a stepping motor is used to control a sample introduction driving system, so that cell culture dishes can simultaneously enter an illuminating system part and an imaging system part of the monitor; an LED (light-emitting diode) lamp is used as the illuminating system to illuminate the cell culture dishes, and cells are imaged on a CCD (charge-coupled device) through a microscopic lens with a long working distance; and cell images obtained after CCD imaging are subjected to image amplification processing through an image acquisition card and an image processing apparatus so as to obtain relatively perfect images, and the images are presented on a PC (personal computer) display. The cell microscopic observation monitor is quick and convenient to operate and low in cost, realizes automatic operation, and uses a cell factory microscopic monitoring system with a long working distance to realize the quick observation monitoring of cells in the multi-layer culture dishes in the cell factory. The cell microscopic observation monitor is widely used for cell real-time monitoring in the field of biopharmaceutical industry.

Owner:CHANGCHUN UNIV OF SCI & TECH

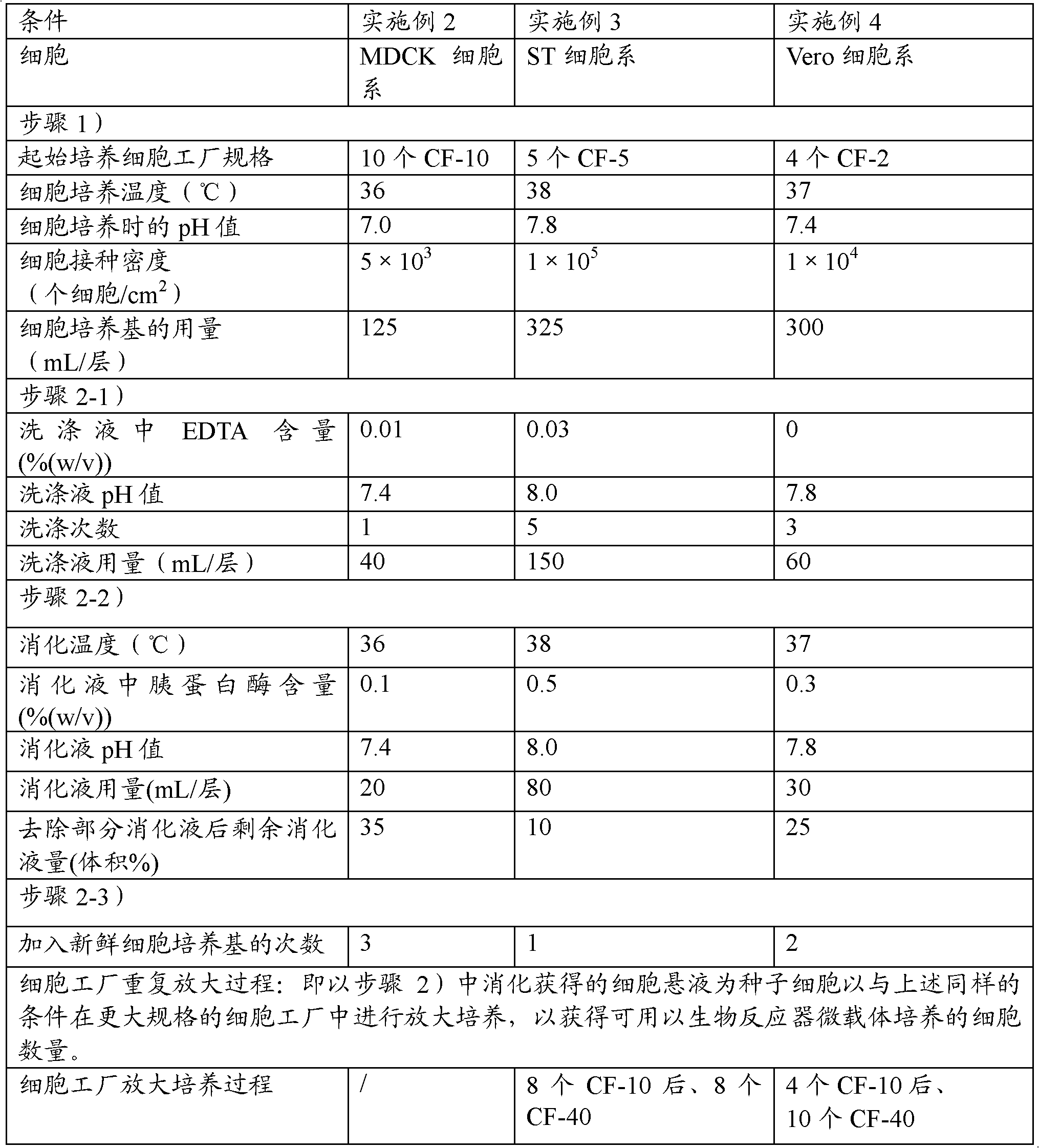

Method for scale-up culture of animal cells

InactiveCN102807964AAchieving scale-upSave production spaceVertebrate cellsArtificial cell constructsCell factoryBiochemistry

The invention relates to a method for scale-up culture of animal cells. The method includes the following steps of firstly, culturing animal cells in a cell factory; secondly, digesting the cultured animal cells, namely removing culture solution, and washing the cultured animal cells by pH7.4-8.0 washing solution; removing the washing solution by adding pH7.4-8.0 digestive solution 20-80mL per layer, allowing the digestive solution to evenly flow to each layer to digest the cells at 36-38 DEG C, removing partial digestive solution when more than 60% of cells fall off from the cell culture surface, and continuing to digest by the residual 10-35% of digestive solution; and adding fresh cell culture solution containing serum or digestive solution inhibitor to finish digesting and performing cell suspension again, and adding the culture solution for once to three times repeatedly; and thirdly, inoculating obtained cell suspension to a bioreactor for culture.

Owner:BEIJING SKYWING TECH CO LTD

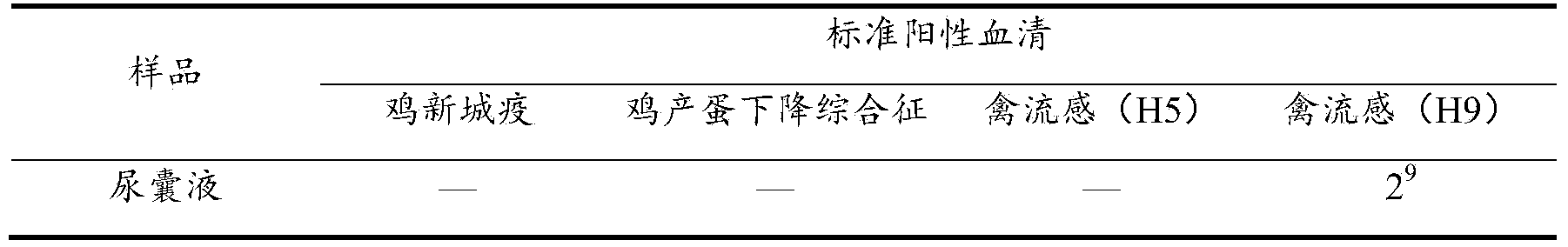

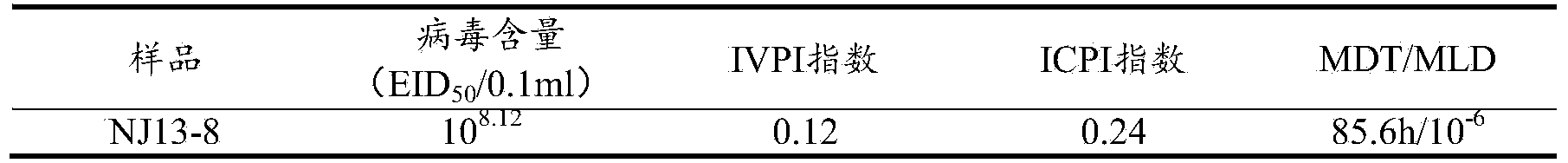

Method for producing inactivated vaccine of H9N2 subtype of avian influenza virus and product of inactivated vaccine

InactiveCN104338127AHigh titerAvoid biosafety issuesAntiviralsAntibody medical ingredientsCell factoryCytotoxicity

The invention discloses a method for producing an inactivated vaccine of H9N2 subtype of avian influenza virus and a product of the inactivated vaccine, and belongs to the field of production and application of inactivated vaccines of H9N2 subtype of avian influenza virus. The method comprises the following steps: (1) culturing a MDCK cell by utilizing a cell factory; (2) inoculating H9N2 subtype of avian influenza virus, and proliferating virus in the cell factory, wherein the microbial preservation number of the H9N2 subtype of avian influenza virus is CGMCC No.9325; and (3) harvesting the virus, and preparing the inactivated vaccine. Immune protection tests prove that the protective rate of the H9N2 subtype of avian influenza virus produced by the method is 100 percent, and the antibody level of a cytotoxicity immunity group at each point in time is higher than that of a germ toxicity immunity group, and rises relatively high. Virus liquid produced by the method can be used for preparing medicines or reagents for preventing or treating H9N2 subtype of avian influenza virus.

Owner:JIANGSU ACAD OF AGRI SCI

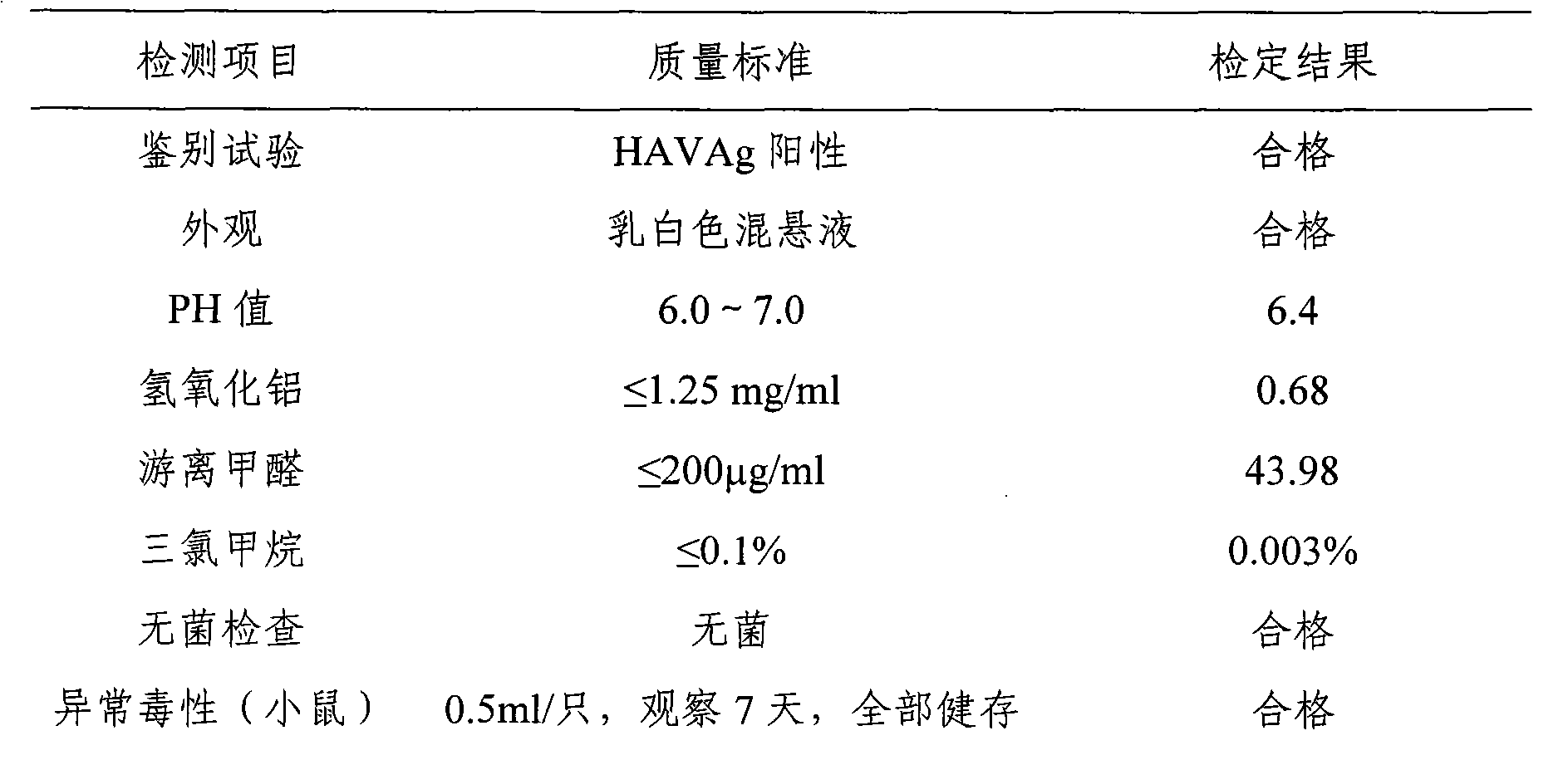

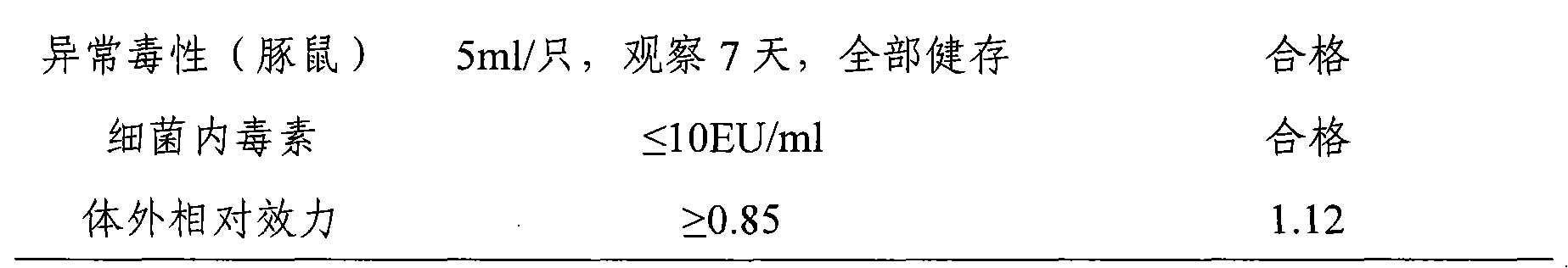

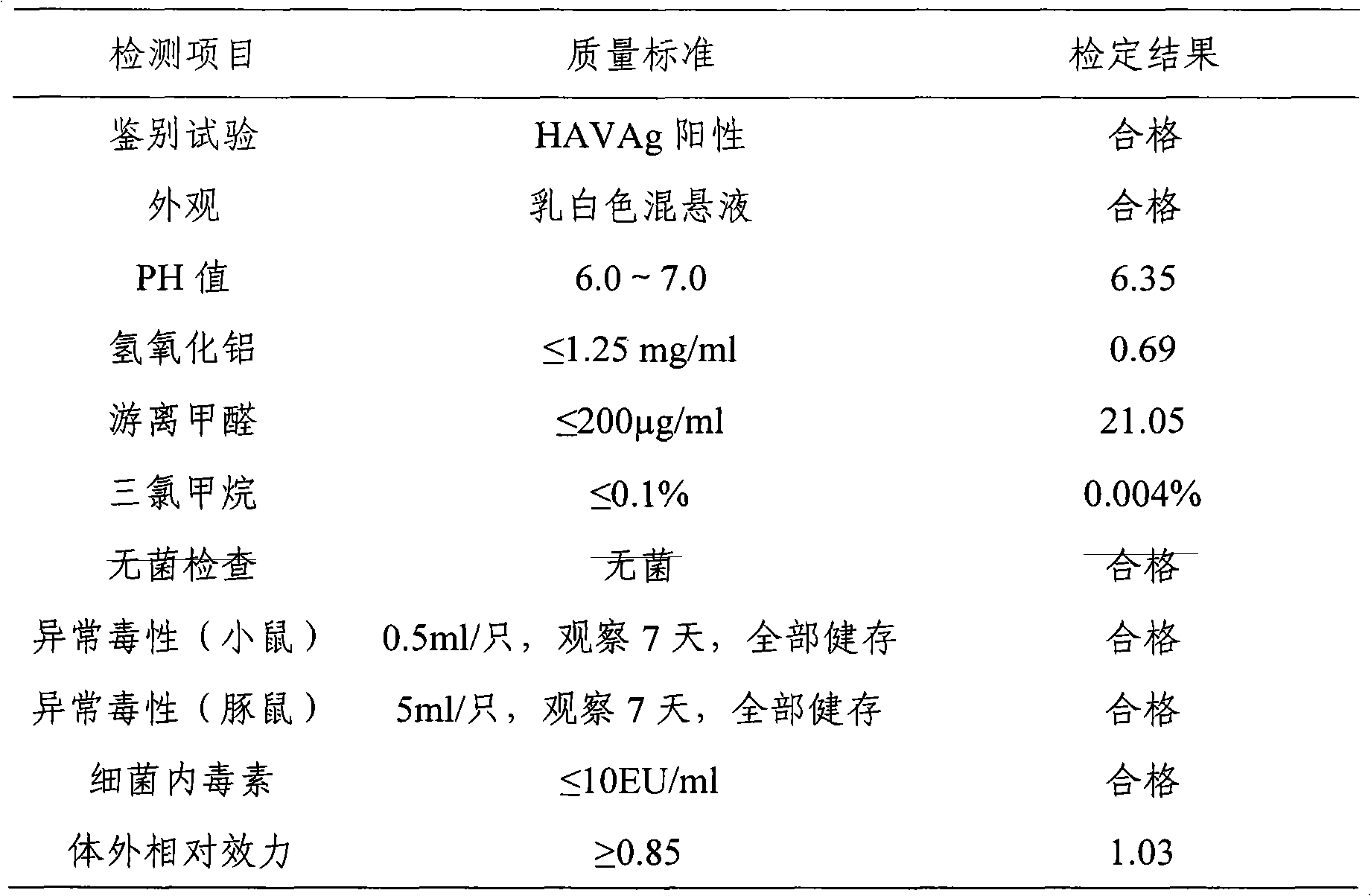

Method of preparing hepatitis A inactivated vaccine

ActiveCN102058882AIncrease production capacityHigh purityAntiviralsViruses/bacteriophagesAdjuvantCell factory

The invention provides a method of preparing a hepatitis A inactivated vaccine, which comprises the following steps of inoculating mixed and absorbed hepatitis A virus strain SH and a human embryo diploid cell MRC-5 to hepatitis A virus propagated in a cell factory, digesting the cell in the virus propagation peak to obtain cell virus liquid, removing impurity proteins of the cell by ultrasonication, chloroform extraction and ultrafiltration through ultrafiltration membranes, degerming and filtering by gel filtration chromatography and purification, and absorbing by an aluminium hydroxide adjuvant so that the hepatitis A inactivated vaccine is prepared. The result of in vivo effectiveness experiments performed on a mouse shows that the hepatitis A inactivated vaccine prepared by the method of the invention has higher ED50 and better immunogenicity than the contract strain. The method of the invention can improve the safety of the vaccine, simplify the technique, shorten the productionperiod, reduce the production cost, and realize the scale production of the hepatitis A inactivated vaccine.

