Patents

Literature

36results about How to "Reduce load error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

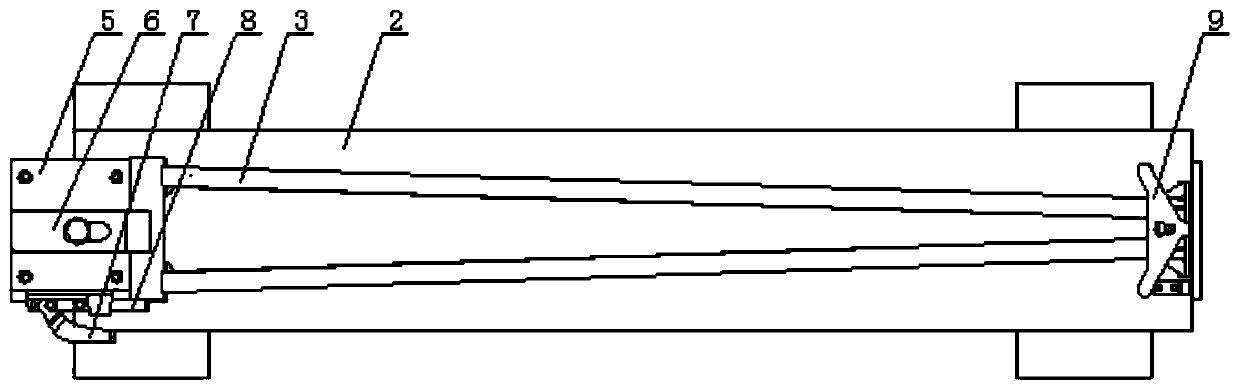

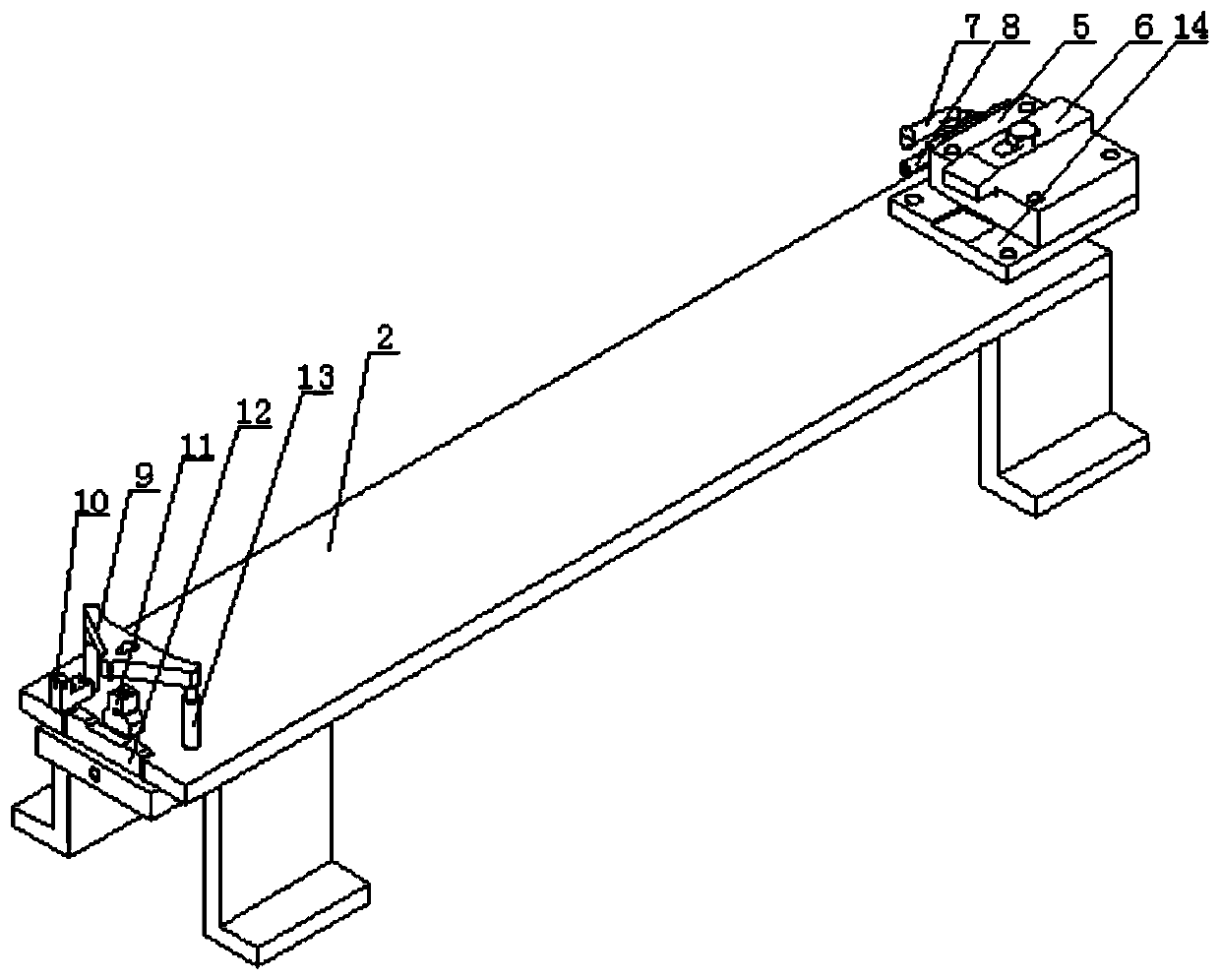

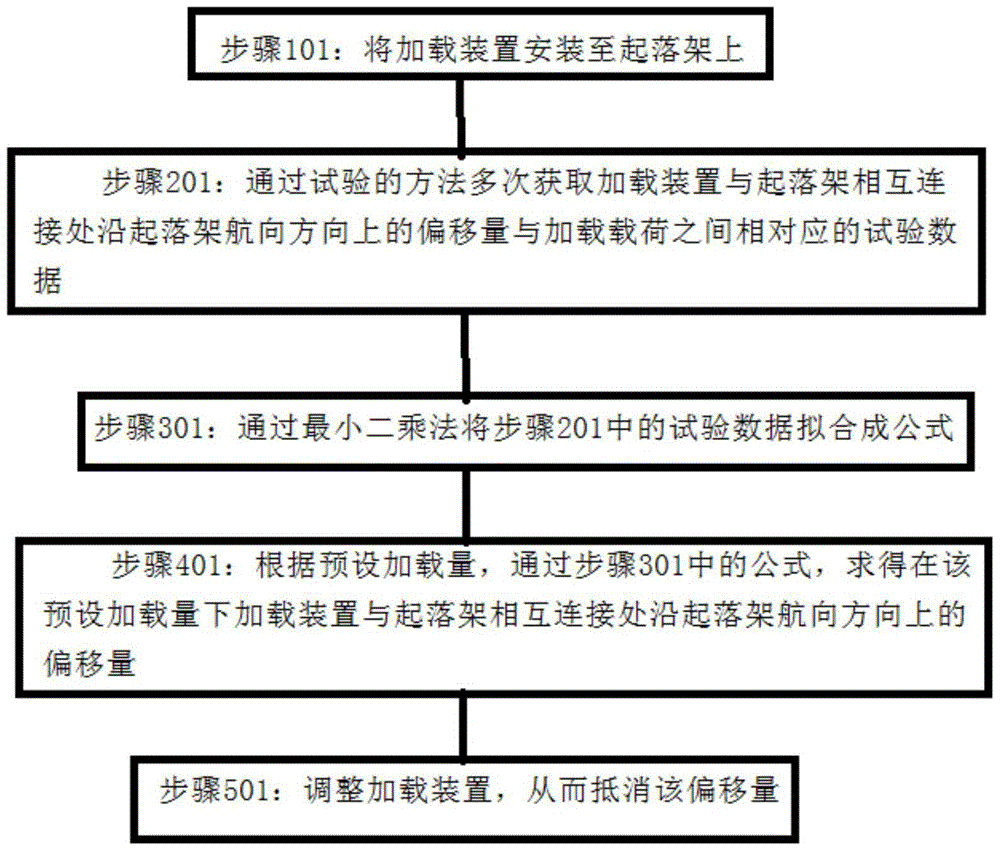

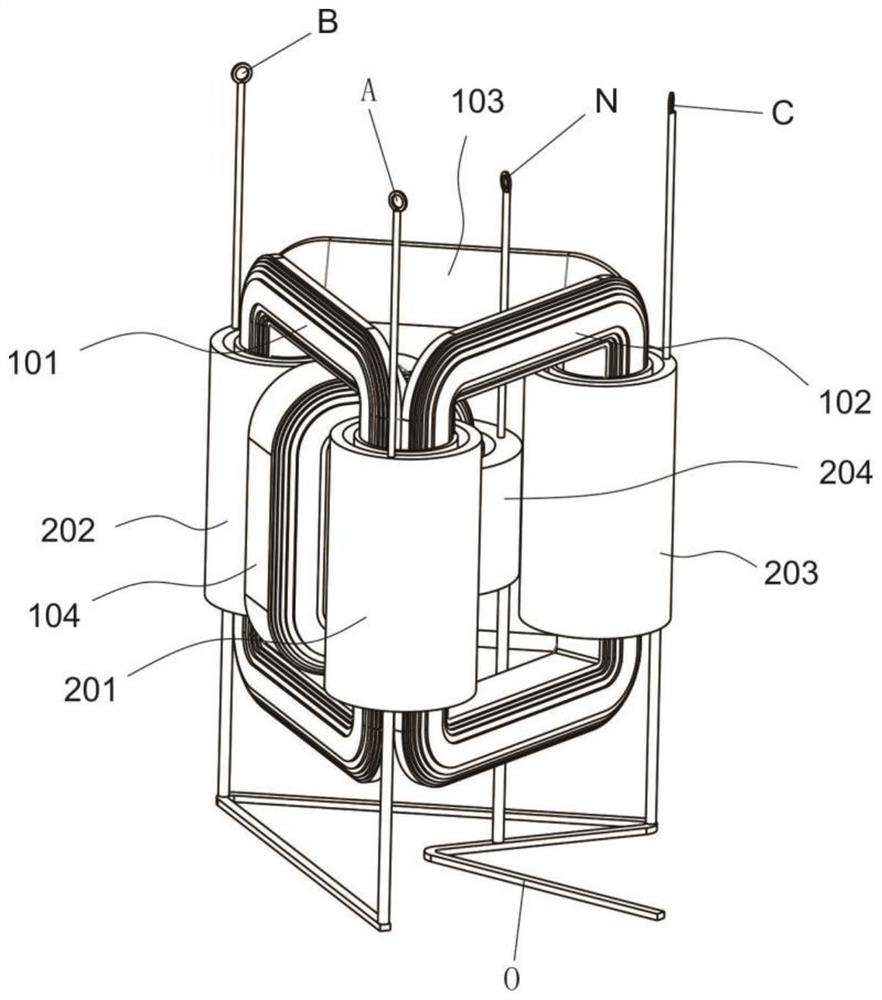

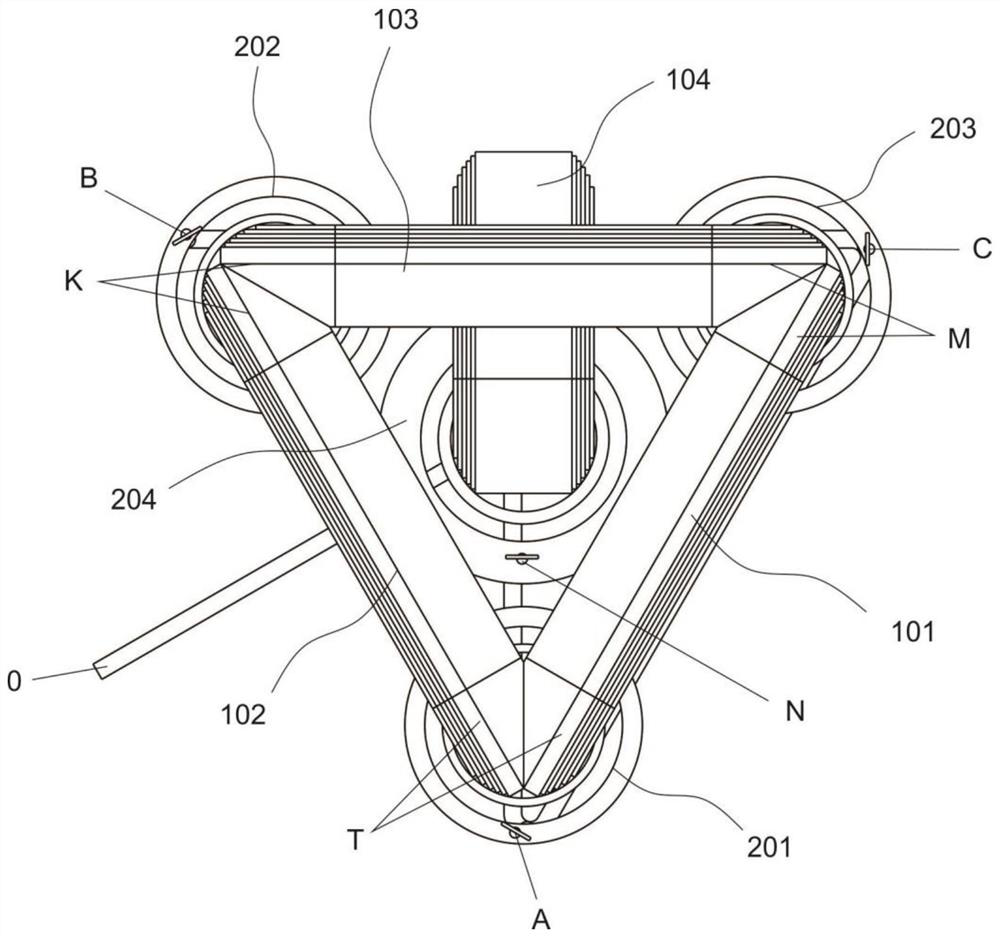

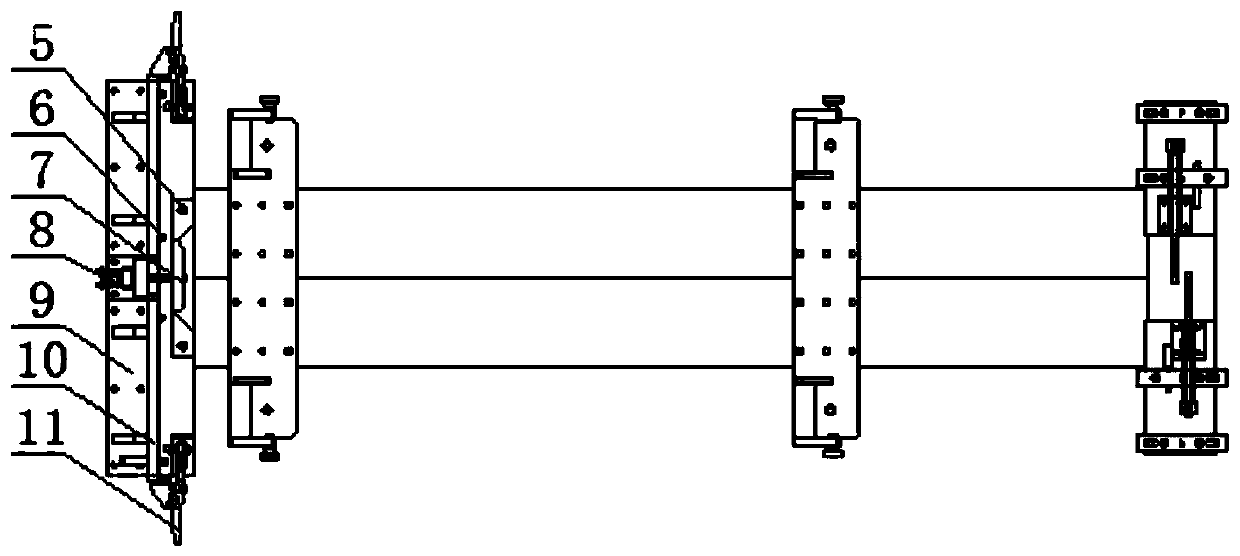

Load correction method applied to undercarriage loading

ActiveCN105083587AGuaranteed to be verticalReduce load errorAircraft components testingControl theoryReliability engineering

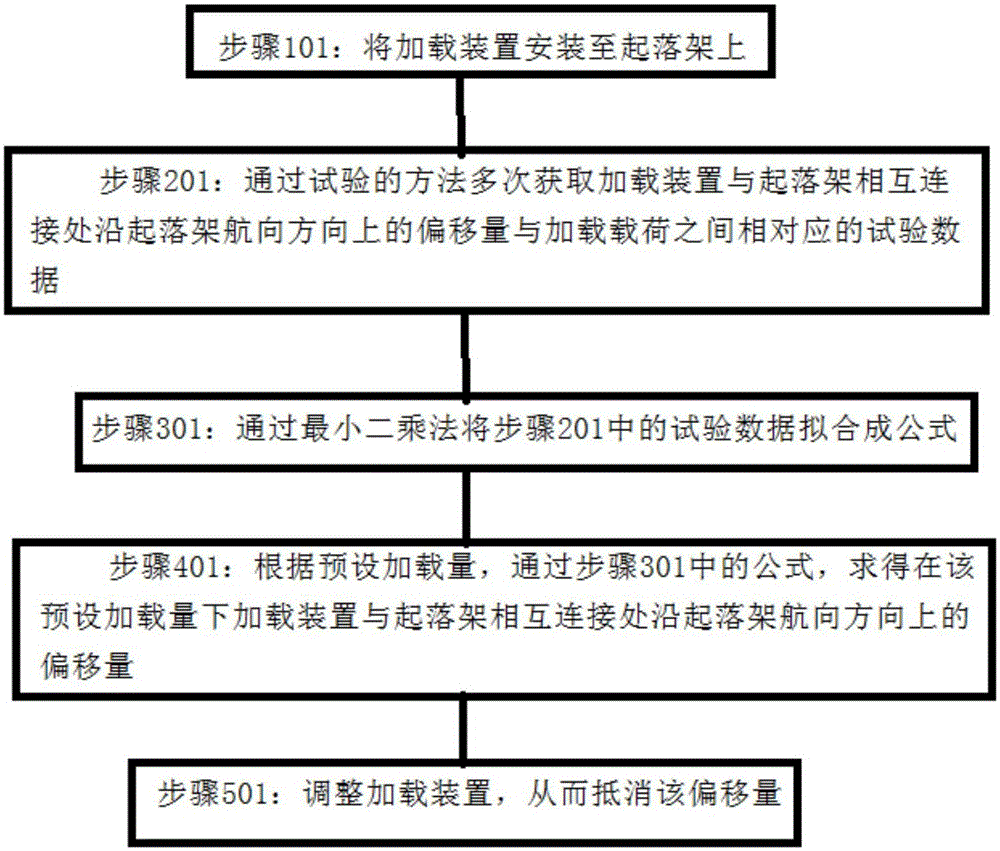

The invention discloses a load correction method applied to undercarriage loading. The method comprises the steps of 101, installing a loading device on an undercarriage; 201, acquiring corresponding test data between the offset, in the heading direction of the undercarriage, at the position where the loading device is connected with the undercarriage and a load multiple times through testing; 301, fitting the test data obtained in the step 201 into a formula by means of the least square method; 401, obtaining the offset, in the heading direction of the undercarriage, at the position where the loading device is connected with the undercarriage according to a preset load by means of the formula obtained in the step 301; 501, adjusting the loading device so as to counteract the offset. In this way, load error generated by an undercarriage loading system is effectively reduced so that the test load error can meet the control requirement, and then the problem that offset exists in the prior art is solved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

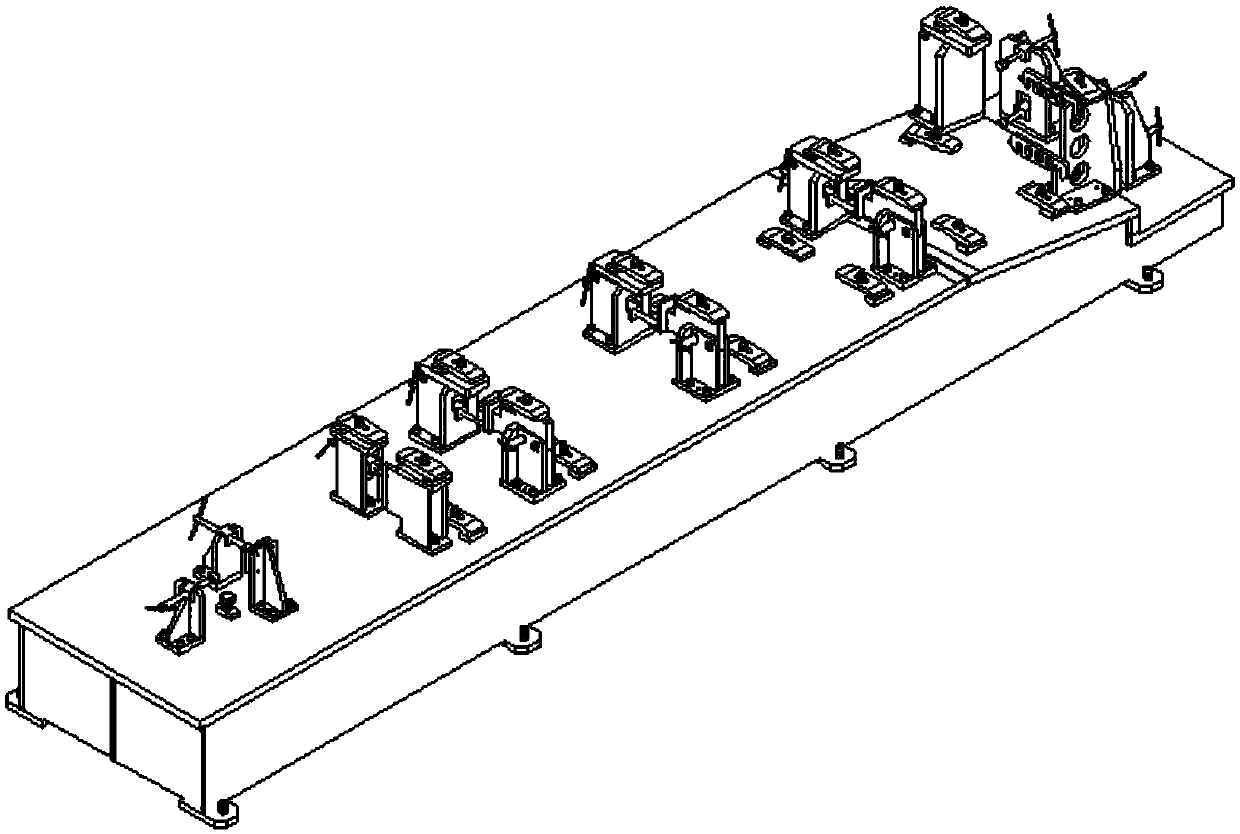

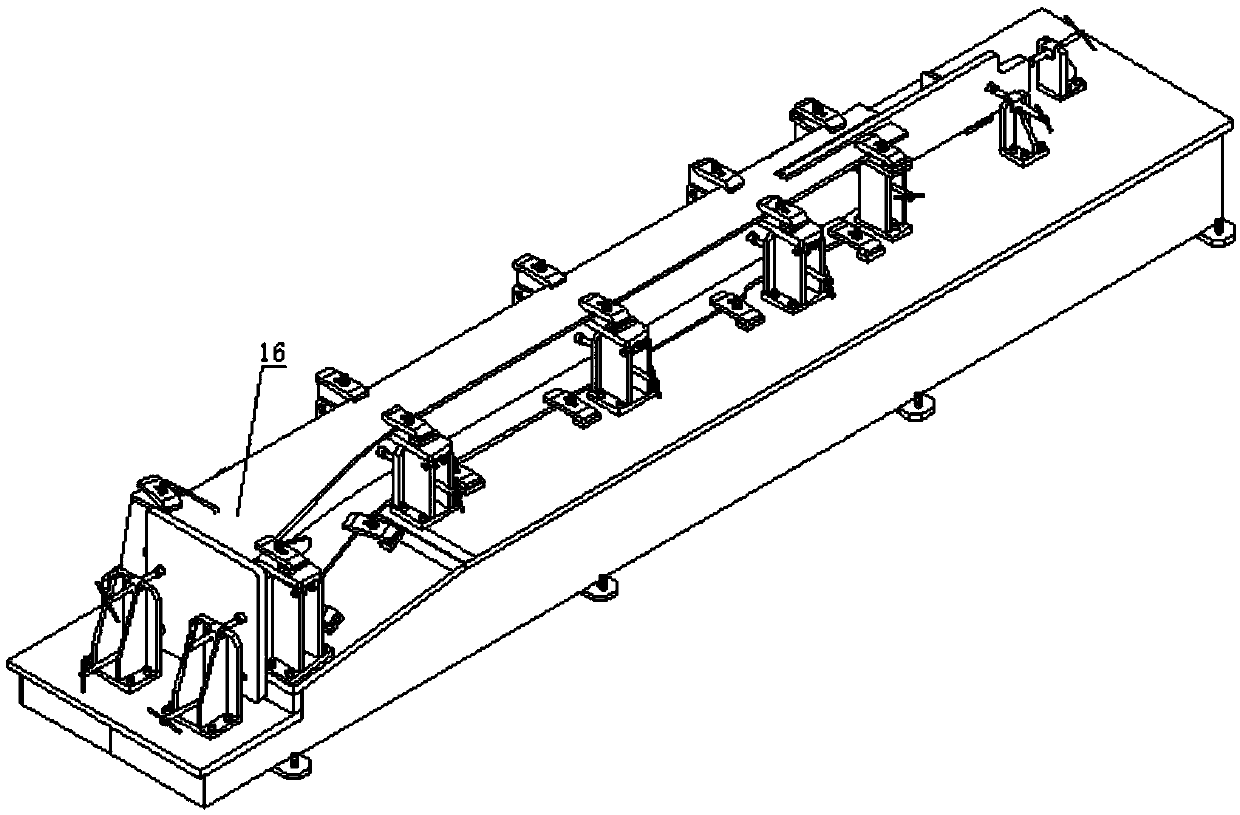

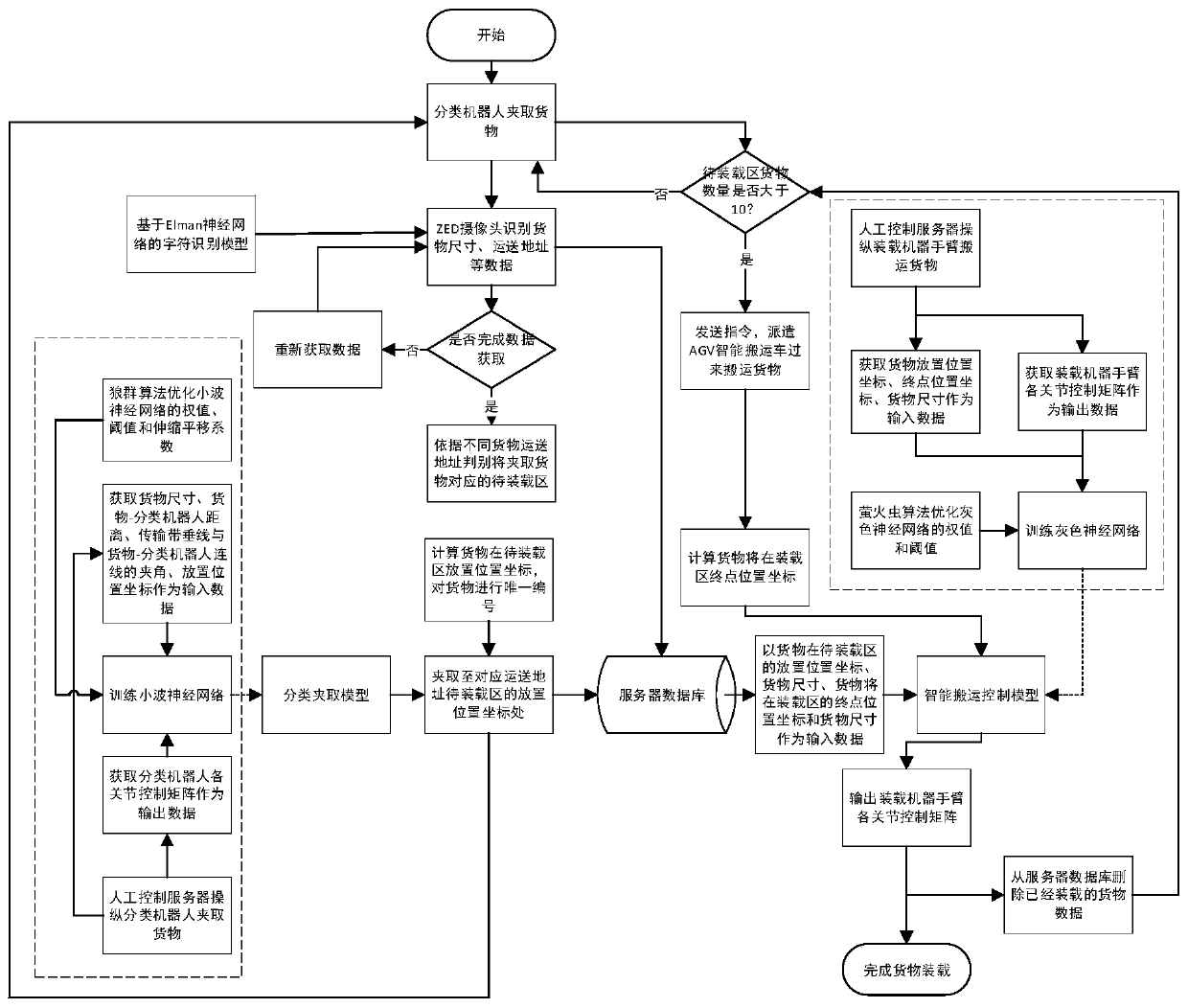

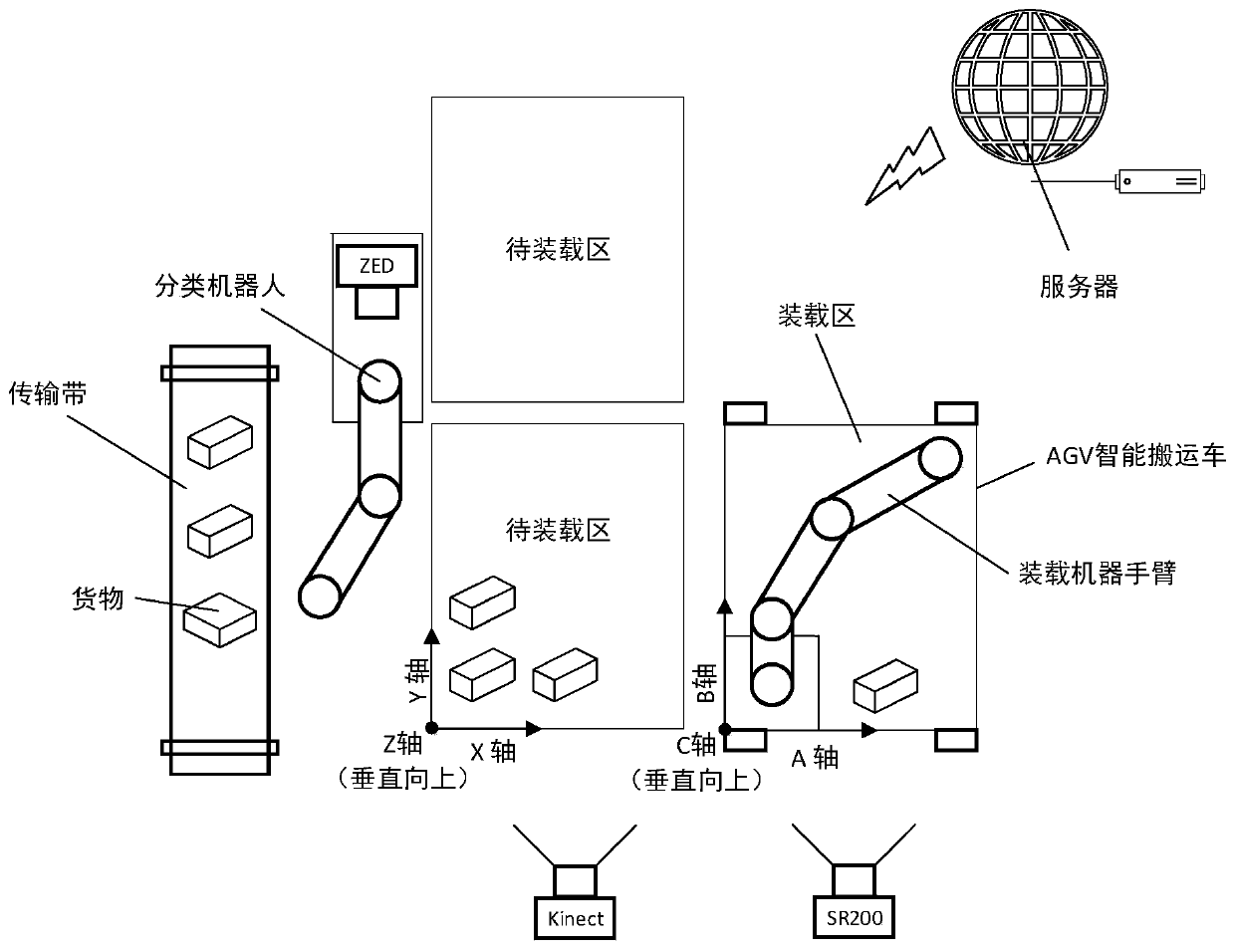

Loading method and device of intelligent logistics environment robot

ActiveCN108942946ASimple structureEasy to operateProgramme-controlled manipulatorMachine visionLogistics management

