Front silver paste for high-contact and high-adhesion PERC single crystal solar cell and preparation method

A technology of solar cells and high adhesion, applied in the manufacture of cables/conductors, equipment for manufacturing conductive/semiconductive layers, circuits, etc., to achieve good printability, solve high series resistance, and solve the effects of cell degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

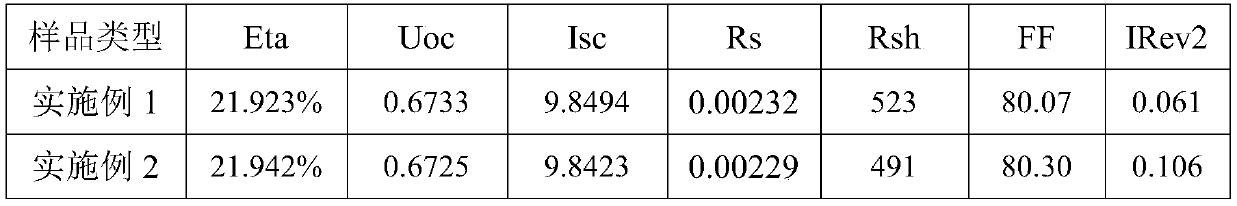

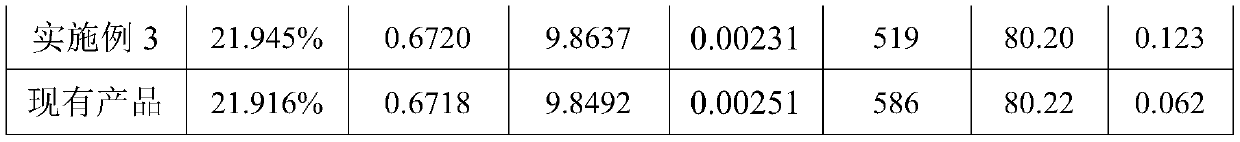

Examples

Embodiment 1

[0032] The front silver paste for a high-contact and high-adhesion PERC monocrystalline solar cell of this embodiment is made of the following raw materials in mass percentage: 30% of silver powder with a particle size of 700nm, 59.5% of silver powder with a particle size of 1-2 μm, glass powder 2.8%, organic vehicle 6.5%, inorganic additives 1.2%.

[0033] The inorganic additives are cerium dioxide and nano silver powder.

[0034] The organic vehicle is made of the following raw materials in mass percentage: Dow STD-4 ethyl cellulose 7%, acrylic resin 3%, dimethyl phthalate 10%, propylene glycol methyl ether acetate 3%, propylene glycol methyl ether 5% %, butyl carbitol 15%, butyl carbitol acetate 20%, alcohol ester dodeca 10%, oleic acid 2%, TDO 6%, polyamide wax 10%, silicone oil 5%, esterification modification Rosin 4%.

[0035] The preparation method of silver paste for PERC crystalline silicon solar cells with high contact and high adhesion comprises the following step...

Embodiment 2

[0049] The front silver paste for a high-contact and high-adhesion PERC monocrystalline solar cell of this embodiment is made of the following raw materials in mass percentage: 20% of silver powder with a particle size of 700nm, 69.8% of silver powder with a particle size of 1-2 μm, glass powder 2.5%, organic vehicle 6.6%, inorganic additives 1.1%.

[0050] The inorganic additives are nano-zinc powder and nano-silver powder.

[0051] The organic vehicle is made of the following raw materials in mass percentage: Dow STD-4 ethyl cellulose 7%, acrylic resin 3%, dimethyl phthalate 10%, propylene glycol methyl ether acetate 4%, propylene glycol methyl ether 5% %, butyl carbitol 15%, butyl carbitol acetate 20%, alcohol ester dodeca 10%, oleic acid 2%, TDO 5%, polyamide wax 10%, silicone oil 4%, esterification modification Rosin 5%.

[0052] The preparation method of the front silver paste for the high-contact and high-adhesion PERC monocrystalline solar cell comprises the followin...

Embodiment 3

[0059] The front silver paste for a high-contact and high-adhesion PERC monocrystalline solar cell of this embodiment is made of the following raw materials in mass percentages: 25% of silver powder with a particle size of 700nm, 64.8% of silver powder with a particle size of 1-2 μm, glass powder 2.6%, organic vehicle 6.6%, inorganic additives 1.0%.

[0060] The inorganic additives are nano palladium powder and nano silver powder.

[0061] The organic vehicle is made of the following raw materials in mass percentage: Dow STD-4 ethyl cellulose 8%, acrylic resin 2%, dimethyl phthalate 8%, propylene glycol methyl ether acetate 4%, propylene glycol methyl ether 6% %, butyl carbitol 12%, butyl carbitol acetate 22%, alcohol ester dodeca 10%, oleic acid 2%, TDO 5%, polyamide wax 12%, silicone oil 5%, esterification modification Rosin 4%.

[0062] The preparation method of the front silver paste for the high-contact and high-adhesion PERC monocrystalline solar cell comprises the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com