Automatic control system of cell factory

An automatic control system and cell technology, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of insufficient production capacity, high risk of personnel misoperation, intensive labor intensity, etc. , to achieve stable operation, improve production efficiency, and reduce the chance of vaccine infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

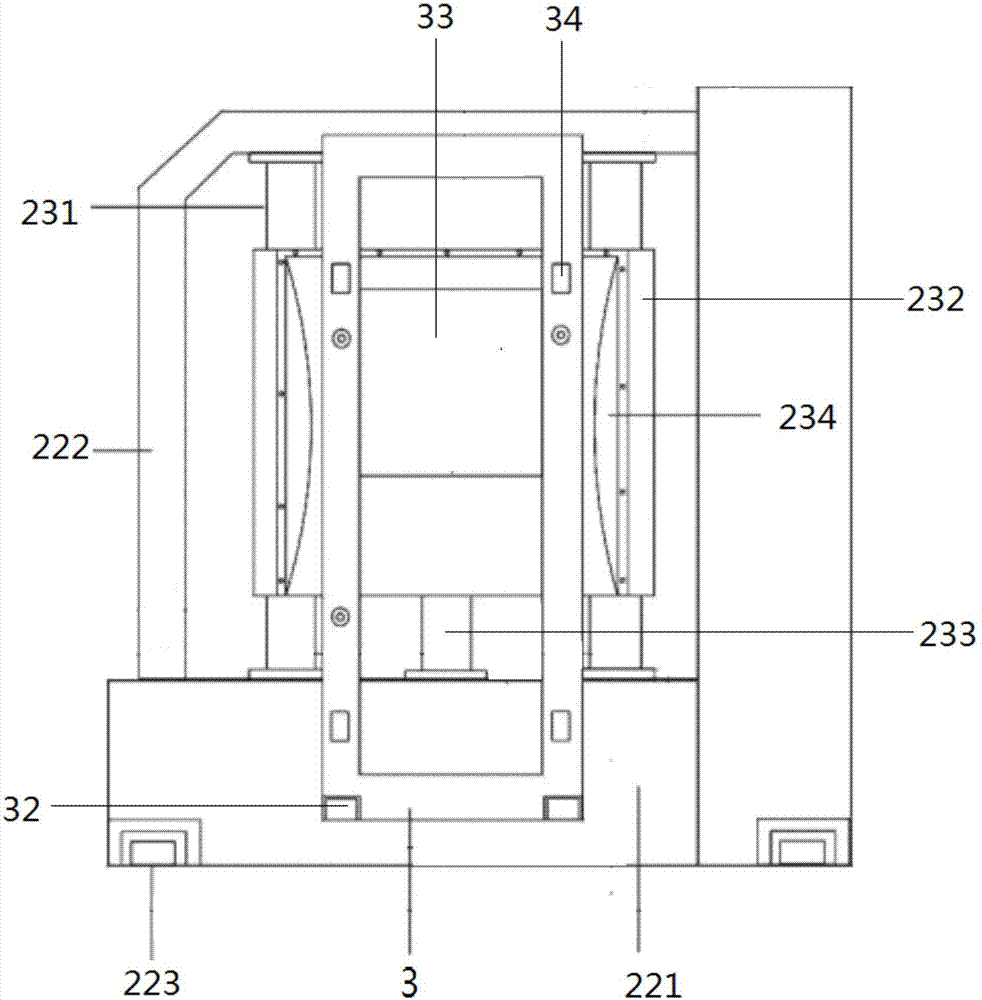

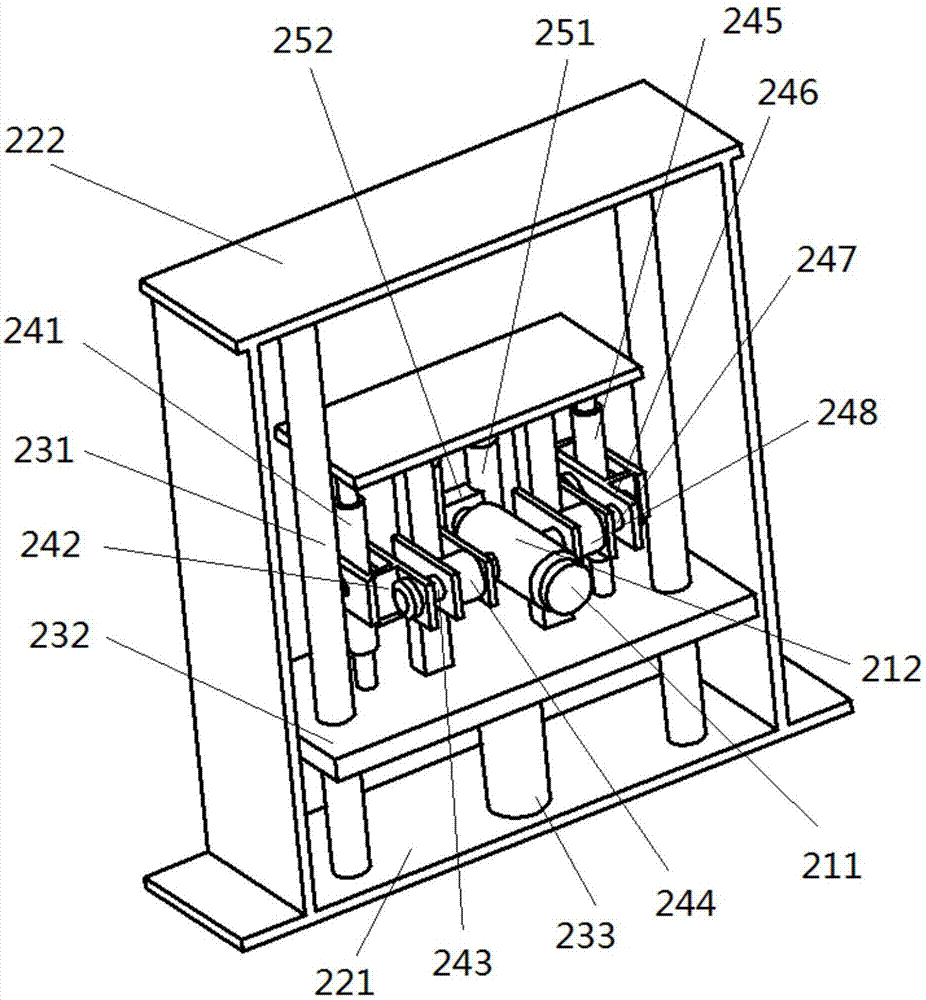

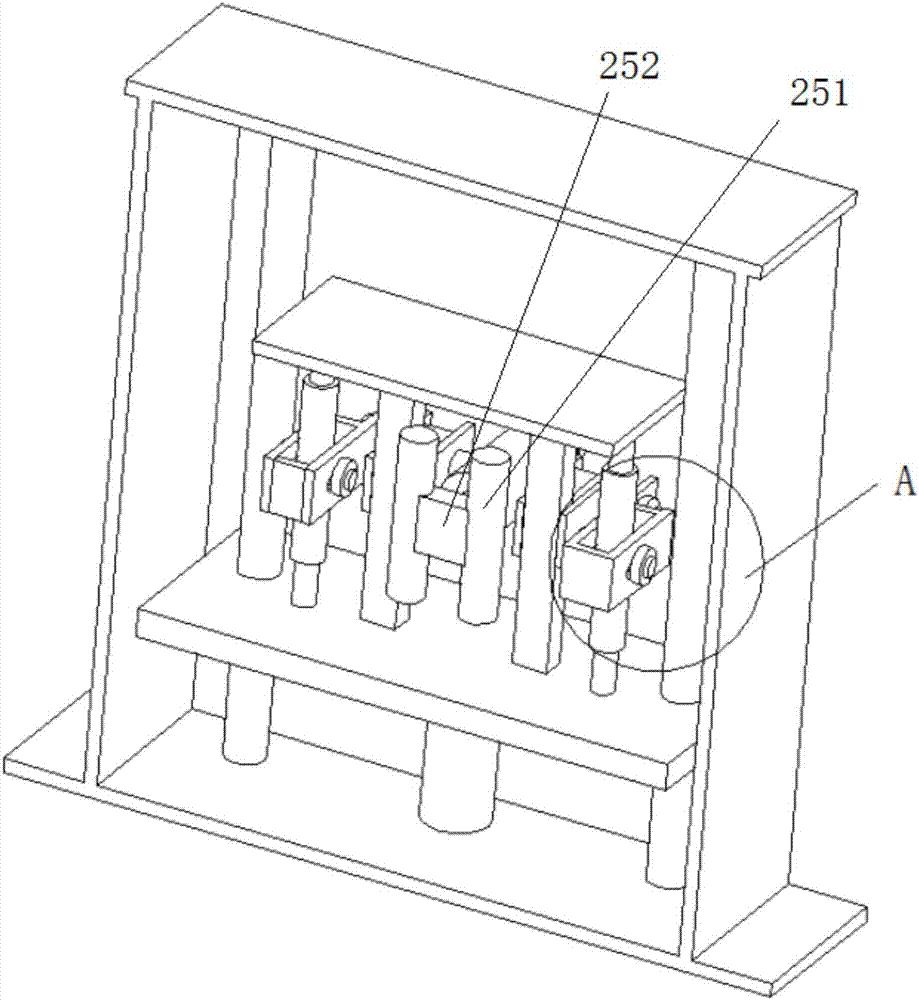

[0041] Such as Figure 1-7 As shown, the cell factory automatic control system of the present invention includes a cell factory transport vehicle and a control device for realizing the lifting, tilting and rotation of the cell factory transport vehicle. The control device includes a main shaft, a support component, a vertical lift control component, a tilt control component, a rotation control component and a controller.

[0042] The main shaft includes a central rotating shaft 211 and a fixed shaft 212 sleeved on the outside of the central rotating shaft; the support assembly includes a base 221 and an upper support frame 222 fixed above the base; The supporting frame 232 and the first lifting source 233, the lifting guide column 231 is fixedly arranged between the base 221 and the upper bottom surface of the upper supporting frame 222, the main shaft is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com