Owner:SHENZHEN KANGTAI BIOLOGICAL PROD

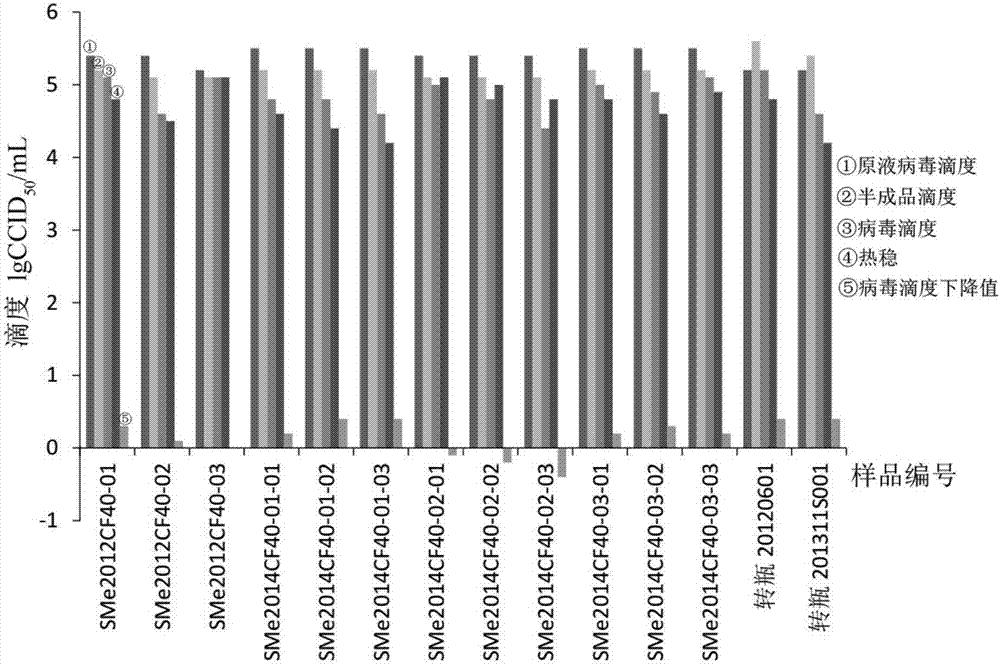

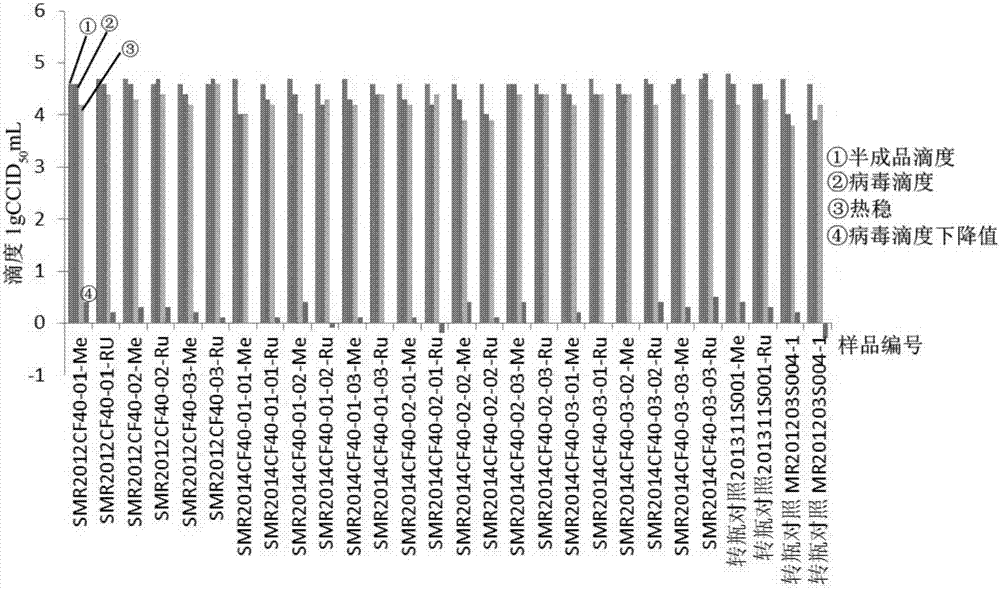

Cell-factory-based measles virus stock solution and measles-series attenuated live vaccine preparation

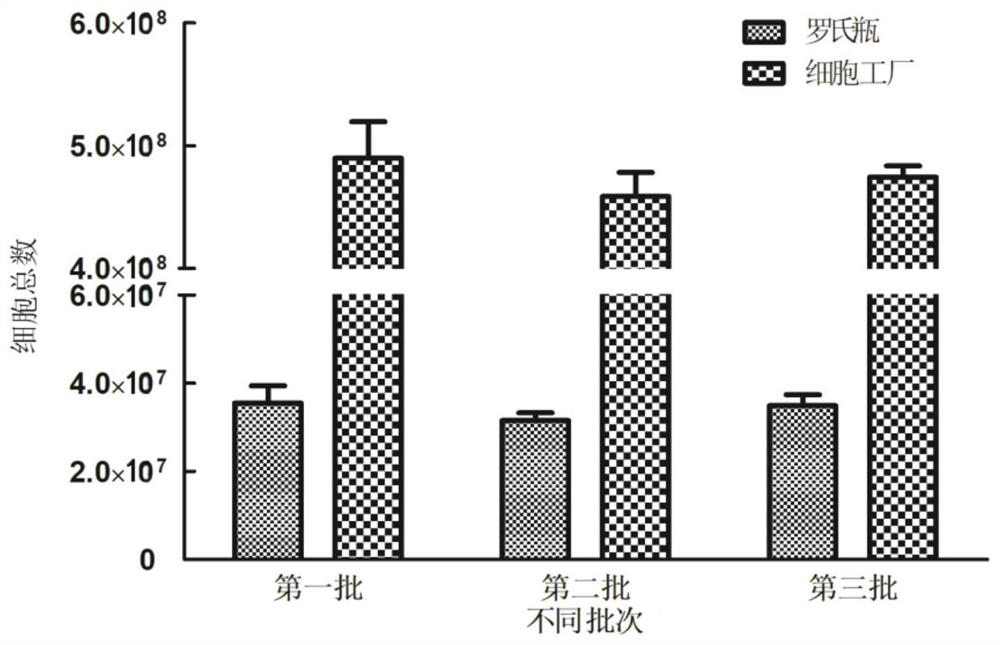

InactiveCN107418936AAchieve trainingSmall batch-to-batch varianceSsRNA viruses negative-senseSsRNA viruses positive-senseCell factoryCulture fluid

The invention provides a cell-factory-based measles virus stock solution and a measles-series attenuated live vaccine preparation. A preparation method of the measles virus stock solution includes selecting SPF chick-embryo cells, and adding cell culture fluid to prepare cell suspension liquid, and adding the cell suspension liquid into a cell factory; inoculating the cell factory with working seeds of measles viruses and the cell suspension liquid according to the ratio of the working seeds to the cell suspension liquid being (0.005-0.05):1, and standing and cultivating the cell factory at the temperature of 33+ / -1 DEG C for 3-4 days, pouring out archeocyte culture fluid, and replacing with fresh cell growth liquid for continuous cultivation; during cytopathy, collecting single measles virus liquid step by step. In an equal production scale, the batch number of cell dissociation is reduced, and the high-titer measles virus liquid is obtained, so that quality uniformity of measles-series vaccine products is improved effectively, and product yield is increased.

Owner:BEIJING BIOLOGICAL PROD INST CO LTD

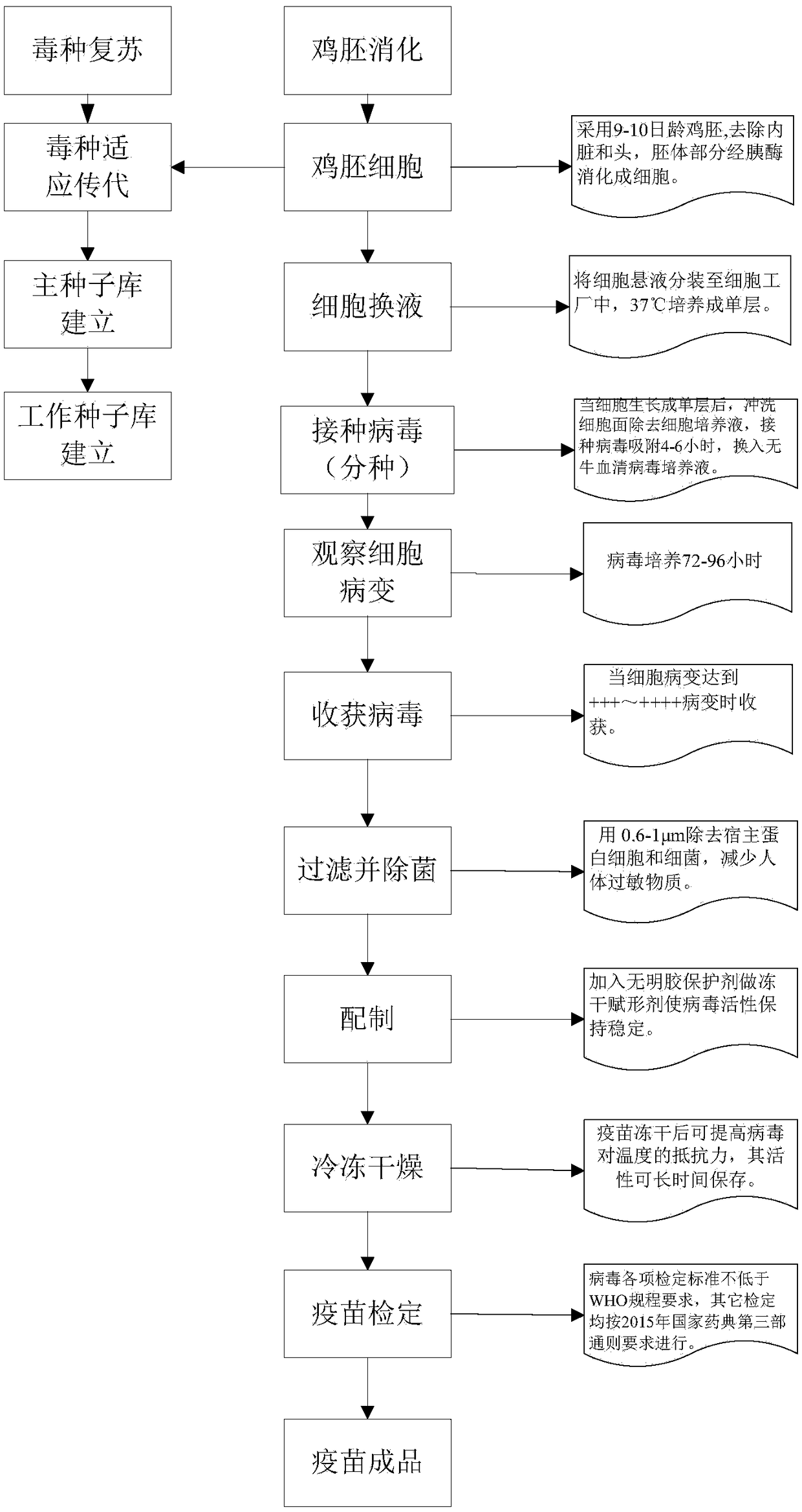

Method for preparing lyophilized hepatitis A attenuated live vaccine using cell factory

The invention discloses a method for preparing a freeze-dried live attenuated hepatitis A vaccine by utilizing a cell factory. The method has good process controllability, is uneasy to pollute enviroment, is suitable for industrialized and mass production, improves the utilization rate of a culture space by more than 3 times, ensures that the growth density of cells reaches between 4.0x10<6> and 5.0x10<6> cells per ml, assures the multiplication space of viruses, and also effectively solves the problem of cell residue after the cell factory digests through methods such as sterile washing, centrifugal treatment and so on, so as to continuously use the cell factory for cell culture and improve the reuse rate of the cell factory.