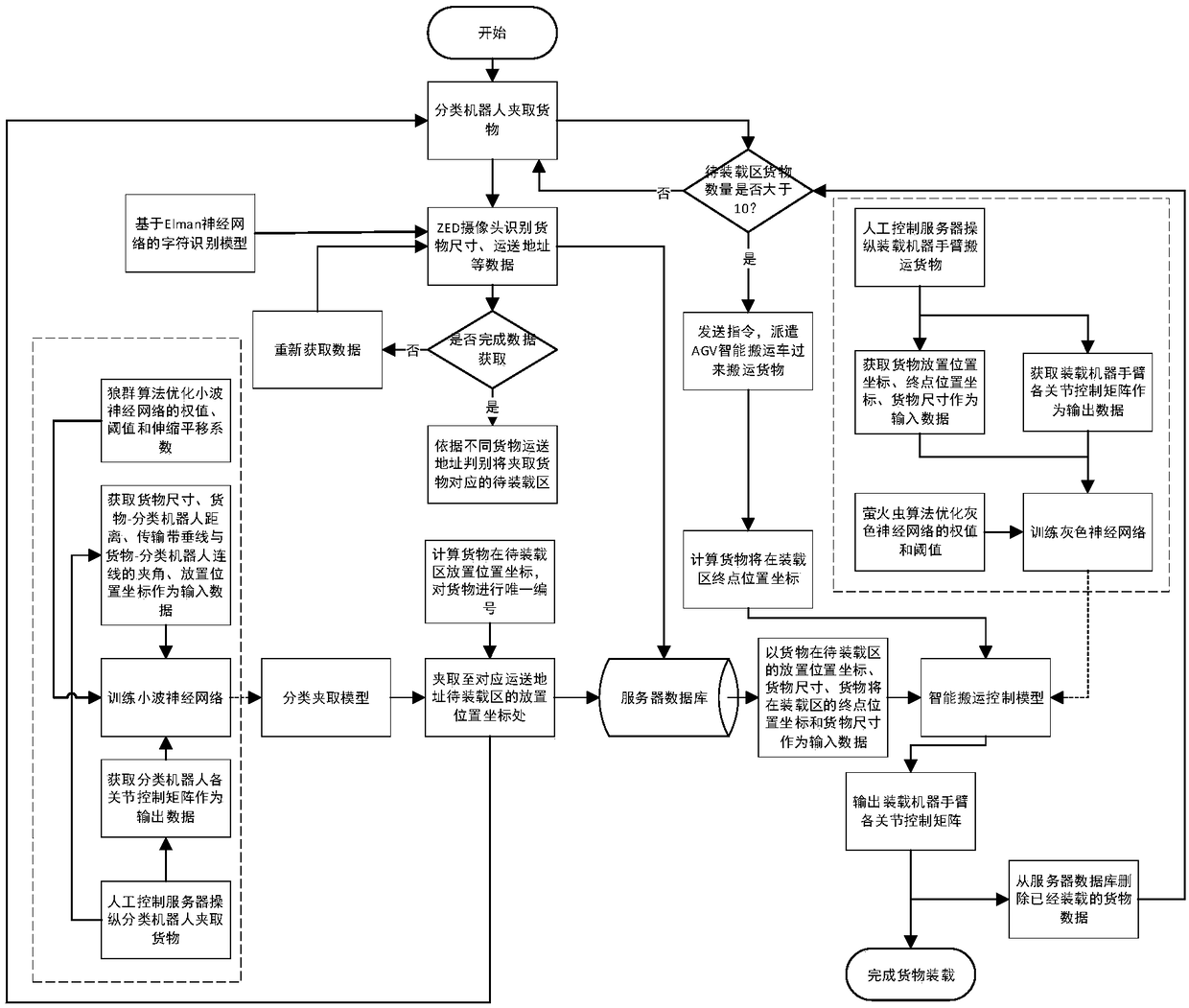

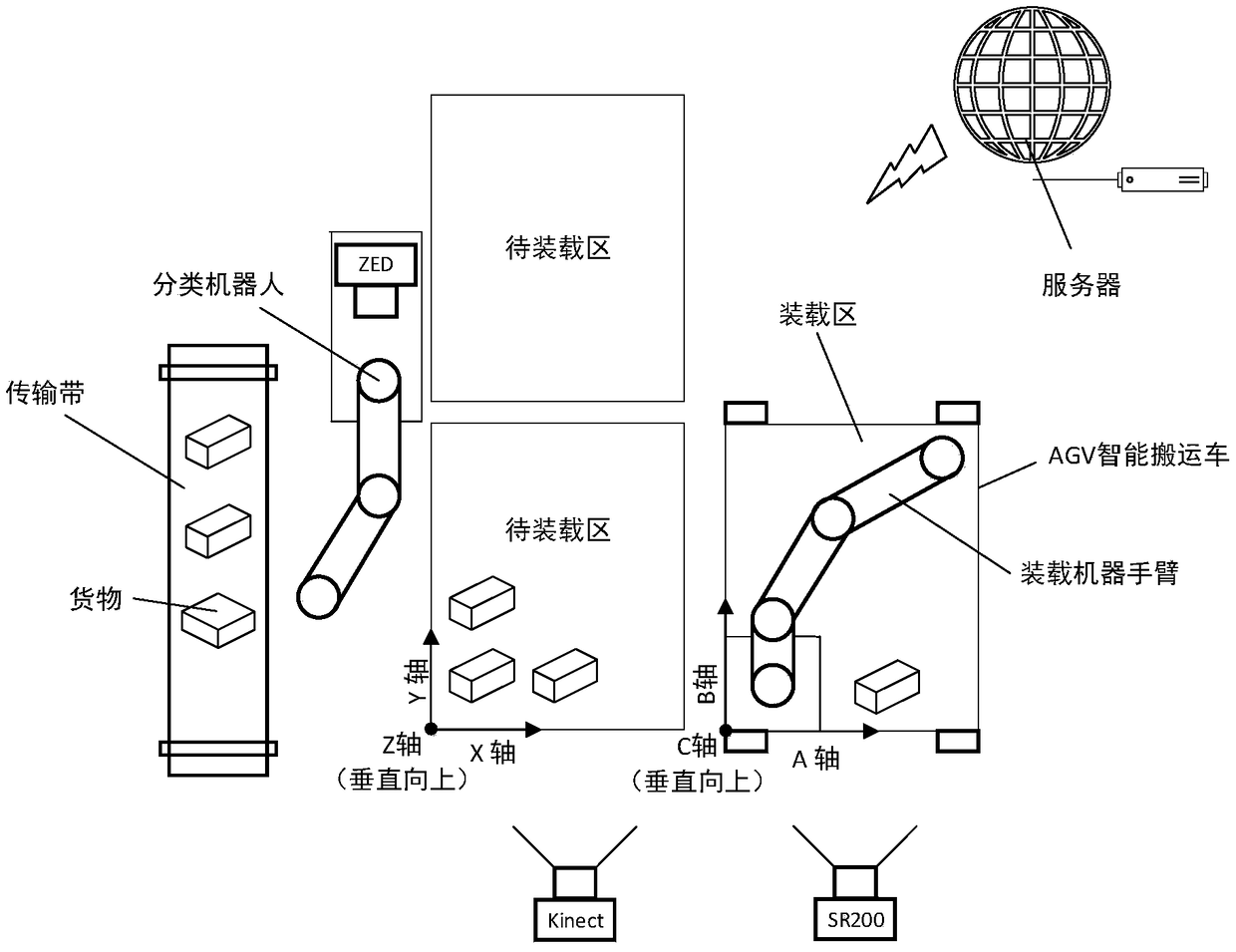

The invention discloses a loading method and device of an intelligent logistics environment robot. The method comprises the following steps that firstly, cargo information is acquired in real time; secondly, the coordinates of the placement positions of cargoes in to-be-loaded areas corresponding to conveying addresses are calculated; thirdly, a classification robot is utilized for clamping the cargoes to the corresponding to-be-loaded areas used for temporary storage from a conveying belt; fourthly, the coordinates of the final positions of the cargoes in loading areas of an AGV intelligent carrier; and fifthly, the cargoes are carried to the loading areas of the AGV intelligent carrier according to a control matrix obtained by an intelligent carrying control model. The cargo sizes, the cargo conveying addresses, the cargo position coordinates and other information are automatically acquired by combining machine vision, the classification robot and the intelligent carrier are utilizedfor automatically and intelligently classifying and loading the cargoes by setting up a neural network model, the loading error rate is greatly reduced, and the loading efficiency is improved.

Owner:CENT SOUTH UNIV

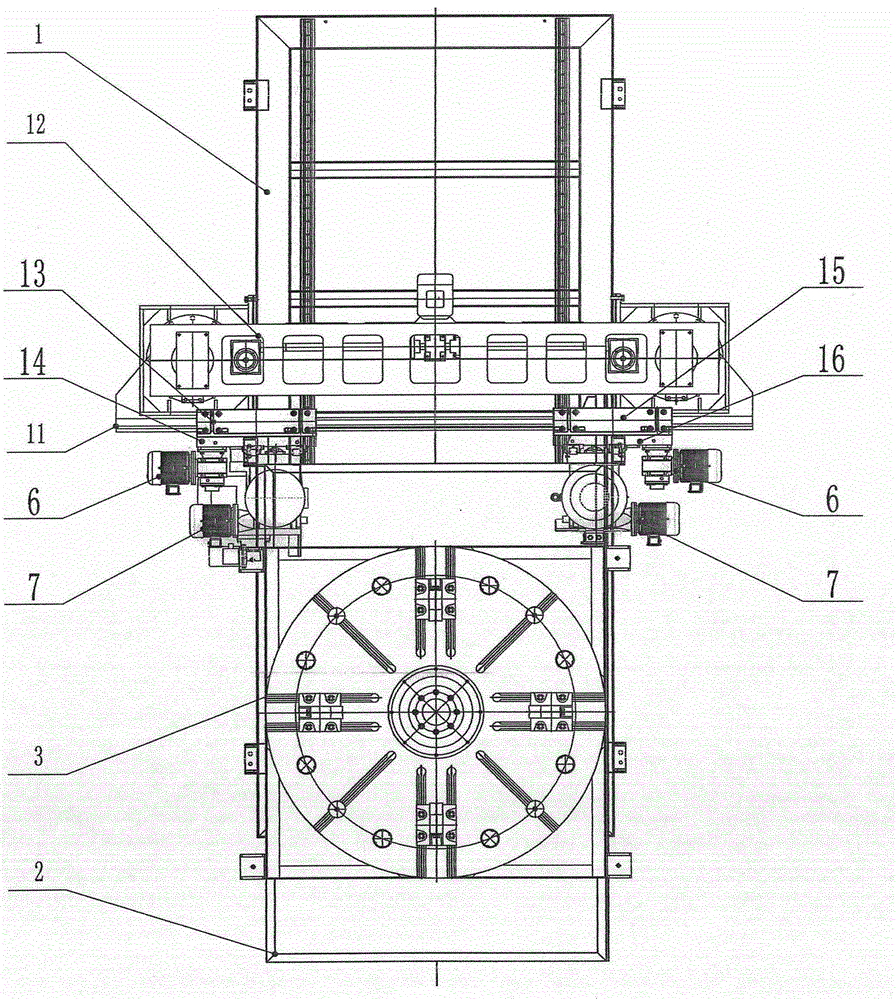

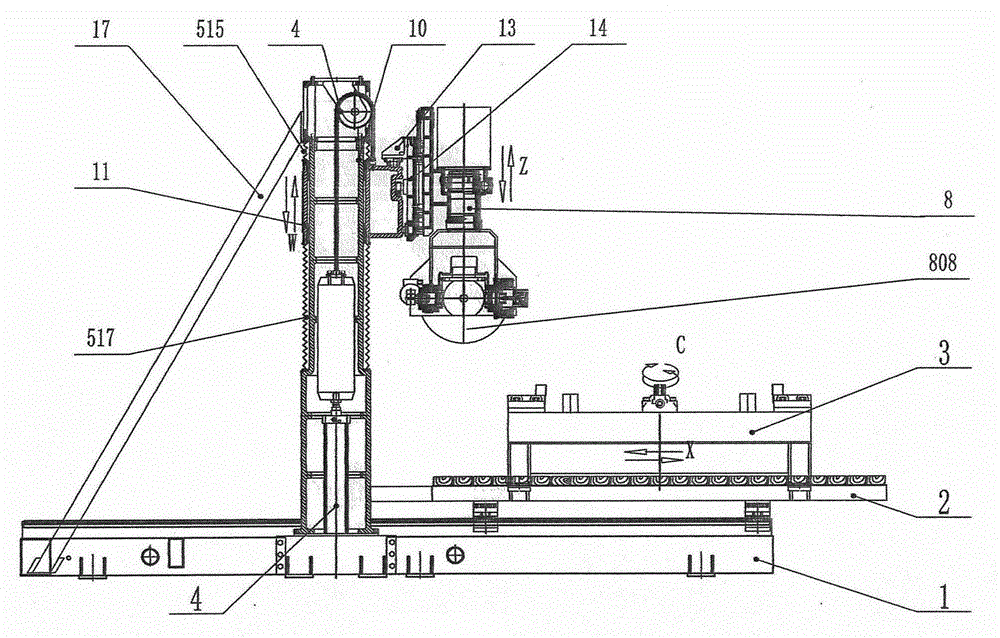

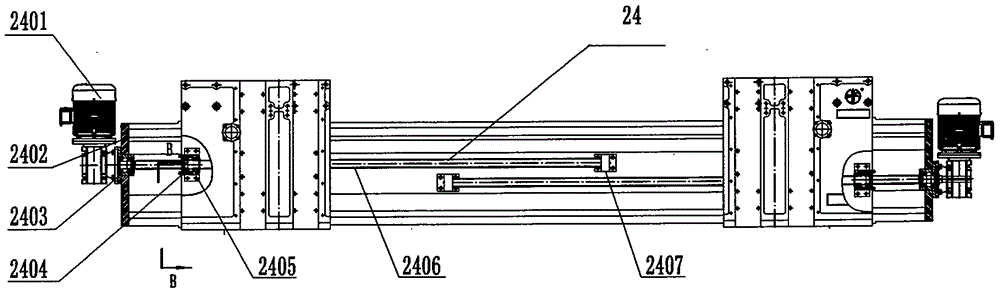

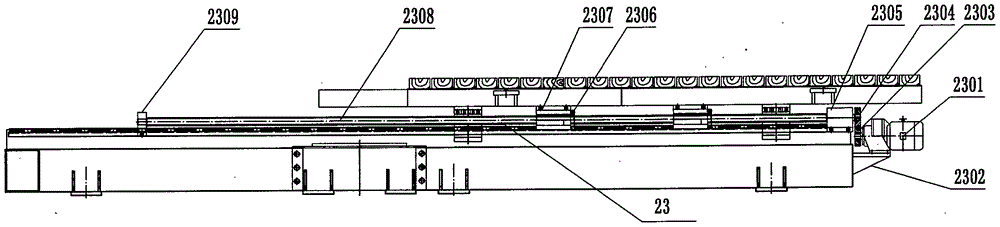

Gantry type double-blade multi-axis numerical control cutting-carving all-in-one machine

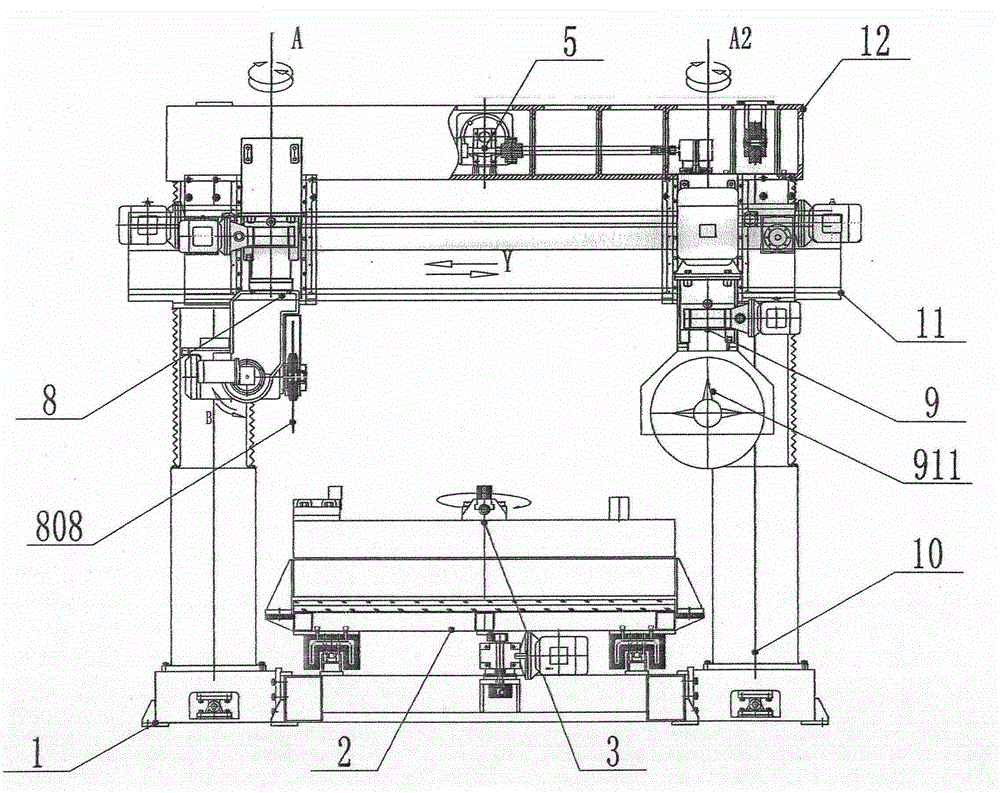

ActiveCN104924466ASimple structureQuality improvementWorking accessoriesStone-like material working toolsNumerical controlSlide plate

Provided is a gantry type double-blade multi-axis numerical control cutting-carving all-in-one machine, comprising a gantry structure of a main machine base, a stand columns and a top beam, and a cross beam, a translation workbench, and power head assemblies. The machine is characterized in that the number of the power head assemblies is two. A first power head assembly and a second power head assembly do rotary motion respectively through two same worm gear rotation executive devices, and are respectively connected with a left cross-shaped sliding plate and a right cross-shaped sliding plate through a linear guide rail pair, and are respectively driven by a hydraulic mechanism and are slidably cooperated up and down along the linear guide rail pair. The left cross-shaped sliding plate and the right cross-shaped sliding plate are arranged on two sides of the cross beam, and are slidably cooperated with the cross beam through a cross-shaped sliding plate drive device. The cross beam is slidably cooperated along the stand columns in an up-down manner through a cross beam elevating device which is arranged on the top beam. The translation workbench is hinged with an auxiliary rotary workbench. The auxiliary rotary workbench is cooperated with the translation workbench through an auxiliary rotary workbench shaft, and is locked by a locking device. Single machine can complete all processes, and can complete a plurality of processes by one-time assembling. The machine is high in processing precision and high in work efficiency.

Owner:蔡崇友

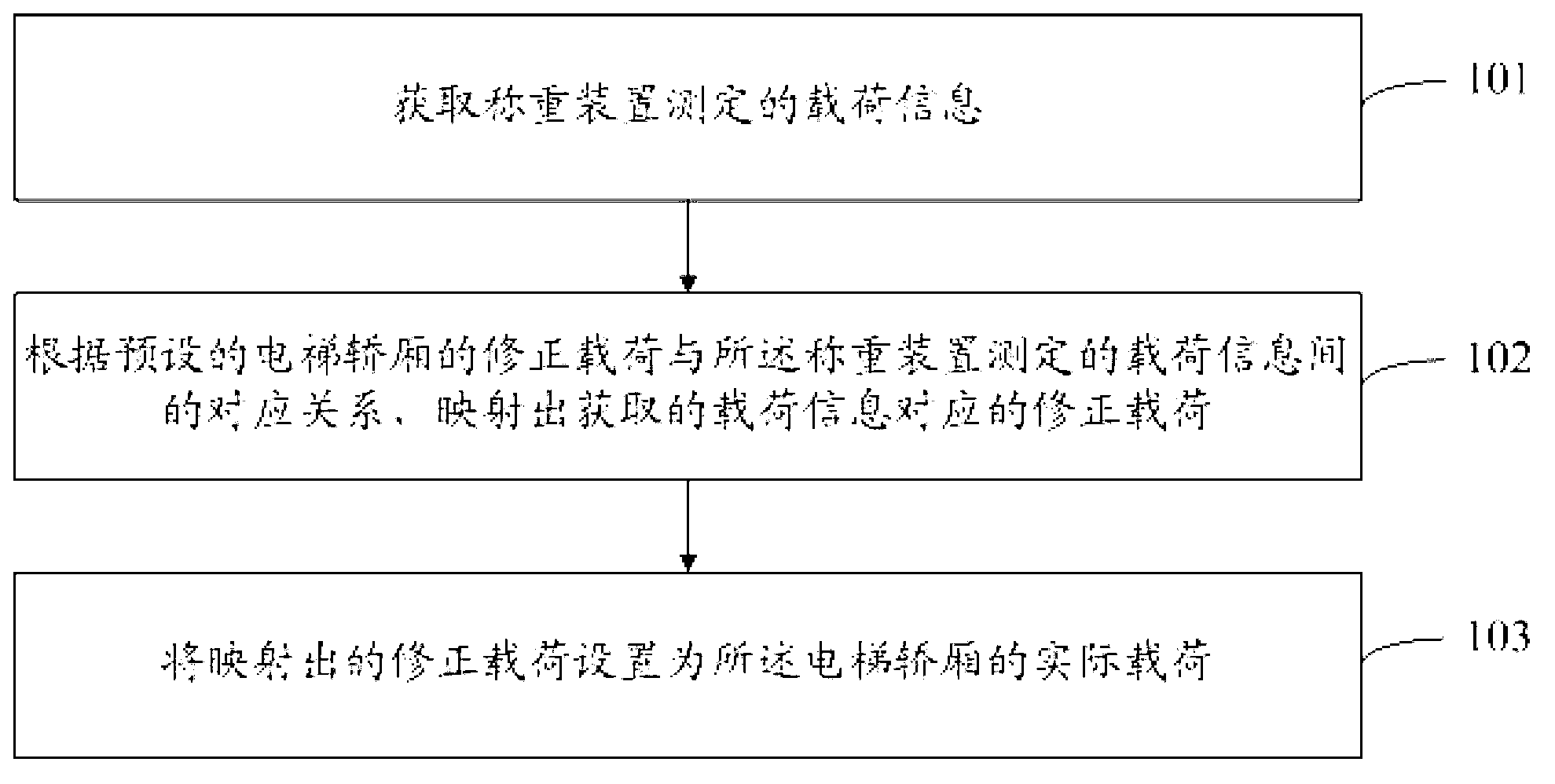

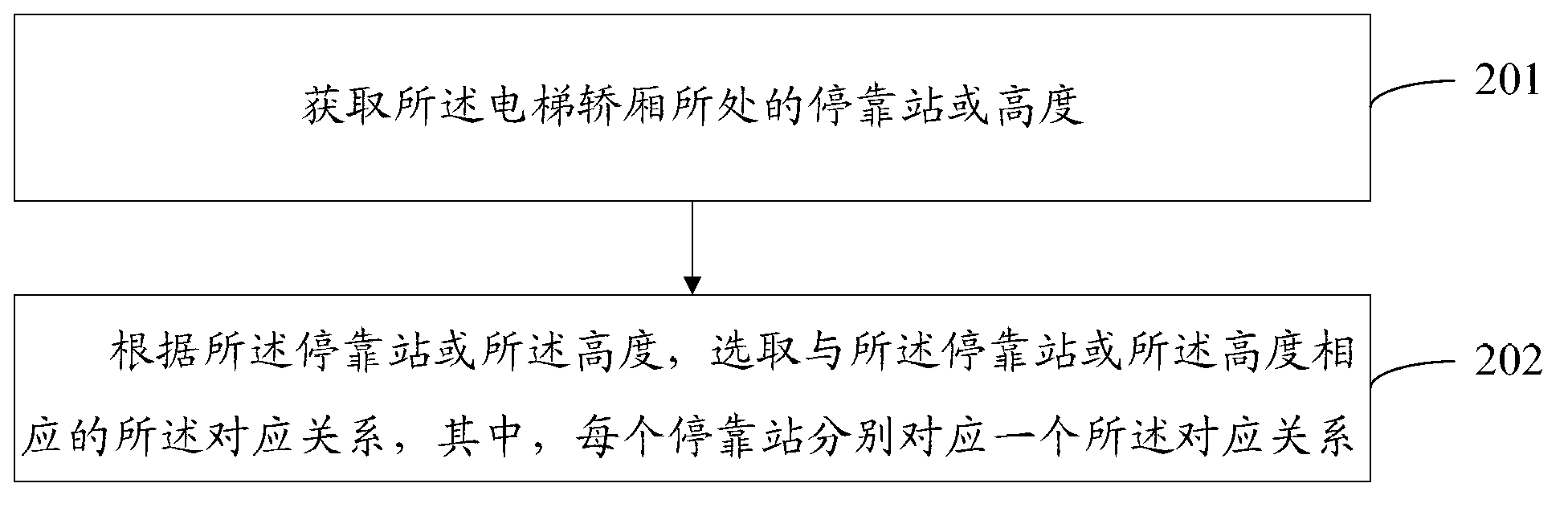

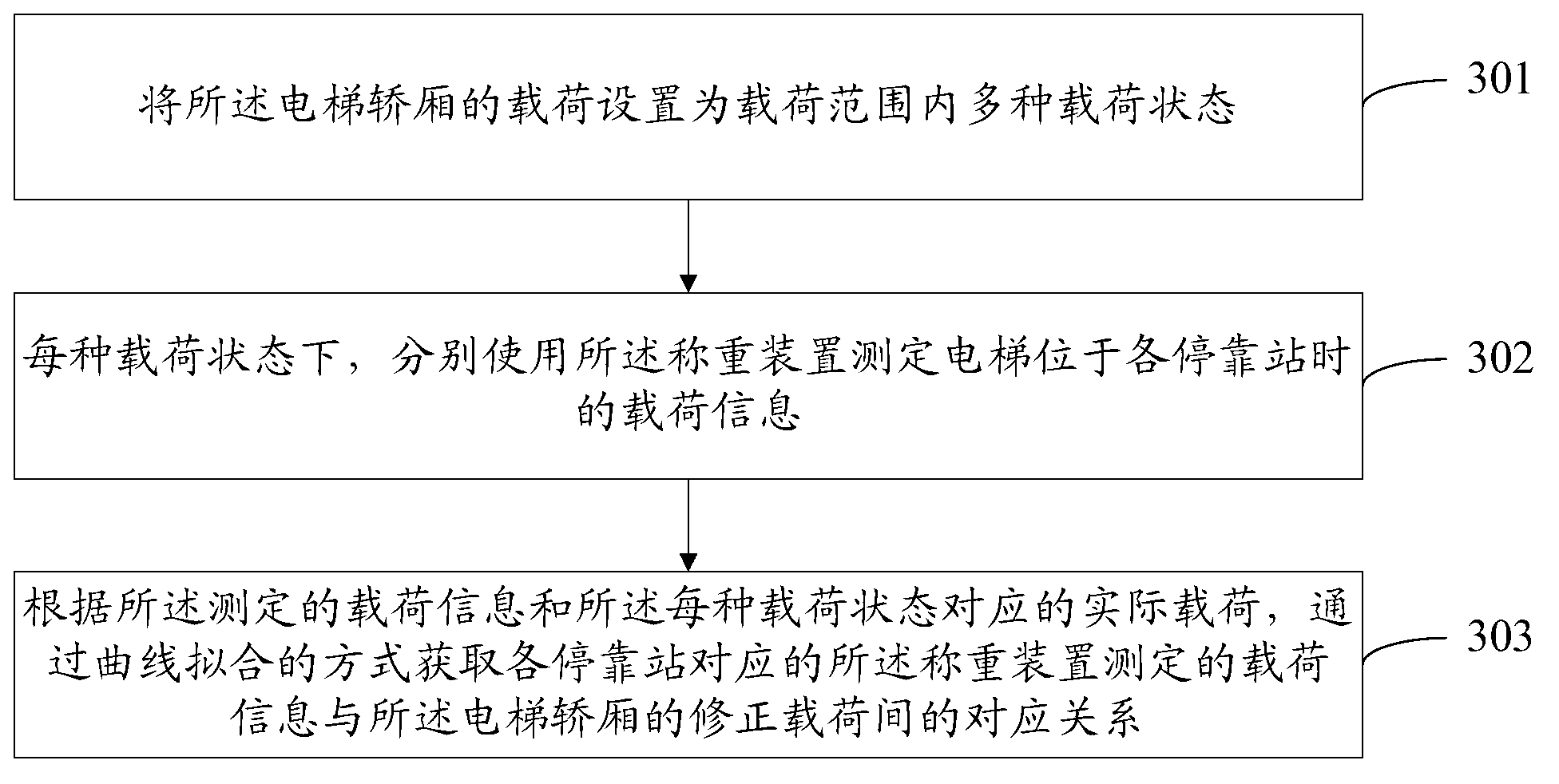

Method and system for acquiring elevator loads

The invention discloses a method and system for acquiring elevator loads. The method comprises the following steps that load information measured by a weighing device is acquired; revised loads corresponding to acquired load information are mapped out according to corresponding relations of prearranged revised loads of an elevator car and the load information measured by the weighing device; the revised loads which are mapped out are set as actual loads of the elevator car. The method and system for acquiring the elevator loads can effectively reduce load errors caused by the defective workmanship of an elevator and provides an accurate load basis for operations such as starting torque placing or giving of all kinds of replying orders of the elevator.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

