An automatic liquid-adding control method for realizing constant volume of volumetric flask

A control method and volumetric flask technology, which are applied in the field of chemical analysis and quantitative analysis, can solve problems such as time-consuming, labor-intensive, low work efficiency, and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

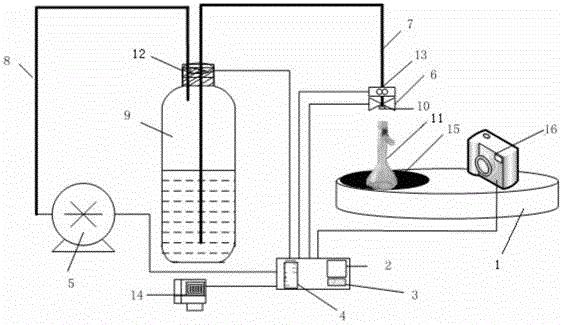

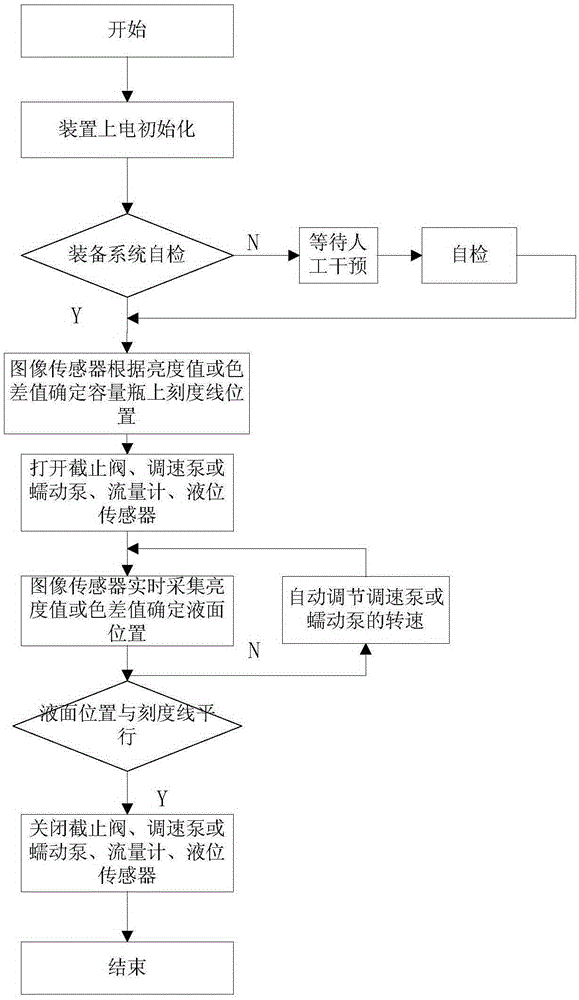

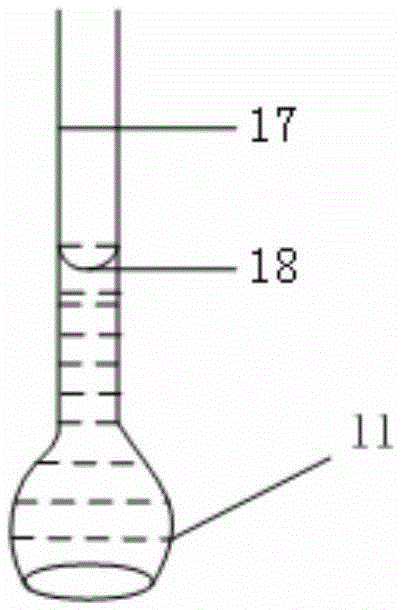

[0018] See attached figure 1 As shown, the device structure implementing the technical solution of the present invention includes a balance 1 connected to a control device 4, a display screen 2, and a keyboard 3. The display screen 2 and the keyboard 3 are in the form of a touch screen, and the control device 4 communicates with the balance through a USB or RS232 interface. 1 is connected to obtain the reading of balance 1 in real time. It is characterized in that: the bottom of a volumetric flask 11 placed on the weighing tray of balance 1 is a colored gasket 15, which is used to increase the chromaticity difference at the liquid level. Vertically above the volumetric bottle 11 is a liquid outlet 10 at one end of the liquid outlet pipe 7. A stop valve 6 is arranged on the liquid outlet pipe 7. A flow meter 13 is also arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com