Owner:长春生物制品研究所有限责任公司

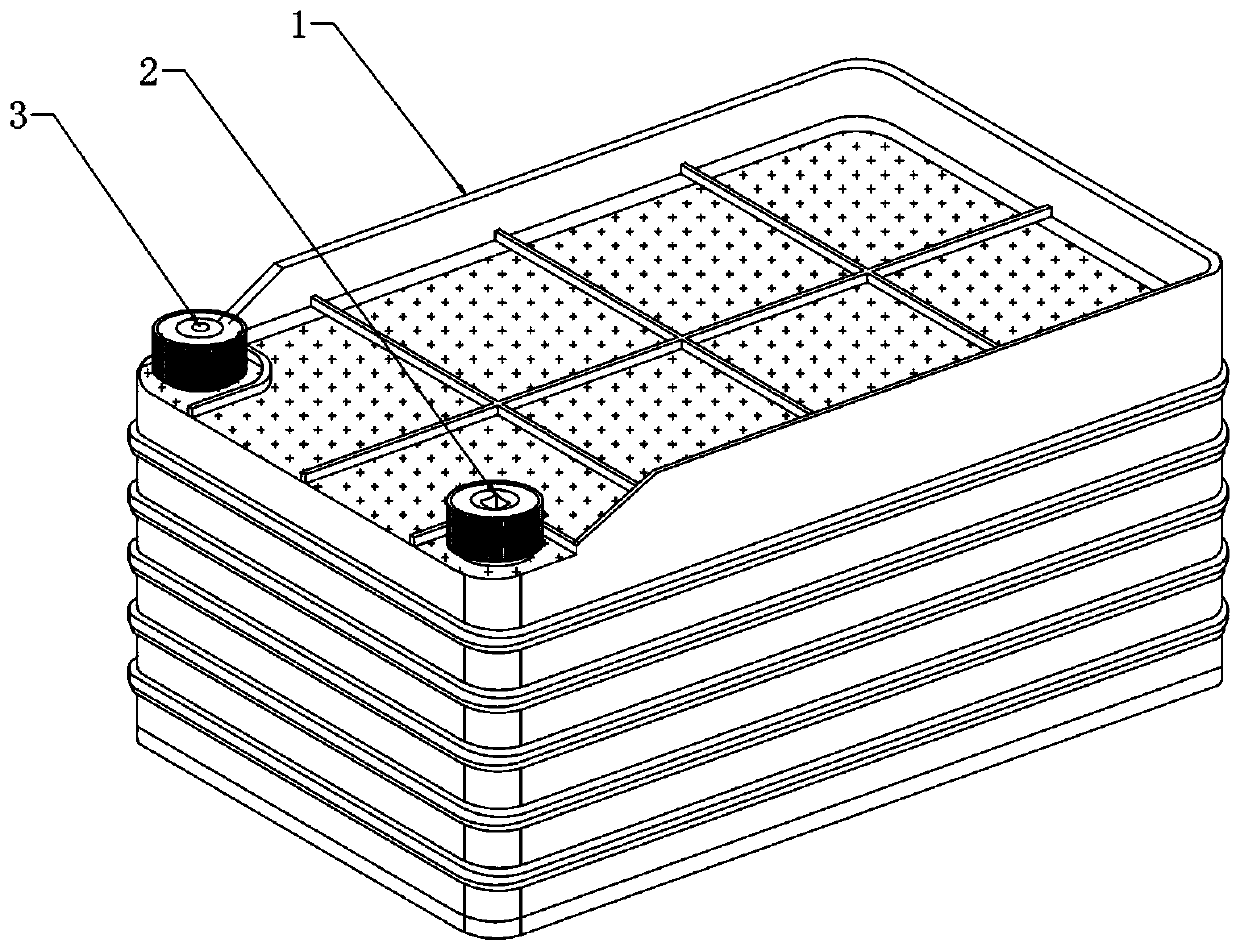

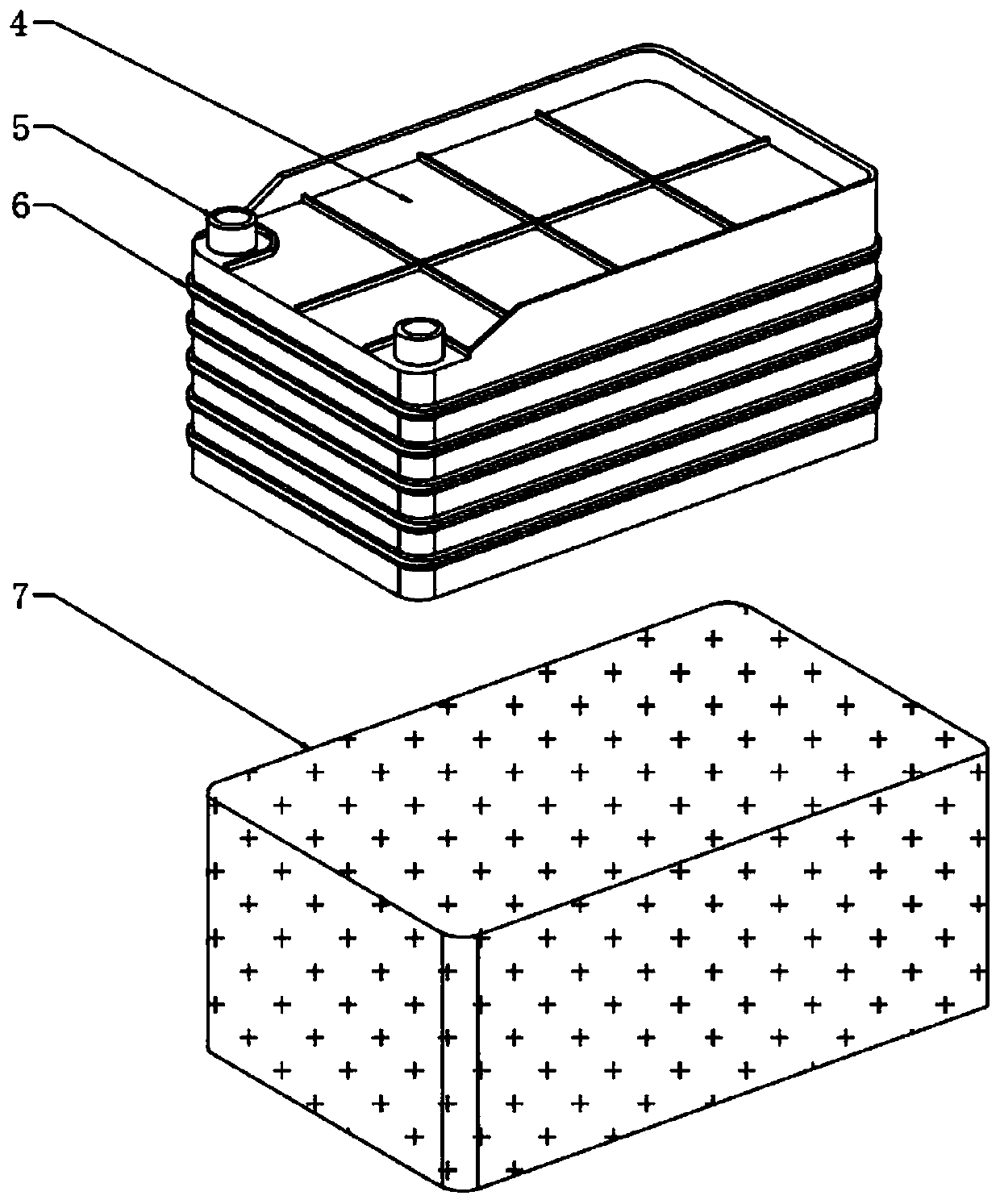

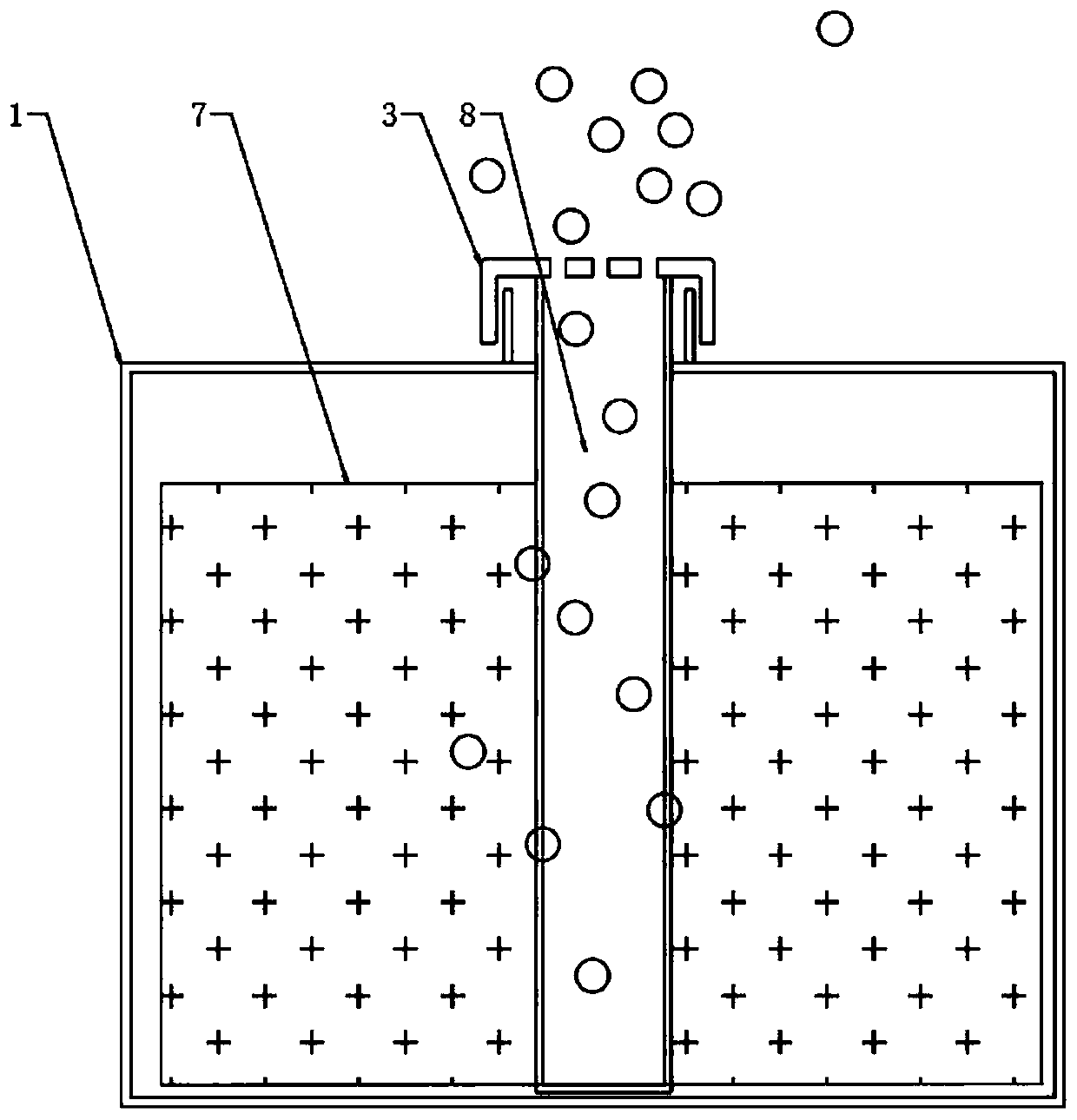

Novel multi-layer adherent cell culture container structure

InactiveCN110283725AProcess controlEasy to controlTissue/virus culture apparatusCell factoryEngineering

The invention relates to the field of culture containers, in particular to a novel multi-layer adherent cell culture container structure. The novel multi-layer adherent cell culture container structure comprises a multi-layer cell factory main body, a bayonet cover and a breathable cover, wherein the interior of the multi-layer cell factory main body is provided with a plurality of groups of multi-layer culture surfaces in an equally-spaced mode from top to bottom; multi-layer culture surface fixed grooves are formed in the multi-layer cell factory main body at the position close to the multi-layer culture surfaces; extension tube openings are formed in the side, close to a base surface and a back surface, of the upper end of the multi-layer cell factory main body respectively; the bayonet cover is fixedly mounted at the upper end of the extension tube opening in the side, close to the base surface, of the upper end of the multi-layer cell factory main body; the breathable cover is fixedly mounted at the upper end of the extension tube opening in the side, close to the back face, of the upper end of the multi-layer cell factory main body; the interior of the breathable cover is provided with an extension tube; and the exterior of the extension tube is provided with a breathable film. Through the application of the breathable cover, the container can be used for flooded culture, the storey height is reduced, the culture area is greatly increased under the same height, and the utilization rate of space is promoted.

Owner:INNOVEL INTELLIGENT TECH CO LTD

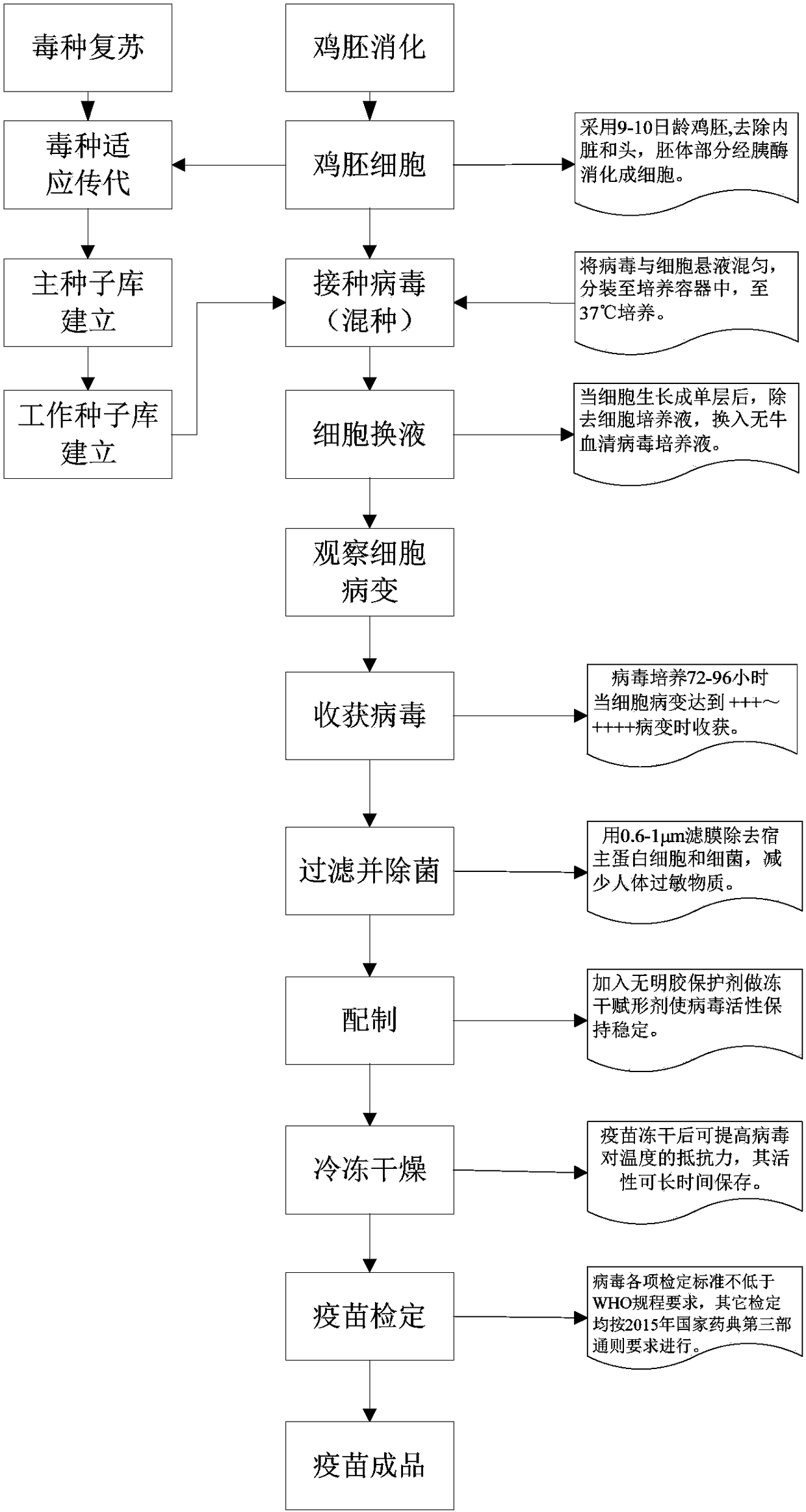

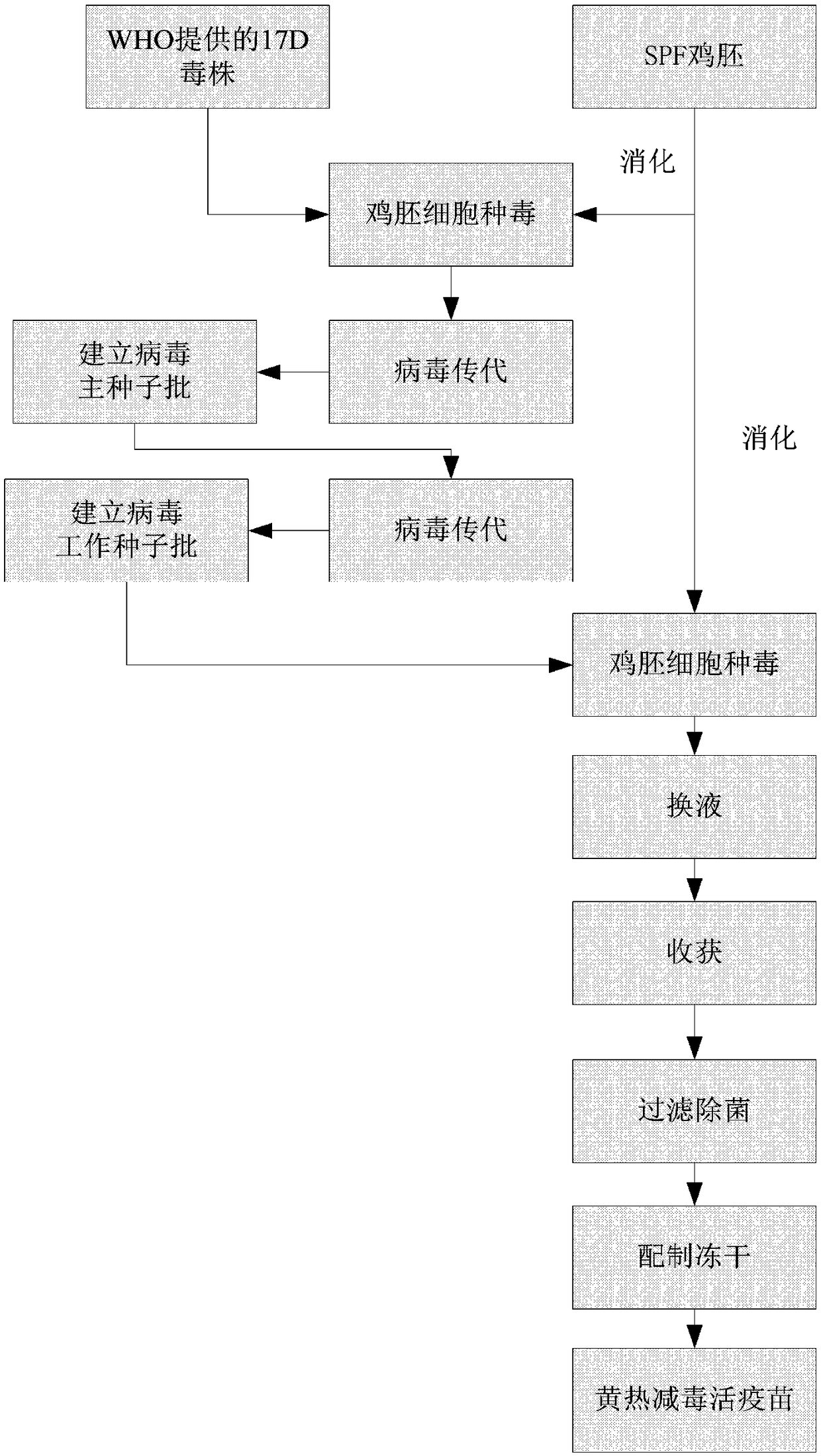

Process for producing yellow fever attenuated live vaccine by using SPF chicken embryo cells

The invention belongs to the field of biological products, and particularly relates to a process for producing a yellow fever attenuated live vaccine by using SPF chicken embryo cells. According to the process, a 17D attenuated vaccine strain provided by WHO is used, and is subjected to passage adaptation by using chicken embryo cells to prepare virulent seeds, chicken embryo cells cultured by cell factory are inoculated as matrix cells for virus culture, culture is performed, the virus solution is collected, sterilization is performed, a gelatin-free protection agent is added, and freeze drying is performed to prepare the finished product vaccine. According to the present invention, the efficacy index of vaccine meets the WHO standard, other quality test standards meet the requirement ofthe Pharmacopoeia of the People's Republic of China Volume 3 (2015 edition), and the product is used for preventing yellow fever infection.