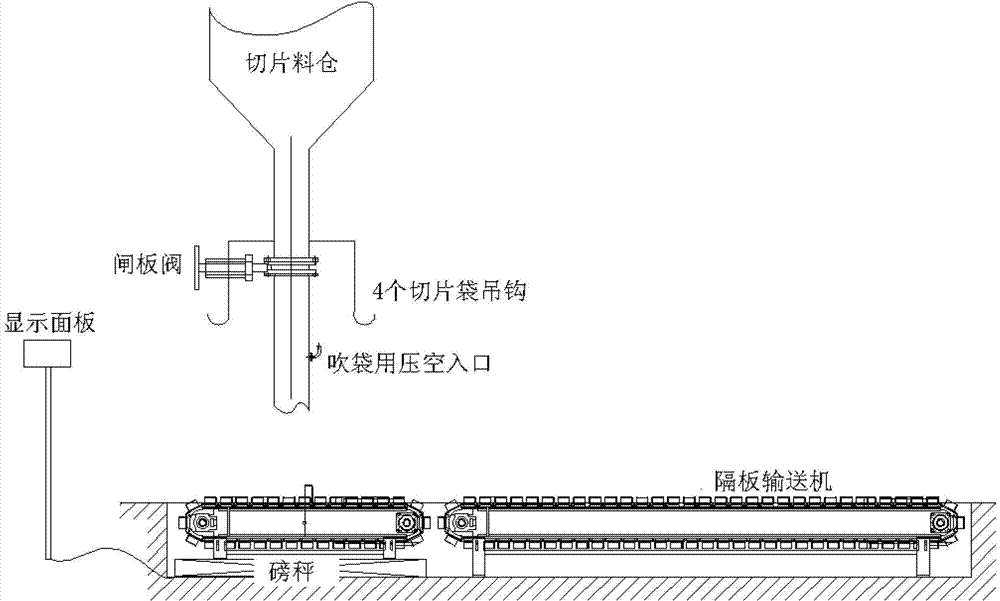

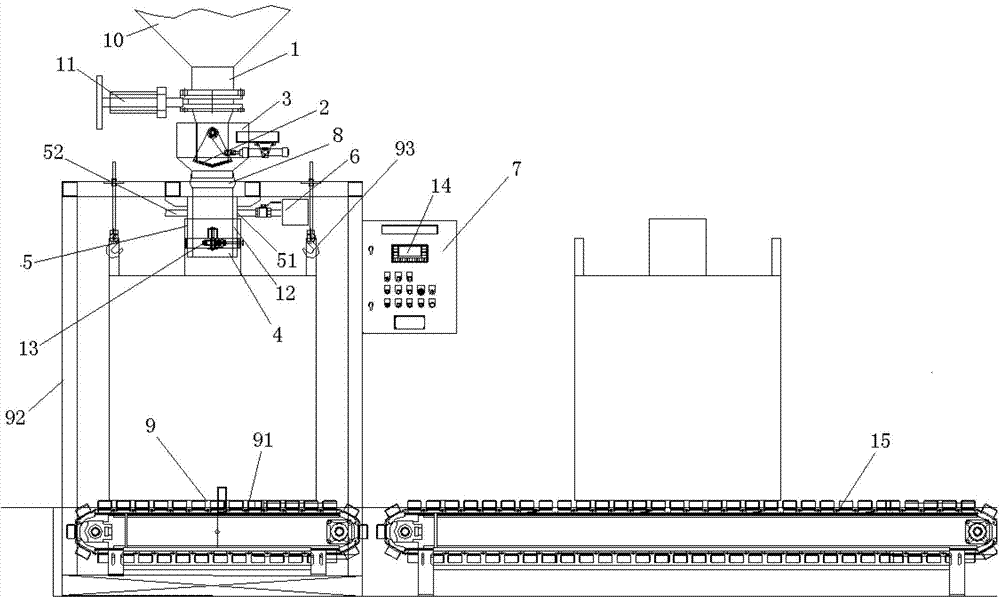

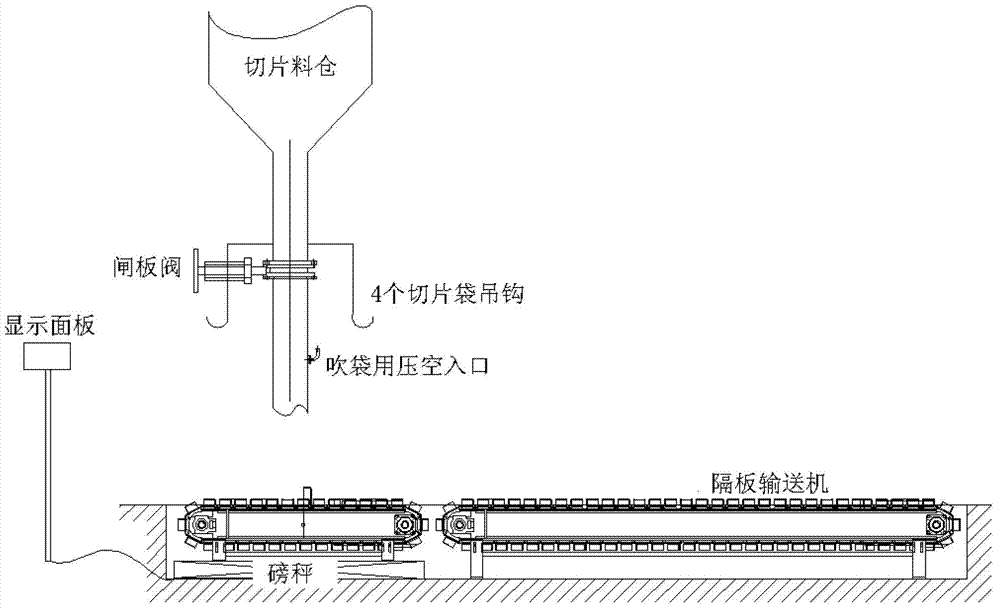

Packer for polyester chips

InactiveCN102765498AReduce labor intensityControl the blanking speedWrapper twisting/gatheringSolid materialPolyesterEngineering

A packer for polyester chips comprises a feeding pipe, a fan-shaped valve plate, a discharging hopper, a blanking pipe, a sleeve, an air blowing device and a control device, wherein the lower end of the feeding pipe is in an arc shape, the fan-shaped valve plate is installed at the lower portion of the feeding pipe in a shaft mode, and a valve plate surface of the fan-shaped valve plate is matched with the lower end of the feeding pipe. The discharging hopper is arranged below the feeding pipe and the fan-shaped valve plate, the blanking pipe is connected onto the discharging hopper through a flexible connection sleeve, the upper end of the sleeve is fixedly connected outside the blanking pipe, and a cavity with upper end sealed and lower end opened is formed by the sleeve and the outer wall of the blanking pipe. The sleeve is further provided with an air inlet and an exhaust device, the air blowing device is connected with the air inlet, and the control device is connected with the fan-shaped valve plate, the air blowing device and the exhaust device.

Owner:JIANGSU CHALLEN FIBER S&T

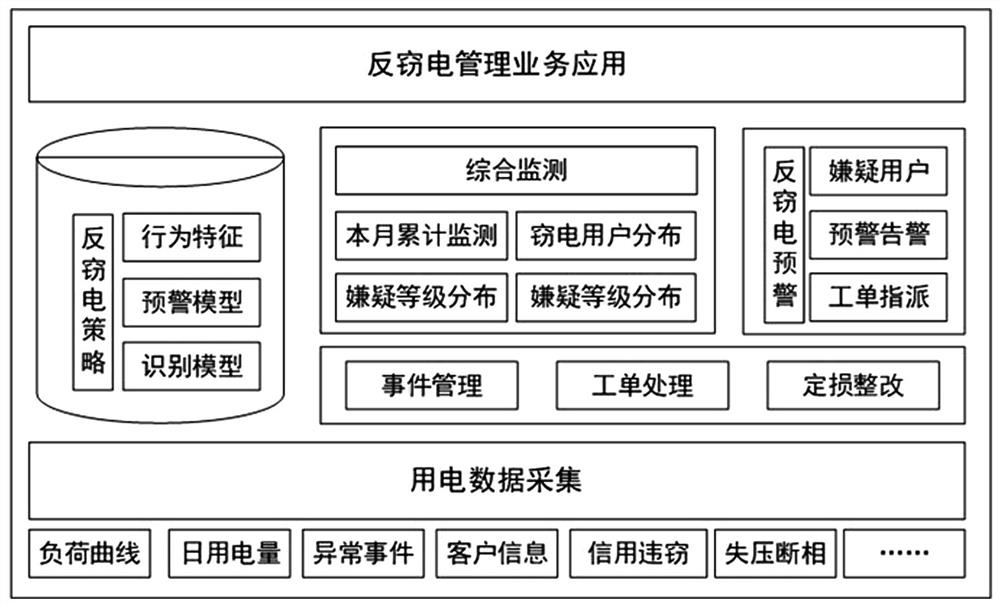

Electricity stealing prevention monitoring method and system based on electricity utilization big data

PendingCN113484572AGuaranteed analysis resultsScientifically effective and accurate identificationTime integral measurementData acquisitionPower usage

The invention belongs to the technical field of electricity stealing monitoring of power grid monitoring, and particularly relates to an electricity stealing prevention monitoring method and system based on electricity utilization big data. The system comprises a power utilization data acquisition module, an anti-electricity-stealing strategy management module, a comprehensive monitoring module, an anti-electricity-stealing abnormal early warning module, an event management module and a loss assessment rectification service module. According to the invention, the suspected electricity stealing user can be scientifically, effectively and accurately identified, the accuracy, comprehensiveness, timeliness and reliability of electricity stealing detection are improved, and the detection cost is reduced; and through double analysis of electric power business application data and electric energy information acquisition data, various data are summarized, a scientific and accurate data analysis model is established, a system monitors and screens a metering device and line loss of each level in real time on line, and positions suspected electricity stealing users, intelligent analysis and diagnosis are carried out, and abnormal problem data are alarmed, so that a more efficient and intelligent technical means is provided for preventing electricity stealing, reducing line loss and increasing power supply, and the electricity stealing behavior is effectively prevented and attacked.

Owner:国网吉林省电力有限公司信息通信公司

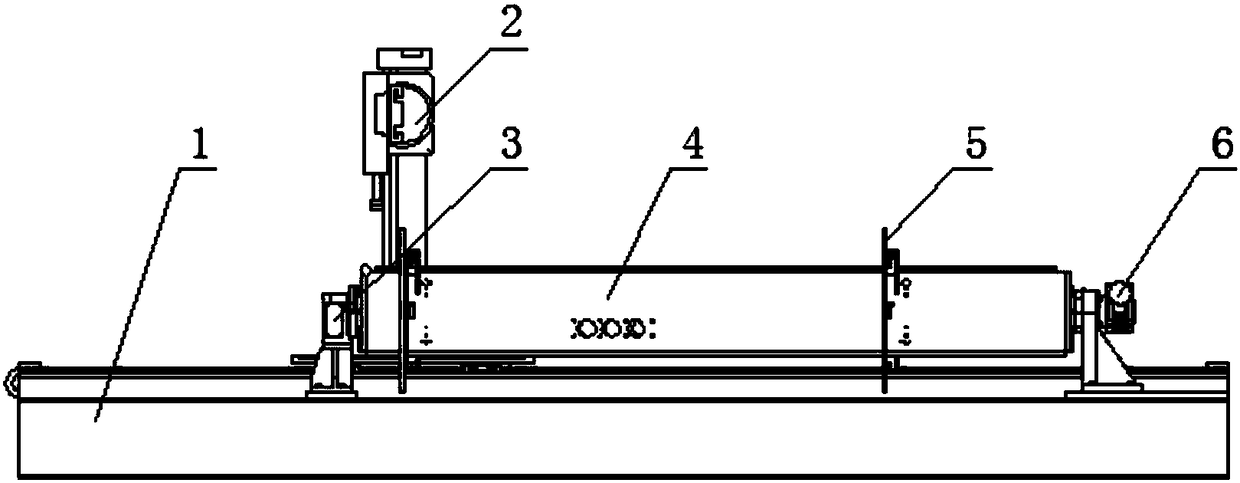

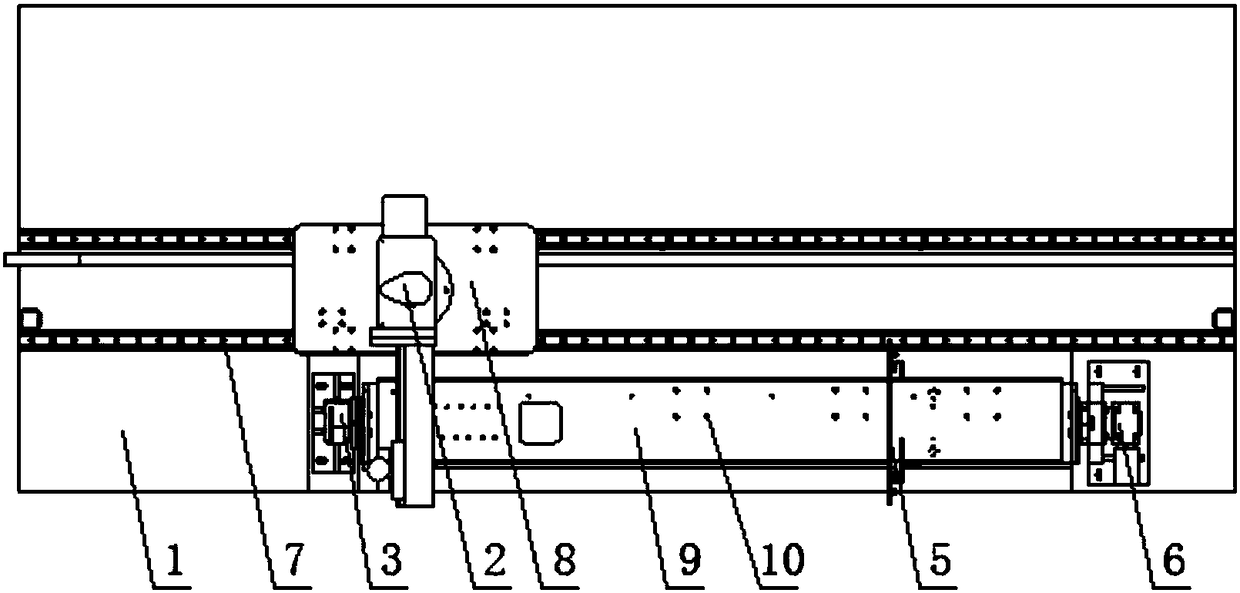

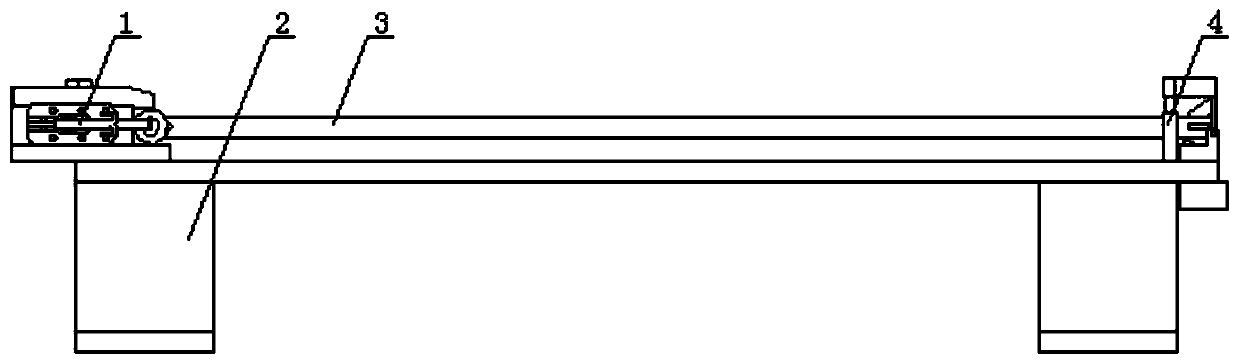

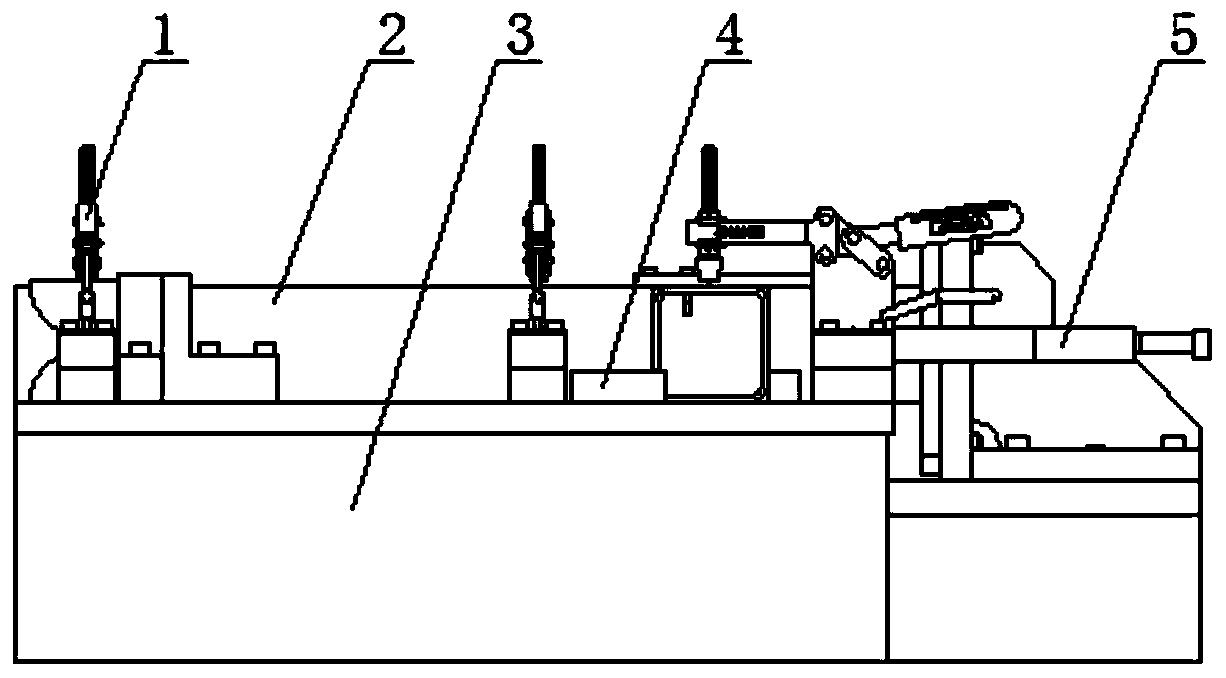

Wind generating set bracket drilling device

InactiveCN108237246AEnsure processing standardizationHigh speedPositioning apparatusMetal-working holdersReducerWorkload

The invention relates to a wind generating set bracket drilling device. The wind generating set bracket drilling device comprises a base, a radial drilling machine, a tailstock and a motor reducer assembly; a guide rail is installed at the rear end of the upper surface of the base, a sliding table is mounted on the guide rail, and the radial drilling machine is mounted on the sliding table; and the tailstock and the motor reducer assembly are mounted on the base at the front end of the guide rail, a fixed mould is rotatably mounted between the tailstock and the motor reducer assembly, a dismountable mould is installed on the fixed mould in a buckled mode, and multiple drill jigs are mounted both on the fixed mould and the dismountable mould. The wind generating set bracket drilling deviceis reasonable in design, simple in structure, convenient to operate and high in specificity, by using the device, machining of four surfaces of a workpiece can be completed in one clamping condition,therefore the working process is simplified, the workload is reduced, the production efficiency is improved, and the machining quality is guaranteed, and finally the product qualification rate is improved and the production cost of an enterprise is reduced.

Owner:TIANJIN JINLAI PRECISION MACHINERY

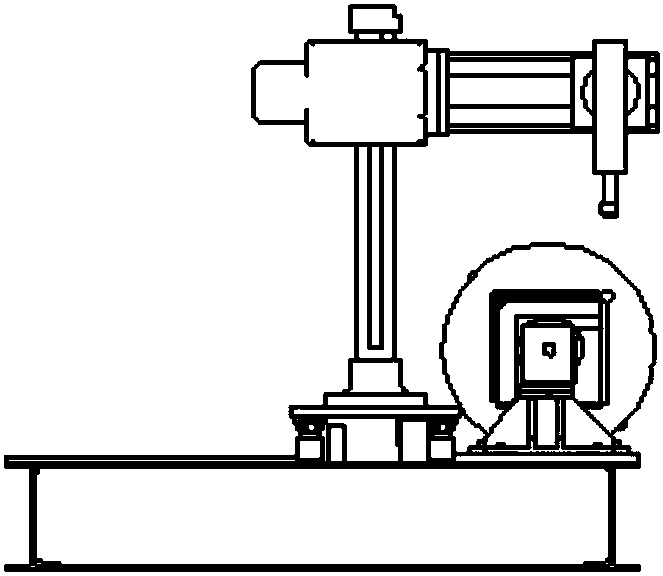

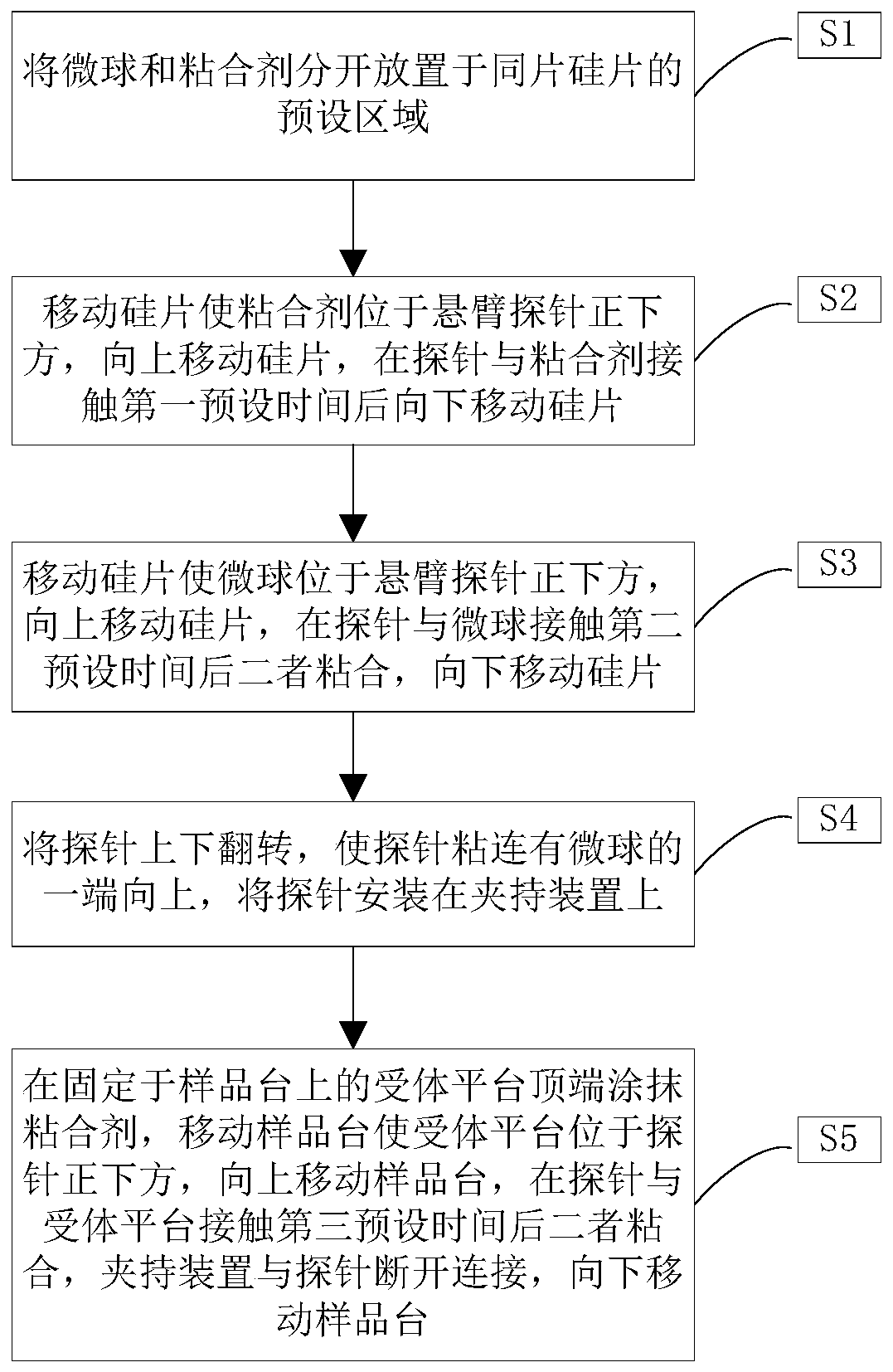

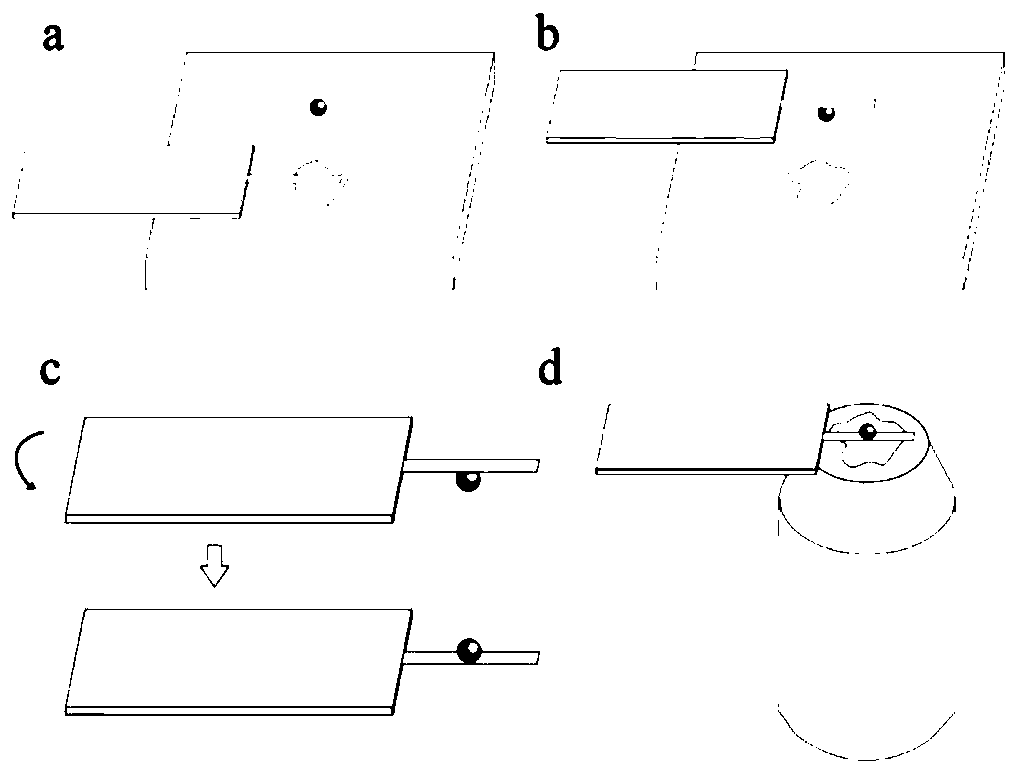

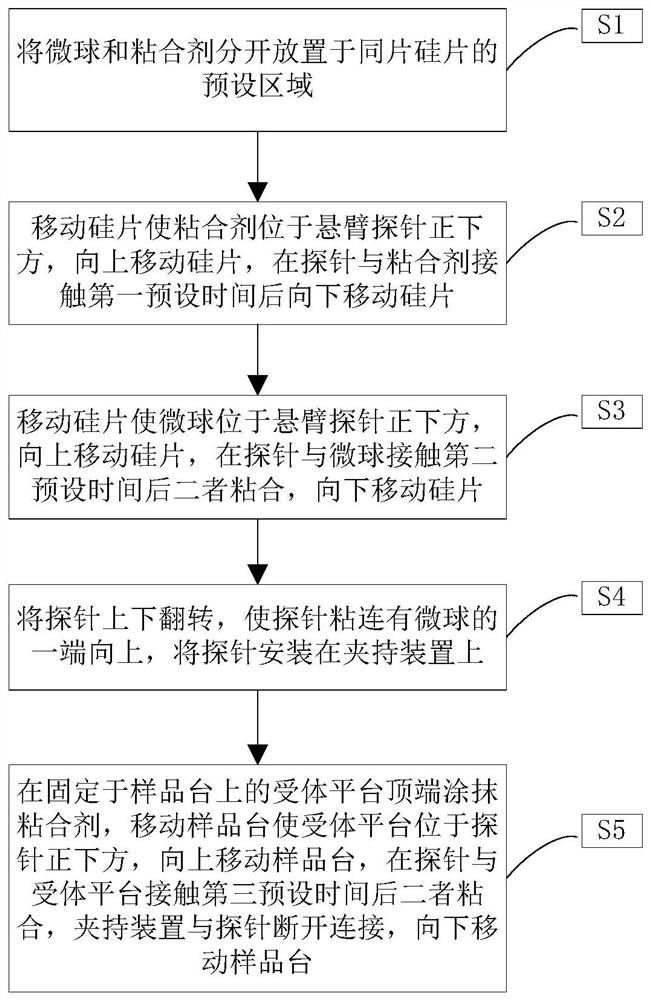

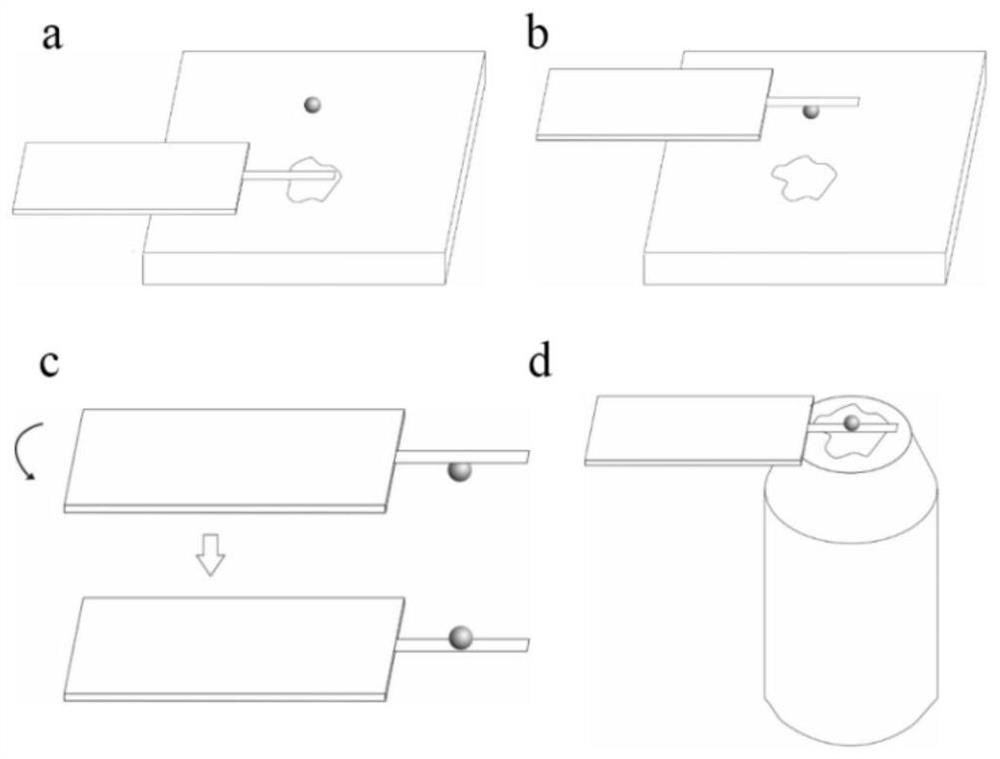

Microsphere probe preparation method based on micro-cantilever transfer

ActiveCN110155938APrecise positioningFlexible bondingPrecision positioning equipmentSoldering apparatusMicro nanoContact pressure

The invention provides a microsphere probe preparation method based on micro-cantilever transfer, and belongs to the technical field of micro-nano manufacturing. The preparation method is simple in process and low in cost, and can be used for preparing the microsphere probe for testing micro-nano processing or indentation mechanical properties and the like; flexible bonding of any granular material can be realized, and any granular material can be randomly matched with any receptor platform; the cantilever can serve as a transfer layer while transferring the microspheres, so that the contact area of the microspheres and the receptor platform is increased, and the contact pressure is further reduced to reduce the deformation of the receptor platform; accurate positioning of the microspheresat the tip of the receptor in the probe preparation process can be achieved through the micro-cantilever, and the situation that the small-size microspheres are completely soaked into glue and pollute the surface of the microsphere probe in the bonding process can be avoided.

