Clamping installing device suitable for being used during double-tool machining of key block

A key block and workpiece technology, applied in the field of clamping devices, can solve the problems of reduced workpiece machining accuracy, increased workpiece clamping error, and increased rejection rate, and achieves reduction of clamping error, improved machining accuracy, and high matching degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

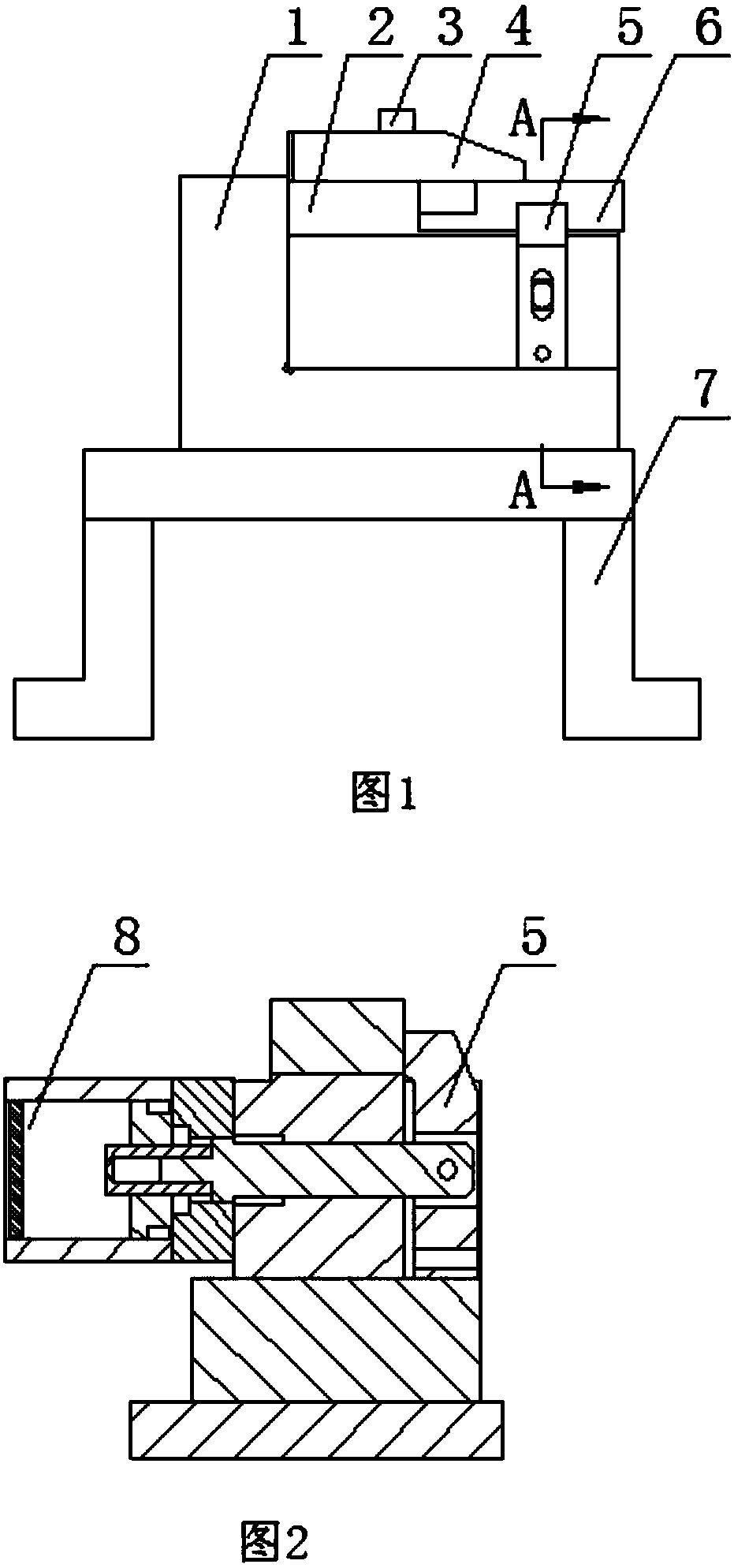

[0016] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings; it should be noted that this embodiment is narrative and not restrictive, and the protection scope of the present invention cannot be limited by this.