Owner:无锡鑫连鑫生物医药科技有限公司

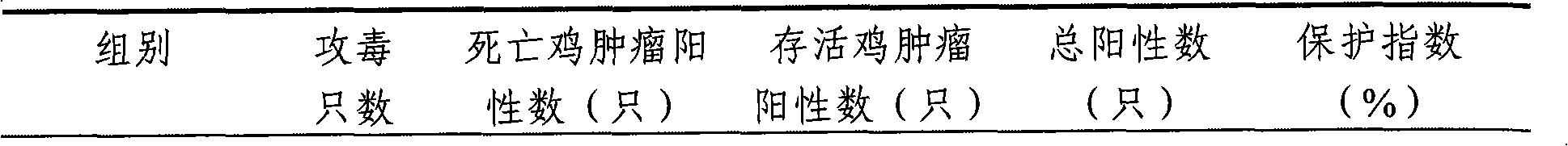

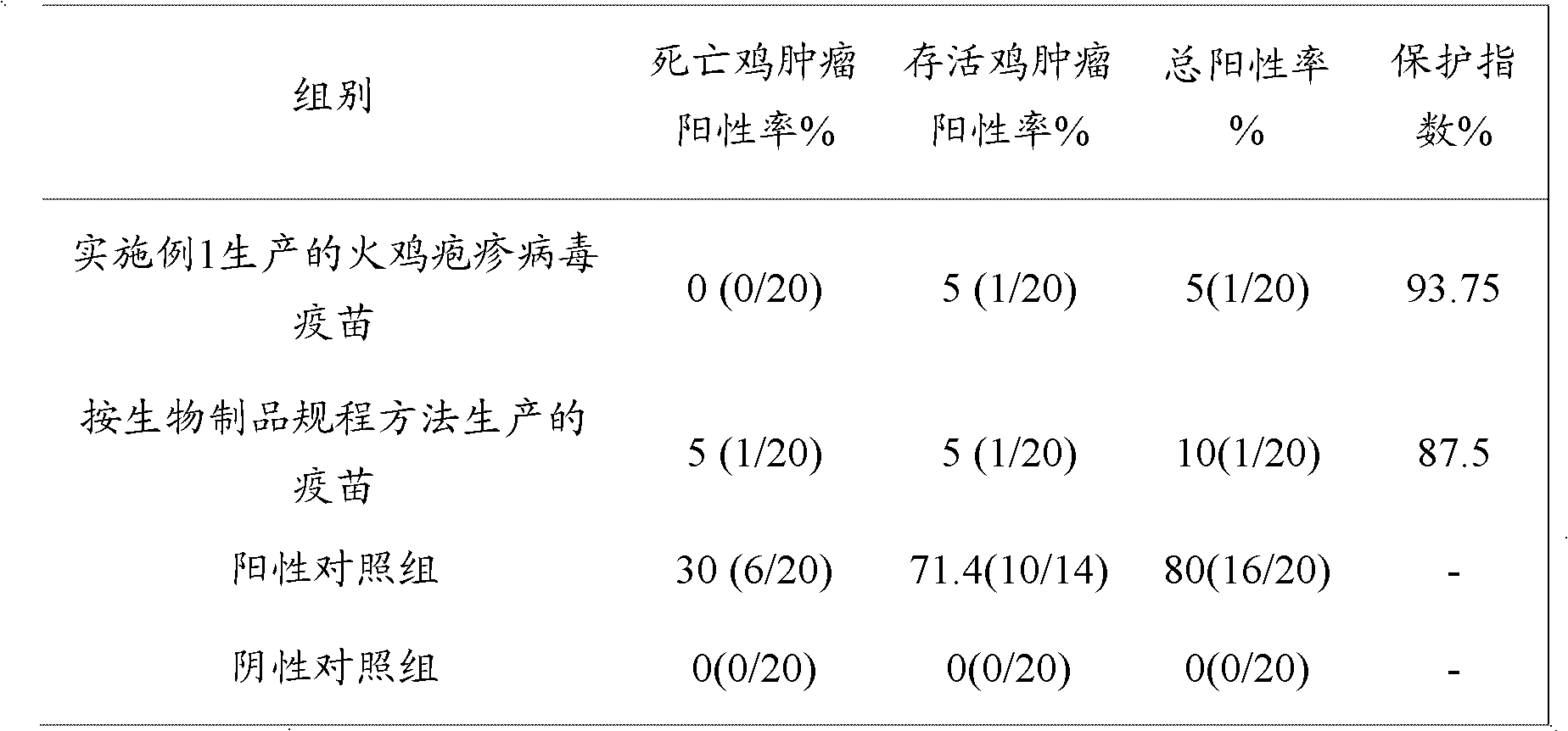

Method for manufacturing Marek's disease vaccine by utilizing cell factory

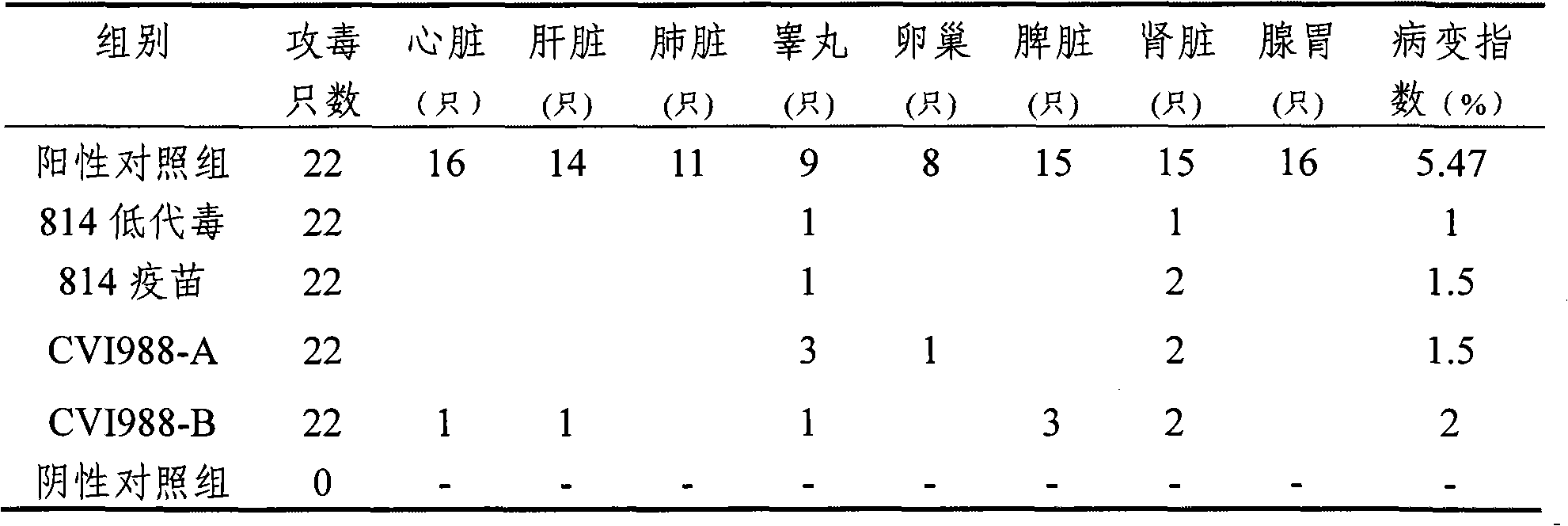

ActiveCN102000328AQuality improvementImprove immune efficiencyAntiviralsViruses/bacteriophagesImmune effectsCell factory

The invention belongs to the technical field of biological medicament making, and discloses a method for preparing a Marek's disease liquid nitrogen vaccine (814-strain) by utilizing a cell factory and the Marek's disease liquid nitrogen vaccine (814-strain) prepared by the method. The Marek's disease liquid nitrogen vaccine (814-strain) produced by utilizing the cell factory has high quality, a high immune efficiency and a stable immune effect; in addition, the Marek's disease liquid nitrogen vaccine also has the advantages of low generation, small plaque, high plaque forming unit (PFU) content, high immunogenicity, low cost, capacity of generating immunoprotection in a relatively short time and the like.

Owner:北京盛华四合生物科技有限公司

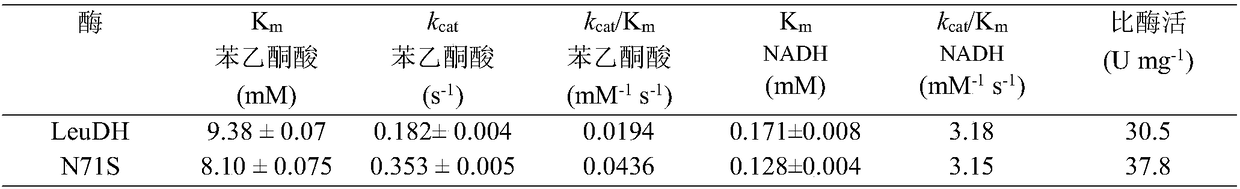

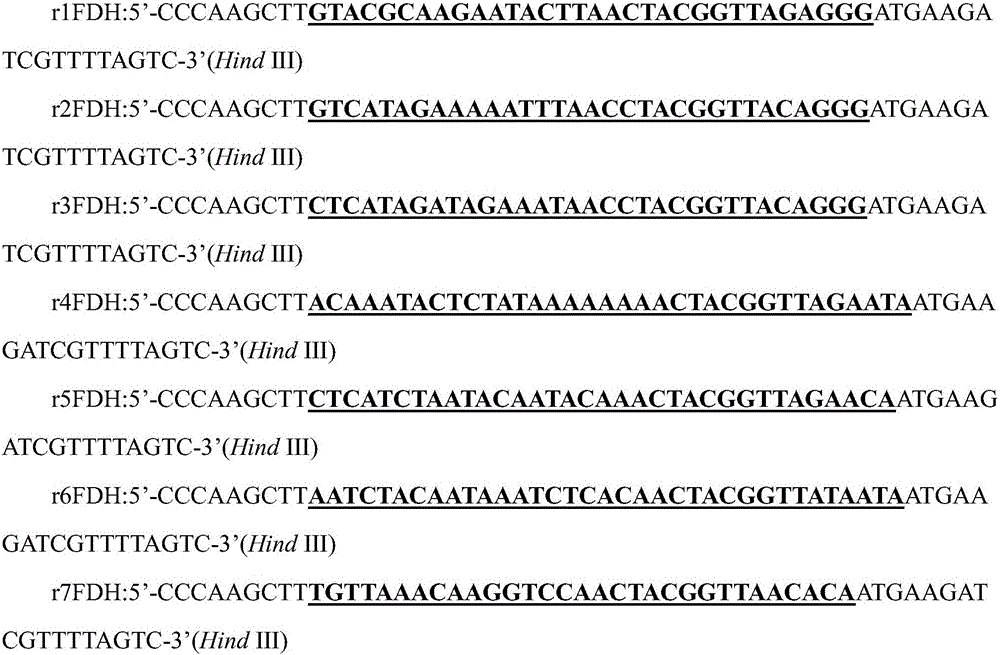

Single cell factory capable of efficiently synthesizing L-phenylglycine as well as construction and application of single cell factory

ActiveCN108103038AOptimize regeneration rateReduce the cost of trainingMicroorganism based processesOxidoreductasesEscherichia coliCell factory

The invention discloses a single cell factory capable of efficiently synthesizing L-phenylglycine as well as construction and application of the single cell factory and belongs to the technical fieldof microorganisms. Firstly, efficient expression of leucine dehydrogenase obtained from Bacillus cereus in escherichia coli is realized, and site-directed mutation is carried out to obtain a mutant N71S with a remarkably improved reduction property; a mutant enzyme and a formate dehydrogenase mutant are co-expressed in the escherichia coli to form an intracellular in-situ co-factor NADH (Nicotinamide Adenine Dinucleotide) circulating system; the expression amount of the formate dehydrogenase mutant is optimized and controlled through a promoter and an RBS (Ribosomal Binding Site) sequence to successfully construct a recombinant escherichia coli single cell factory; the single cell factory is subjected to whole-cell conversion to prepare the L-phenylglycine. The method disclosed by the invention has the advantages of simple and rapid conversion process, low cost, no byproduct and easiness for separation and purification; when conversion is carried out in a 5L fermentation tank for 4h, the yield of the L-phenylglycine can reach 105.7g / l, the conversion rate is 93.3 percent and the space-time yield of the L-phenylglycine is 26.3g / L; an actually practical and effective strategy is provided for industrial production of the L-phenylglycine.

Owner:JIANGNAN UNIV

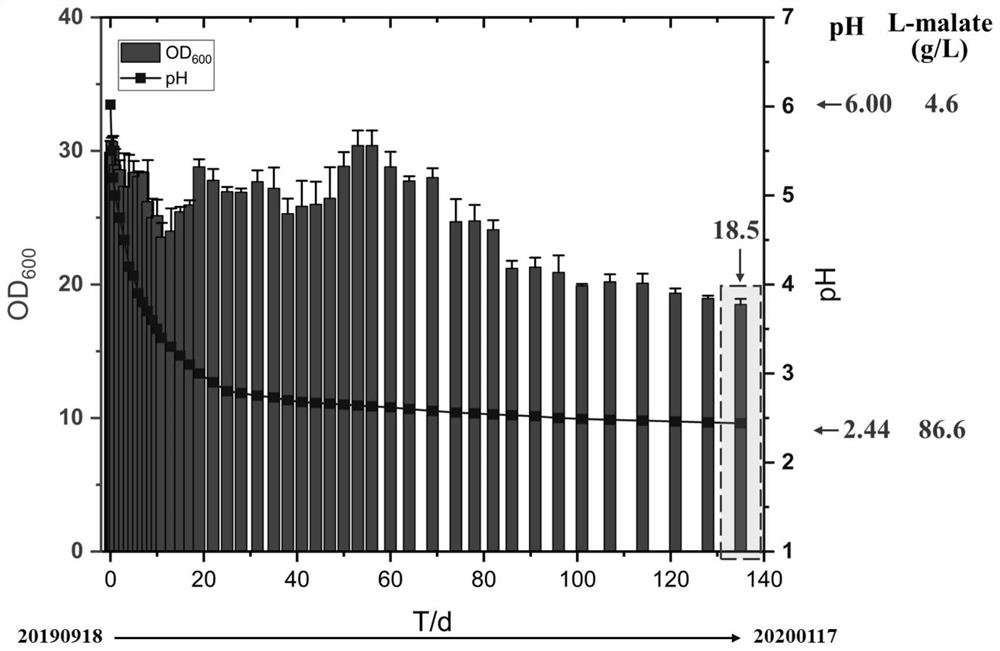

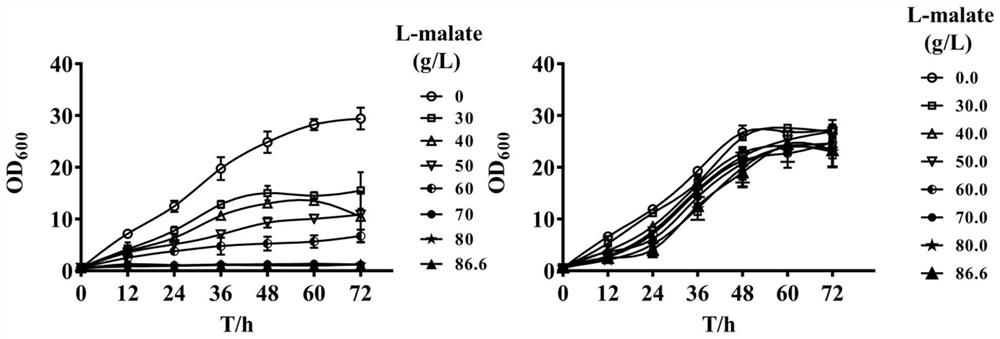

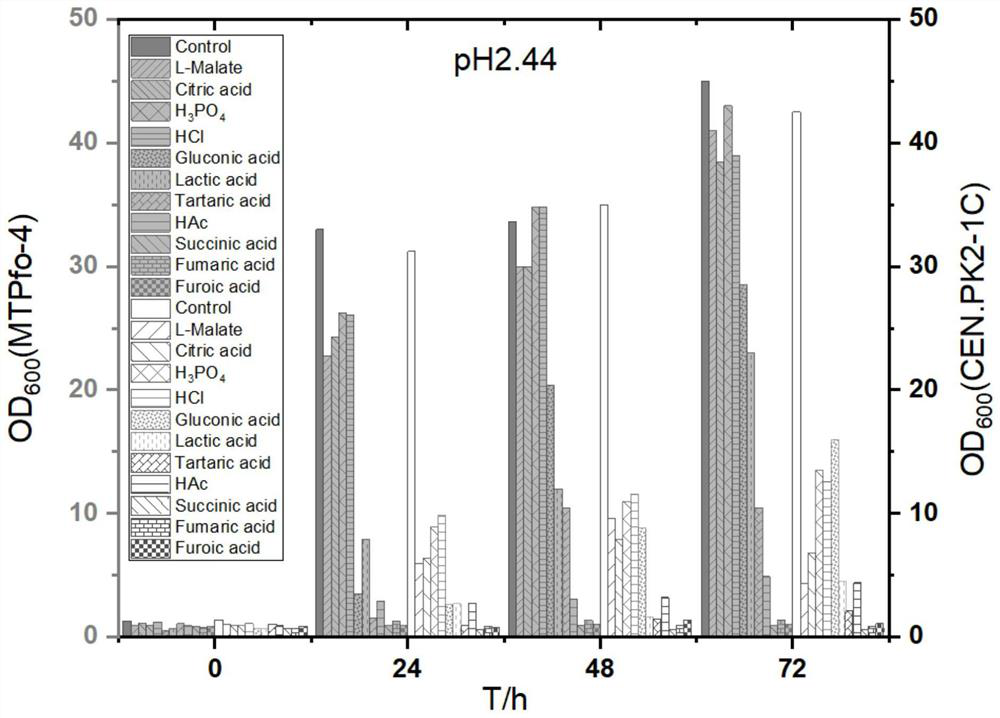

Acid-resistant saccharomyces cerevisiae and application thereof

ActiveCN111676146AStable traitsPromote growthFungiMicroorganism based processesCell factorySuccinic acid