Owner:SOUTHWEST JIAOTONG UNIV

Gantry double-knife multi-axis CNC cutting and carving machine

ActiveCN104924466BSimple structureQuality improvementWorking accessoriesStone-like material working toolsNumerical controlEngineering

Provided is a gantry type double-blade multi-axis numerical control cutting-carving all-in-one machine, comprising a gantry structure of a main machine base, a stand columns and a top beam, and a cross beam, a translation workbench, and power head assemblies. The machine is characterized in that the number of the power head assemblies is two. A first power head assembly and a second power head assembly do rotary motion respectively through two same worm gear rotation executive devices, and are respectively connected with a left cross-shaped sliding plate and a right cross-shaped sliding plate through a linear guide rail pair, and are respectively driven by a hydraulic mechanism and are slidably cooperated up and down along the linear guide rail pair. The left cross-shaped sliding plate and the right cross-shaped sliding plate are arranged on two sides of the cross beam, and are slidably cooperated with the cross beam through a cross-shaped sliding plate drive device. The cross beam is slidably cooperated along the stand columns in an up-down manner through a cross beam elevating device which is arranged on the top beam. The translation workbench is hinged with an auxiliary rotary workbench. The auxiliary rotary workbench is cooperated with the translation workbench through an auxiliary rotary workbench shaft, and is locked by a locking device. Single machine can complete all processes, and can complete a plurality of processes by one-time assembling. The machine is high in processing precision and high in work efficiency.

Owner:蔡崇友

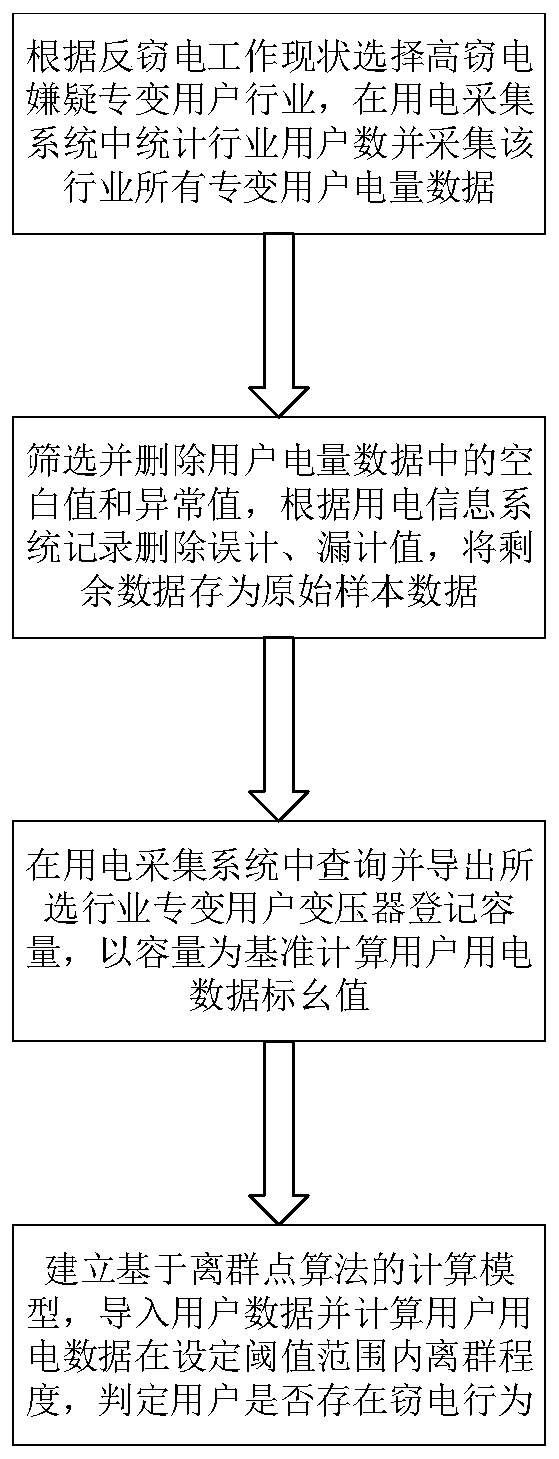

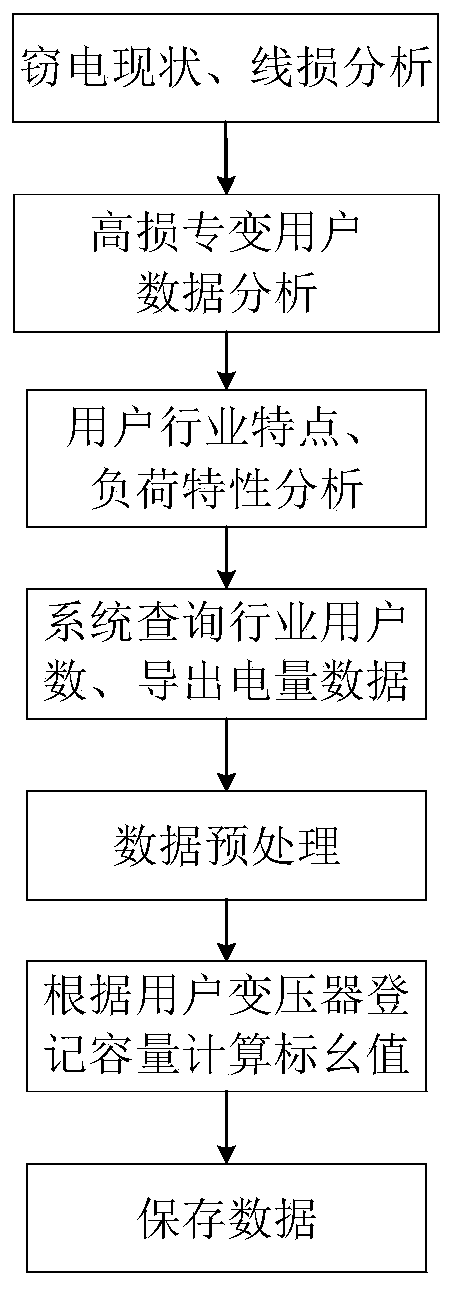

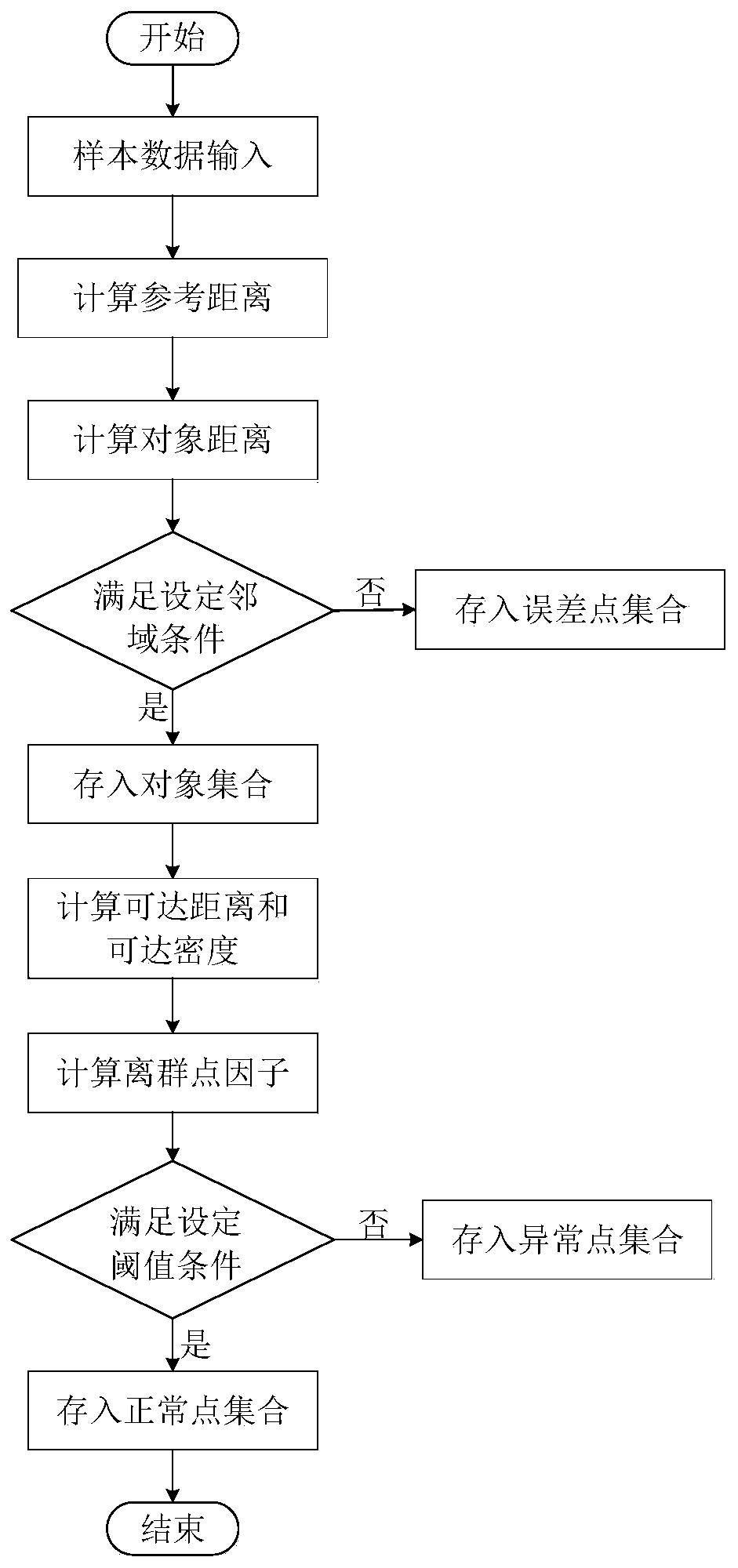

Electricity theft user analysis method based on electricity acquisition system and outlier algorithm

PendingCN110738415AGuaranteed analysis resultsScientifically effective and accurate identificationResourcesTransformerPower usage

The invention relates to an electricity theft user analysis method based on an electricity acquisition system and an outlier algorithm. The method belongs to the field of power consumer data analysis,and comprises the following steps: step 1, selecting a high-electricity-larceny suspected special transformer consumer industry according to the current electricity-theft-preventing working situation, counting the number of industry consumers in an electricity utilization acquisition system, and acquiring electric quantity data of all special transformer consumers in the industry; step 2, preprocessing the data, screening and deleting blank values and abnormal values in the user electric quantity data, deleting miscounting and missing counting values according to records of an electricity consumption information system, and storing residual data as original sample data; step 3, inquiring and exporting the registered capacity of the transformer of the selected industry special transformeruser in the power utilization acquisition system, and calculating the per unit value of the user power utilization data by taking the capacity as the reference; and step 4, establishing a calculationmodel based on an outlier algorithm, importing the user data, calculating the outlier degree of the power utilization data of the user in a set threshold range, and judging whether the user has an electricity theft behavior.

