Brazing device and process for interior of cooling plate sealing cavity under inert gas shielding environment

A technology of protecting the environment and inert gas, which is applied in the field of brazing equipment and technology in the closed cavity of the cooling plate to achieve the effects of improving production efficiency, increasing yield and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

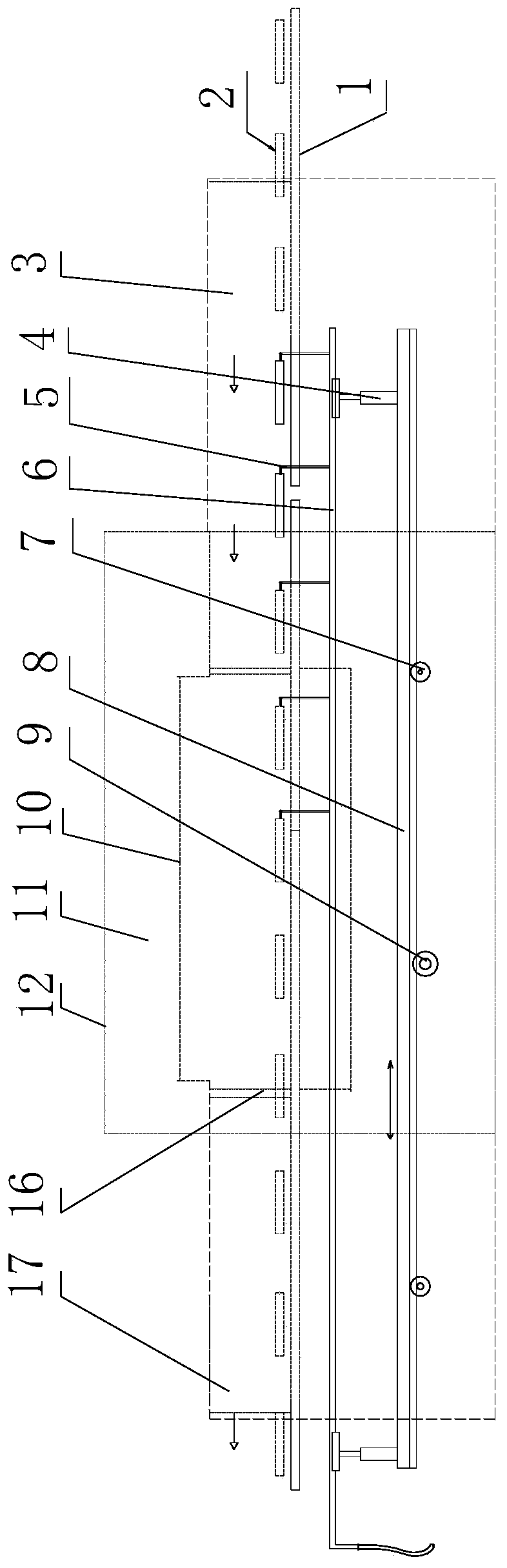

[0024] Described brazing equipment and process, brazing process is as follows:

[0025] 1. Preparation process: The pre-welding process of the aluminum heat dissipation cooling plate workpiece is as follows: evenly apply brazing flux and brazing material on the welding seam of the aluminum heat dissipation cooling plate workpiece;

[0026] 2. Drying and preheating process: place the aluminum heat dissipation cooling plate workpiece in the fixed slot on the chain conveyor, and send it to the drying preheating furnace for drying by the chain conveyor. The drying time is controlled within 5-8 minutes , the drying preheating temperature is controlled at 100-150°C;

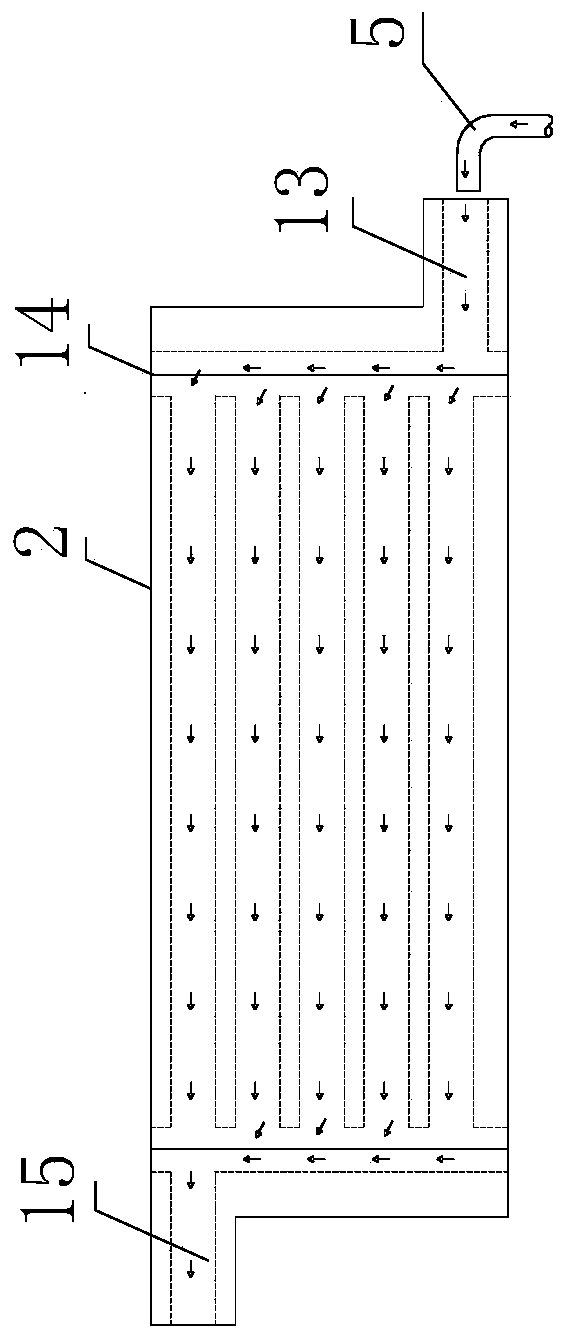

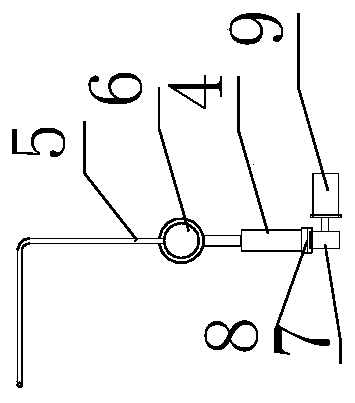

[0027] 3. Nitrogen blowing and deoxygenation process: the workpiece of the aluminum heat dissipation cooling plate enters the brazing furnace after drying the preheating furnace, the nitrogen main pipe of the automatic nitrogen filling and deoxygenation mechanism is lowered by the lifting cylinder, and the nitrogen blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com