The invention discloses an acid-resistant saccharomyces cerevisiae and application thereof. The saccharomyces cerevisiae MTPfo-4 disclosed by the invention is preserved in China Center for Type Culture Collection on June 10, 2020, and the preservation number is CCTCC M 2020199. According to the invention, exogenous malic acid is used as stress pressure, the S. Cerevisiae acid-resistant mutant strain MTPfo-4 is obtained through directed evolution screening in a laboratory, and the minimum tolerance pH is 2.44 which is also the minimum tolerance pH of currently reported saccharomyces cerevisiae.The mutant strain MTPfo-4 which is tolerant to various organic acids at the same time has the advantage that the tolerance to exogenous malic acid is increased to 86.8 g / L. The obtained mutant strainMTPfo-4 is further identified, is stable in character and good in growth, and can tolerate various organic acids (lactic acid, malic acid, succinic acid, fumaric acid, citric acid, gluconic acid andtartaric acid) at the same time, also has strong tolerance to inorganic acids (HCl and H2PO3), which is difficult to achieve in current S. Cerevisiae research reports. The acid-resistant saccharomycescerevisiae is expected to be used for producing various short-chain organic acids in an acid-resistant chassis cell factory.

Owner:JIANGNAN UNIV

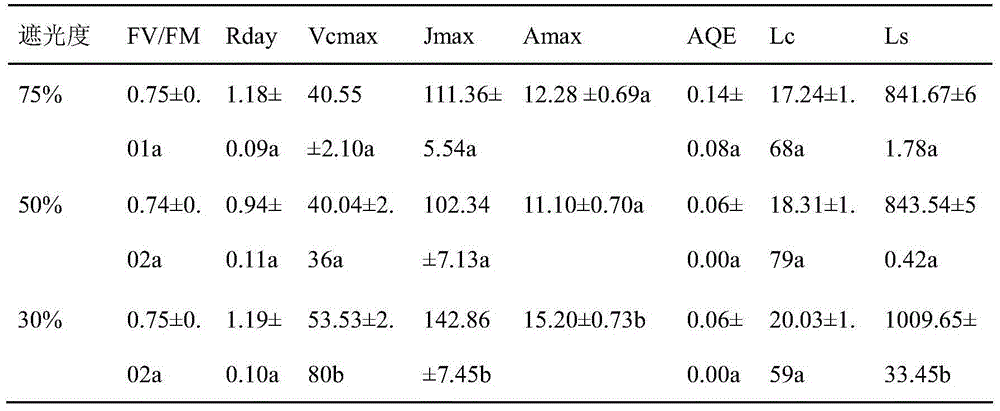

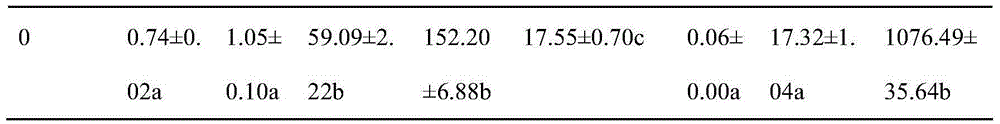

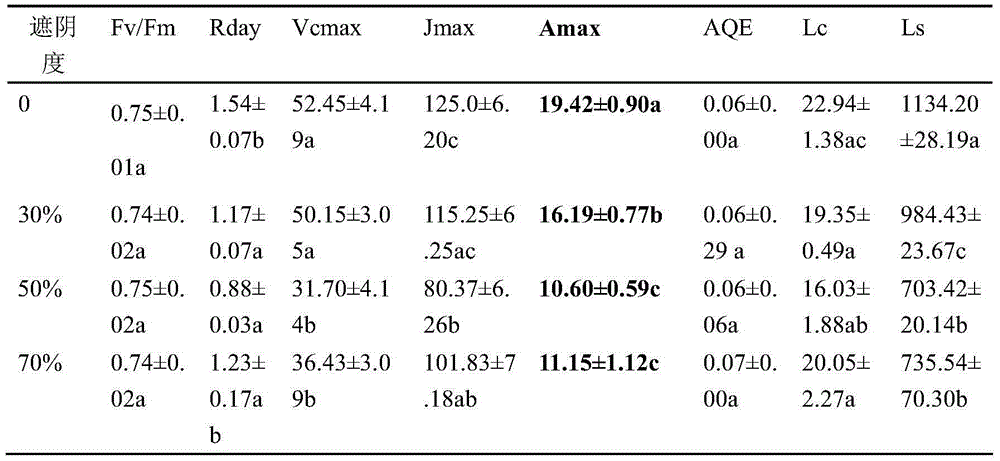

Cultivation method for promoting growth of transgenic tomatoes and accumulation of astaxanthin

Provided is a cultivation method for promoting growth of transgenic tomatoes and accumulation of astaxanthin. The cultivation method comprises the steps of taking the astaxanthin transgenic tomatoes as materials, sowing seeds of the transgenic tomatoes, transplanting seedlings growing for two months after emergency of seedlings, covering the transgenic tomato seedlings with nylon nets respectively to perform shading processing, measuring light intensity through a quantum illumination meter, performing processing respectively according to four light intensity gradients including shading 75 percent of light, shading 50 percent of light, shading 30 percent of light and performing full illumination, performing photosynthesis measurement respectively at a flowering phase and a fruit phase, harvesting the transgenic tomatoes for three times when the transgenic tomatoes are ripe, and measuring contents of the astaxanthin in the transgenic tomatoes. In the planting process, watering is performed in routine to ensure a good moisture state, cooling processing is performed through fans and wet curtains, and deinsectization and disease prevention are performed at regular intervals. According to the cultivation method, the astaxanthin transgenic tomatoes serve as cell factories to produce the astaxanthin efficiently, photosynthetic capacity of the transgenic tomatoes and astaxanthin contents in fruits are optimal under the conditions that the light intensity is 30 percent of sunlight, and the foundation is laid for establishing an artificial efficient astaxanthin-rich transgenic tomato cultivation technique system.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

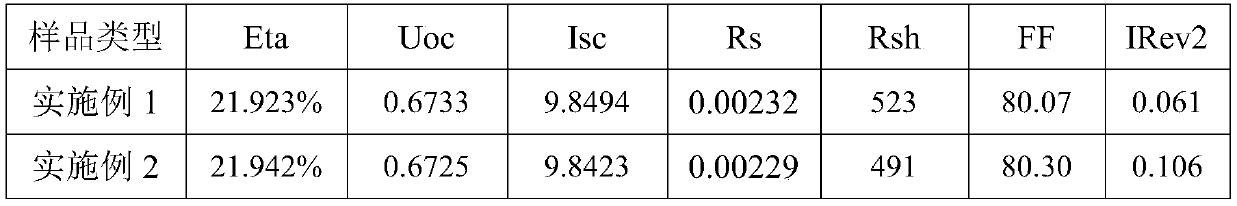

Front silver paste for high-contact and high-adhesion PERC single crystal solar cell and preparation method

InactiveCN110890168AGood printabilitySolve the printing problem of fast printing and high production capacityApparatus for manufacturing conducting/semi-conducting layersNon-conductive material with dispersed conductive materialSilver pasteCell factory

The invention discloses front silver paste for a high-contact and high-adhesion PERC single crystal solar cell and a preparation method. The silver paste is prepared from the following raw materials in percentage by mass: 85-92% of silver powder, 1-5% of glass powder, 5-12% of an organic carrier and 0.1-2% of an inorganic auxiliary agent. The high-contact high-adhesion silver paste for the PERC single crystal solar cell has good series resistance and printability, and solves the problems of quick printing output and high productivity of a cell factory; meanwhile, the slurry is printed on the front surface of the PERC single crystal solar cell and is dried and sintered; the paste has excellent adhesive force and wear resistance, solves the problem of friction scratch after front silver paste is sintered, overcomes the defect caused by mutual friction of battery parts in the transportation process, and provides a good guarantee for the service life of the battery parts at the assembly end.

Owner:上海银浆科技有限公司

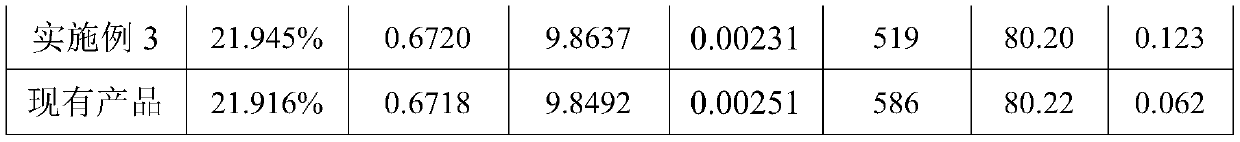

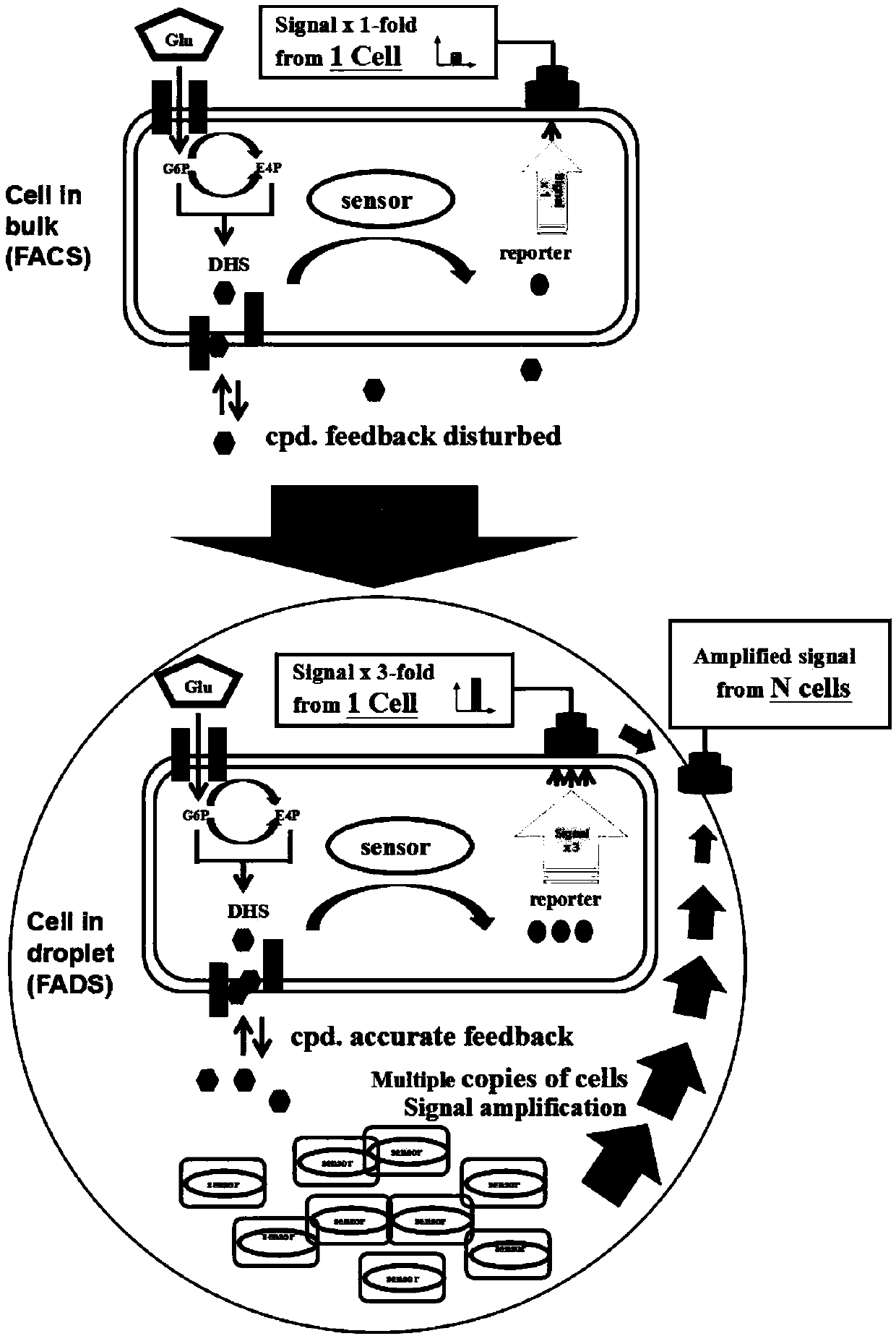

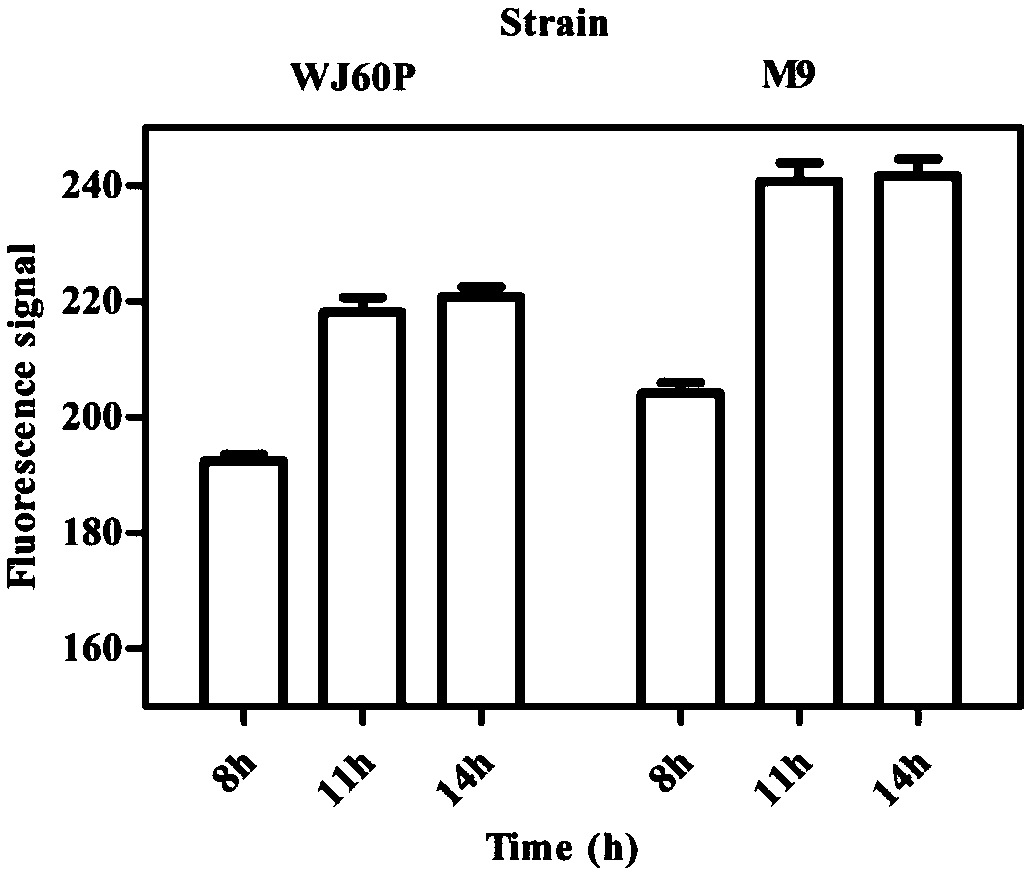

High-flux screening method based on biosensor

ActiveCN109679886AImprove the level ofFluorescence signal difference, increased fluorescence signal difference between dropletsBacteriaMicroorganism based processesFluorescenceHigh flux