Owner:JINZHONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +1

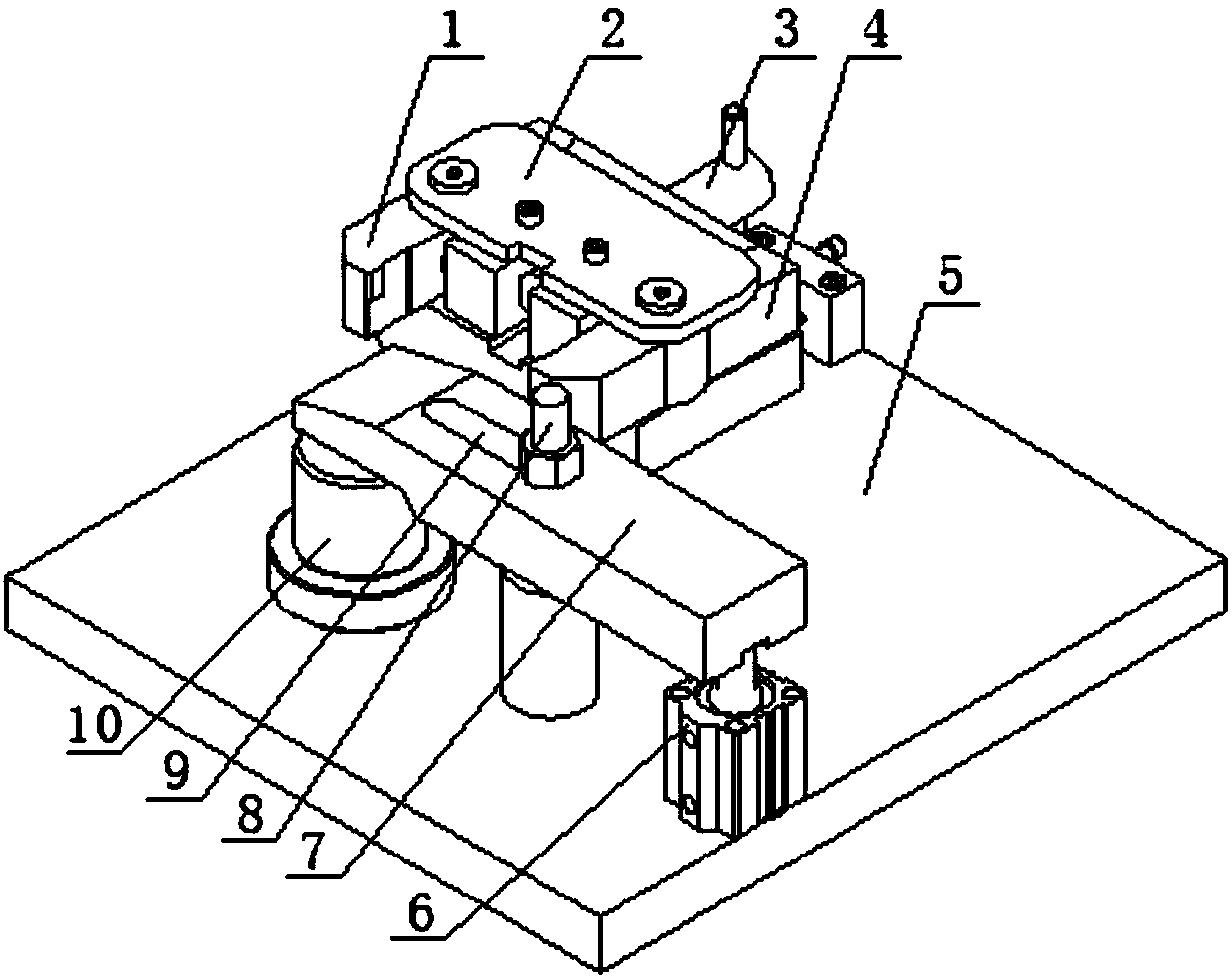

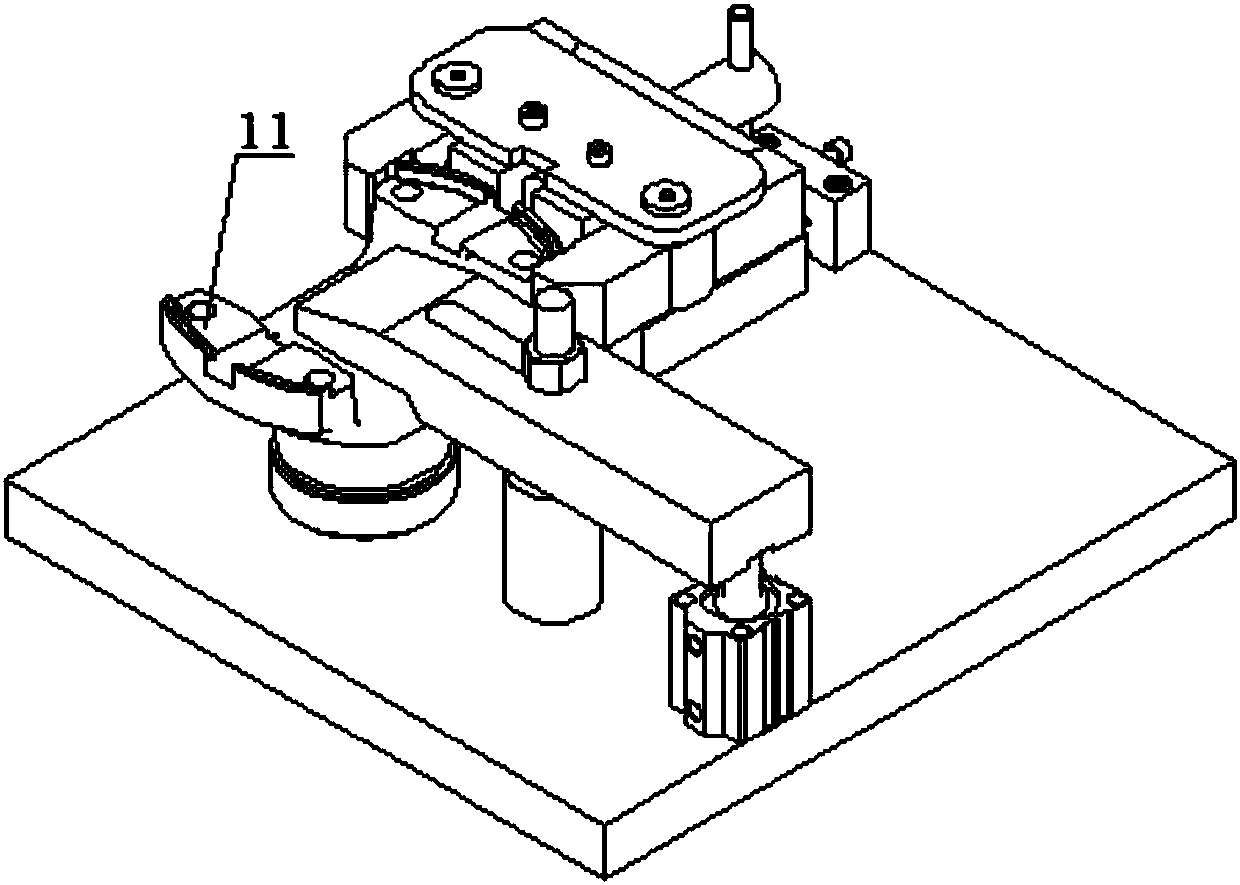

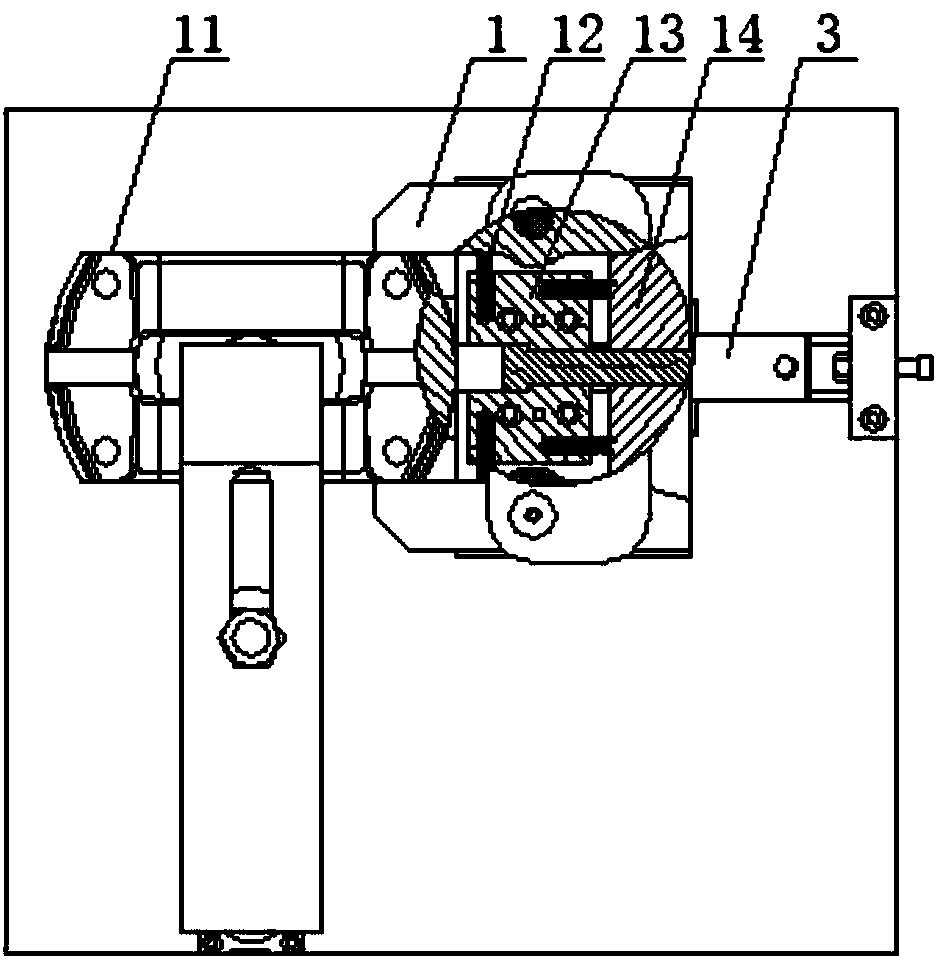

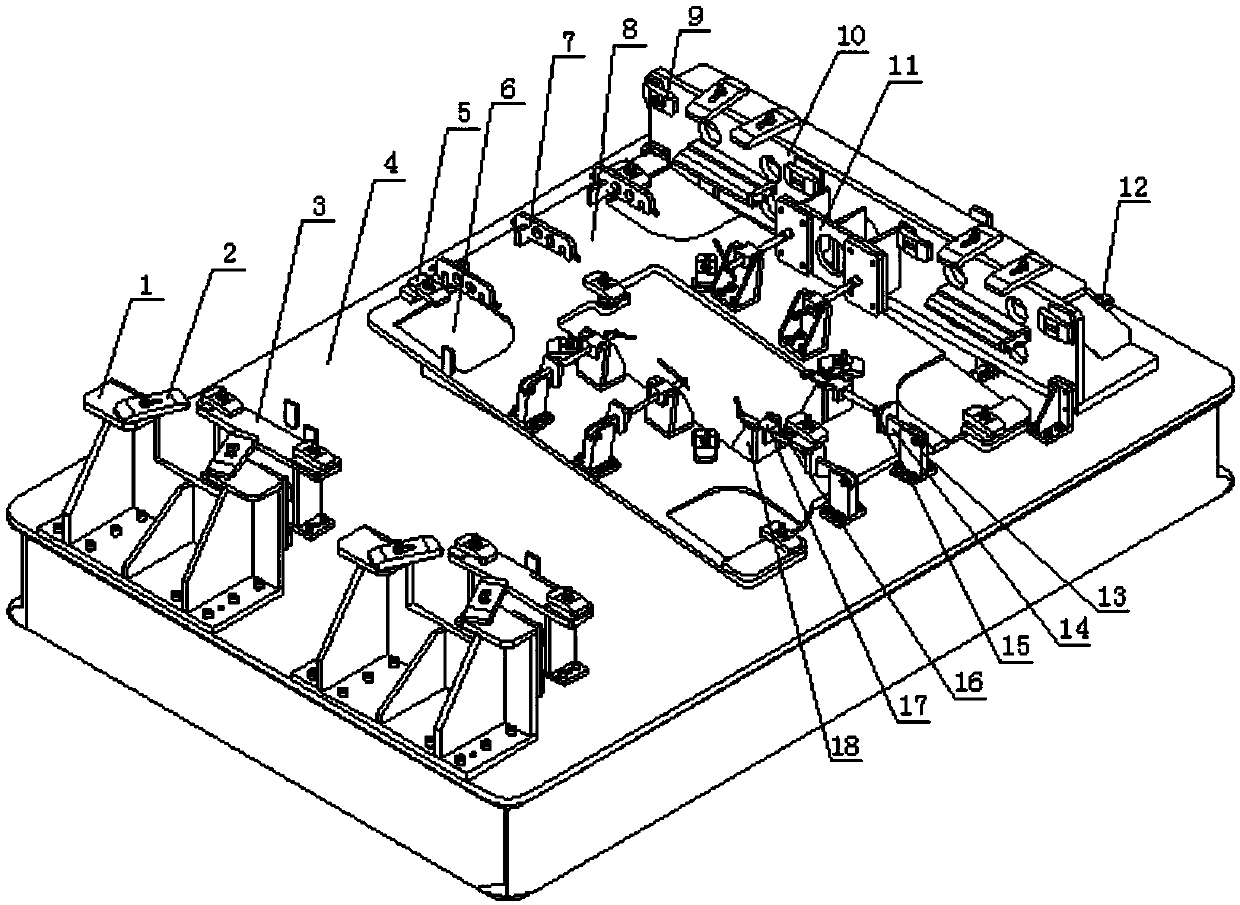

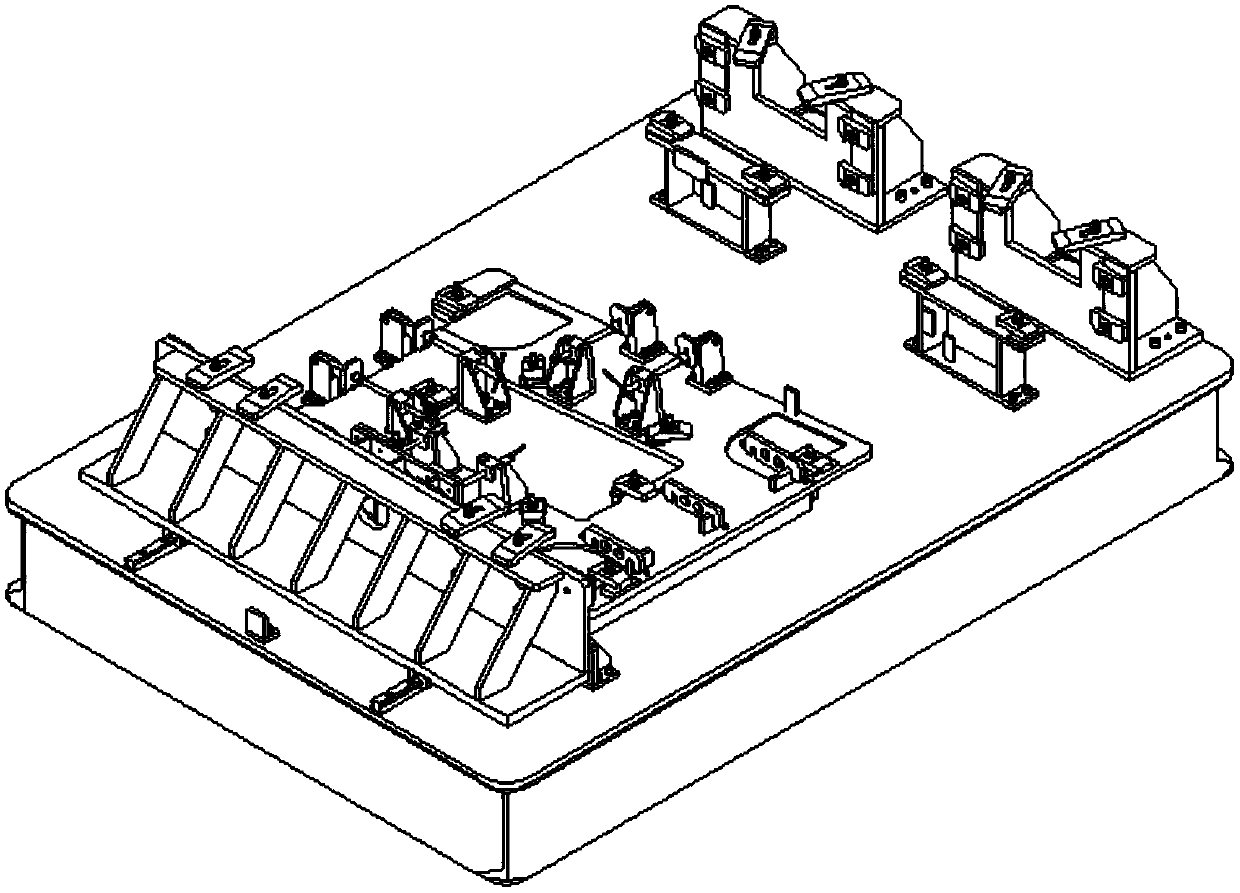

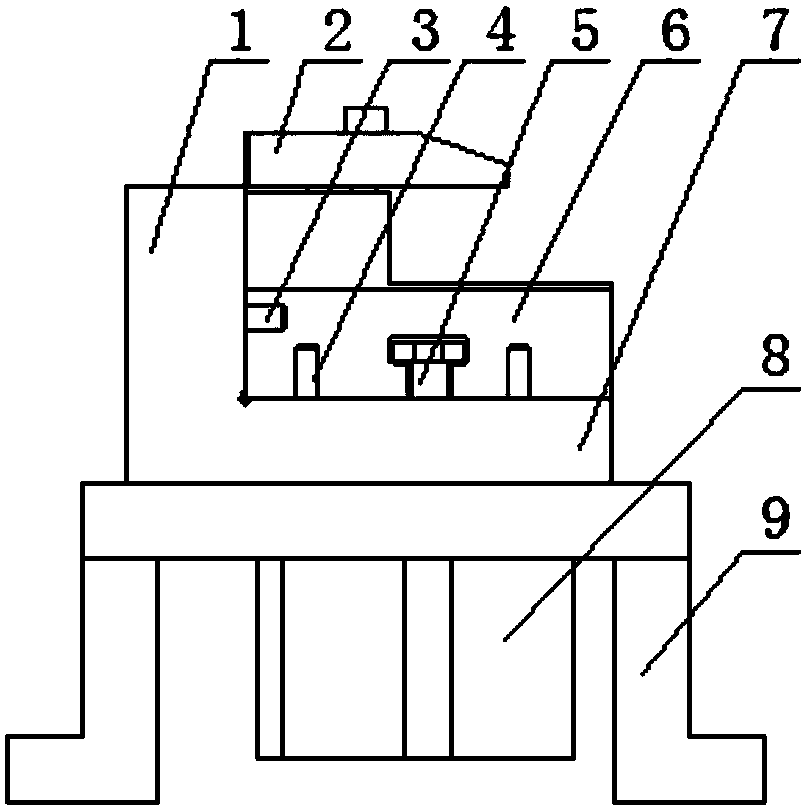

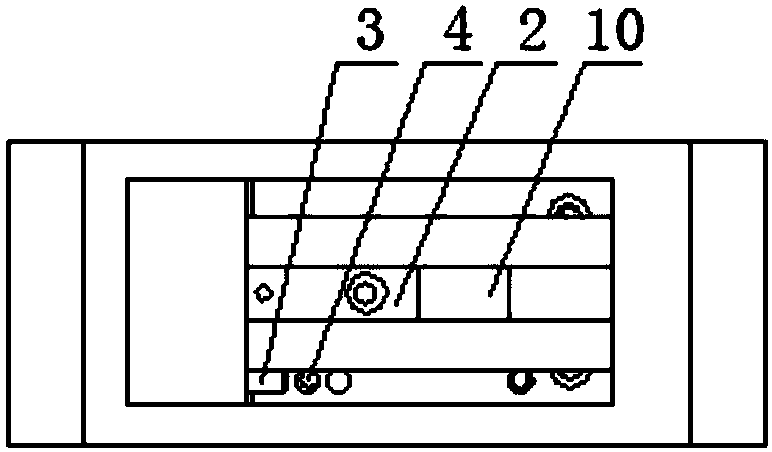

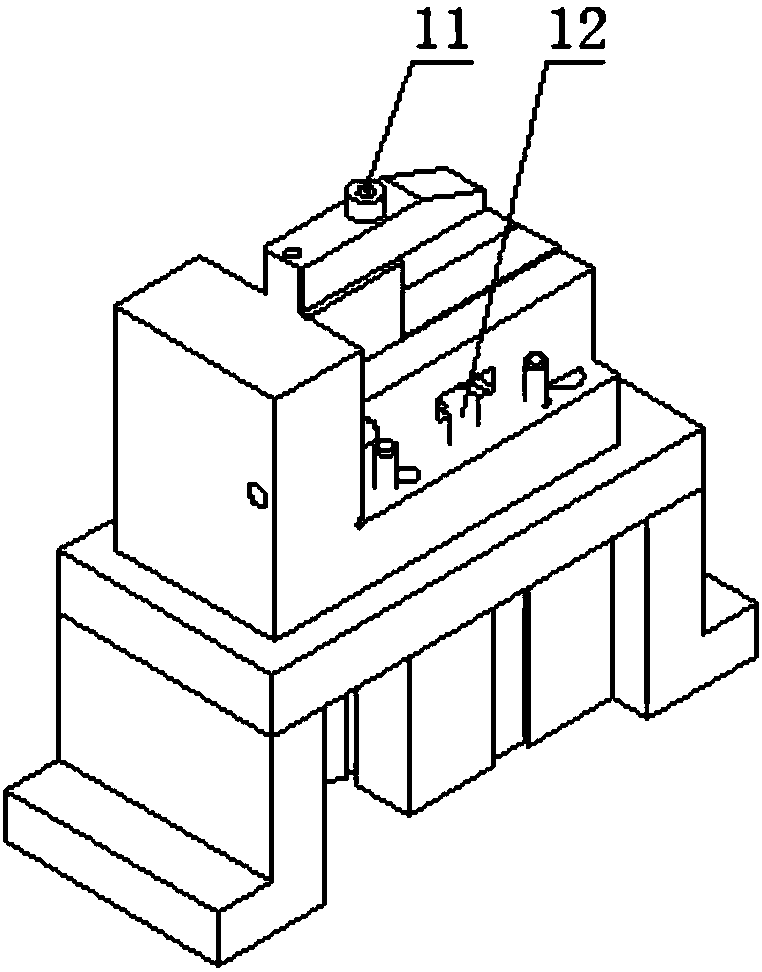

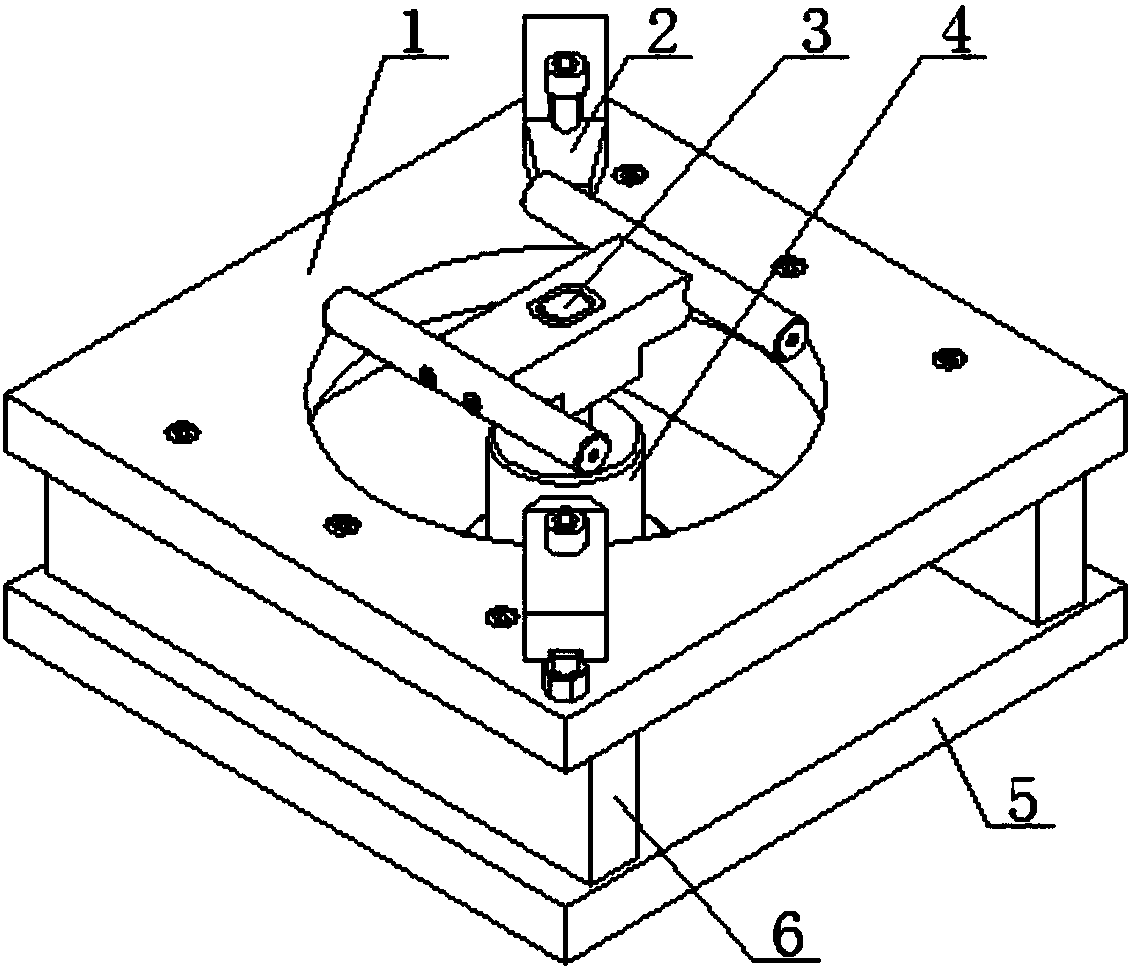

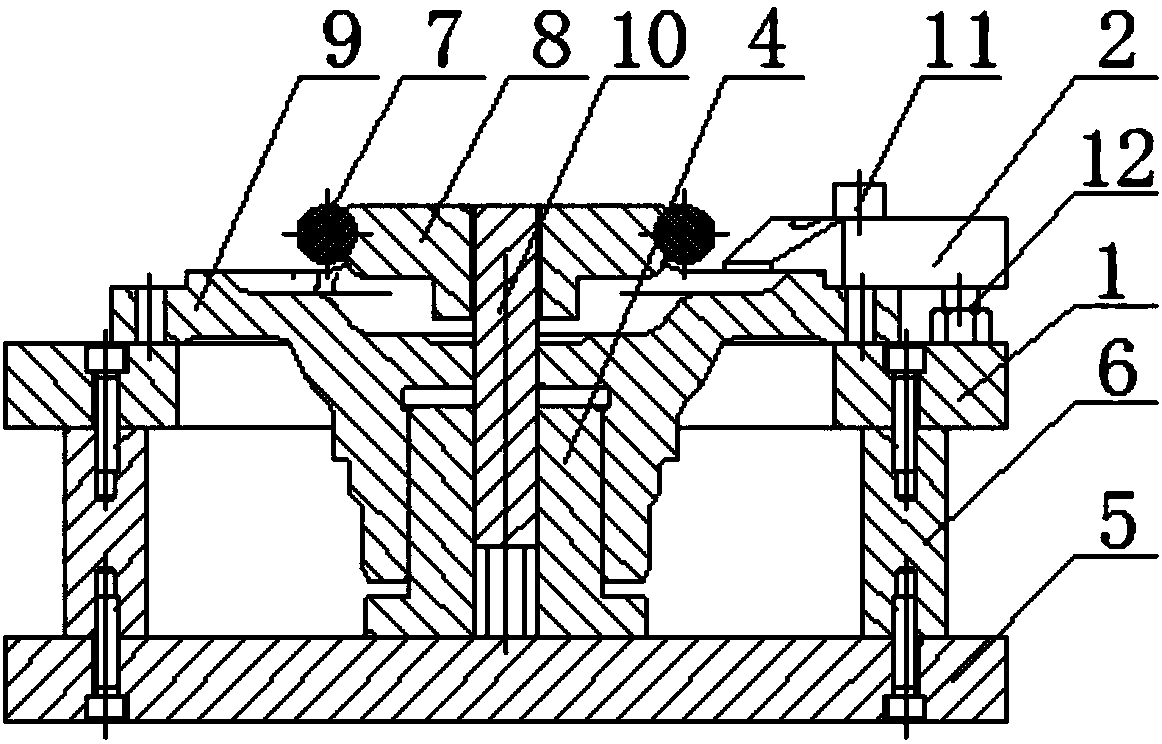

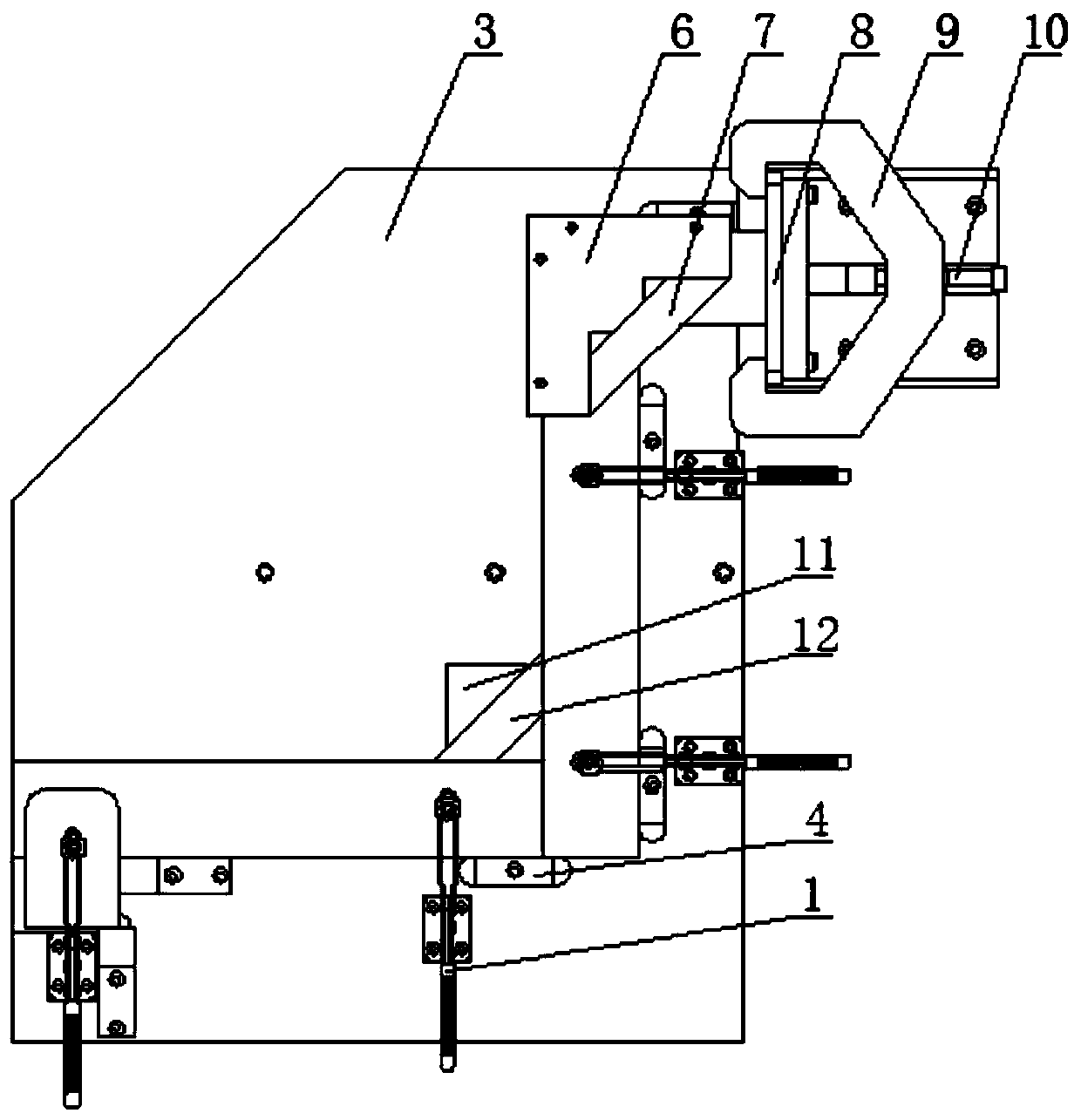

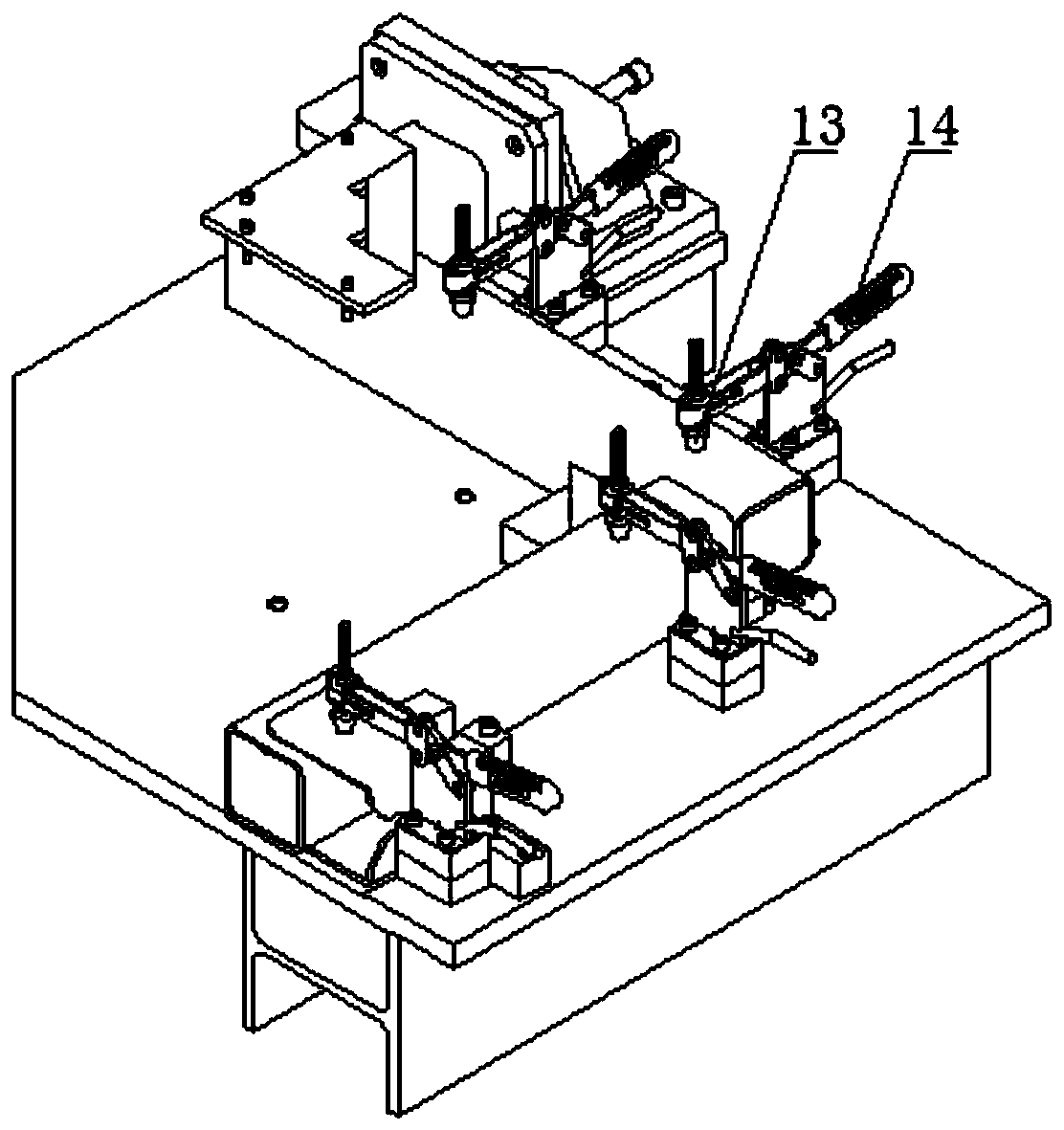

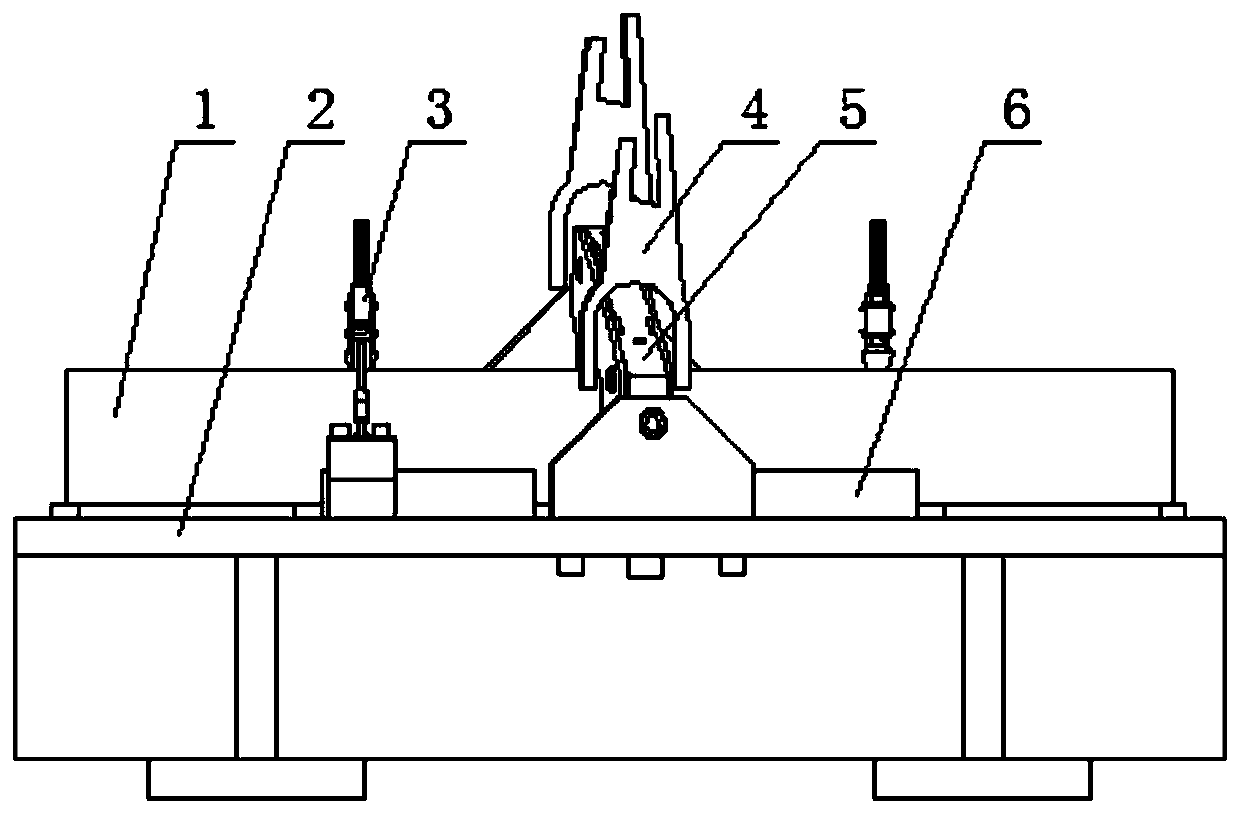

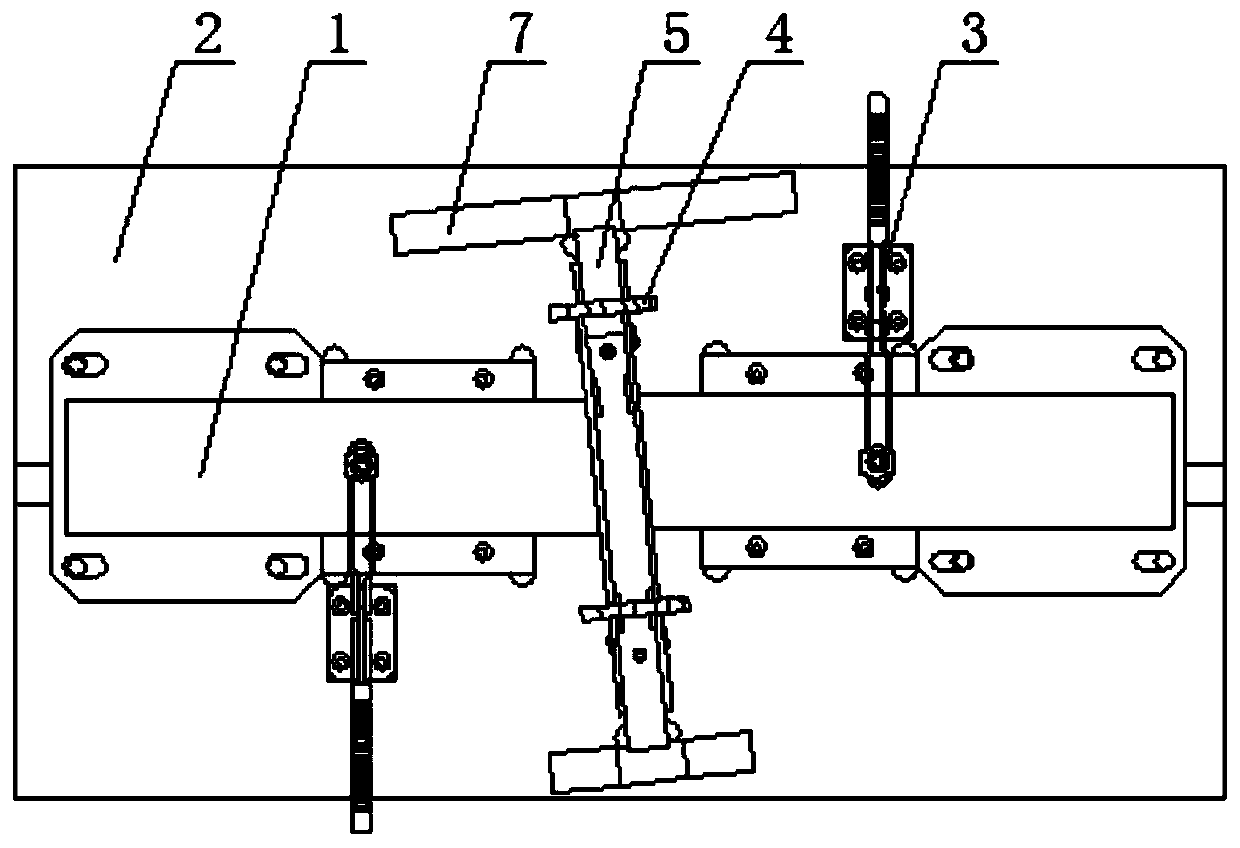

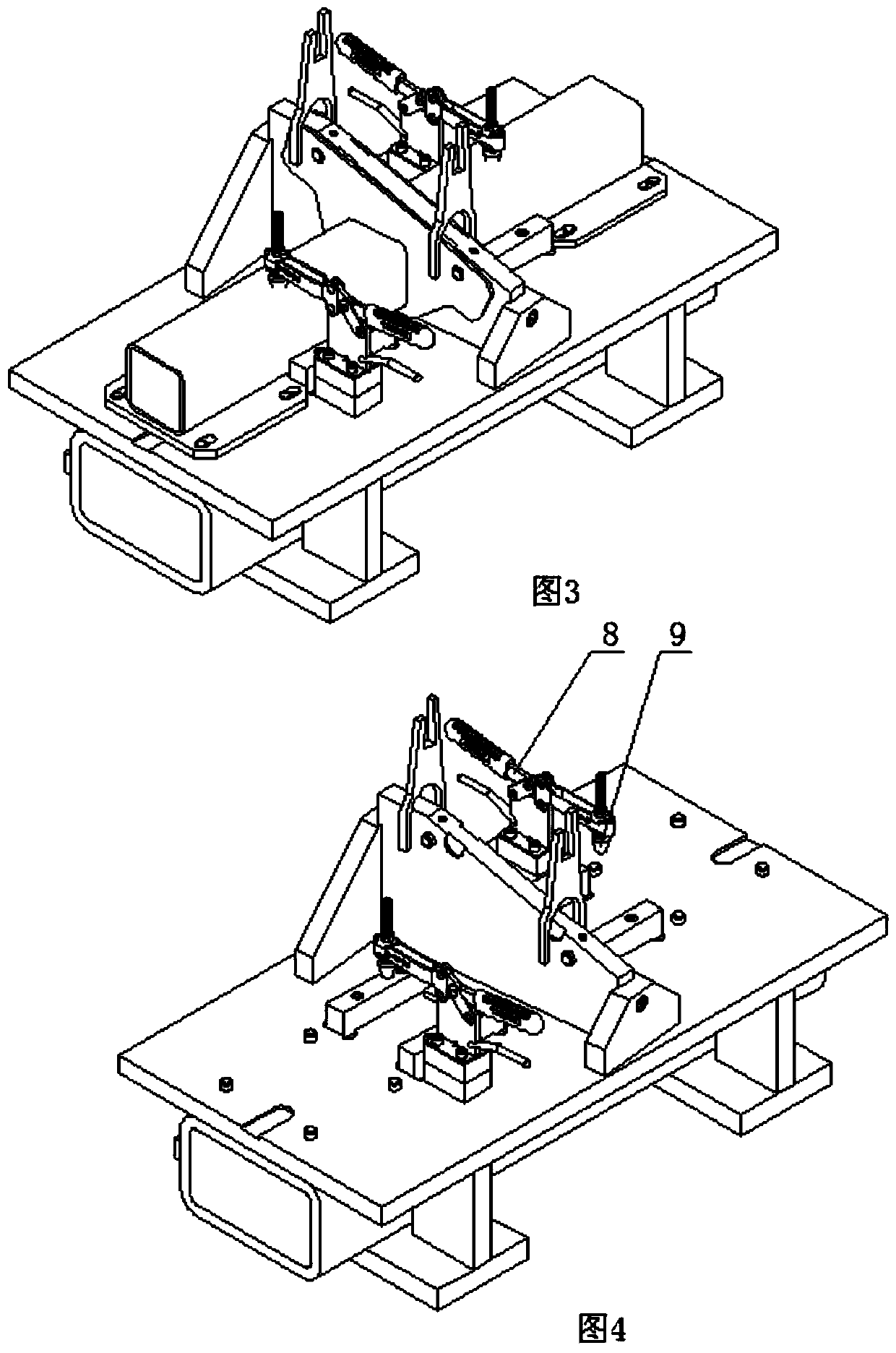

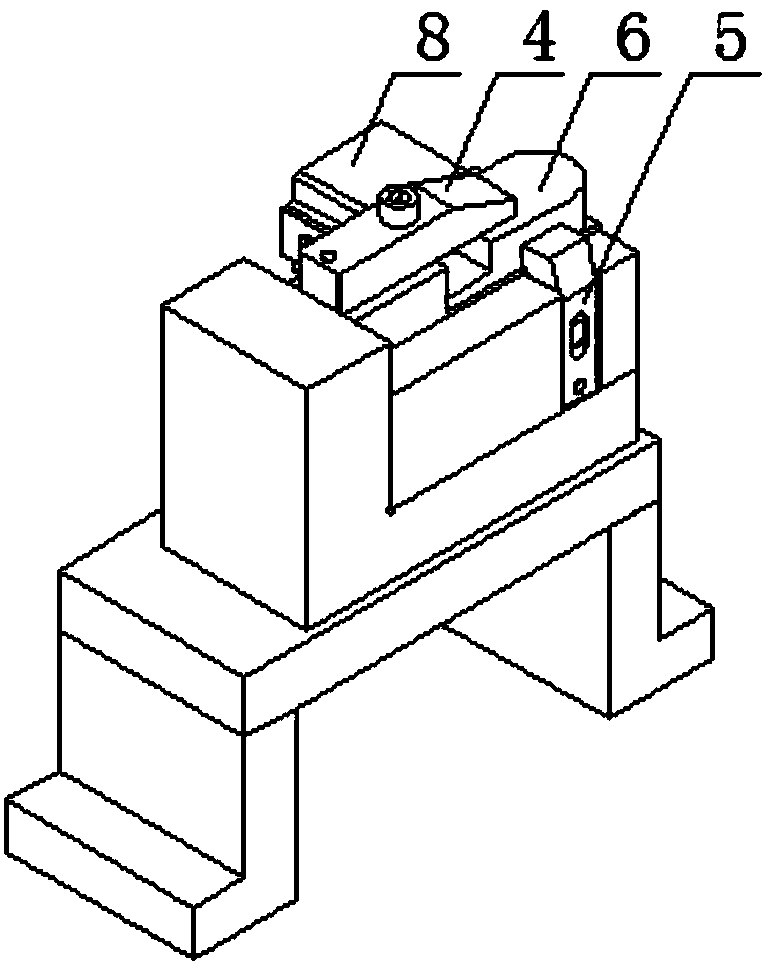

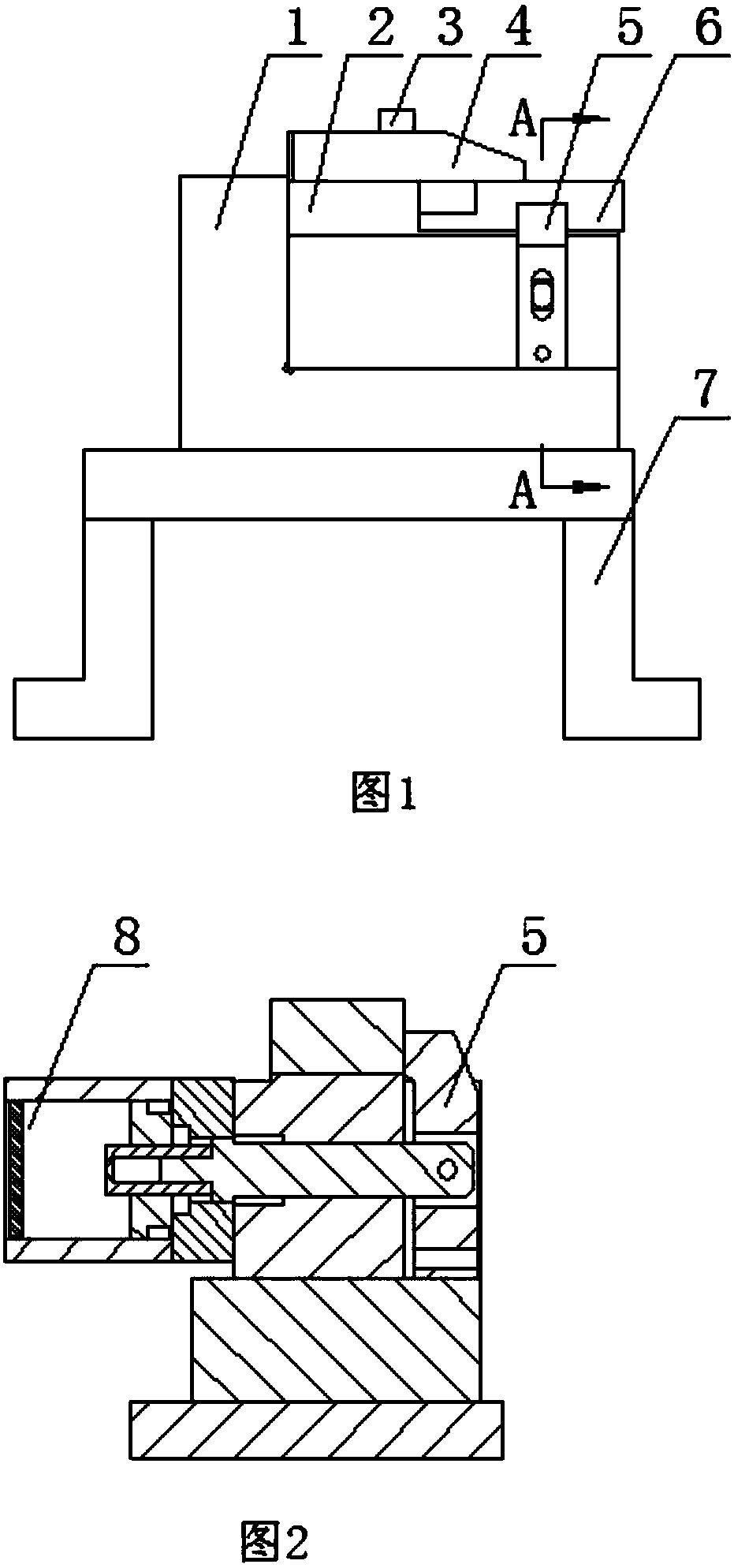

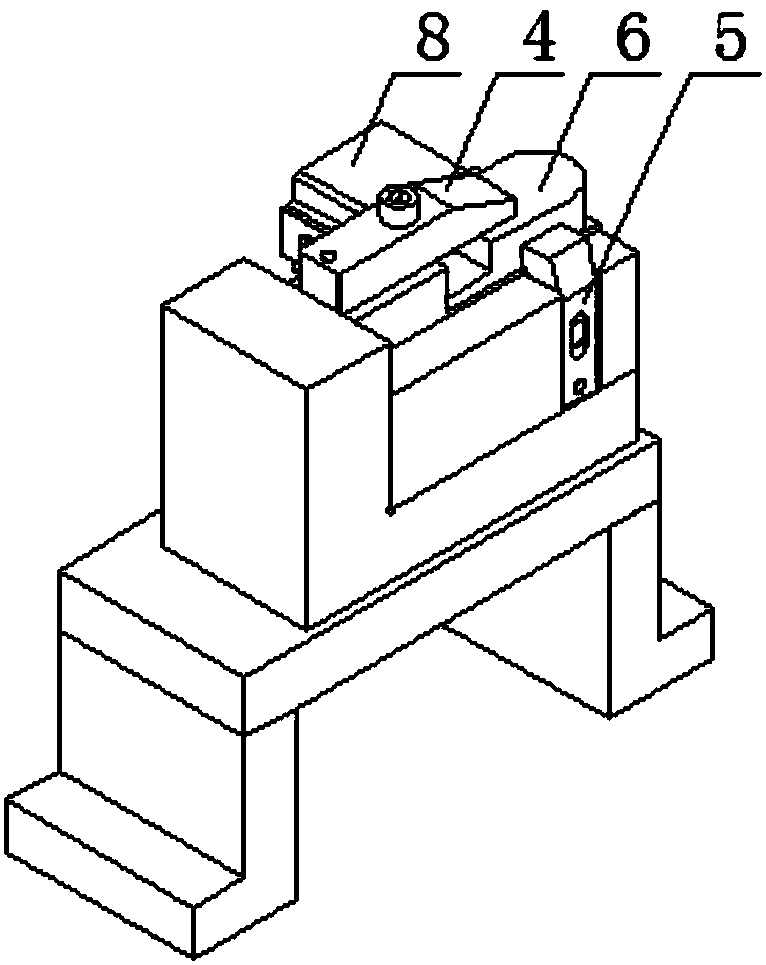

Multiple-working-procedure clamping installation facility capable of improving machining accuracy

InactiveCN109968072APrecise and stable locking and fixingReduce loading errorsPositioning apparatusMetal-working holdersSurface mountingMachining

The invention relates to a multiple-working-procedure clamping installation facility capable of improving machining accuracy. The multiple-working-procedure clamping installation facility capable of improving the machining accuracy comprises a base plate, an oil cylinder, an upper press plate, a mandrel, a linear guide rail, clamping jaws, a handle and a wedge block. The oil cylinder is installedon the upper surface of the base plate and connected with the upper press plate, and the mandrel is arranged at the bottom of the front end of the upper press plate. The linear guide rail is installedon the portion, located on the side of the mandrel, of the base plate. A sliding pedestal is installed on the linear guide rail in a sliding mode, and the two clamping jaws are installed on the leftside and the right side of the sliding pedestal in a hinged mode correspondingly. The handle is arranged on the sliding pedestal, the wedge block is coaxially installed on the handle in a penetrativemode, and the left side wall and the right side wall of the wedge block make contact with the inner walls of the rear ends of the two clamping jaws in a press mode correspondingly. The multiple-working-procedure clamping installation facility capable of improving the machining accuracy is scientific in design, convenient to use and high in degree of automation, can be installed in a machining center and used, and can accomplish machining of multiple working procedures through one-time clamping operation, and therefore the machining accuracy and the working efficiency are greatly improved, andthe product quality is also improved.

Owner:天津市臣涛精密机械设备有限公司

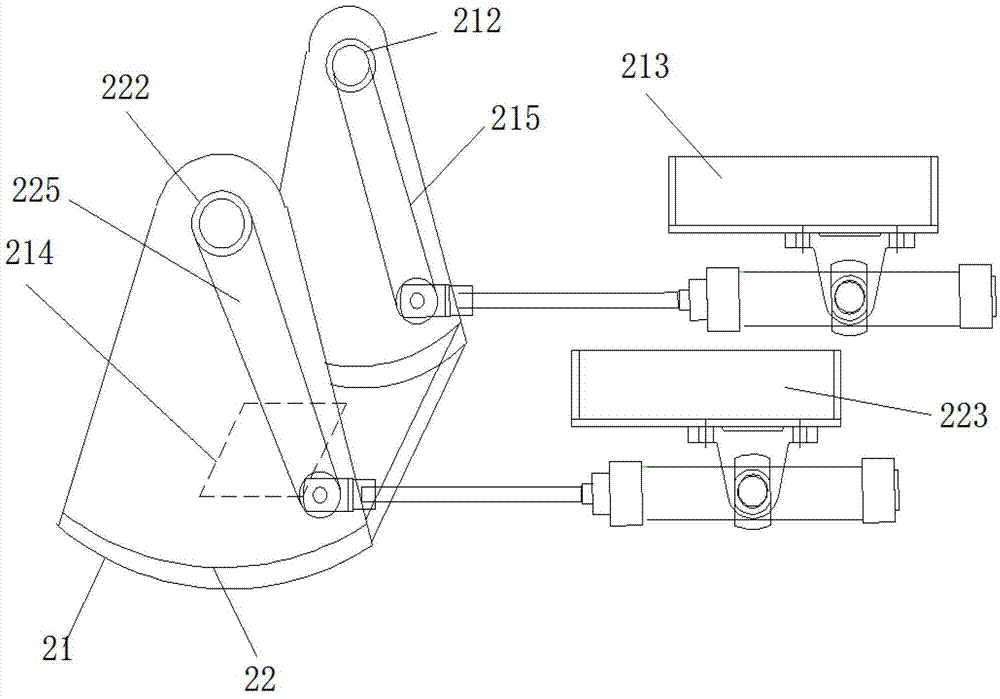

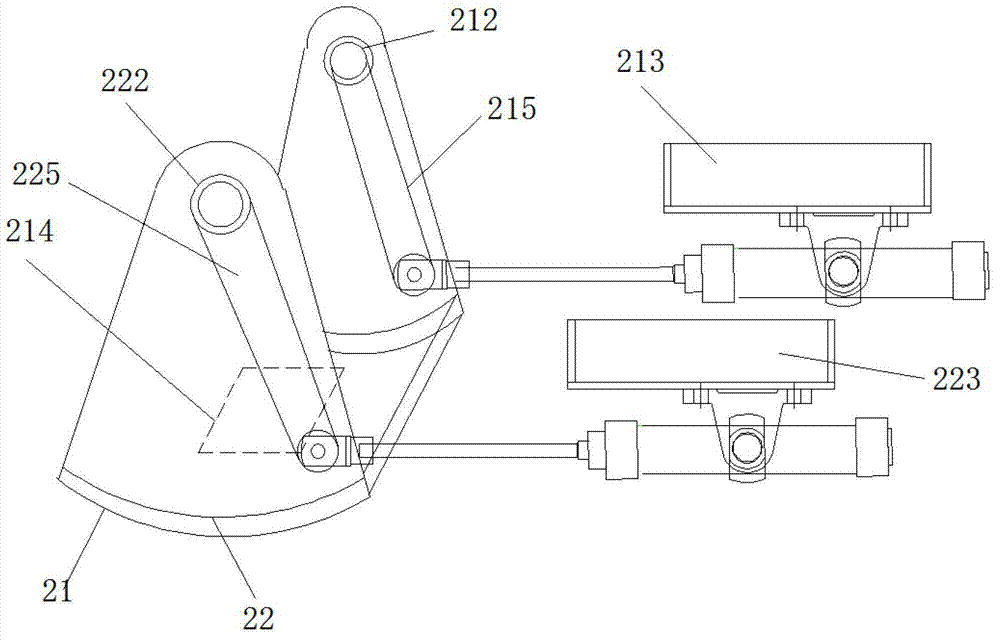

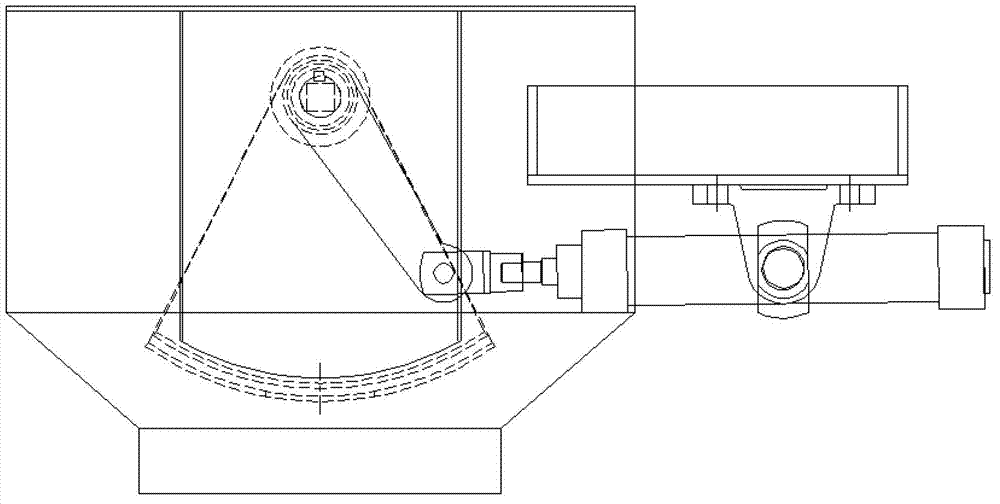

Quadrant valve for polyester chip packer

InactiveCN102777617AReduce labor intensityControl the blanking speedOperating means/releasing devices for valvesSlide valvePolyesterDrive shaft

The invention discloses a quadrant valve for a polyester chip packer, which comprises a fine discharging quadrant valve plate and a discharging closing quadrant valve plate, wherein the bottom of the fine discharging quadrant valve plate is arc-shaped, a fine discharging hole is arranged in the arc-shaped bottom, and the fine discharging quadrant valve plate is arranged on a pipeline through a fine discharging drive shaft, the bottom of the discharging closing quadrant valve plate is arc-shaped, and the discharging closing quadrant valve plate is arranged on the pipeline through a discharging closing shaft. According to the invention, through adoption of a control device, the fine discharging quadrant valve plate and the discharging closing quadrant valve plate can be controlled so as to regulate the blanking speed, so that the blanking speed is reduced when bagging is almost ended, the loading precision is well controlled, the loading error is reduced, and the loading packaging can be completed within an error range without manual regulation. The polyester chip packer provided by the invention has the advantages of reducing manual operation, lowering hand labor cost, reducing labor intensity of workers by adopting an automatic regulating mode, and increasing production efficiency.

Owner:JIANGSU CHALLEN FIBER S&T

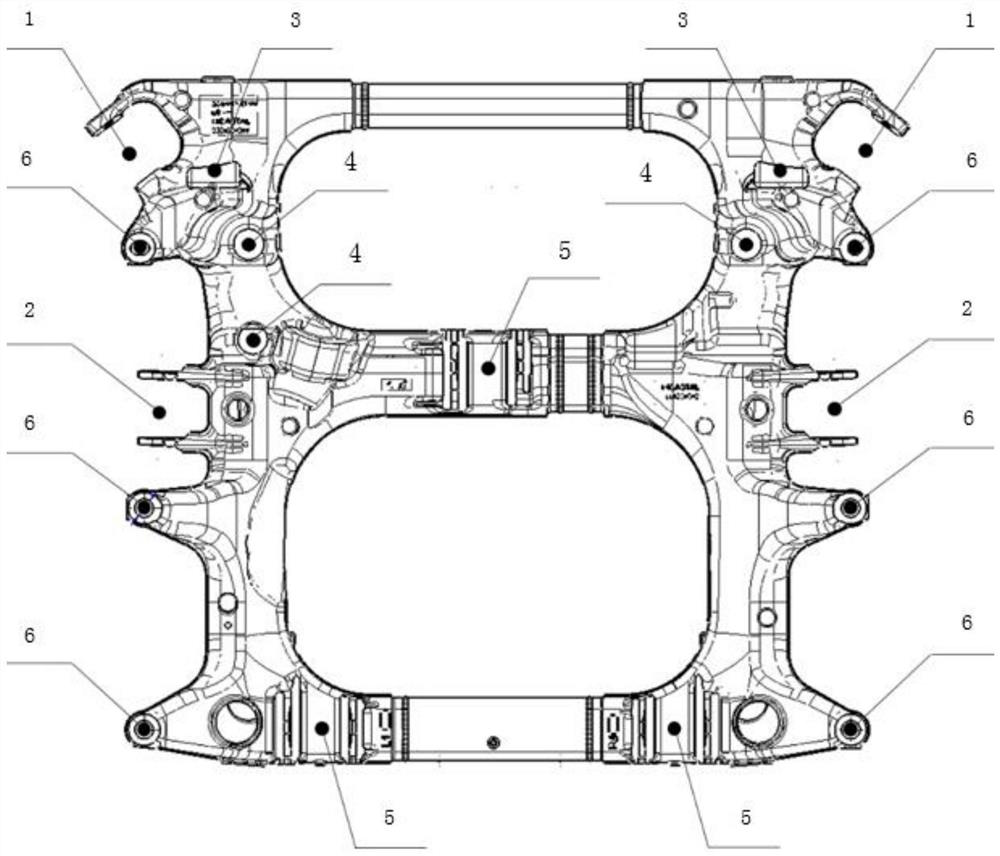

Fixing device for machining end face position holes of supporting frame

InactiveCN111376077APrecise positioningQuick disassemblyPositioning apparatusMetal-working holdersEquipment useIndustrial engineering

