Method and system for acquiring elevator loads

A load and elevator technology, which is applied in the field of elevator load processing, can solve the problems of elevator weighing device weighing error, different weighing, elevator weighing device error, etc., and achieve the effect of weakening the load error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

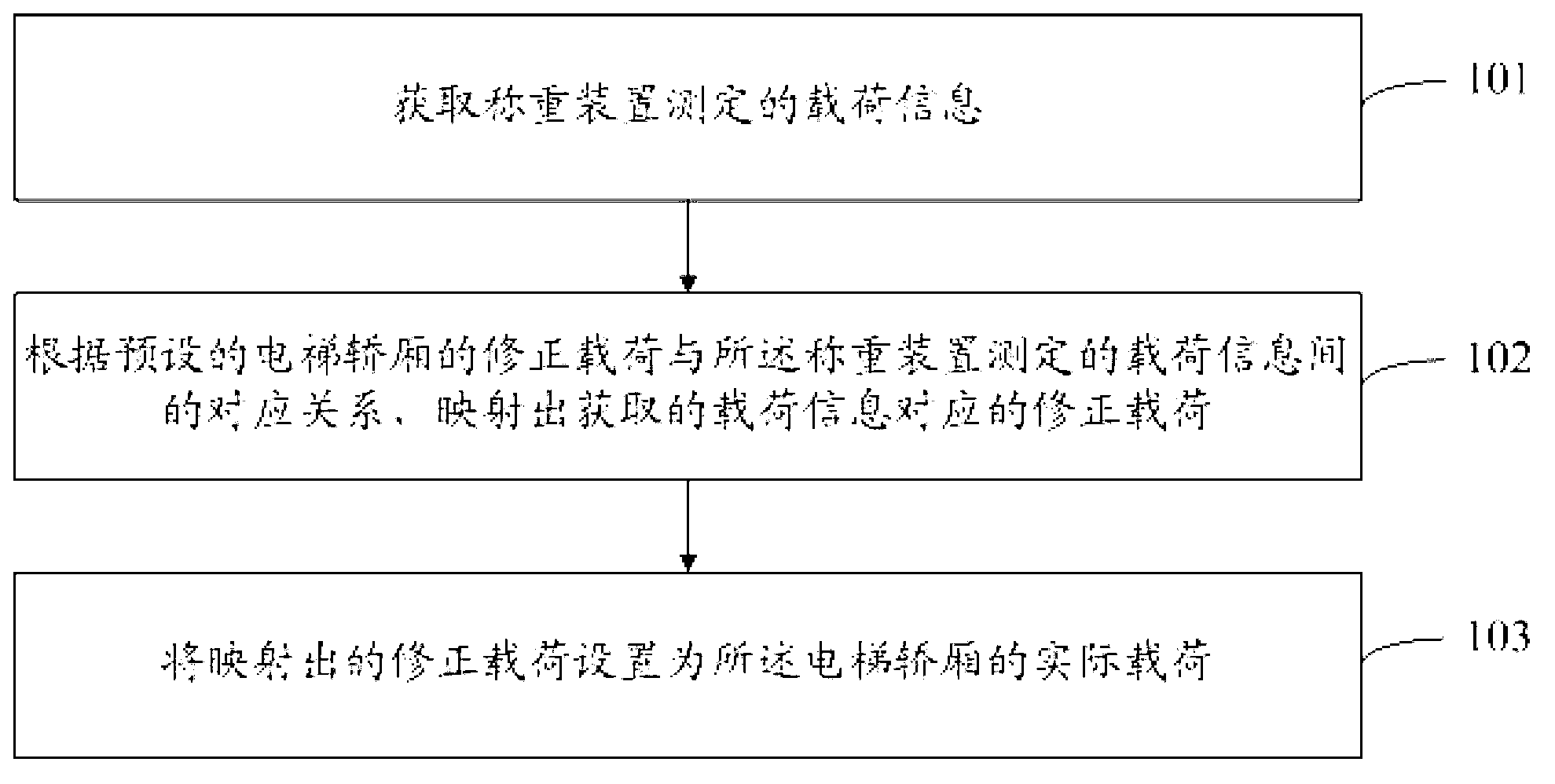

[0023] see figure 1 , figure 1 It is a schematic flowchart of the first embodiment of the method for obtaining elevator load in the present invention.

[0024] The method for obtaining the elevator load of the present embodiment includes the following steps:

[0025] Step 101, acquiring load information measured by a weighing device.

[0026] Step 102, according to the preset correspondence between the corrected load of the elevator car and the load information measured by the weighing device, map the corrected load corresponding to the acquired load information.

[0027] Step 103, setting the mapped corrected load as the actual load of the elevator car.

[0028] The method for obtaining the load of the elevator converts the load measured by the weighing device of the elevator into a corrected load by using a preset corresponding relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com