The invention discloses a high-flux screening method based on a biosensor, and belongs to the technical field of high-flux screening. A way of embedding biosensor-containing cells by liquid drops is adopted to carry out high-flux screening on a metabolite micromolecule 3-dehydrogenation shikimic acid cell factory to realize the efficient enrichment of 3-dehydrogenation shikimic acid high-yield bacterial strains. Compared with a single cell level screening method for combining the biosensor with a flow cytometer, on the one hand, the high-flux screening method disclosed by the invention utilizes the augmentable enrichment characteristics of cells in the liquid drops to enlarge an inter-unicellular fluorescence signal difference for N times to a difference among cell groups; on the other hand, through the characteristics that the liquid drops are used for isolating single cells and secretory products thereof, the influence of other cells and secretory products is eliminated, reductive cells and extracellular metabolite secreted by the reductive cells are truly communicated and fed back; through the above improvement, the screening sensitivity of the profitable positive clone bacterial strains can be effectively improved, and the enrichment efficiency of the profitable positive clone bacterial strains is improved.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

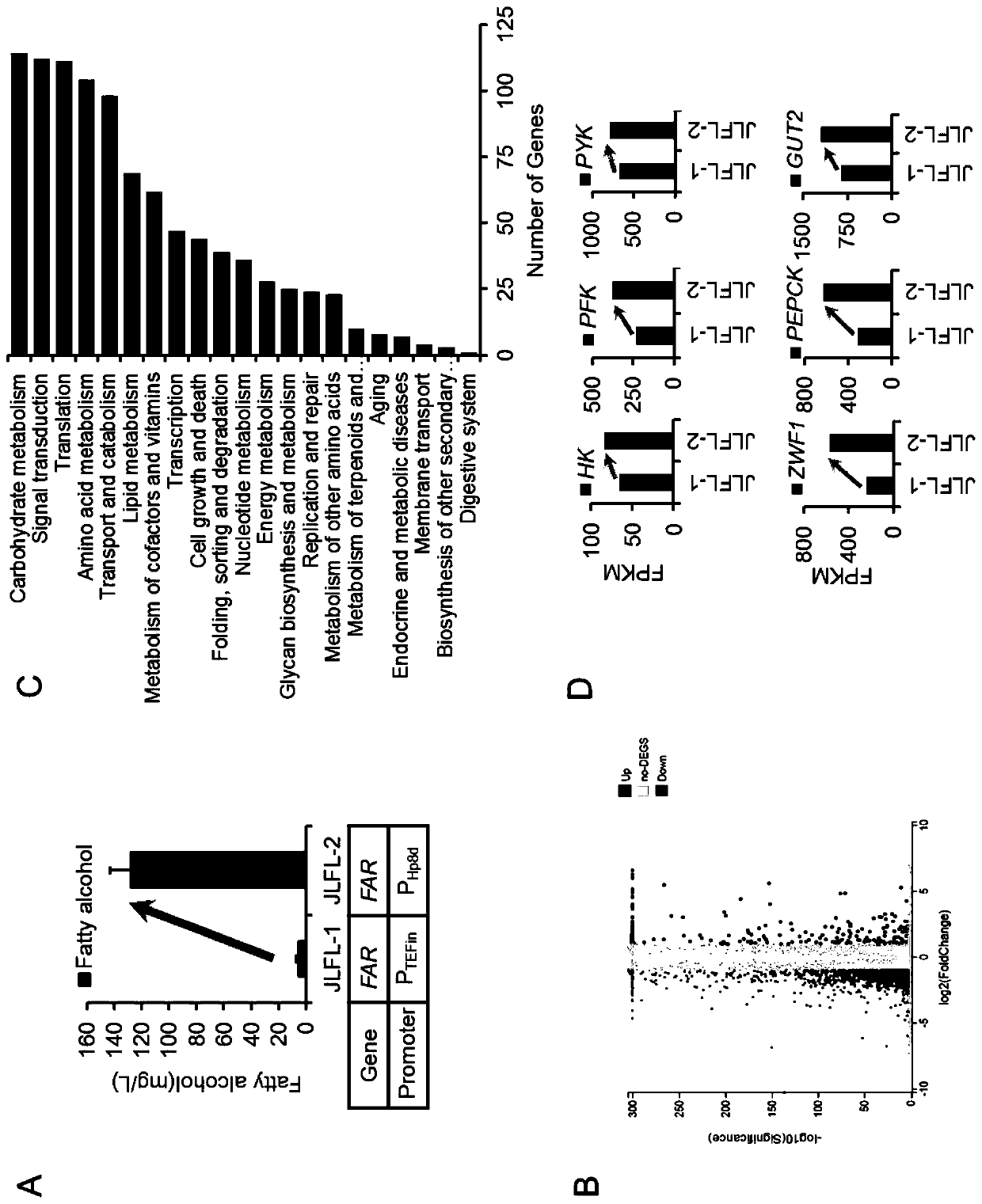

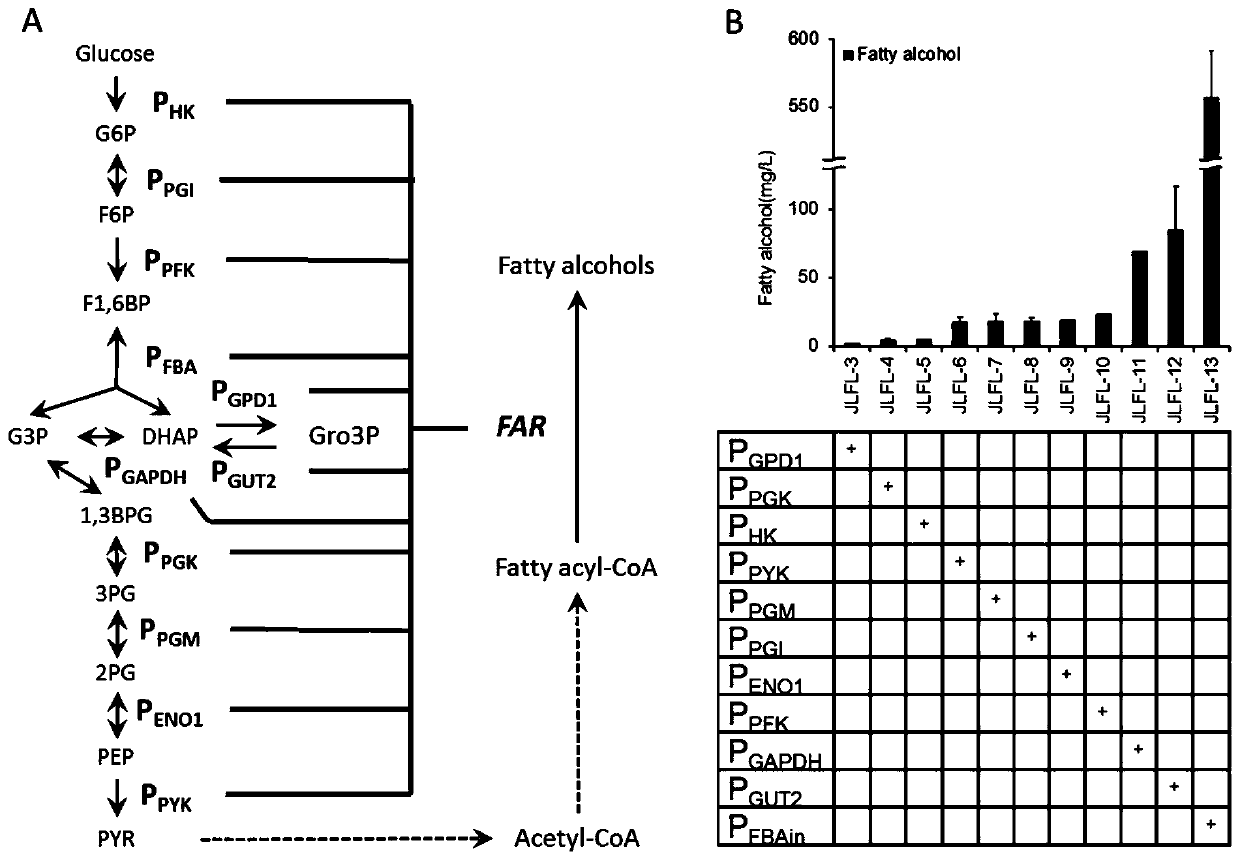

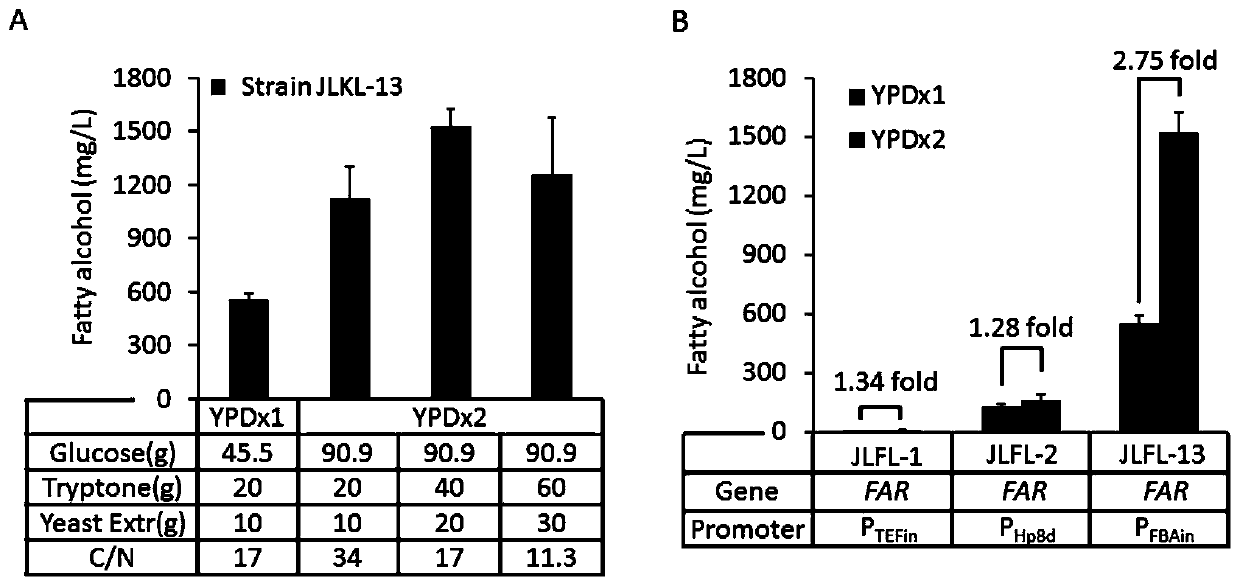

Application of glycometabolism and lipid metabolism for improving synthetic yield of fatty acid derivatives by yarrowia

ActiveCN109929870AHigh synthesis efficiencyRealize a reasonable distributionFungiStable introduction of DNALipid formationCell factory

The invention relates to the technical field of synthetic biology, in particular to an application of glycometabolism and lipid metabolism for improving synthetic yield of fatty acid derivatives by yarrowia. The expression of fatty alcohol and a glycometabolism path can achieve balance and coordination of lipid production and other related pathways to promote rational distribution of cellular metabolism and improve lipid synthesis efficiency. The application finds through experiments that when glycolysis and lipid product production pathways are synergistic, the effective pull-push effect canbe achieved, and the production of the lipid product can up-regulate the expression of the glycolysis, the glycolysis can synergistically further promote the expression of lipid products for gene synthesis, the overall metabolic flux can be greatly improved, and efficient production of the lipid products can be achieved. on the other hand, synergistic expression is also conducive to the realization of dynamic regulation, so that the production of the product can be adjusted in real time according to the different metabolic states of the cells, and further the production efficiency of a cell factory is optimized.

Owner:TIANJIN UNIV

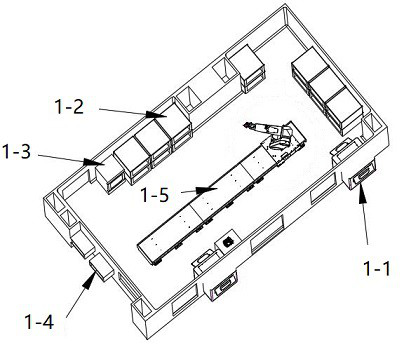

Full-automatic cell production line

ActiveCN113073052ARealize automatic liquid additionRealize automatic liquid changeBioreactor/fermenter combinationsBiological substance pretreatmentsProduction lineRobotic arm

The invention belongs to the technical field of biology, and relates to a full-automatic cell production line. The full-automatic cell production line comprises a culture zone and an operation area,; the culture zone comprises a B-level platform body, and the B-level platform body comprises a culture area, a refrigeration area and a robot provided with a motion track; the motion track of the robot is linearly arranged; the culture area, the refrigeration area and a manual delivery window are all arranged around the track and are all located in an operation area of the robot; a liquid storage table, a cell factory liquid changing device and a centrifugal bottle liquid changing device are integrated in the operation area; a transfer window is adopted between the culture area and the operation area to transfer materials; and the transfer window is provided with a transfer rotating disc and a transfer rotating disc driving mechanism, and the transfer rotating disc is provided with a zero position for the robot in the culture zone to pick and place the materials and a working position for a robotic arm in the operation area to pick and place the materials. The full-automatic cell production line is mainly used for full-automatic cell batch production.