The invention relates to a fixing device for machining end face position holes of a supporting frame. The fixing device comprises a base, a left side positioning mechanism and a right side positioningmechanism. The fixing device for machining the end face position holes of the supporting frame is scientific in design, reasonable in structure, convenient to use, high in specificity and low in manufacturing cost, and by means of the fixing device, the working process can be simplified, the assembling and clamping time can be shortened, the work efficiency can be improved, and the product quality can be guaranteed.

Owner:天津市臣涛精密机械设备有限公司

A Load Correction Method in Landing Gear Loading

ActiveCN105083587BGuaranteed to be verticalReduce load errorAircraft components testingControl theoryReliability engineering

The invention discloses a load correction method applied to undercarriage loading. The method comprises the steps of 101, installing a loading device on an undercarriage; 201, acquiring corresponding test data between the offset, in the heading direction of the undercarriage, at the position where the loading device is connected with the undercarriage and a load multiple times through testing; 301, fitting the test data obtained in the step 201 into a formula by means of the least square method; 401, obtaining the offset, in the heading direction of the undercarriage, at the position where the loading device is connected with the undercarriage according to a preset load by means of the formula obtained in the step 301; 501, adjusting the loading device so as to counteract the offset. In this way, load error generated by an undercarriage loading system is effectively reduced so that the test load error can meet the control requirement, and then the problem that offset exists in the prior art is solved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

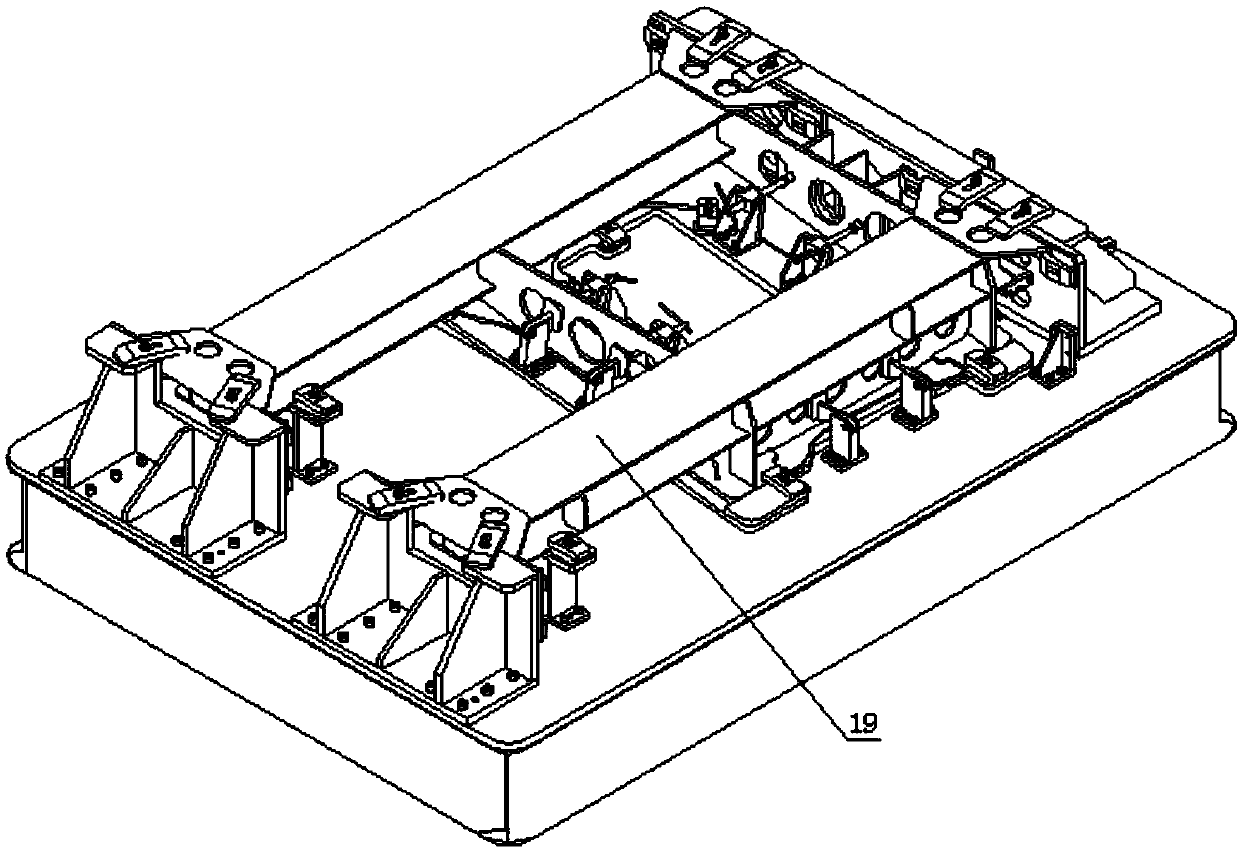

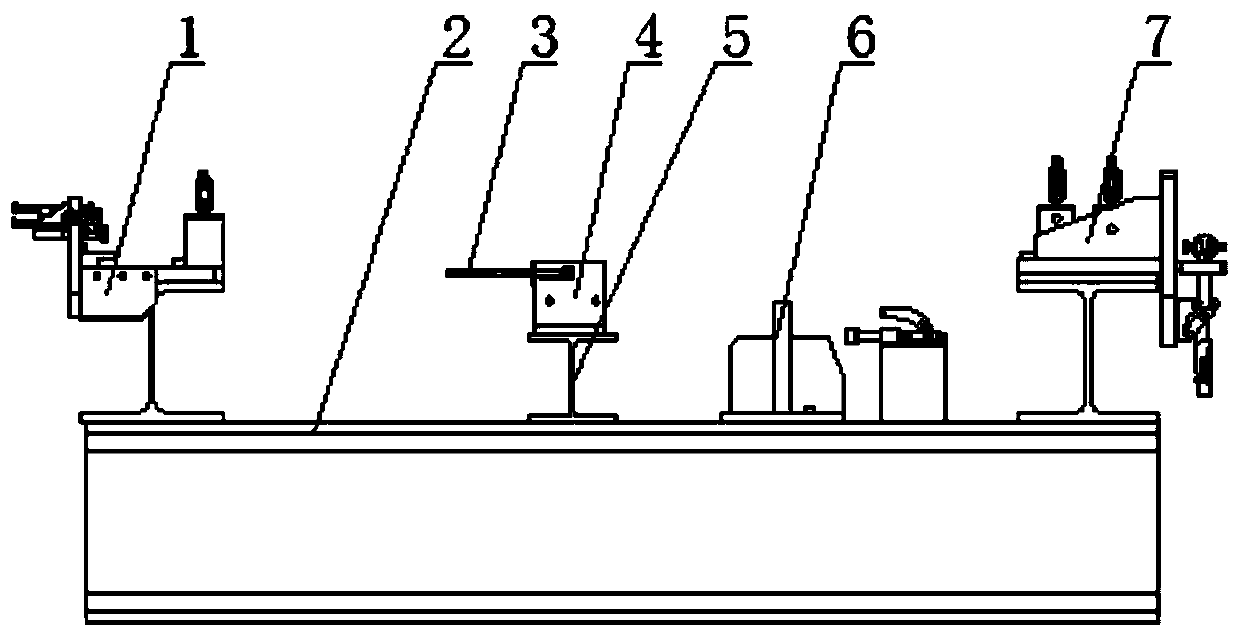

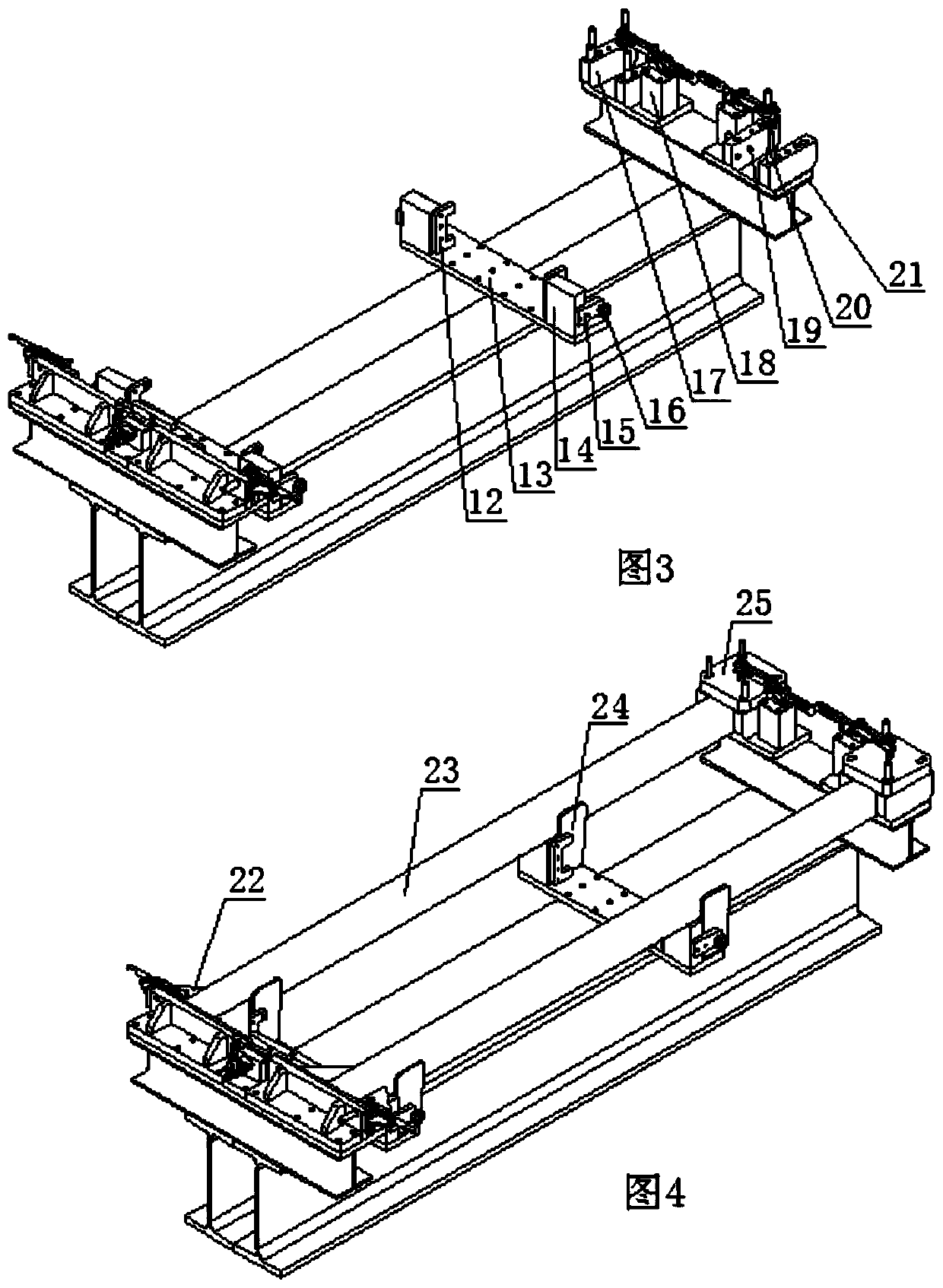

Supporting beam assembling equipment high in clamping precision

InactiveCN111376197AImprove accuracyPlay the role of fixing and fastening the workpieceWelding/cutting auxillary devicesWork holdersEconomic benefitsEngineering

The invention relates to supporting beam assembling equipment high in clamping precision. A base, a workbench, lower pressing plates, upper pressing plates, side pressing plates, side positioning mechanisms, side jacking mechanisms, a sliding type end portion positioning mechanism and a fixed type end portion positioning mechanism are included. The workbench is arranged on the upper surface of thebase. Positioning grooves are manufactured in the middle portion and the four corners of the workbench correspondingly. The part, on the side edge of each positioning groove, of the workbench is provided with the corresponding lower pressing plate. The workbench is provided with the multiple side positioning mechanisms and the multiple side jacking mechanisms. The part, on the right side of the workbench, of the base is provided with the sliding type end portion positioning mechanism. The part, on the left side of the workbench, of the base is provided with the fixed type end portion positioning mechanism. The supporting beam assembling equipment high in clamping precision is scientific in design, reasonable in structure, convenient to operate and high in practicability; and by usage of the equipment, the work efficiency can be improved, the workpiece machining quality can be guaranteed, the rejection rate is reduced, and economic benefits of enterprises are improved.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

A preparation method of microsphere probe based on microcantilever transfer

ActiveCN110155938BPrecise positioningFlexible bondingPrecision positioning equipmentSoldering apparatusMicrosphereNano manufacturing

The invention provides a microsphere probe preparation method based on microcantilever transfer, which belongs to the technical field of micro-nano manufacturing. The invention has simple process and low cost, and can be used for the preparation of microsphere probes for micro-nano processing or indentation mechanical properties testing; the invention can realize flexible bonding of any granular material, and can be matched with any receptor platform arbitrarily; The cantilever can act as a transfer layer while transferring the microspheres, increasing the contact area between the microspheres and the receptor platform, thereby reducing the contact pressure to reduce the deformation of the receptor platform; Accurate positioning of the tip of the body, and can avoid the small size of the microspheres completely immersed in the glue during bonding, polluting the surface of the microsphere probe.