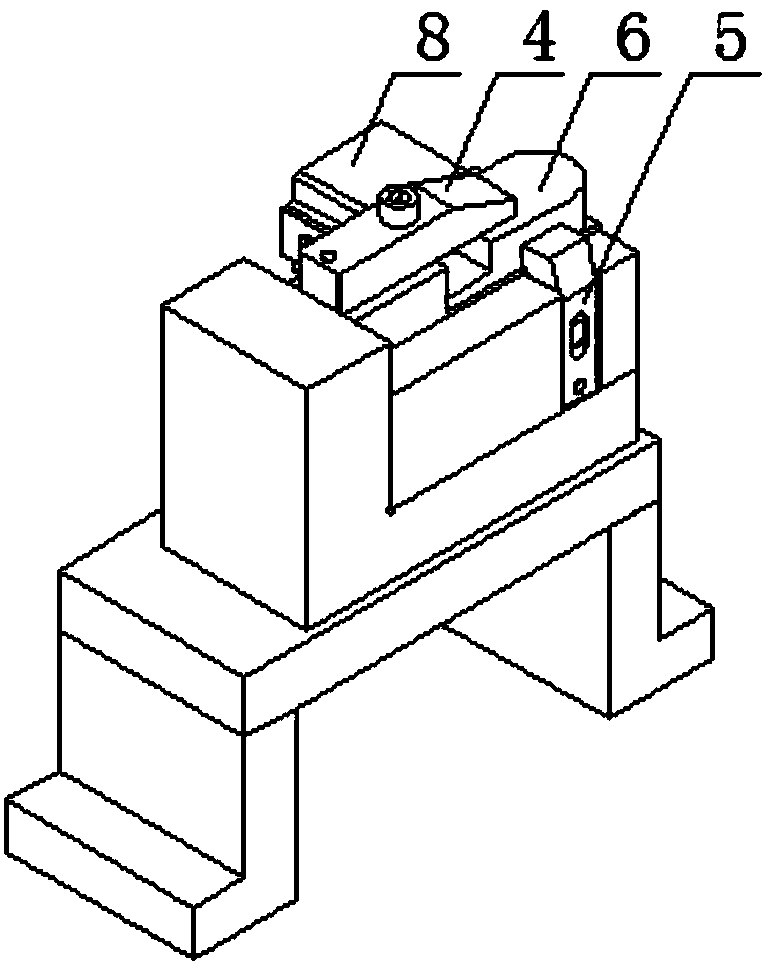

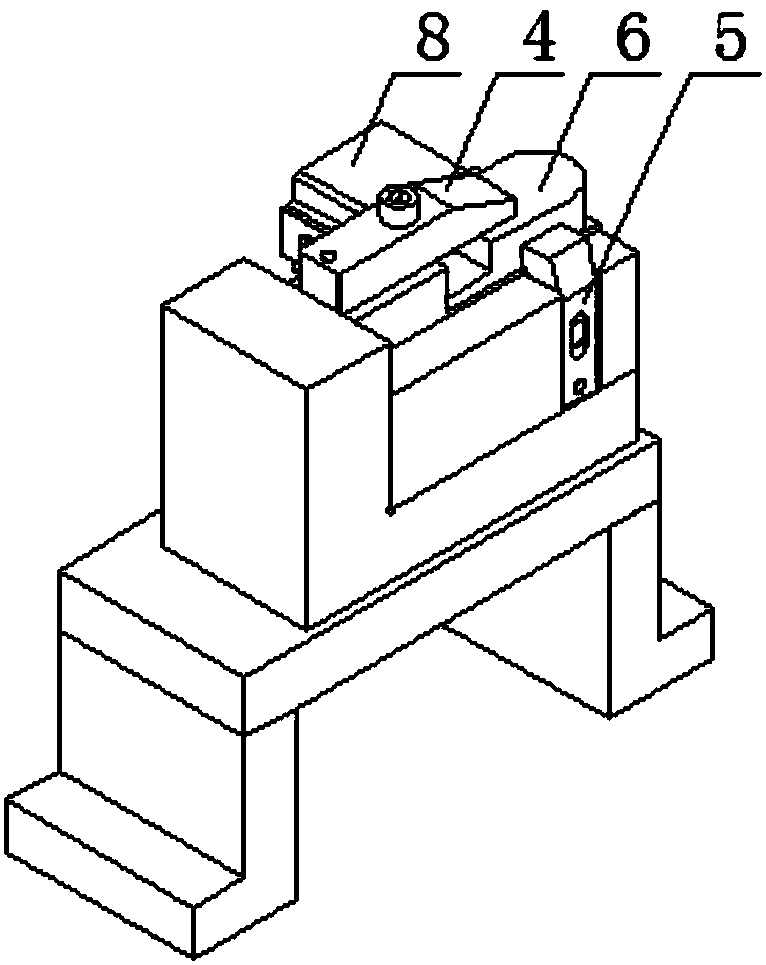

[0017] A clamping device suitable for double-knife processing of key blocks includes a base 7, a positioning block 1, an upper pressing plate 4, a cylinder 8 and a side baffle 5. The base is a bench structure composed of a top plate and two supporting legs. A positioning block is installed on the upper surface of the base, and a workpiece mounting groove is formed on the upper surface of the positioning block. A vertical plate 2 is formed on the side of the workpiece mounting groove. The upper part of the vertical plate is installed with an upper pressing plate through the top wire 3. The front end of the upper pressing plate is located above the workpiece installation groove.

[0018] A cylinder is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com