Owner:HELP STEM CELL INNOVATIONS CO LTD

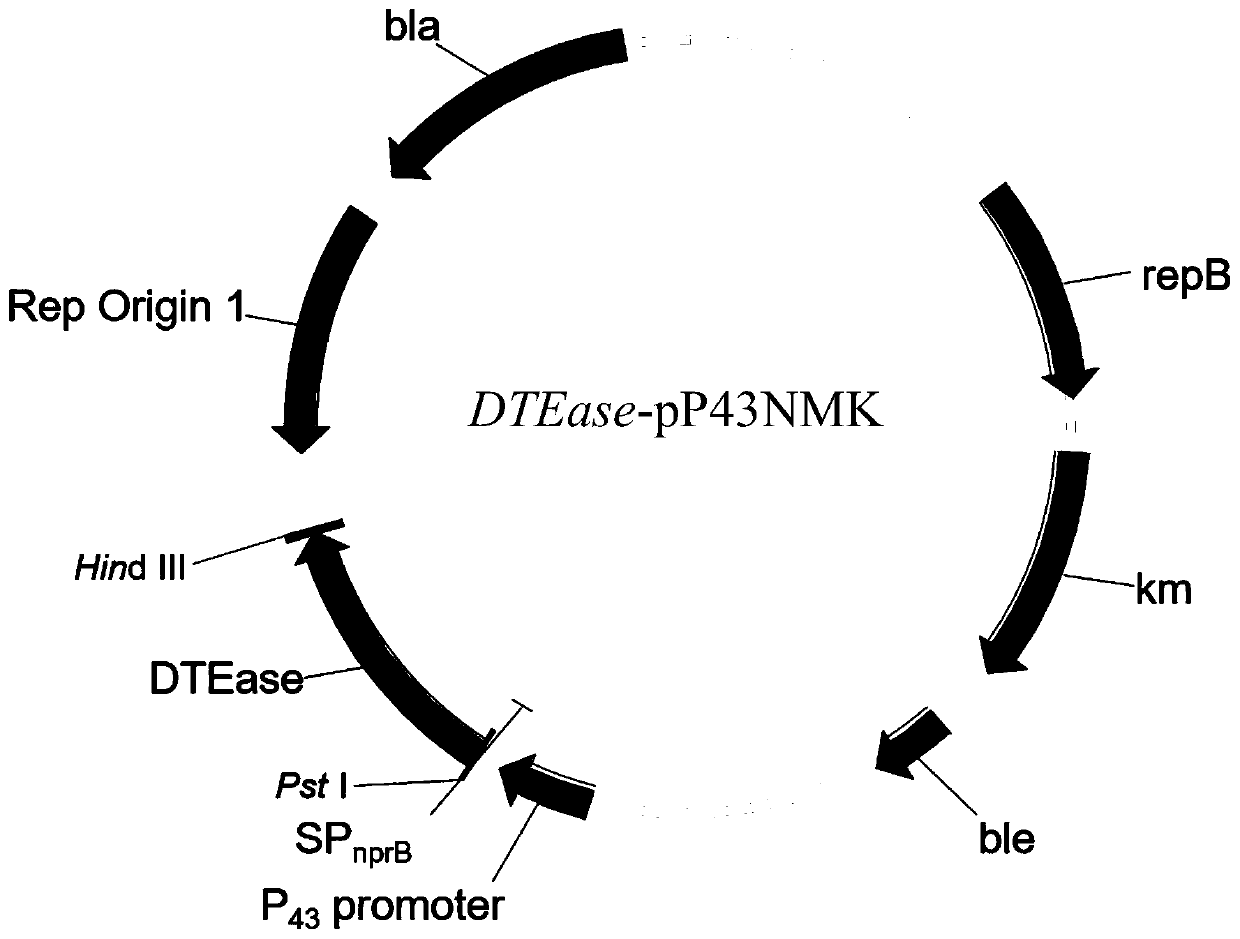

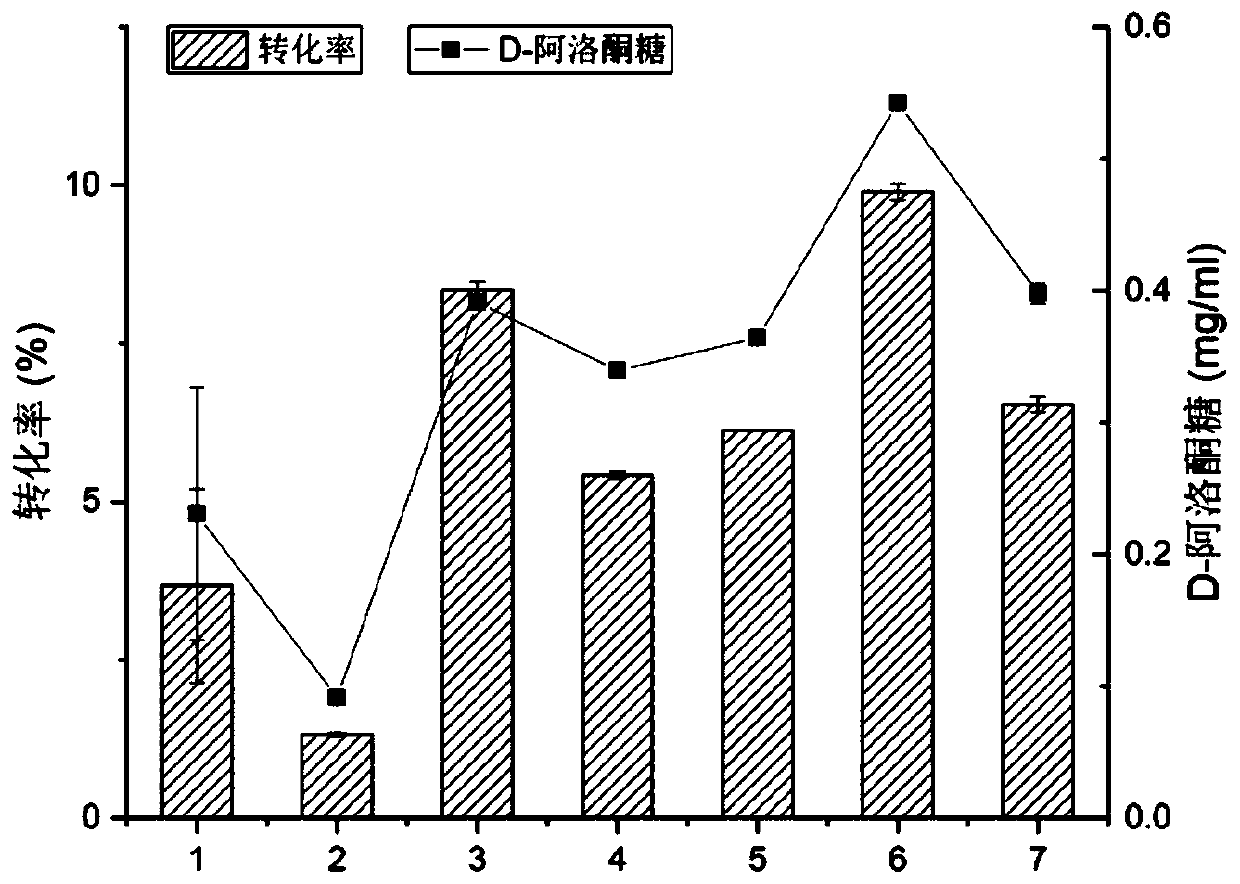

Genetic engineering bacterium highly producing D-allulose and application of genetic engineering bacterium

ActiveCN111206009AReduce manufacturing costBacteriaMicroorganism based processesBiotechnologyTagatose

The invention discloses a genetic engineering bacterium highly producing D-allulose and application of the genetic engineering bacterium. A food-grade strain bacillus subtilis is used as a host bacterium, D-tagatose 3-epimerase (DTEase) is efficiently expressed through gene recombination, and a cell factory for producing D-allulose by directly using D-fructose is formed. The genetic engineering bacterium highly producing the D-allulose is obtained by screening, through optimization of a fermentation process, the yield of the D-allulose reaches 4.56 g / L, and the conversion rate of a substrate is 56.26%, and the production efficiency of the D-allulose is 0.19 g / L*h.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

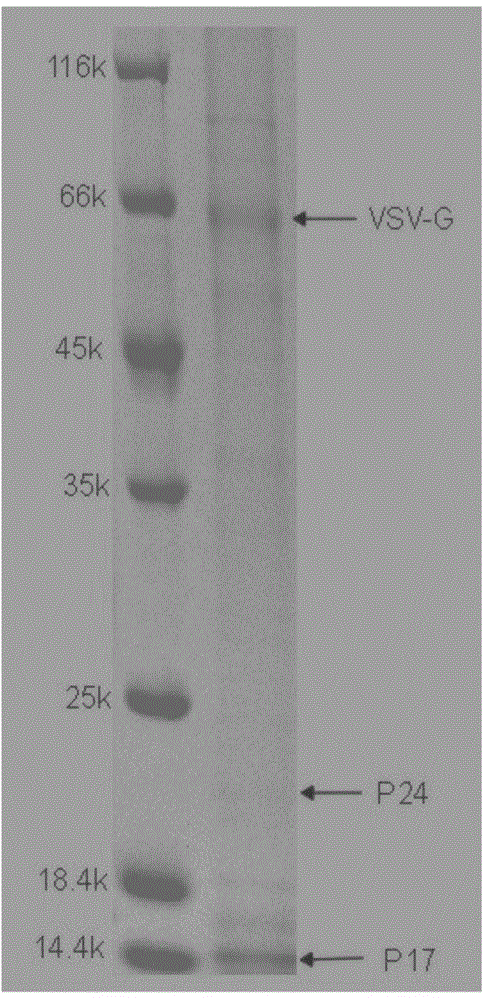

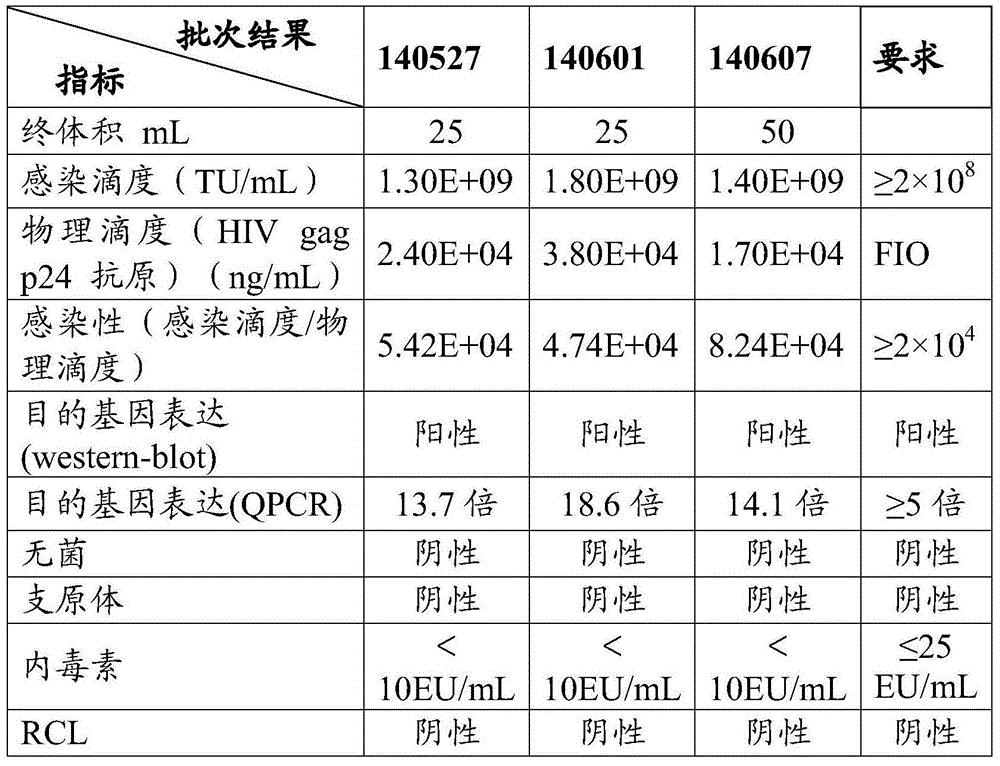

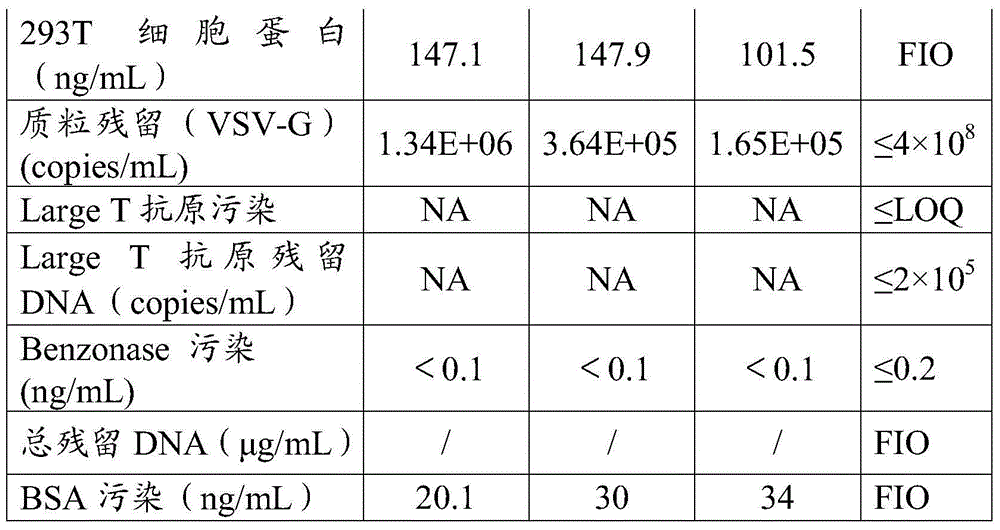

Method for purifying slow virus

InactiveCN104371982AMeet production needsResidue reductionMicroorganism based processesRecovery/purificationPurification methodsFiltration

The invention relates to a method for purifying a slow virus. The method comprises the following steps: (S10) providing a cell culture containing the slow virus; (S20) carrying out centrifugal concentration on the cell culture, and filtering to obtain virus suspension; (S30) purifying the virus suspension by virtue of anion exchange chromatography; and (S40) purifying the virus suspension by virtue of gel filtration chromatography. A process for purifying the slow virus is easy to amplify, can be used for processing large amounts of virus liquid produced by cell factories or bioreactors on a large scale, can meet production requirements of slow virus liquid, is stable and is good in repeatability; furthermore, the purified slow virus liquid prepared by virtue of the method is not polluted by exogenous factors, is low in residues of cell host protein and host DNA, good in safety, and high in purity and titer and can completely meet requirements of clinic gene therapy.

Owner:武汉维诺赛生物技术有限公司

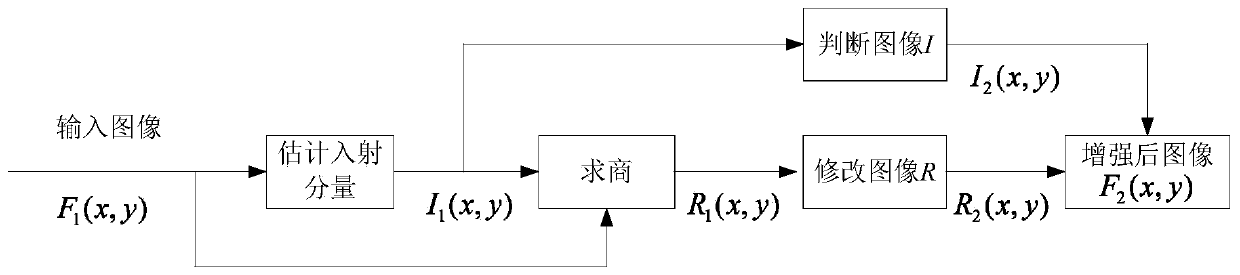

Bioreactor cell culture quality evaluation method

PendingCN110910367ARealize automatic evaluationImage enhancementImage analysisBiotechnologyCell factory

The invention discloses a bioreactor cell culture quality evaluation method, and relates to the technical field of bioreactors. The bioreactor cell culture quality evaluation method comprises image enhancement, image segmentation, smoothing processing, connected region extraction, standard cell area judgment and cell distribution statistics, and completes automatic evaluation of the cell culture quality through statistics of the number of cells. According to the bioreactor cell culture quality evaluation method, the growth state of the cultured cells can be automatically evaluated, and a reliable guarantee means is provided for promoting the application of a large-scale cell culture technology in a cell factory.

Owner:CHANGCHUN UNIV OF SCI & TECH

III type turkey herpes virus freeze-drying vaccine

The invention belongs to the technical field of biopharming, and discloses a method for preparing a chicken Marek's disease turkey herpes virus Fc126 strain live vaccine by utilizing a cell factory and the turkey herpes virus vaccine (Fc126 strain) prepared by utilizing the method. The turkey herpes virus vaccine (Fc126 strain) prepared in the cell factory is good in quality, high in immunization potency and stable in immunization effect. In addition, the turkey herpes virus vaccine (Fc126 strain) has the advantages of being low in generation, high in content of plaque forming unit (PFU), low in cost, simple in operation technology, easy to control and the like.

Owner:PU LIKE BIO ENG

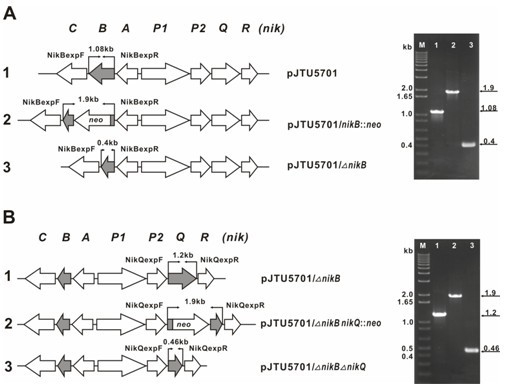

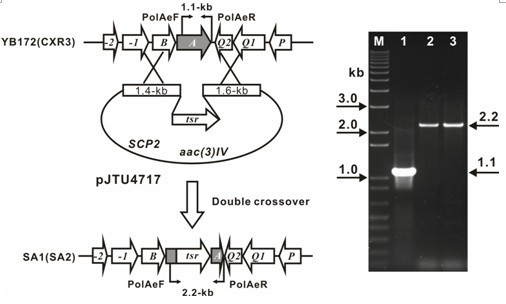

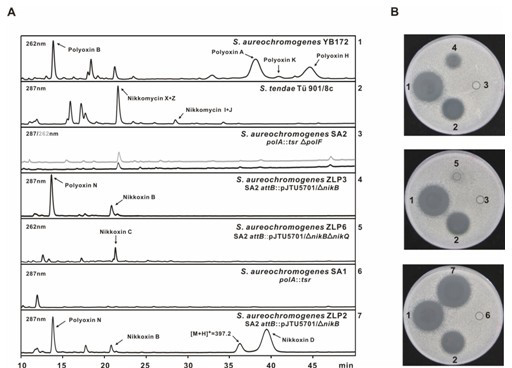

Polyoxin-nikkomycin hybrid antibiotic and preparation method thereof

InactiveCN102603867AIncrease productionEnhanced inhibitory effectAntimycoticsBacteriaHeterologousBiosynthetic genes

The invention discloses a polyoxin-nikkomycin hybrid antibiotic and a preparation method thereof. Heterologous expression is performed by mutating a biosynthesis gene cluster and introducing a polyoxin industrial strain. Through mass spectrum and nuclear magnetic resonance detection, four polyoxin-nikkomycin hybrid antibiotics are generated. Three of the polyoxin-nikkomycin hybrid antibiotics have more remarkable antibacterial activity on human or plant disease fungi. The hybrid antibiotics are produced by taking the polyoxin industrial strain as a 'cell factory', the antibiotic yield is high, and industrial value is achieved.

