Patents

Literature

50 results about "Hardpoint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hardpoint (more formally known as a station or weapon station) is a location on an airframe designed to carry an external or internal load. This includes a station on the wing or fuselage of a civilian aircraft or military aircraft where external jet engine, ordnance, countermeasures, gun pods, targeting pods or drop tanks can be mounted.

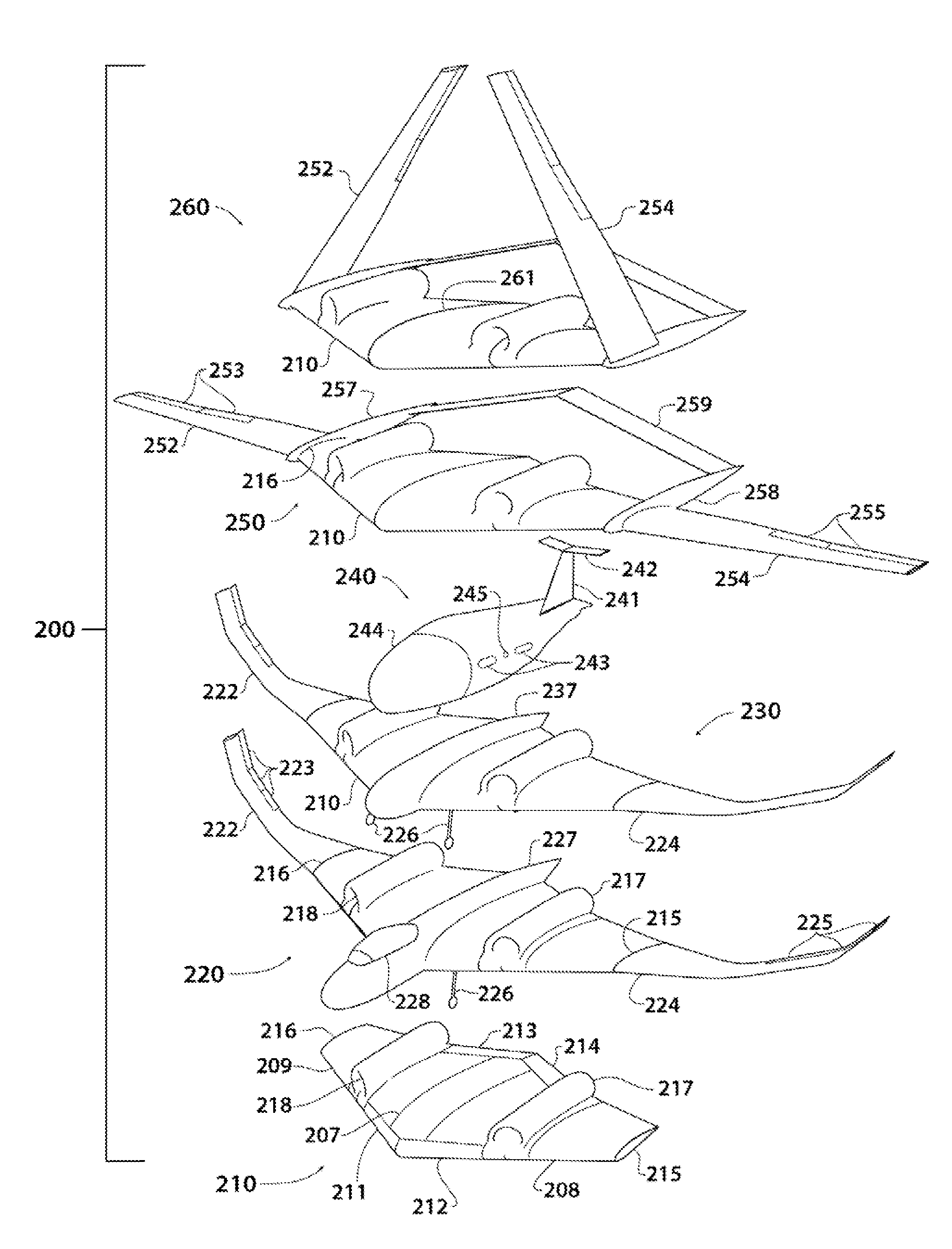

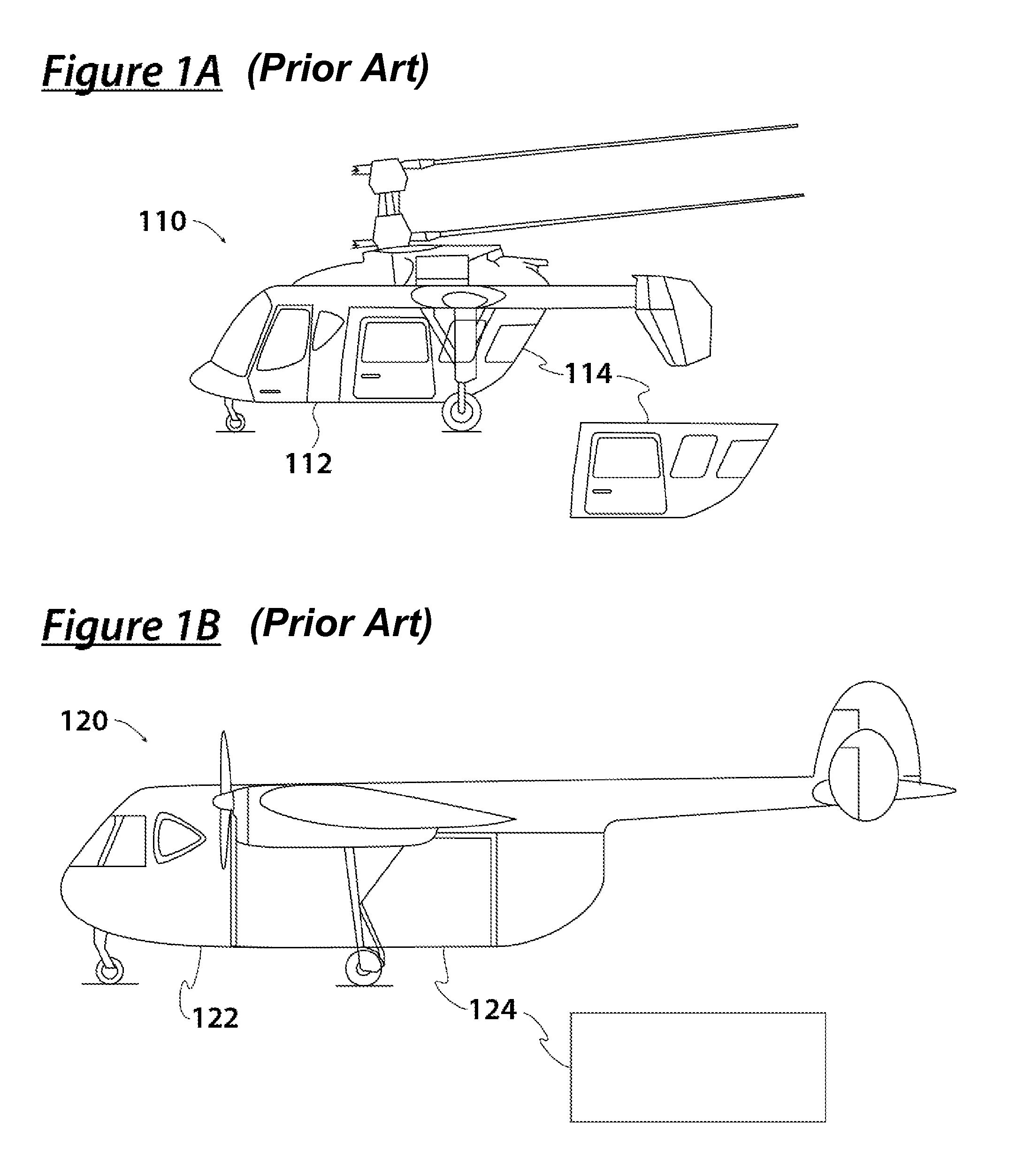

