System for grabbing part from material frame under visual guidance of robot and control method

A technology of robot vision and control method, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of repeated operations on parts, too high requirements for material frames, and difficult operations, so as to improve accuracy and stability. performance, reduce position deviation, and reduce equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

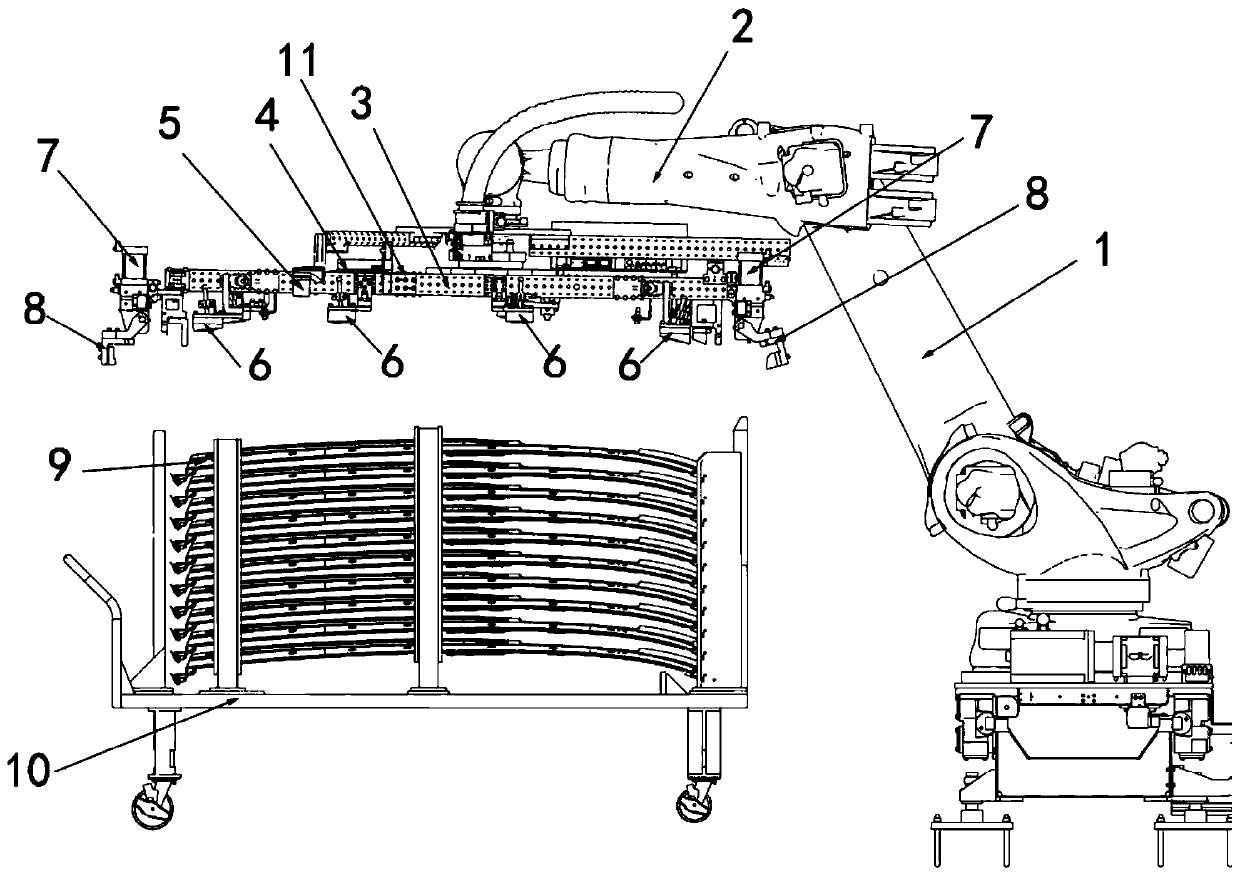

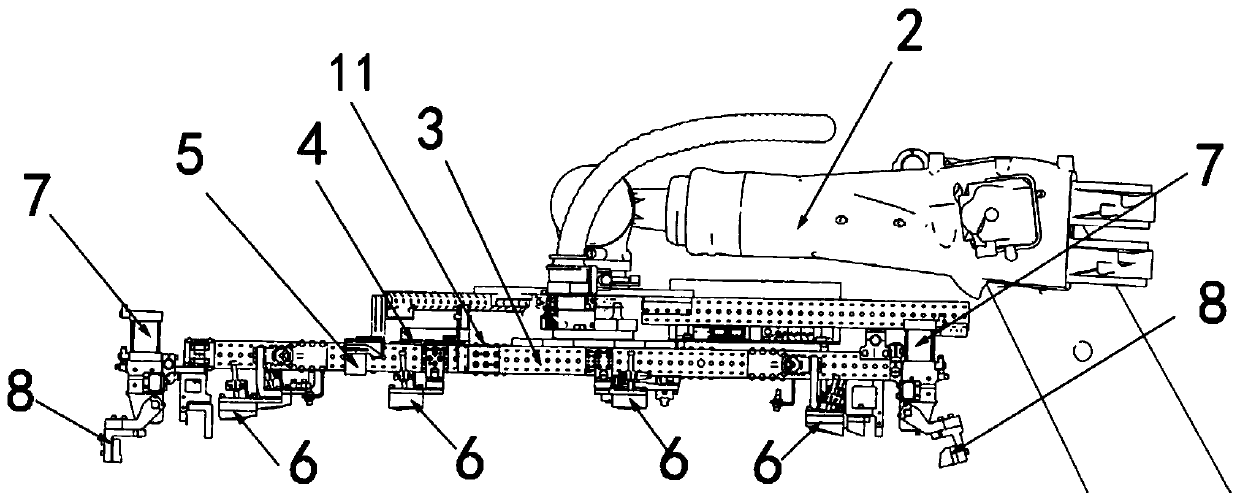

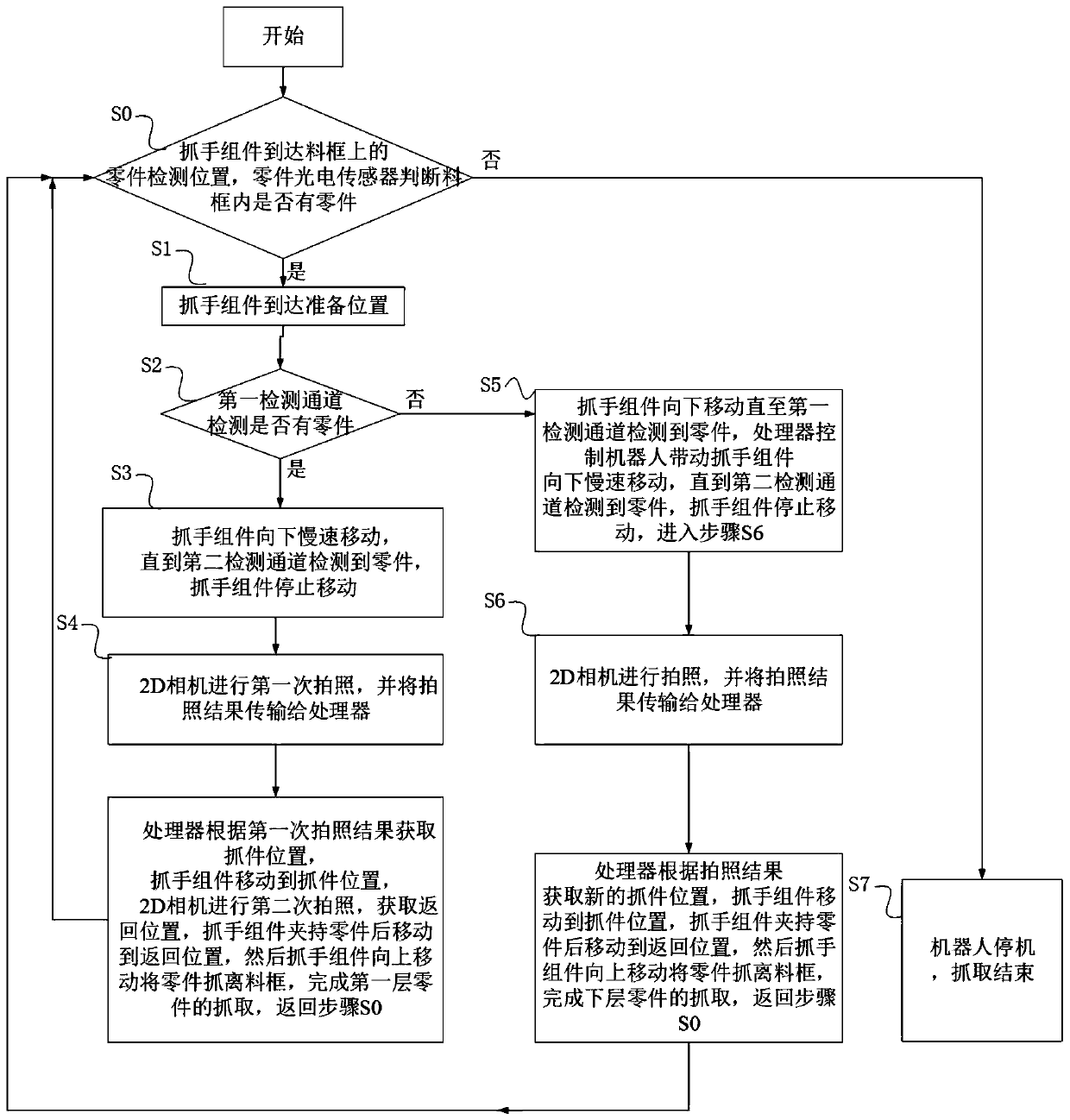

[0047] A system for grabbing parts from a material frame guided by robot vision, the system is used to grab parts 9 from a material frame 10, such as figure 1 As shown, the part 9 is a plurality of parts 9 with the same shape, which are stacked layer by layer in the material frame 10. The system includes a robot 1, a processor and a gripper assembly. The gripper assembly includes a main beam 3 and a part position sensing module. And the clamping module, the robot 1 is used to drive the gripper assembly to move, the part position sensing module is used to obtain the position information of the part 9 and the material frame 10, the clamping module is used to grab the part 9, and the processor is used to process the position information and according to The position information controls the moving action of the robot 1 and the grasping action of the clamping module, and the robot 1, the part position sensing module and the clamping module are respectively connected to the processo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com