Owner:WUHAN UNIV

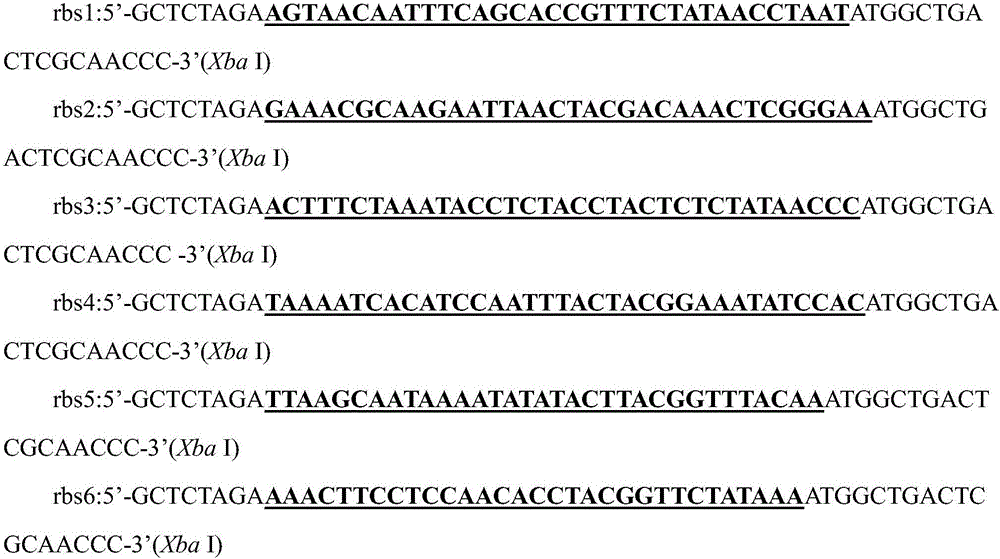

Single-cell plant for efficiently synthesizing alpha-aminobutyric acid, as well as construction and application thereof

ActiveCN106399216AOptimize regeneration rateReduce the cost of trainingCarbon-nitrogen lyasesBacteriaBiotechnologyEscherichia coli

The invention discloses a single-cell plant for efficiently synthesizing alpha-aminobutyric acid, as well as construction and application thereof, and belongs to the technical field of microorganisms. An escherichia coli single-cell plant which is constructed and recombined by tandem expression of L-threonine deaminase, L-amino acid dehydrogenase and a dehydrogenase gene for providing cofactor NADH circulation is used for efficiently synthesizing the alpha-aminobutyric acid, and the expression quantity of the L-threonine deaminase is optimized and controlled by rbs sequence, so that the problem of conversion inhibition caused by quick accumulation of an intermediate product ketobutyric acid is solved; meanwhile, the expression quantity of the dehydrogenase for providing cofactor NADH circulation is optimized and controlled by a promoter and the rbs sequence, so that the regeneration rate of the NADH is increased and the yield is finally increased. The single-cell plant is used for performing full-cell conversion, so that substances in and out obstacles can be reduced, the conversion rate is increased, cofactor intracellular circulation is promoted, an external source does not need to be added, and the cost is low. Within 20 hours, the yield of the recombinant escherichia coli single-cell plant in a 5-liter fermentation tank is 204 g / L, the space time yield is 10.2 g / L*h, and an actual and effect strategy is provided for industrial production.

Owner:JIANGNAN UNIV

Large-scale preparation method of F genotype mumps attenuated live vaccine

PendingCN111840534AImprove effectivenessEnsure safetySsRNA viruses negative-senseViral antigen ingredientsCell factoryGenotype

The invention discloses a large-scale preparation method of an F genotype mumps attenuated live vaccine. The preparation method comprises the following steps: passage and counting of KMB-17 cells, preparation of a virus harvesting liquid, preparation of a vaccine stock solution, preparation of a vaccine semi-finished product and preparation of a finished product. The F genotype mumps virus attenuated live vaccine is prepared on a large scale by taking human diploid cells as a matrix in a cell factory for the first time, so that the production cost can be reduced and the production time can besaved while the safety and the quality stability of the vaccine are ensured. Compared with traditional Roche flask culture, the method has the advantages that the amount of required virus seeds is small, 60000 vaccine finished products can be obtained only by 60-84 mL of virus seeds in each batch, the yield is high, the cost is low, the quality is stable, and the like, and the method has good application prospects in preventing and controlling infection and transmission of epidemic parotitis in China.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

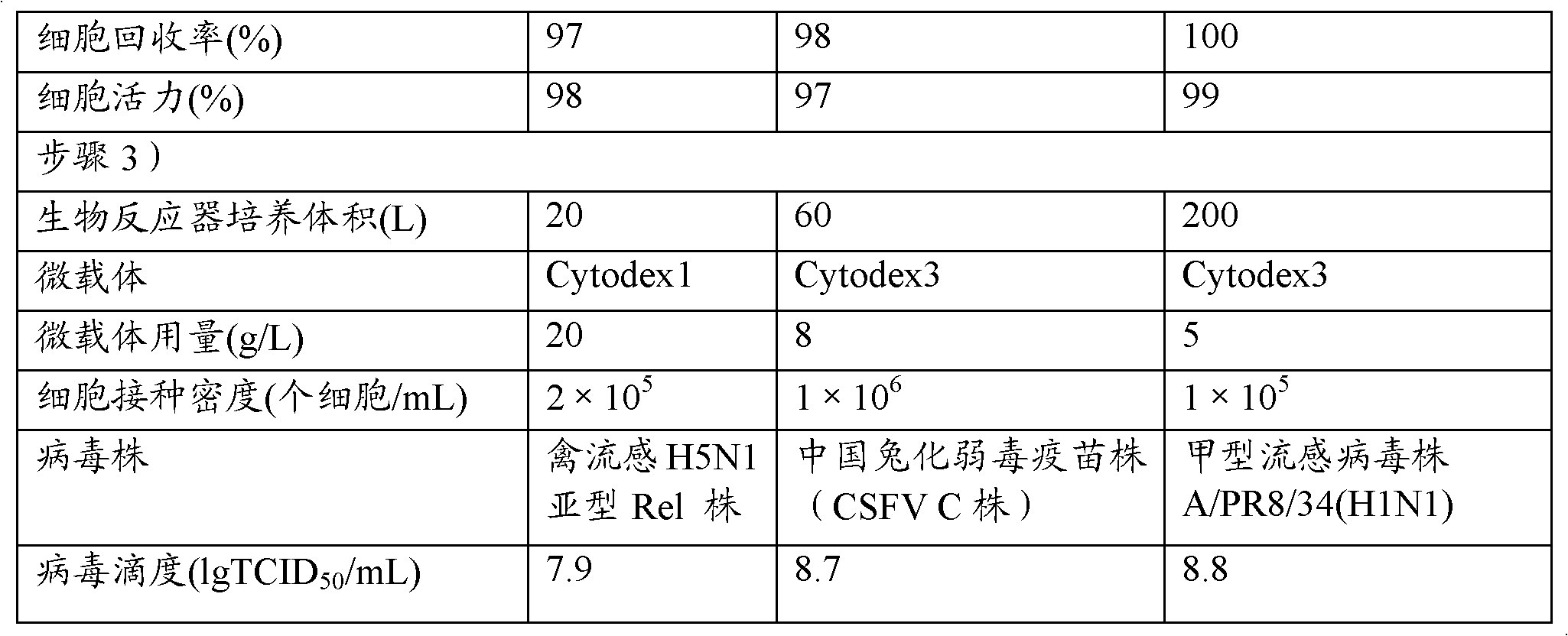

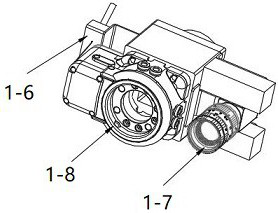

Automatic control system of cell factory

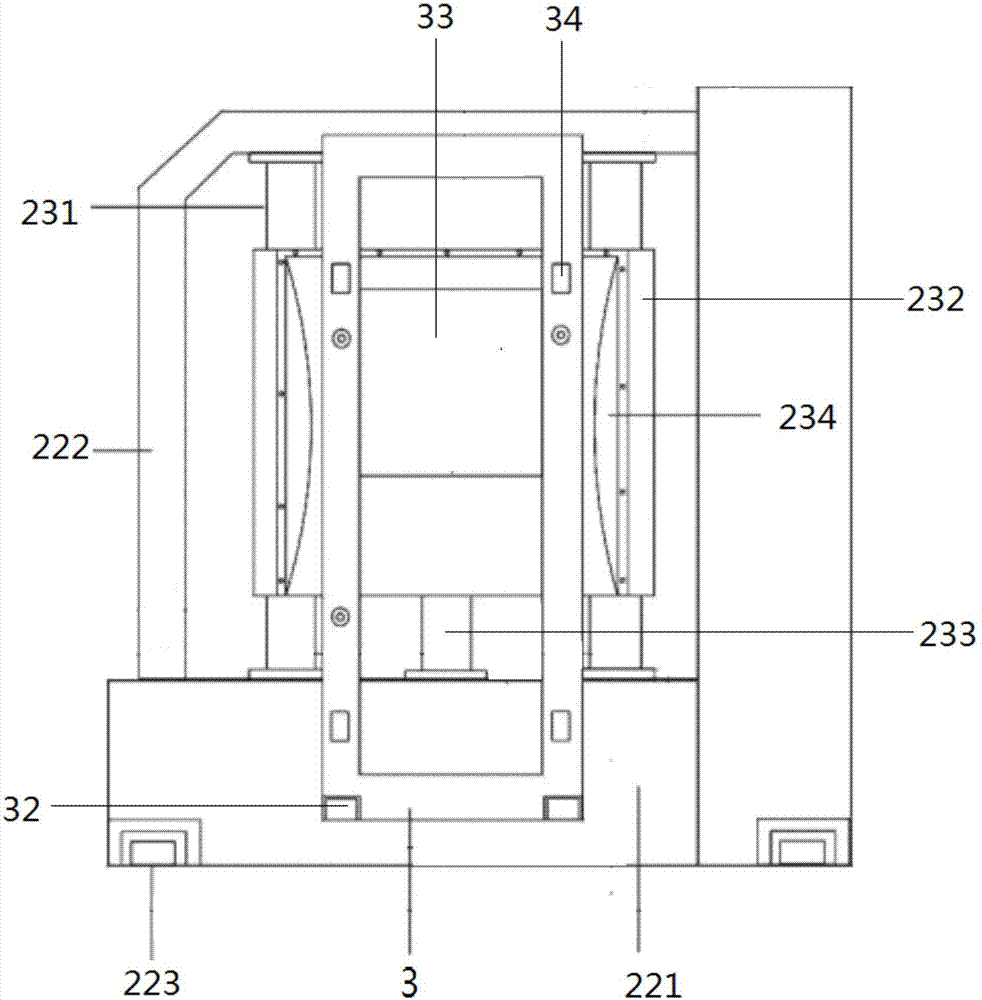

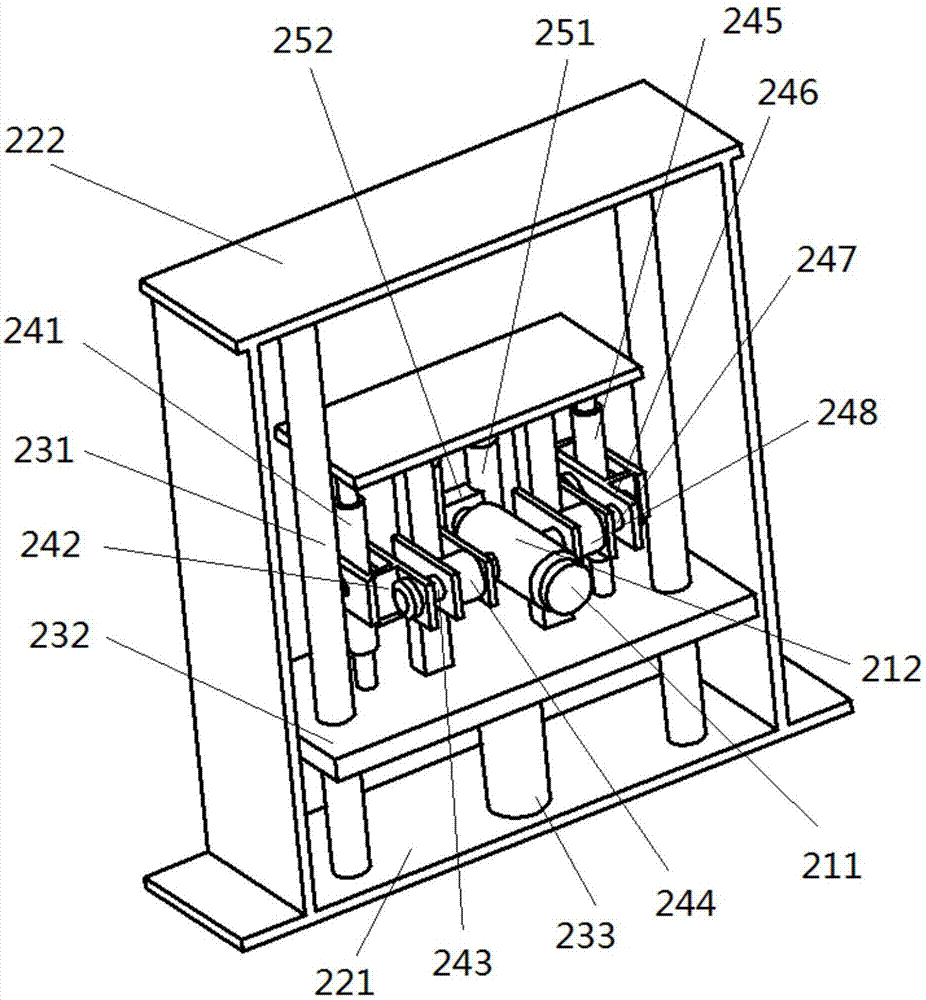

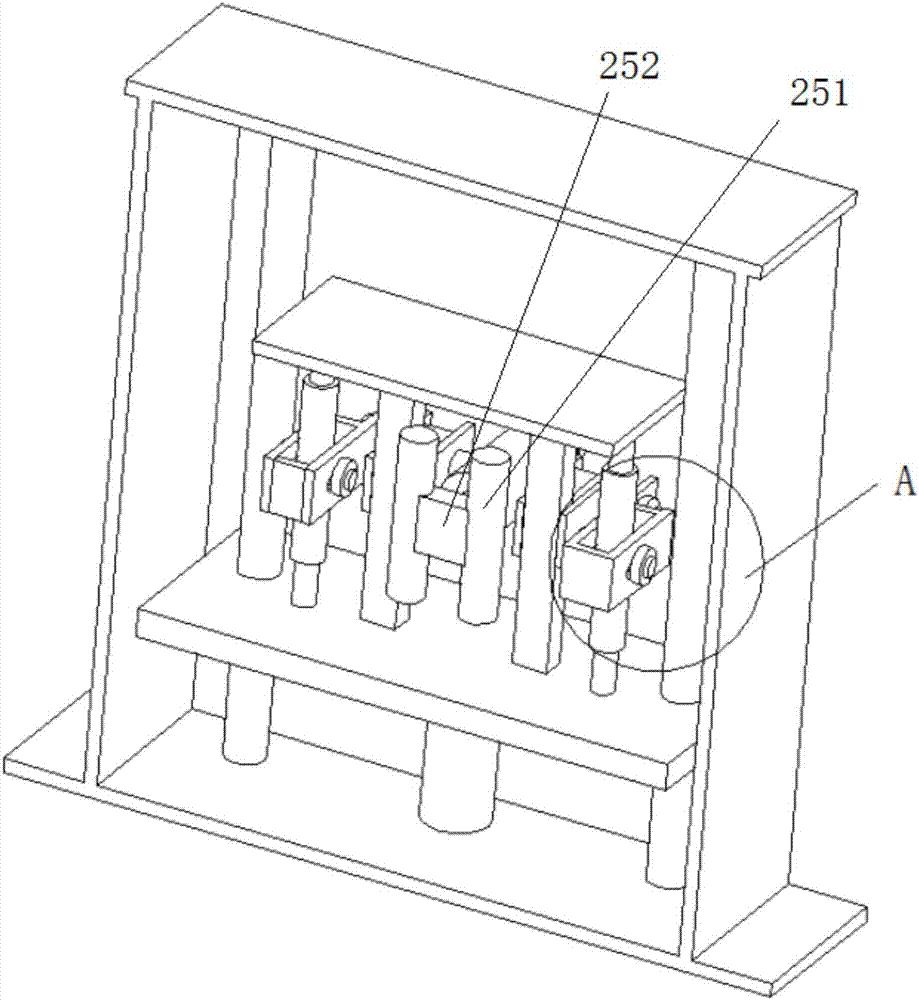

ActiveCN106919137ARealize automatic program controlReduce the chance of infectionTotal factory controlProgramme control in sequence/logic controllersAutomatic controlCell factory

The invention relates to an automatic control system of a cell factory. The system comprises a control device achieving rising, descending, inclining and rotation of a cell factory carrier. The control device comprises a main shaft, a support assembly, a vertical rising and descending control assembly, an inclining control assembly, a rotation control assembly and a controller. The main shaft comprises a central rotation shaft and a fixed shaft sleeving the outer side of the central rotation shaft. The controller is used for controlling actions of the vertical rising and descending control assembly, the inclining control assembly and the rotation control assembly. By applying the automatic control system, production efficiency can be improved; automatic process control in irrigation and harvesting procedures of vaccines is achieved; in a simulation experiment, 4 / 5 of workers in the irrigation and harvesting procedures are reduced; and contamination rate of the vaccines caused by misoperation of workers in an operation process is remarkably reduced.

Owner:李满发

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com