Load loading method and device, equipment and storage medium

A technology of load and load conditions, applied in the fields of load loading methods, devices, equipment and storage media, can solve problems such as time-consuming, error-prone, and design that affects vehicle performance, so as to reduce loading error rate and improve accuracy , The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

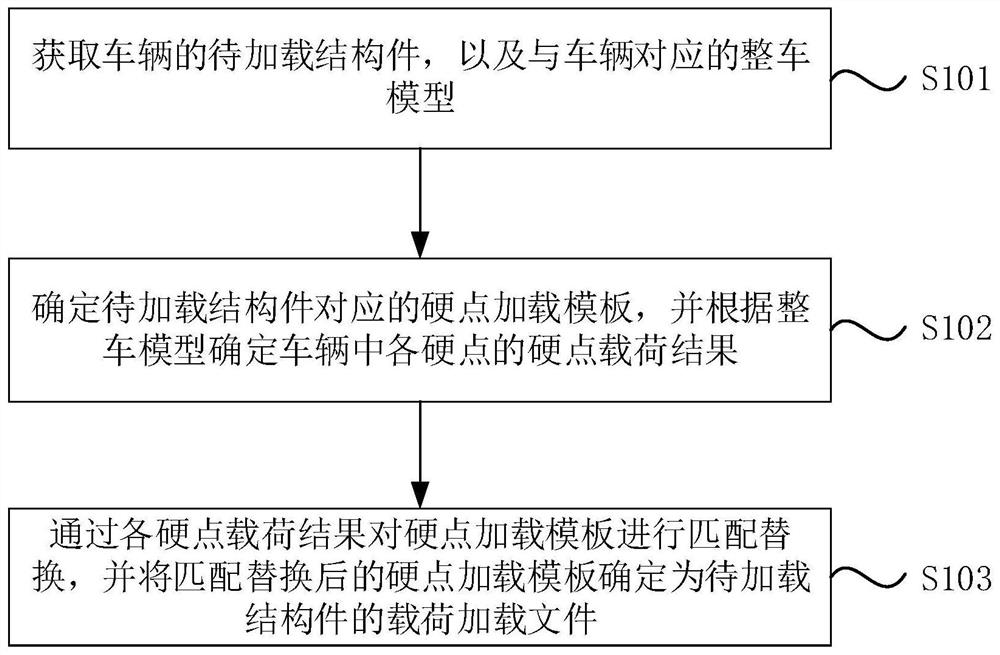

[0054] figure 1 It is a flow chart of a load loading method provided by Embodiment 1 of the present invention. This embodiment is applicable to the case of loading structural parts of a vehicle to be loaded during the simulation of vehicle structural strength and durability. This method can be implemented by a load loading device To execute, the load loading device may be implemented by software and / or hardware, and the load loading device may be configured on a computer device, and the computer device may be composed of two or more physical entities, or may be composed of one physical entity. Generally speaking, the computer equipment may be a notebook, a desktop computer, a smart tablet, and the like.

[0055] Such as figure 1 As shown, a load loading method provided in Embodiment 1 specifically includes the following steps:

[0056] S101. Obtain the structural parts to be loaded of the vehicle and the vehicle model corresponding to the vehicle.

[0057] In this embodimen...

Embodiment 2

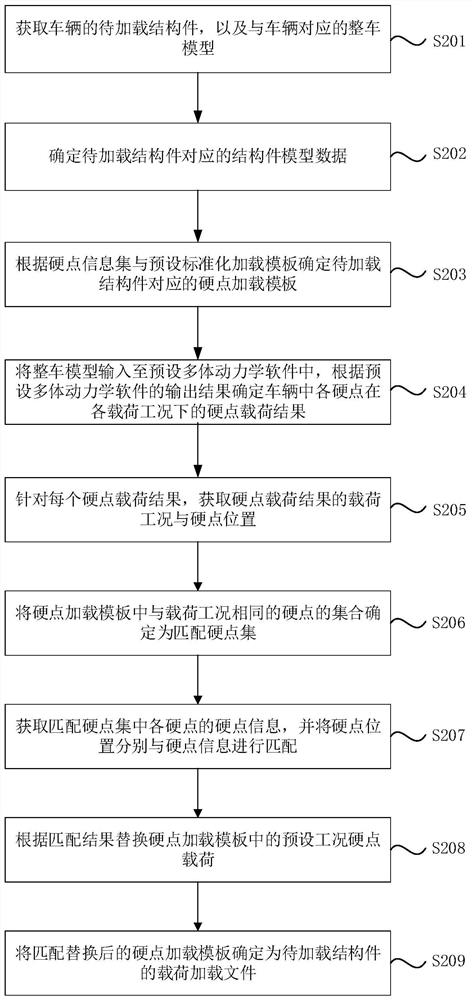

[0067] figure 2 It is a flow chart of a load loading method provided by Embodiment 2 of the present invention. The technical solution of the embodiment of the present invention is further optimized on the basis of the above-mentioned optional technical solutions. The hard point loading template corresponding to the structure, for each hard point load result, determine its corresponding load case and hard point position, and determine the hard point matching its working condition in the hard point loading template according to the load case Then match each hard point in the hard point set with the hard point corresponding to the hard point load result, replace the hard point load result into the hard point loading template according to the matching result, and finally generate the load file corresponding to the structure to be loaded . The determined load loading file can be directly used for the load loading of the structural parts to be loaded without manual participation, ...

Embodiment 3

[0109] Figure 8 A schematic structural diagram of a load loading device provided in Embodiment 3 of the present invention, the load loading device includes: a model acquisition module 31 , a load result determination module 32 and a loading file determination module 33 .

[0110] Among them, the model acquisition module 31 is used to obtain the structural parts to be loaded of the vehicle, and the vehicle model corresponding to the vehicle; the load result determination module 32 is used to determine the hard point loading template corresponding to the structural parts to be loaded, and according to the vehicle model The model determines the hard point load results of each hard point in the vehicle; the loading file determination module 33 is used to match and replace the hard point loading templates through the hard point load results, and determine the hard point loading templates after matching and replacement as to-be-loaded Loading file for structural members.

[0111] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com