Electric translational type slab clamp with slide compensation mechanism

A compensation mechanism, translation technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of insufficient clamping force, falling blanks, slippage of jaw teeth, etc., to improve safety and reliability, and improve clamping efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

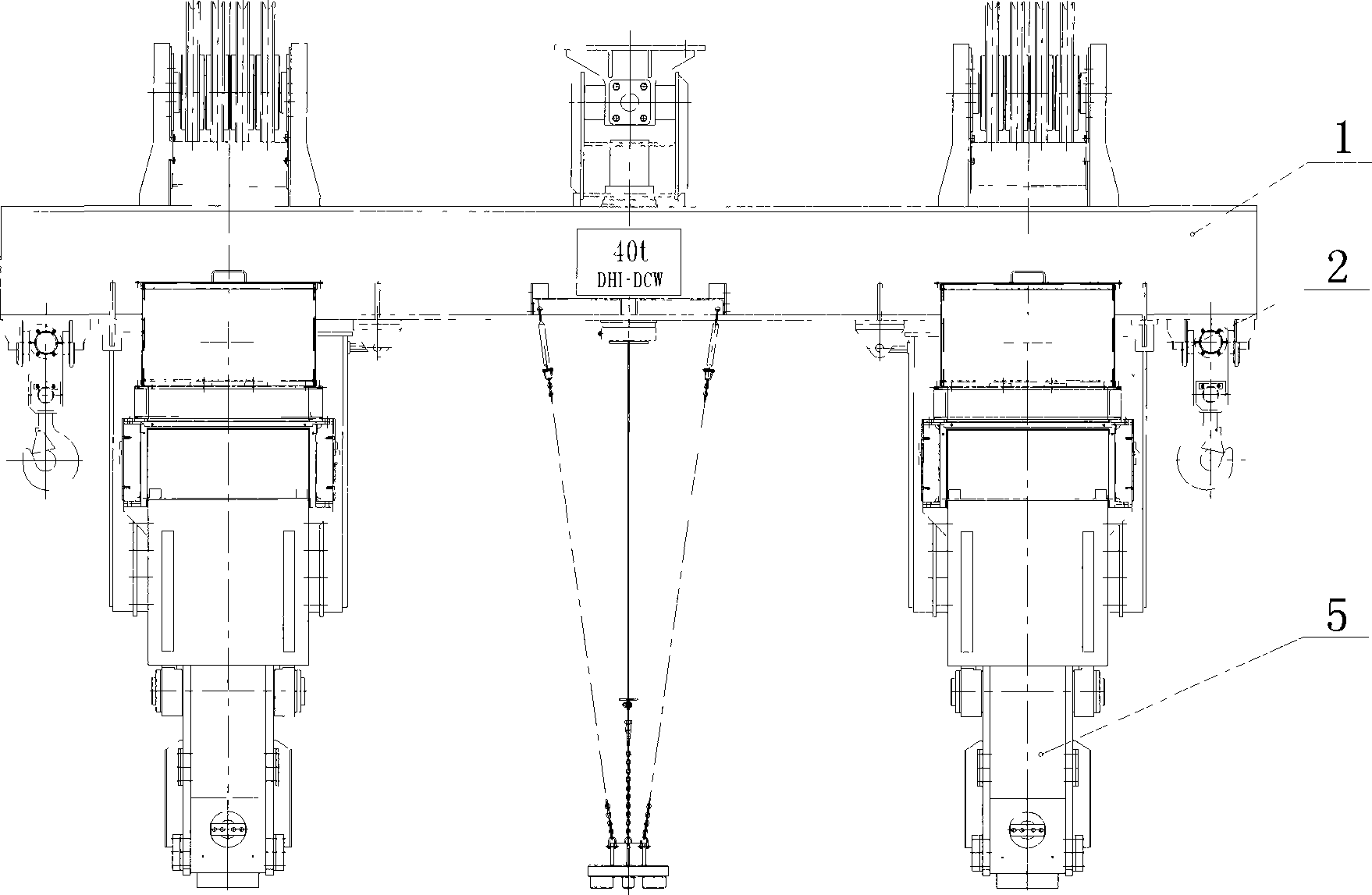

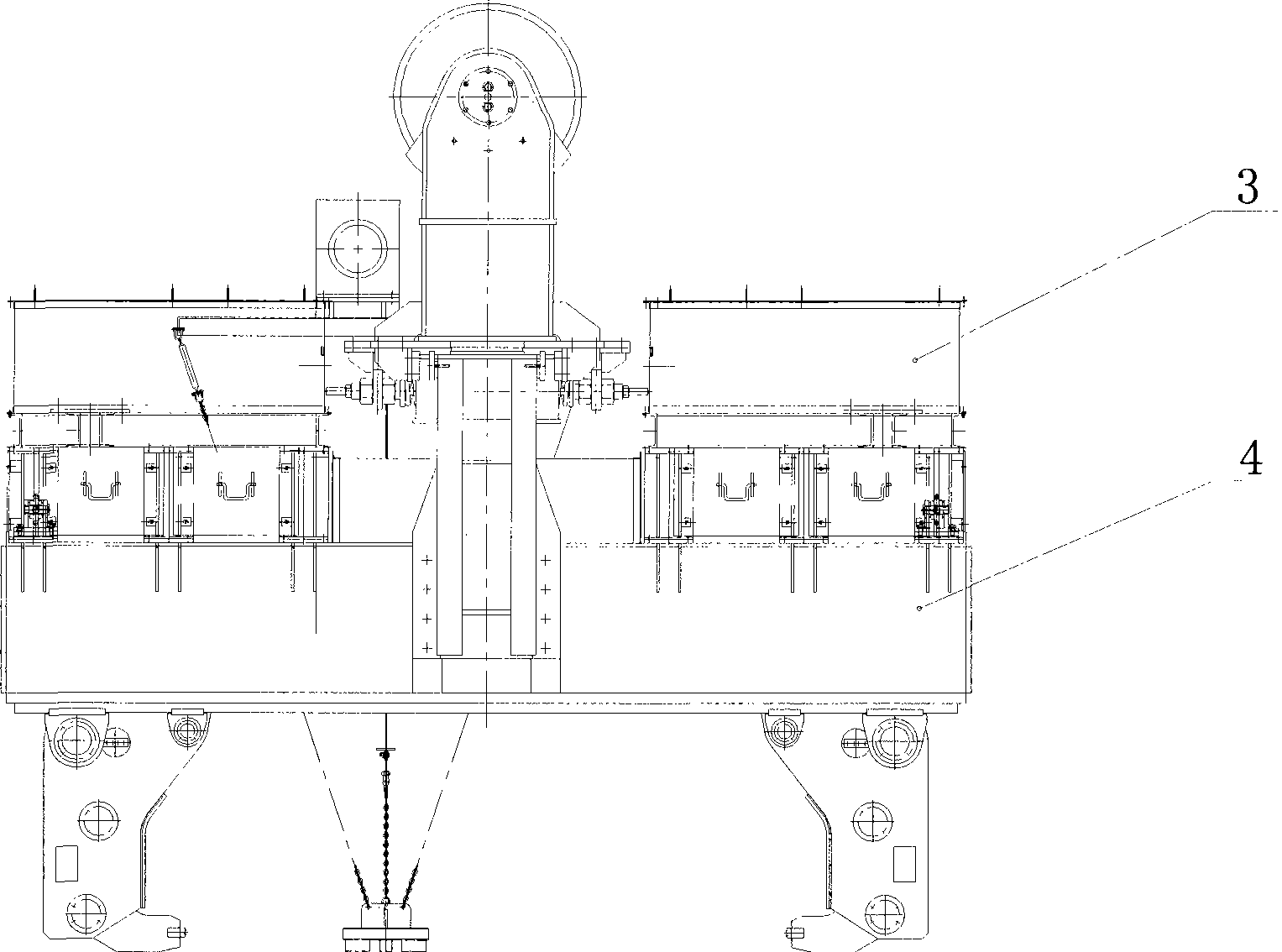

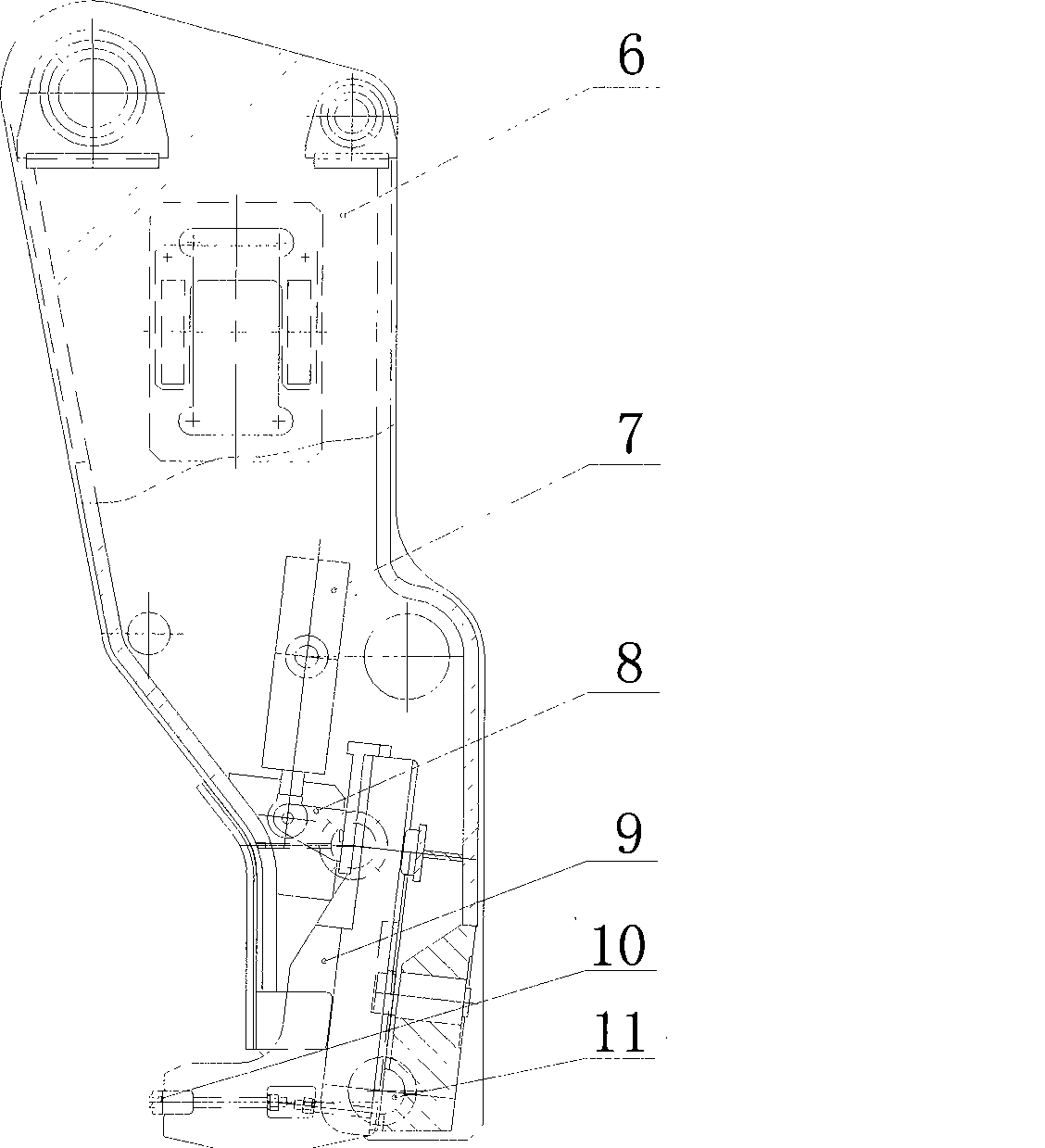

[0014] like Figure 1~Figure 4 The shown electric translational slab tongs with a sliding compensation mechanism include an opening and closing mechanism 3, a clamp arm assembly 5, an upper beam 1, a lower beam 4, and a hanging beam frame 2. The opening and closing mechanism 3 includes a three-in-one driving motor , sprockets, chains, nuts and screw rods; the clamp arm assembly 5 includes inclined slideways, clamp frames, guide sliders 9, clamp teeth 10, sliding support hinges 11, and sliding compensation mechanisms 7.

[0015] The sliding compensation mechanism 7 is composed of a hydraulic combination oil cylinder integrating a return spring, especially a disc spring, which includes a coupling device 12, a gland 13, a piston rod 14, a small sleeve 15, a cylinder body 16, a spring 17, a spacer 18, and a piston 19 , Cylinder bottom 20; Among them, 12 is a connecting device, which connects the hydraulic combination oil cylinder and the guide slider 9 through a hinge; 13 is a gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com