Owner:SOUTHWEST JIAOTONG UNIV

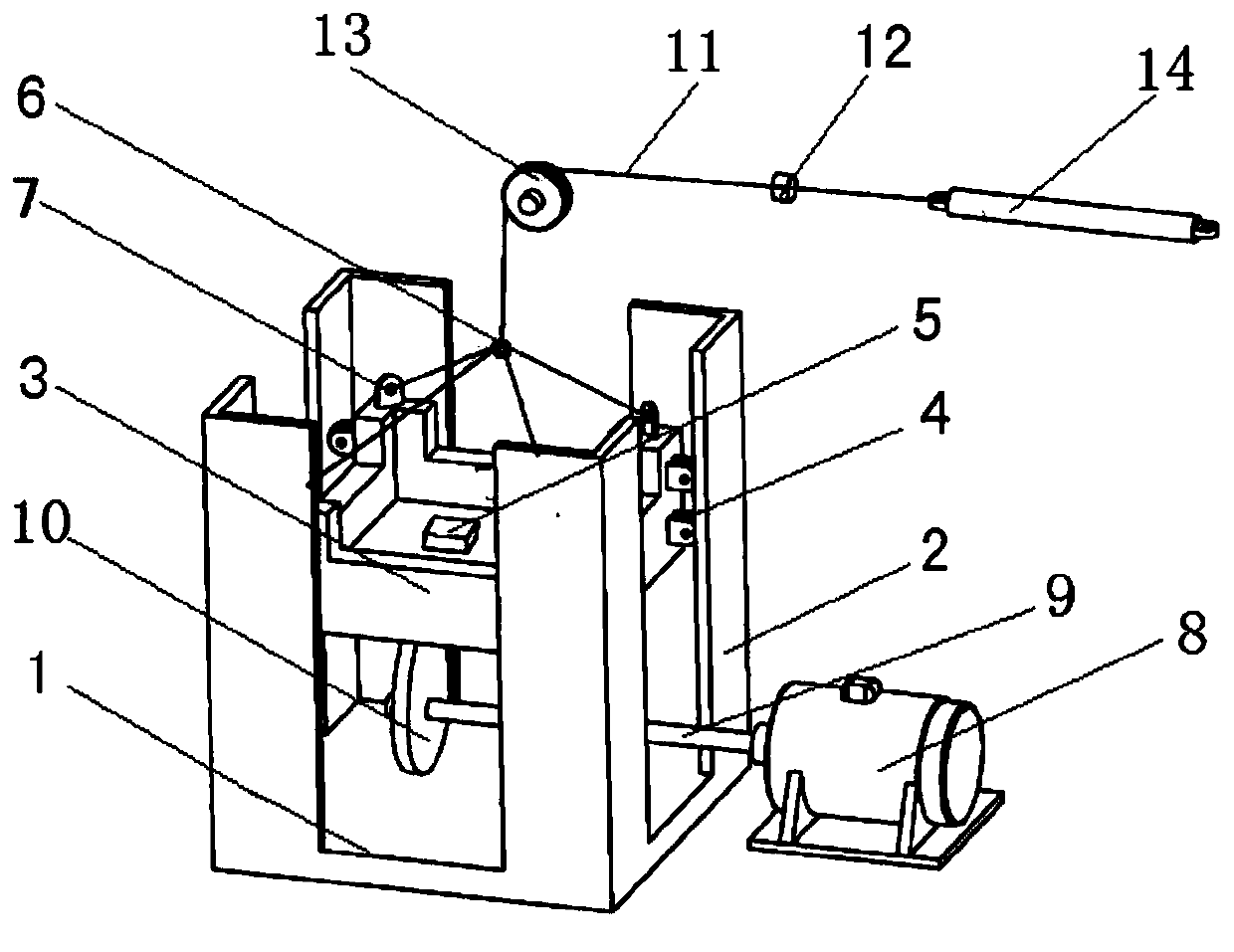

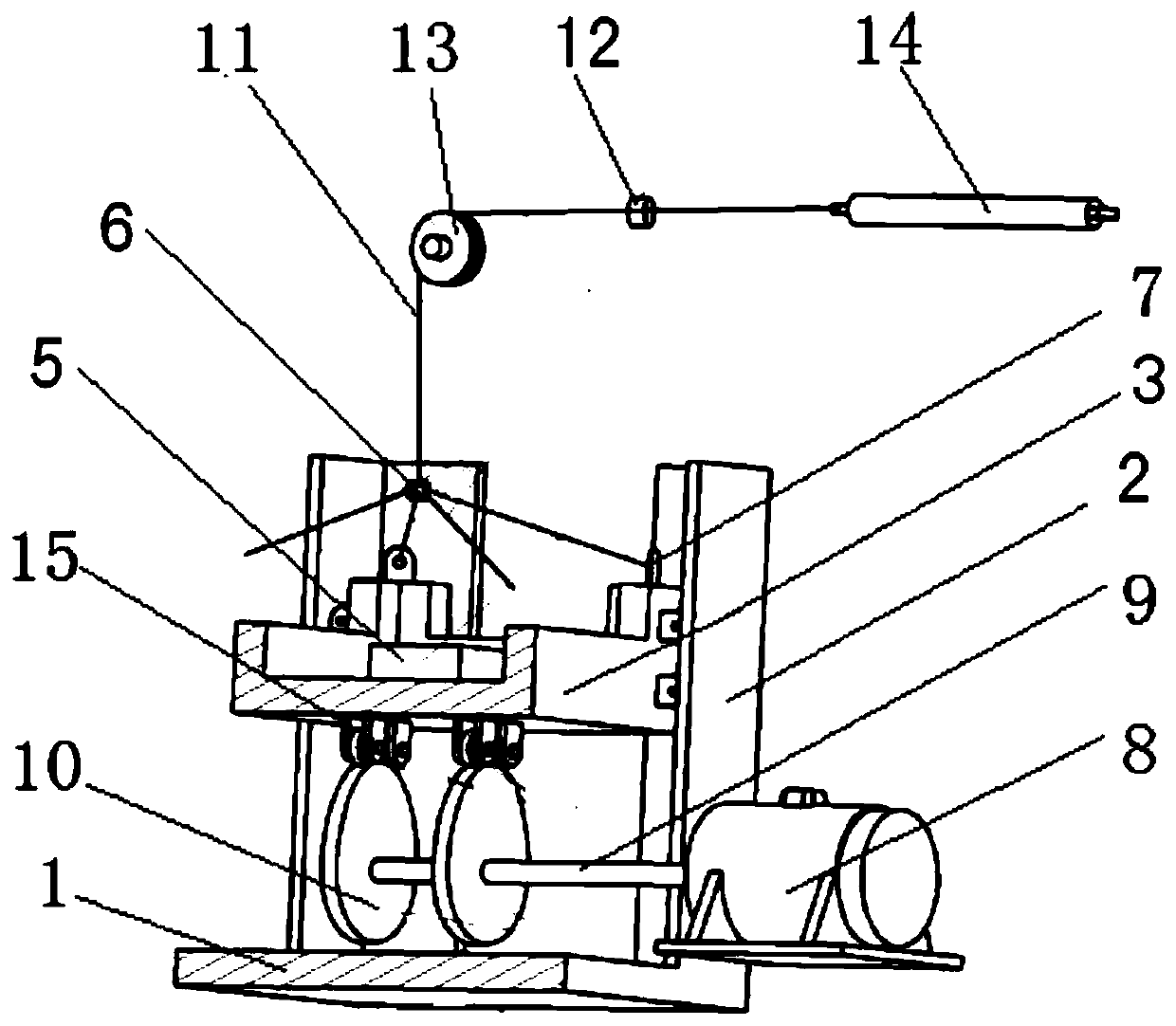

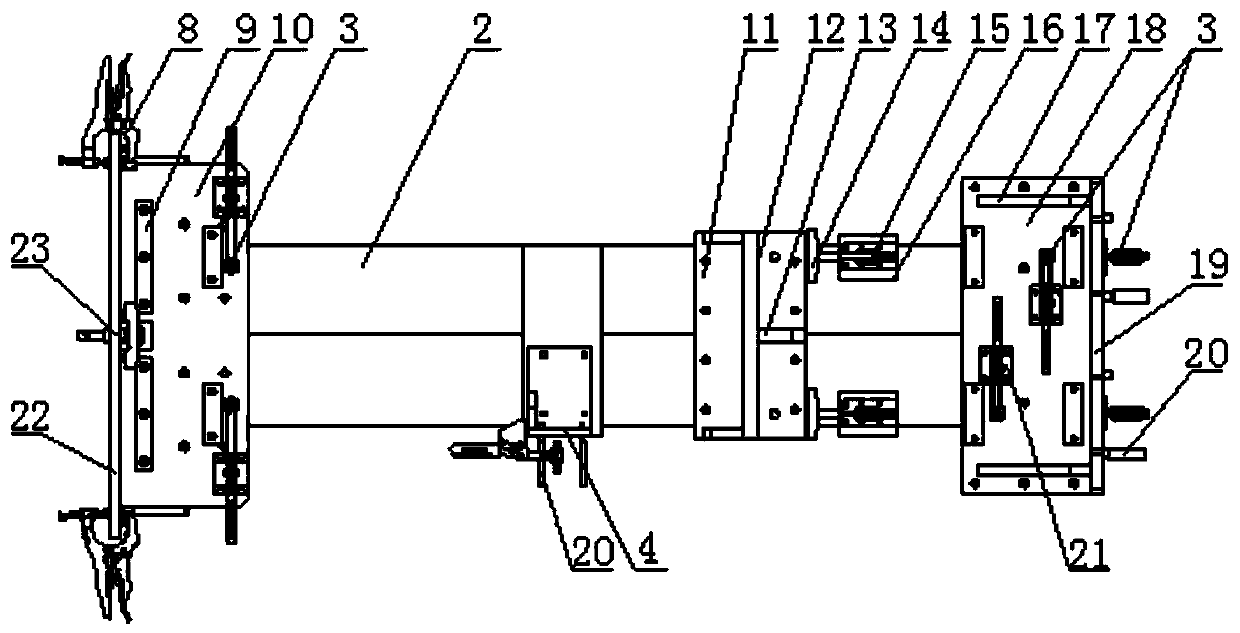

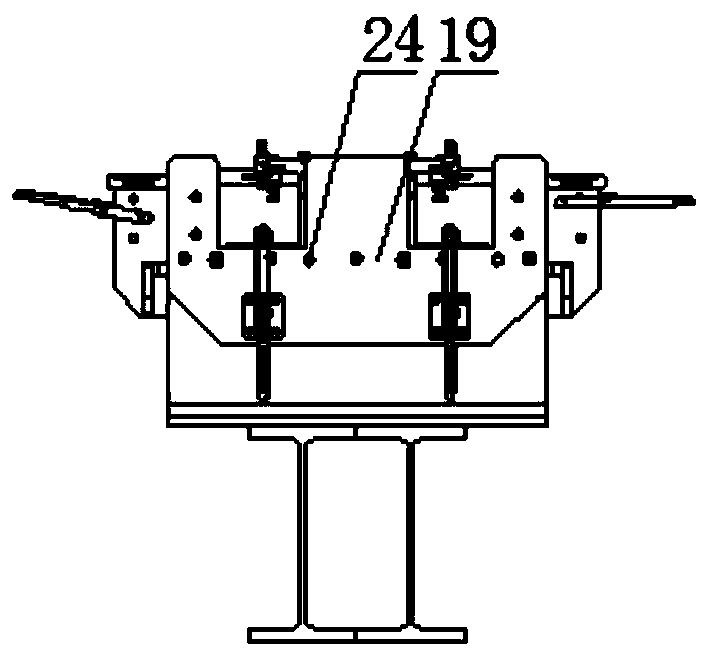

Loading method and loading device for fatigue test

InactiveCN110907266AReal-time feedback payloadSimple structureMaterial strength using repeated/pulsating forcesFatigue loadingDrive shaft

The invention discloses a loading method and a loading device for a fatigue test. The loading device comprises a loading device and a power device, the loading device comprises a displacement limitingbase, a loading platform and a loading mass block, and the loading platform is provided with a plurality of displacement pulleys. The displacement pulleys are matched with a vertical sliding rail onthe displacement limiting base, a traction point is arranged at the upper end of the loading platform, and the power device comprises a motor and a cam. The cam is located on a transmission shaft of the motor and is matched with a transmission pulley at the bottom of the loading platform, and the motor drives the loading platform to move up and down along the vertical sliding rail through the cam.A traction rope for transmitting load is arranged, a force sensor is arranged on the traction rope, one end of the traction rope is connected with the traction point of the loading platform, and theother end of the traction rope is connected with a fatigue test piece. The loading platform is driven by the cam on the transmission shaft to move up and down along the vertical sliding rail, and theloading platform transmits fatigue load to the fatigue test piece through the traction rope.

Owner:XIAN AIRCRAFT IND GROUP

Locating and mounting device with quick workpiece replacing function

InactiveCN109968071AMeet needsReduce the number of card loadingWork clamping meansPositioning apparatusSurface mountingEngineering

The invention relates to a locating and mounting device with a quick workpiece replacing function. The locating and mounting device comprises a base, a fixed locating block, a workpiece locating blockand a plurality of locating columns; the fixed locating block is mounted on the upper surface of the base; the workpiece locating block is put in the fixed locating block; a workpiece mounting grooveis formed in the upper surface of the workpiece locating block; a pressing plate positioned above the workpiece mounting groove is mounted at the upper part of the workpiece locating block; a horizontal locating step through slot is formed in the lower part of the workpiece locating block; and a locking block is inserted in the locating step through slot, and is connected onto a piston rod of anair cylinder. The locating and mounting device wit hthe quick workpiece replacing function, provided by the invention, is reasonable in design, practical in structure, flexible to use, high in practicability, time-saving and labor-saving in use, and capable of reducing clamping frequency and the labor capacity of workers and improving the product processing precision.

Owner:天津市臣涛精密机械设备有限公司

A three-phase anti-resonance voltage transformer

ActiveCN112489956BSave materialSave raw materialsTransformersTransformers/inductances coils/windings/connectionsPhysicsLoad loss

The invention discloses a three-phase anti-resonance voltage transformer, which comprises a three-column iron core, which has a first column, a second column and a third column, and the three-column iron core is distributed in an equilateral triangle structure; and a first coil, a second coil The second coil and the third coil, the first coil, the second coil and the third coil are respectively wound on the first post, the second post and the third post; the present invention has compact structure, small volume, light weight and Save raw materials; the excitation current of the three-phase voltage transformer is small, and the no-load loss is low, which reduces the no-load error of the product and then reduces the overall error of the product, improves the accuracy, and avoids the problem of large three-phase error deviation; it can be passed Enlarging the cross-section of the iron core, increasing the number of turns of the winding, and other methods greatly increase the zero-sequence impedance and improve the performance of anti-ferromagnetic resonance; greatly improve the accuracy of the product, and meet the latest requirements of the power sector to improve the error margin; further reduce the occurrence of ferromagnetic The possibility of resonance has played a double anti-resonance effect.

Owner:GUIZHOU POWER GRID CO LTD

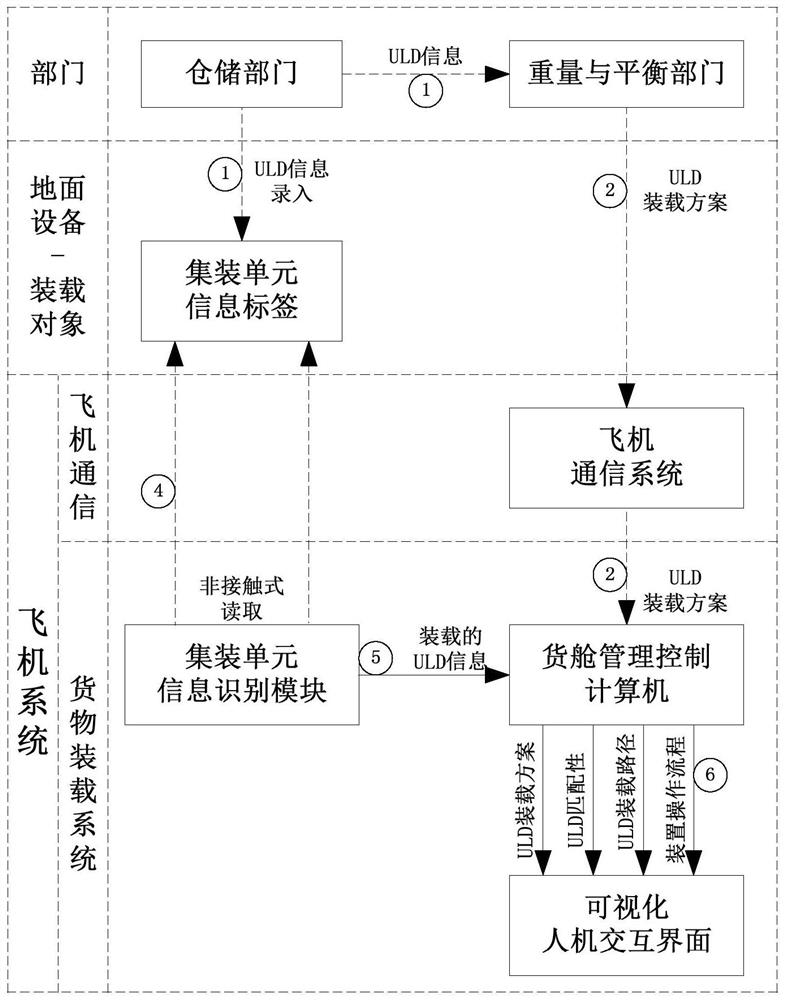

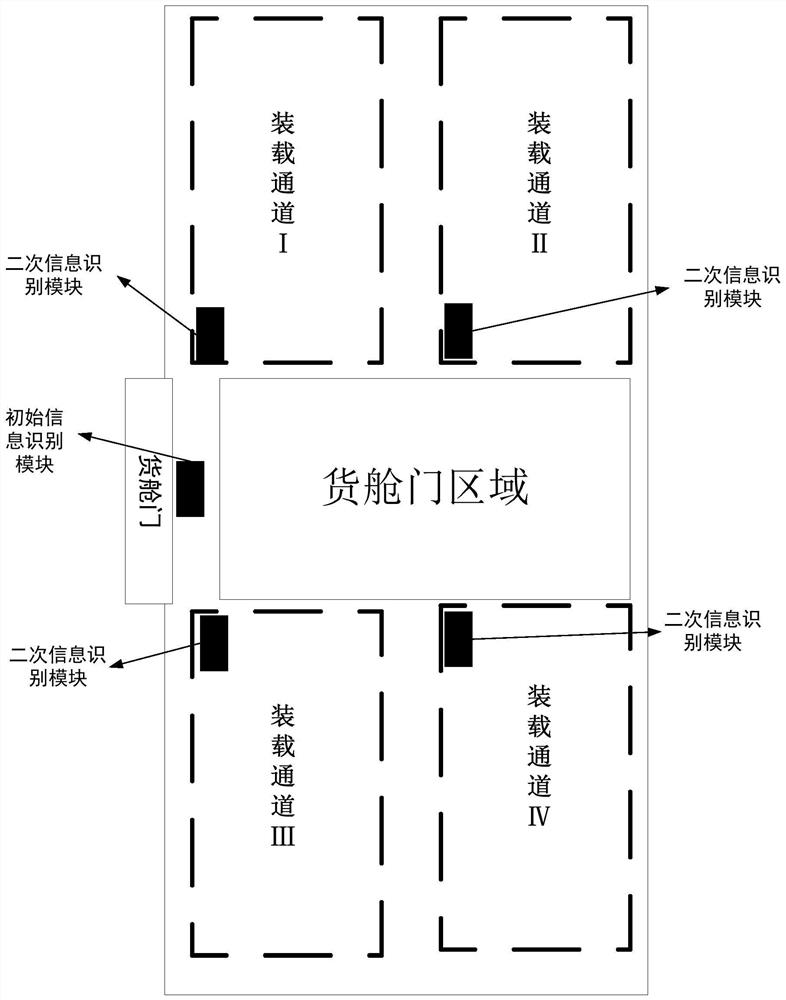

Loading system of packaging unit in civil cabin

PendingCN112819411AReduce load errorLower skill requirementsCo-operative working arrangementsLogisticsConstruction engineeringInteraction interface

The invention provides a loading system of a packaging unit in a civil aircraft cabin. The loading system comprises an initial information identification module, a cargo hold management control computer, a man-machine interaction interface and secondary information identification modules corresponding to loading channels in a civil aircraft cargo hold. The initial information identification module is arranged at a cargo hold door frame and is used for detecting information of a packaging unit passing through the cargo hold door frame; the cargo hold management control computer is used for determining a final loading position of the container unit, a path for moving the container unit from the current position to the final loading position and an operation flow for moving the container unit from the current position to the final loading position when the container unit carries out loading according to the approved container unit loading scheme; the secondary information identification module is used for detecting information of the packaging units entering the corresponding loading channels and sending the information to the cargo hold management control computer; and the cargo hold management control computer is also used for indicating an operator to continue operation when the loading position of the packaging unit is located in the loading channel. Automatic checking and loading can be realized.

Owner:QINGAN GRP

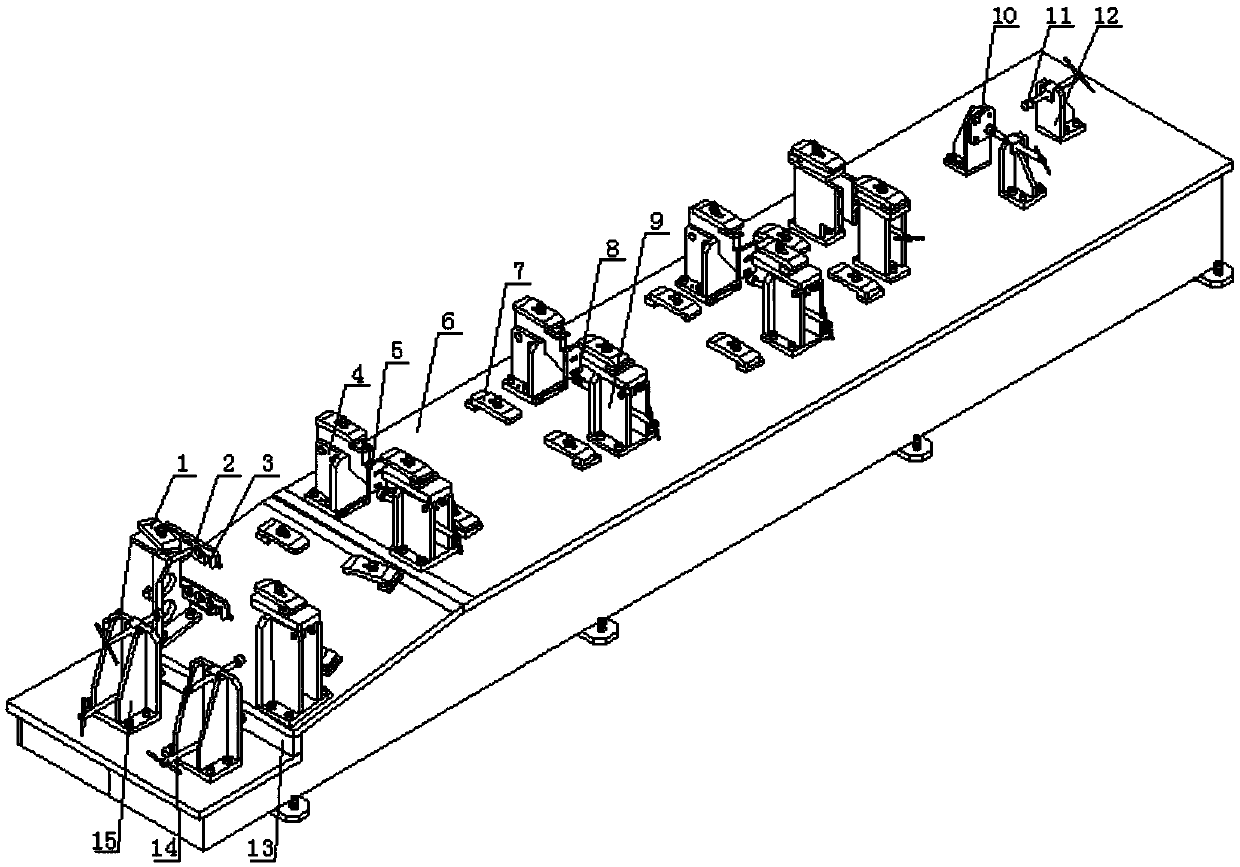

Positioning equipment for assembling hoisting beam left bracket

InactiveCN111375950AReduce manufacturing costHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesPositioning equipmentStructural engineering

The invention relates to a positioning equipment for assembling a hoisting beam left bracket. The positioning equipment comprises a workbench, a left-end fixing mechanism, a right-end fixing mechanismand a side plate fixing mechanism. The left-end fixing mechanism is installed on the left side of the upper surface of the workbench. The right-end fixing mechanism is installed on the right side ofthe upper surface of the workbench. The side plate fixing mechanism is installed on the upper surface of the workbench and is located between the left-end fixing mechanism and the right-end fixing mechanism. The positioning equipment for assembling the hoisting beam left bracket is scientific in designing, reasonable in structure, easy and convenient to use and high in specificity, has the dislocation prevention function, and is used to assemble the hoisting beam left bracket; and by using the positioning equipment, workpieces can be disassembled or assembled easier, the processing quality isimproved, production is quickened, and the production cost is reduced.

Owner:TIANJIN JINLAI PRECISION MACHINERY

Special positioning and clamping equipment for assembling wind power boundary beam

InactiveCN111376196AImprove accuracyPlay the role of fixing and fastening the workpieceWork holdersStructural engineeringWorkbench

The invention relates to special positioning and clamping equipment for assembling a wind power boundary beam. The special positioning and clamping equipment comprises a workbench, a left end plate jacking mechanism, lower pressing plates, vertical plate positioning mechanisms, vertical plate jacking mechanisms, upper pressing plates and a rear fork plate positioning and jacking mechanism, whereina vertical positioning surface is formed in a left side of an upper surface of the workbench; the left end plate jacking mechanism is installed on the upper surface of the workbench on a left side ofthe positioning face, a plurality of lower pressing plates are installed on the upper surface of the workbench on a right side of the positioning face, the vertical plate positioning mechanisms and the vertical plate jacking mechanisms are installed on the workbench, and the upper pressing plate is installed on the upper end face of each vertical plate positioning mechanism and the upper end faceof each vertical plate jacking mechanism; and the rear fork plate positioning and jacking mechanism is mounted on the right side of the upper surface of the workbench. The special positioning and clamping equipment for assembling the wind power boundary beam is scientific in design, reasonable in structure, convenient to operate and high in practicability, is simple and convenient to use and easyto master, and can bring convenience to worker; and the working efficiency can be improved, and the machining quality of a workpiece is guaranteed.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

A smart logistics environment robot loading method and device

ActiveCN108942946BSimple structureEasy to operateProgramme-controlled manipulatorNerve networkMachine vision

The invention discloses a loading method and device of an intelligent logistics environment robot. The method comprises the following steps that firstly, cargo information is acquired in real time; secondly, the coordinates of the placement positions of cargoes in to-be-loaded areas corresponding to conveying addresses are calculated; thirdly, a classification robot is utilized for clamping the cargoes to the corresponding to-be-loaded areas used for temporary storage from a conveying belt; fourthly, the coordinates of the final positions of the cargoes in loading areas of an AGV intelligent carrier; and fifthly, the cargoes are carried to the loading areas of the AGV intelligent carrier according to a control matrix obtained by an intelligent carrying control model. The cargo sizes, the cargo conveying addresses, the cargo position coordinates and other information are automatically acquired by combining machine vision, the classification robot and the intelligent carrier are utilizedfor automatically and intelligently classifying and loading the cargoes by setting up a neural network model, the loading error rate is greatly reduced, and the loading efficiency is improved.

Owner:CENT SOUTH UNIV

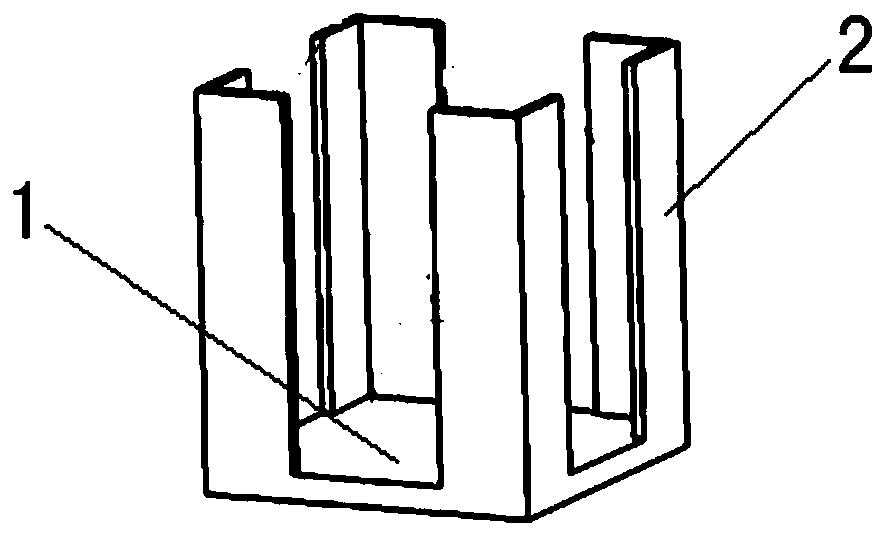

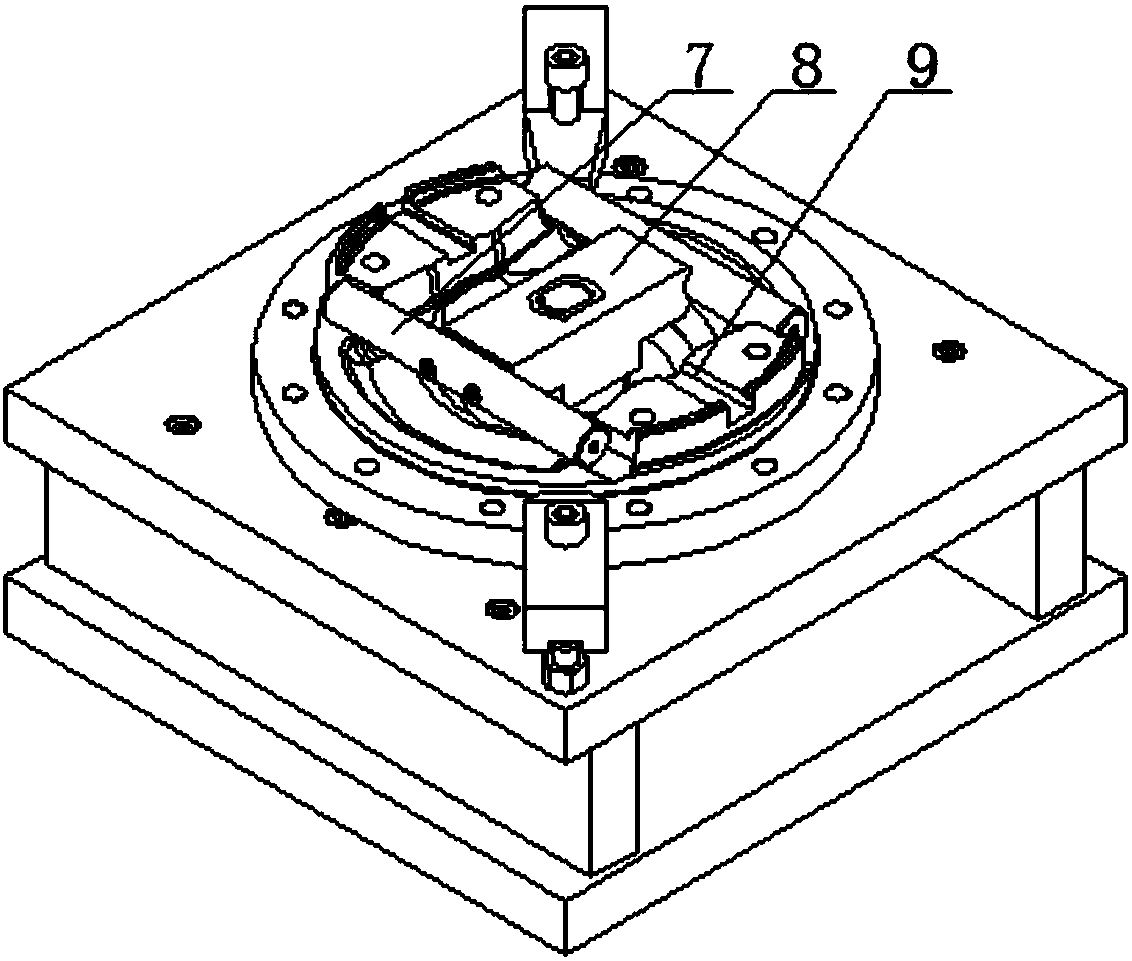

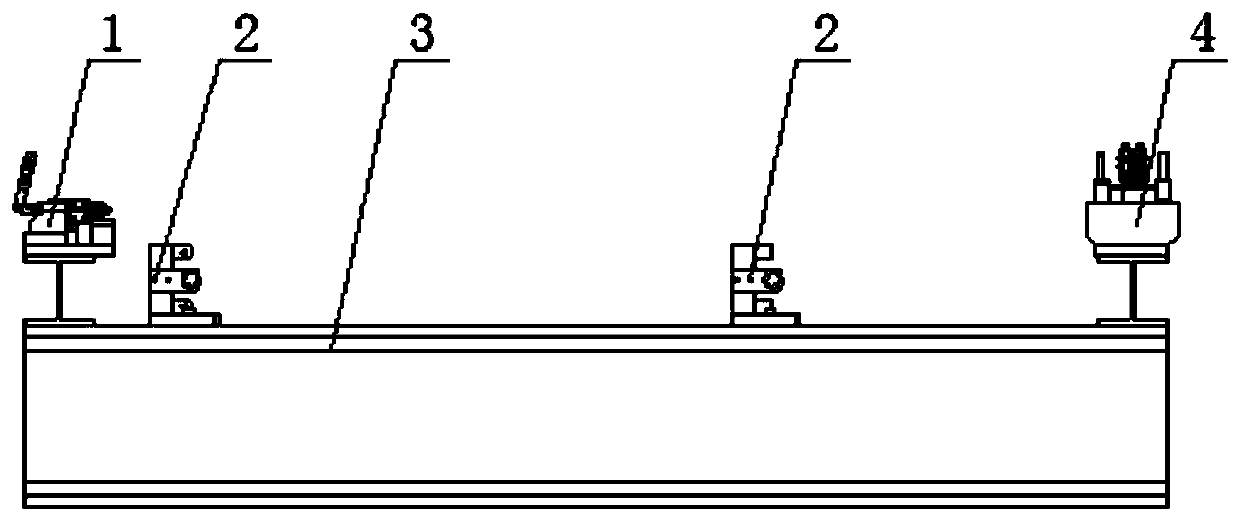

Multi-procedure machining positioning and installing equipment for machining center

InactiveCN109968059AReduce loading errorsImprove machining accuracyOther manufacturing equipments/toolsPositioning apparatusEngineeringMechanical engineering

The invention relates to multi-procedure machining positioning and installing equipment for a machining center. A frame type base, a core shaft, a center positioning frame and manual pressing plates are included. The frame type base is composed of a bottom plate, a top plate and side plates, wherein the bottom plate and the top plate are connected through the side plates, and a through hole is manufactured in the center of the top plate. The vertically-arranged core shaft is arranged at the center of the bottom plate, and the core shaft and the through hole of the top plate are coaxially arranged. A shaft hole is manufactured in the axis of the core shaft, and the center positioning frame is inserted in the shaft hole and located above the through hole. The two manual pressing plates are symmetrically arranged on the upper surface of the top plate, and the front ends of the two manual pressing plates are arranged towards the through hole of the top plate. The multi-procedure machiningpositioning and installing equipment for the machining center is reasonable in structure, ingenious in design, convenient to use, high in practicability and low in manufacturing cost; and by usage ofthe equipment, the clamping error can be reduced, the work efficiency is improved, the machining precision is improved, and the product quality is improved.

Owner:天津市臣涛精密机械设备有限公司

Equipment used positioning and mounting right bracket of hoisting beam

InactiveCN111375935AReduce manufacturing costHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWorkbench

The equipment relates to equipment used positioning and mounting a right bracket of a hoisting beam. The equipment comprises a workbench, a left end fixing mechanism, side plate fixing mechanisms anda right end fixing mechanism, the left end fixing mechanism is installed on the left side of the upper surface of the workbench, and the right end fixing mechanism is installed on the right side of the upper surface of the workbench; and the two side plate fixing mechanisms are mounted on the upper surface of the workbench and between the left end fixing mechanism and the right end fixing mechanism. The equipment used positioning and mounting the right bracket of the hoisting beam is scientific in design, reasonable in structure, easy and convenient to use, high in specificity and capable of preventing dislocation, the workpiece dismounting and mounting difficulty can be reduced by using the equipment, and therefore the machining quality is improved, the production progress is accelerated,and the production cost is saved.

Owner:TIANJIN JINLAI PRECISION MACHINERY

Device for rapidly locating wind turbine hoisting beam

InactiveCN111375952AReduce manufacturing costHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTurbine

The invention relates to a device for rapidly locating a wind turbine hoisting beam. The device for rapidly locating the wind turbine hoisting beam comprises a workbench, an end plate fixing and abutting mechanism, multiple locating blocks, multiple rapid cross beam pressing mechanisms, an upper cover plate and a side tightly-abutting block. The end plate fixing and abutting device is installed onthe back portion of the right side of the upper surface of the workbench. The upper surface of the workbench is divided into a back right machining area, a middle right machining area and a front left machining area. The multiple locating blocks are installed at the positions, on the side edges of the three machining areas, of the upper surface of the workbench correspondingly. The multiple crossbeam rapid pressing mechanisms are installed on the portions, on the side edges of the middle right machining area and the front left machining area, of the upper surface of the workbench correspondingly. The upper cover plate is installed above the connection area between the back right machining area and the middle right machining area. The side tightly-abutting block is arranged on the side edges of the middle right machining area and the front left machining area. The device for rapidly locating the wind turbine hoisting beam is reasonable in structure, easy and convenient to use and highin specificity. The device for rapidly locating the wind turbine hoisting beam can improve the machining precision, improve the machining quality, lower machining difficulty, accelerate clamping speed and improve work efficiency.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

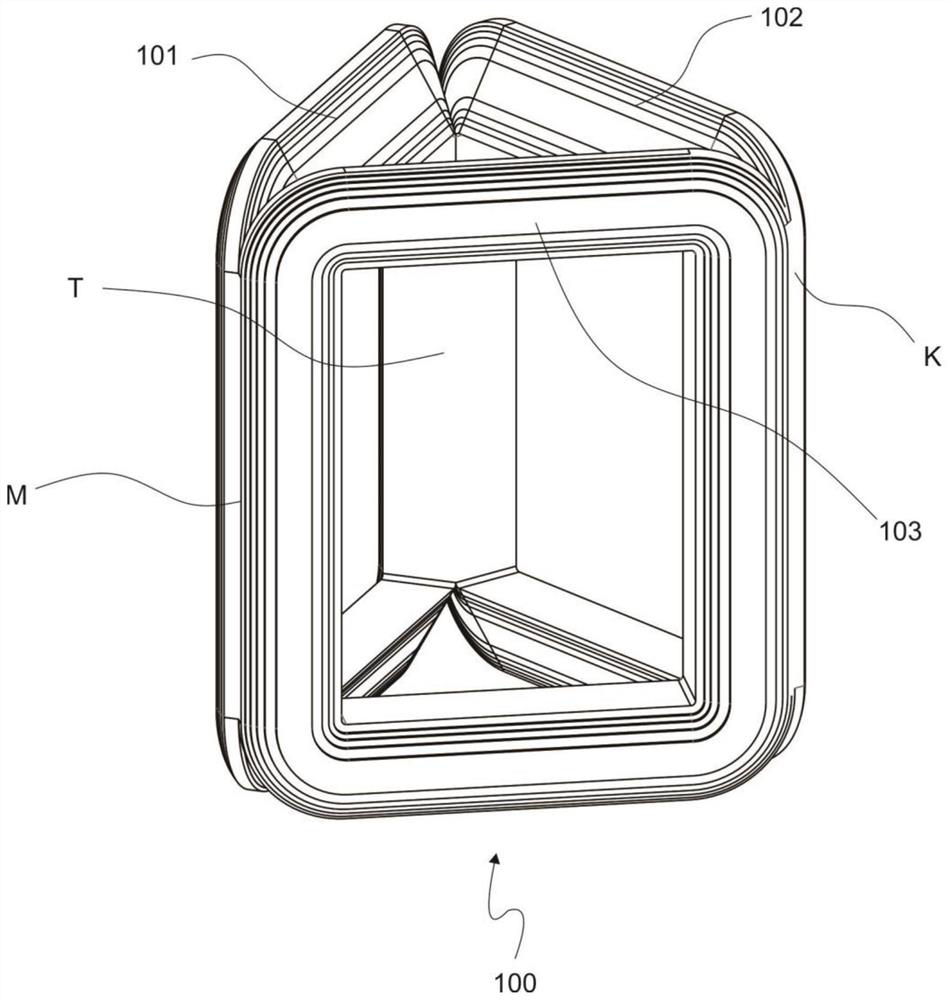

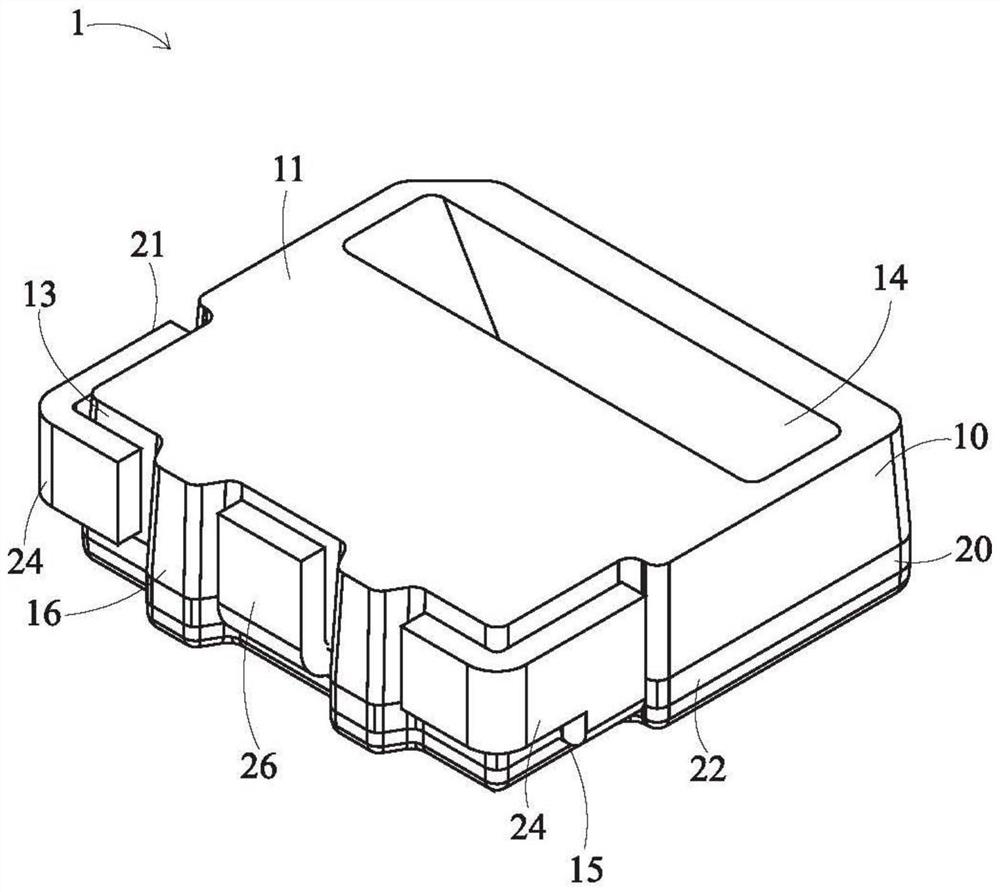

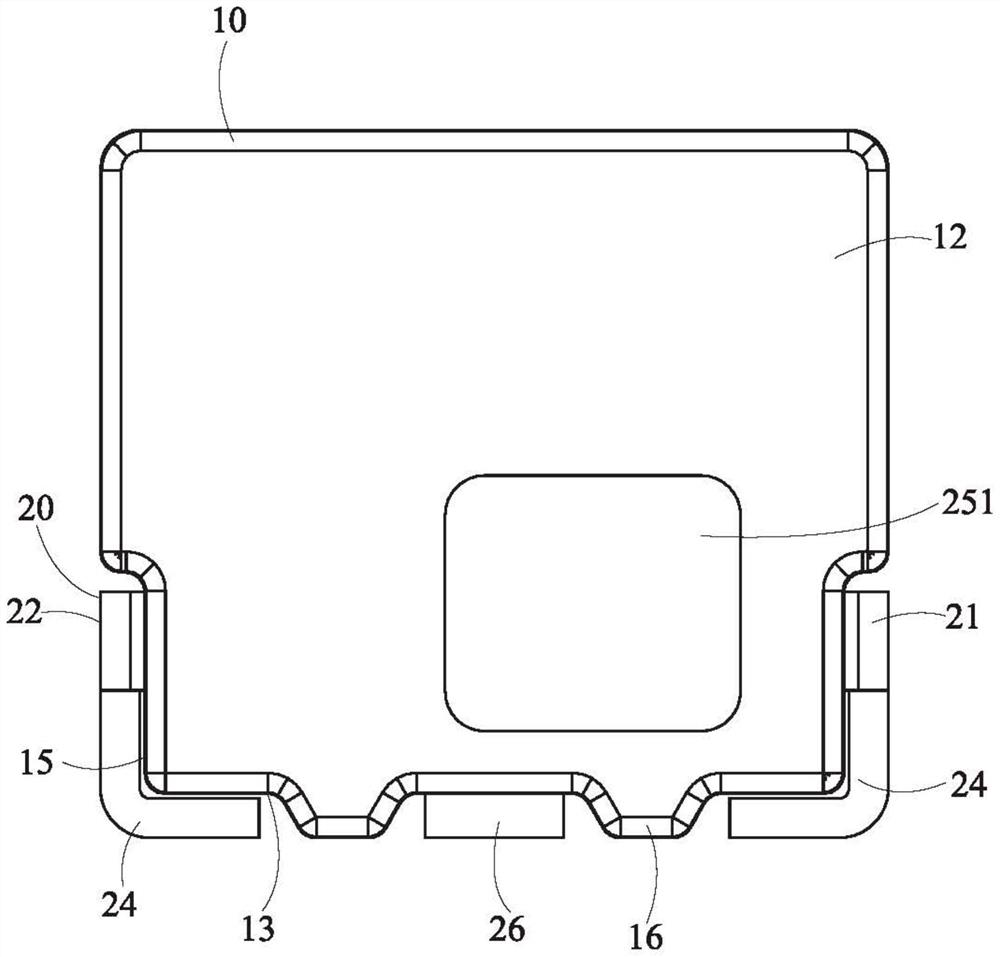

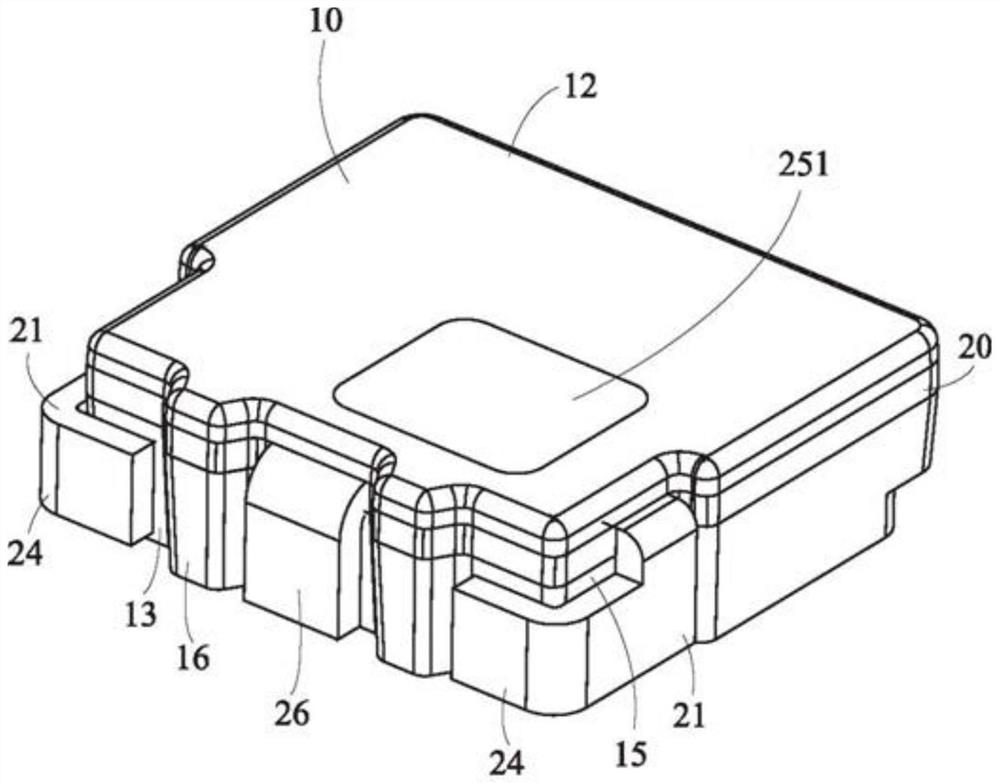

A packaging support structure and a light emitting device including the packaging support mechanism

InactiveCN109148667BReduce load errorReduce performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The present invention provides a packaging support structure and a light-emitting device comprising the packaging support structure. The packaging support structure includes: a casing, the casing includes a light-emitting surface, a backlight surface, a bottom surface and a groove, and A conductive bracket, the conductive bracket is partially covered by the housing, and the conductive bracket includes a first pin and a second pin separated from each other, the first pin and the second pin Each lead includes an electrode portion and a bent portion, the electrode portion is exposed from the housing through the groove, and the electrode portion of the bent portion extends outward to the outside of the housing and toward The bottom surface of the housing is bent; one of the first pin and the second pin further includes a heat dissipation part, and the heat dissipation part extends outward from the electrode part and extends from the The backlight surface of the casing is exposed, and the packaging support structure provided by this embodiment achieves the effect of reducing the error of the upper part and effectively removing heat energy.

Owner:EVERLIGHT ELECTRONICS

Equipment for fixedly installing and positioning wind power hoisting beam

InactiveCN111375953AReduce load errorImprove processing qualityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWorkbench

The invention relates to equipment for fixedly installing and positioning a wind power hoisting beam. The equipment comprises a workbench, a center positioning mechanism, lower fixing blocks, side plate clamping mechanisms and cross beam rapid pressing mechanisms; the center positioning mechanism is installed in the center of the upper surface of the workbench and divides the upper surface of theworkbench into a left station and a right station, the central positioning mechanism comprises side plates and a central partition plate, the lower fixing blocks are installed on the upper surfaces ofthe portions, on the left side and the right side of the center partition plate, of the workbench, the side plate clamping mechanisms are arranged above the front portion and the rear portion of thecenter partition plate, and the cross beam rapid pressing mechanisms are installed on the upper surfaces of the portions, on the left side and the right side of the center partition plate, of the workbench. The equipment for fixedly installing and positioning the wind power hoisting beam is scientific in design, reasonable in structure and easy and convenient to use, and by means of the equipment,the machining difficulty can be lowered, the installing speed can be increased, and the working efficiency can be improved; in addition, convenience can be provided for operation of workers, and themachining quality of products is guaranteed.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

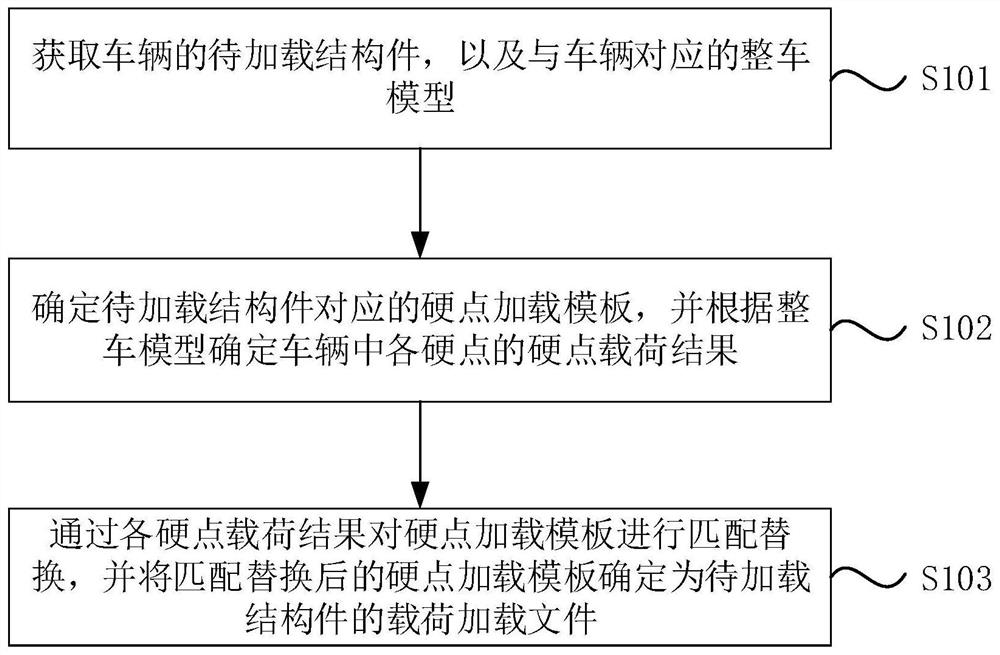

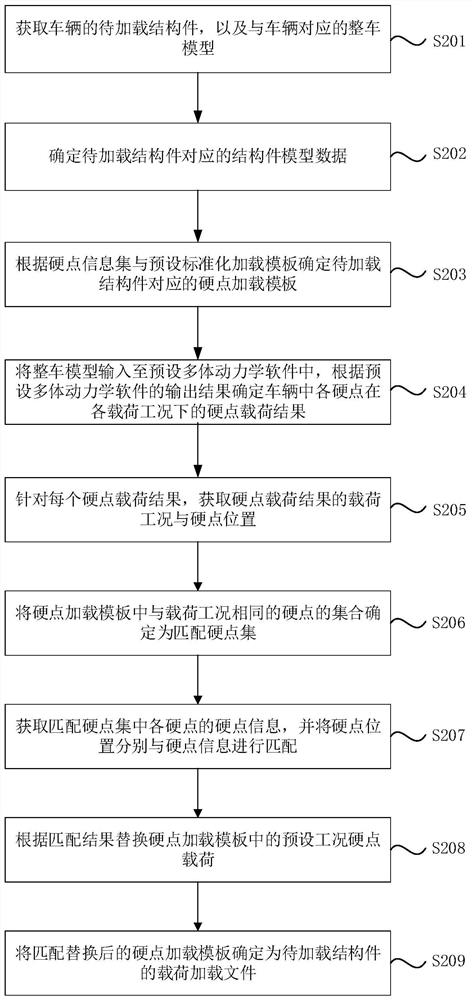

Load loading method and device, equipment and storage medium

ActiveCN113065186AImprove accuracySolve the cumbersome manual loading processGeometric CADDesign optimisation/simulationReliability engineeringHardpoint

The embodiment of the invention discloses a load loading method and device, equipment and a storage medium. The method comprises the steps of obtaining a to-be-loaded structural member of a vehicle and a whole vehicle model corresponding to the vehicle; determining a hard point loading template corresponding to the to-be-loaded structural member, and determining a hard point load result of each hard point in the vehicle according to the whole vehicle model; and matching and replacing the hard point loading template according to the load result of each hard point, and determining the matched and replaced hard point loading template as a load loading file of the to-be-loaded structural member. According to the technical scheme, when structural strength durability simulation is carried out on the to-be-loaded structural component in the vehicle, load loading can be directly and automatically carried out on the to-be-loaded structural component according to the load loading file, the problems that the manual loading process is tedious, consumed time is long, and errors are likely to happen are solved. The working efficiency of loading the load for the structural member is improved, the loading error rate is reduced, and then the accuracy related to the subsequent vehicle performance is improved.

Owner:CHINA FIRST AUTOMOBILE

Clamping installing device suitable for being used during double-tool machining of key block

InactiveCN109968070AReduce loading errorsImprove machining accuracyPositioning apparatusMetal-working holdersMachiningAutomation

The invention relates to a clamping installing device suitable for being used during double-tool machining of a key block. A base, a positioning block, an upper pressing plate, an air cylinder and a side baffle are included. One positioning block is arranged on the upper surface of the base, a workpiece installing groove is manufactured in the upper surface of the positioning block, and a verticalplate is manufactured on the side edge of the workpiece installing groove. The upper pressing plate is arranged at the upper portion of the vertical plate. The front end portion of the upper pressingplate is located above the workpiece installing groove. The air cylinder is arranged on one side edge of the positioning block, a piston rod of the air cylinder extends to the other side of the positioning block, and the end portion of the piston rod is connected with one side baffle. The clamping installing device suitable for being used during double-tool machining of the key block is reasonable in design, practical in structure, high in practicability, high in automation degree, high in specificity and high in matching degree with workpieces; and by usage of the device, the clamping installing time can be shortened, the machining precision and the product qualification rate are improved, the requirements of customers are met, and the clamping installing device is suitable for usage andpopularization in enterprises.

Owner:天津市臣涛精密机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com