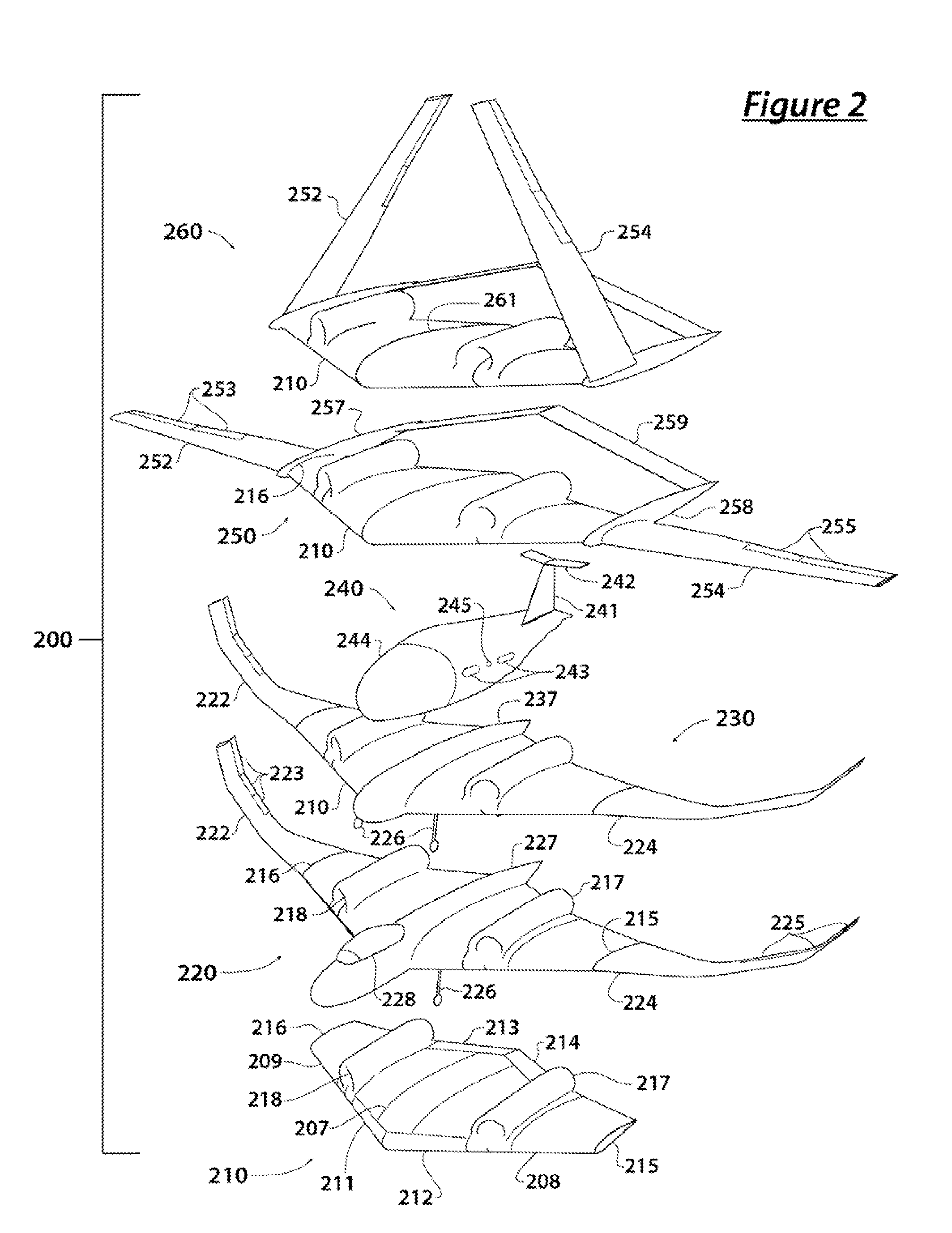

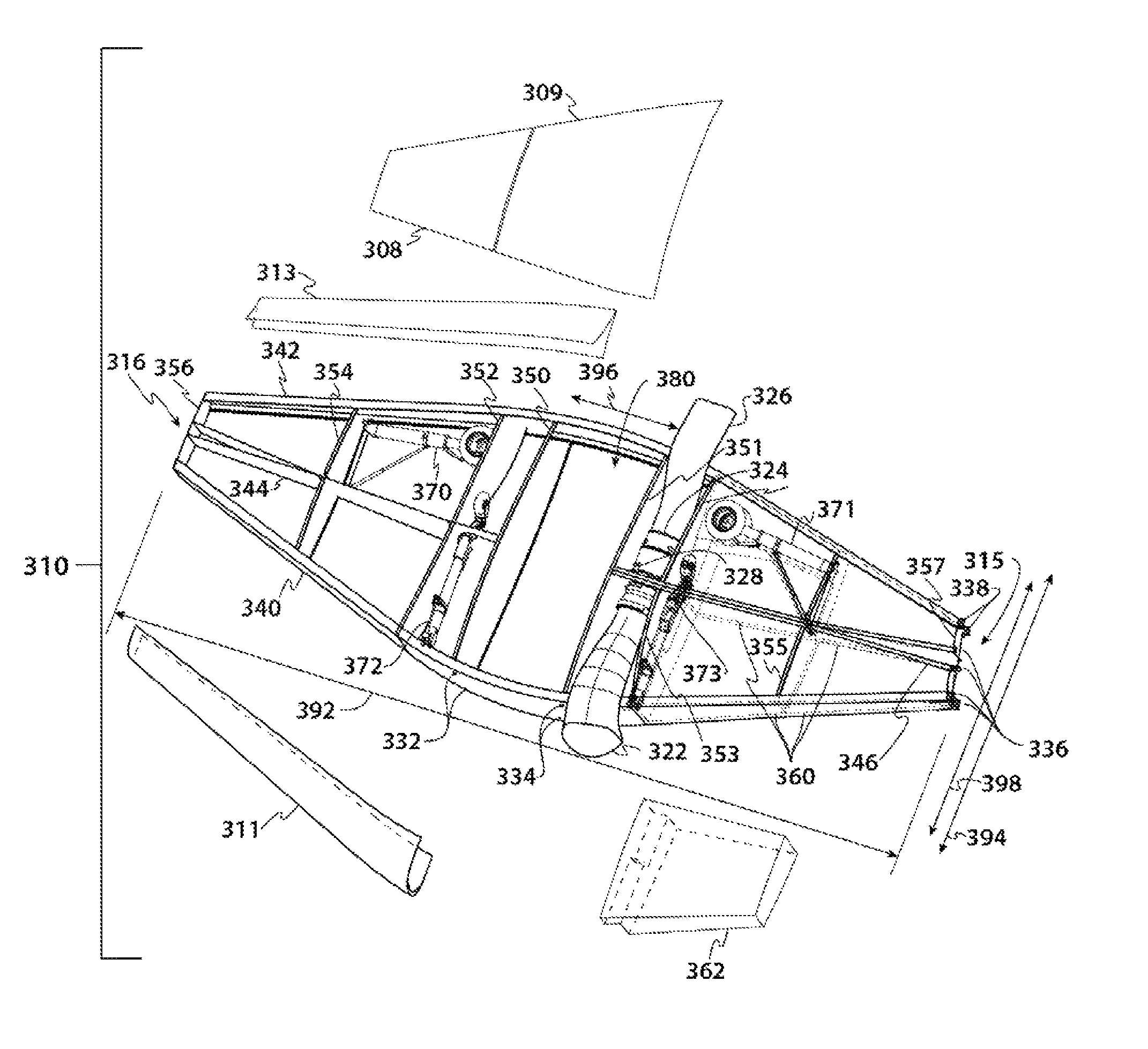

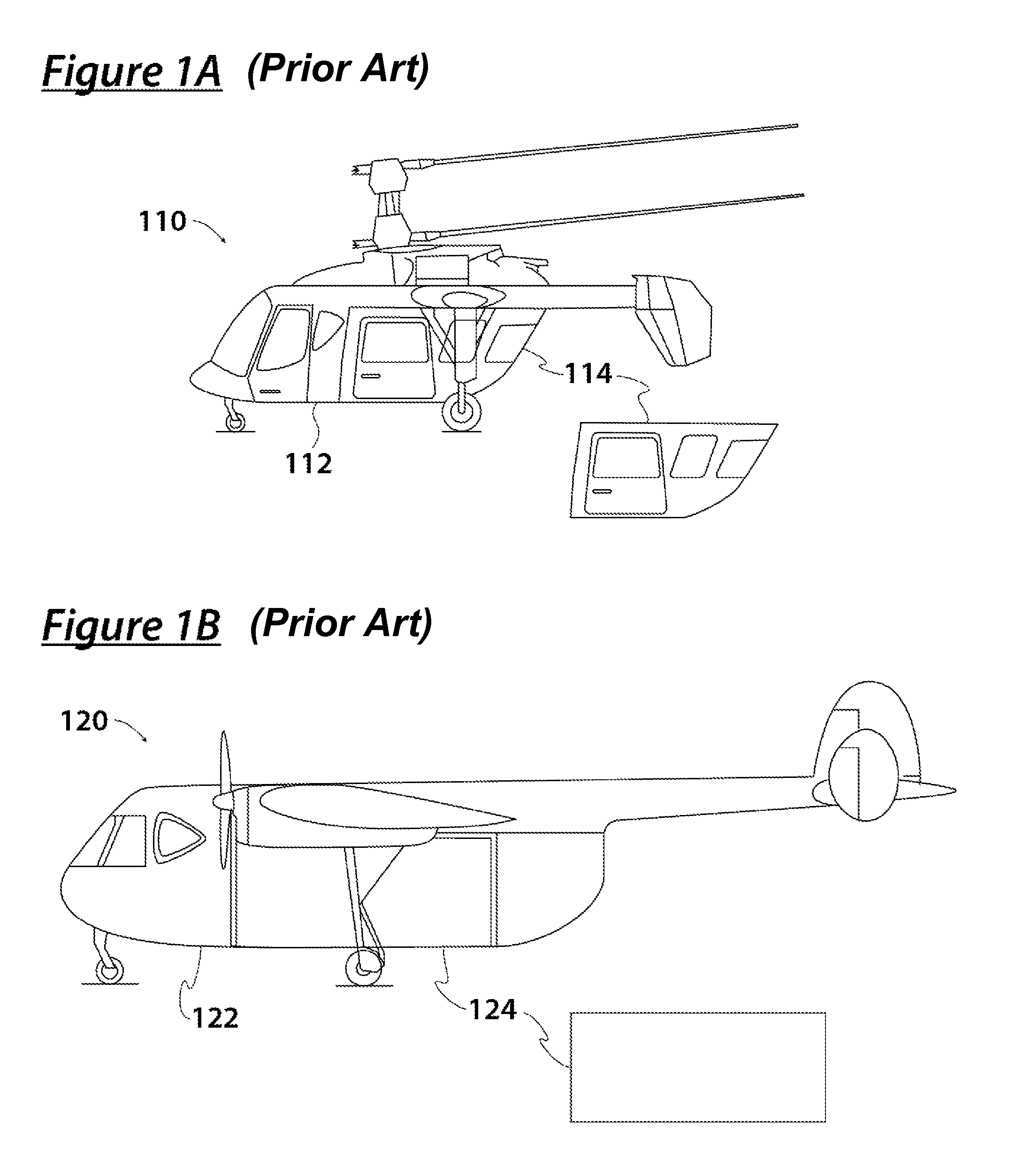

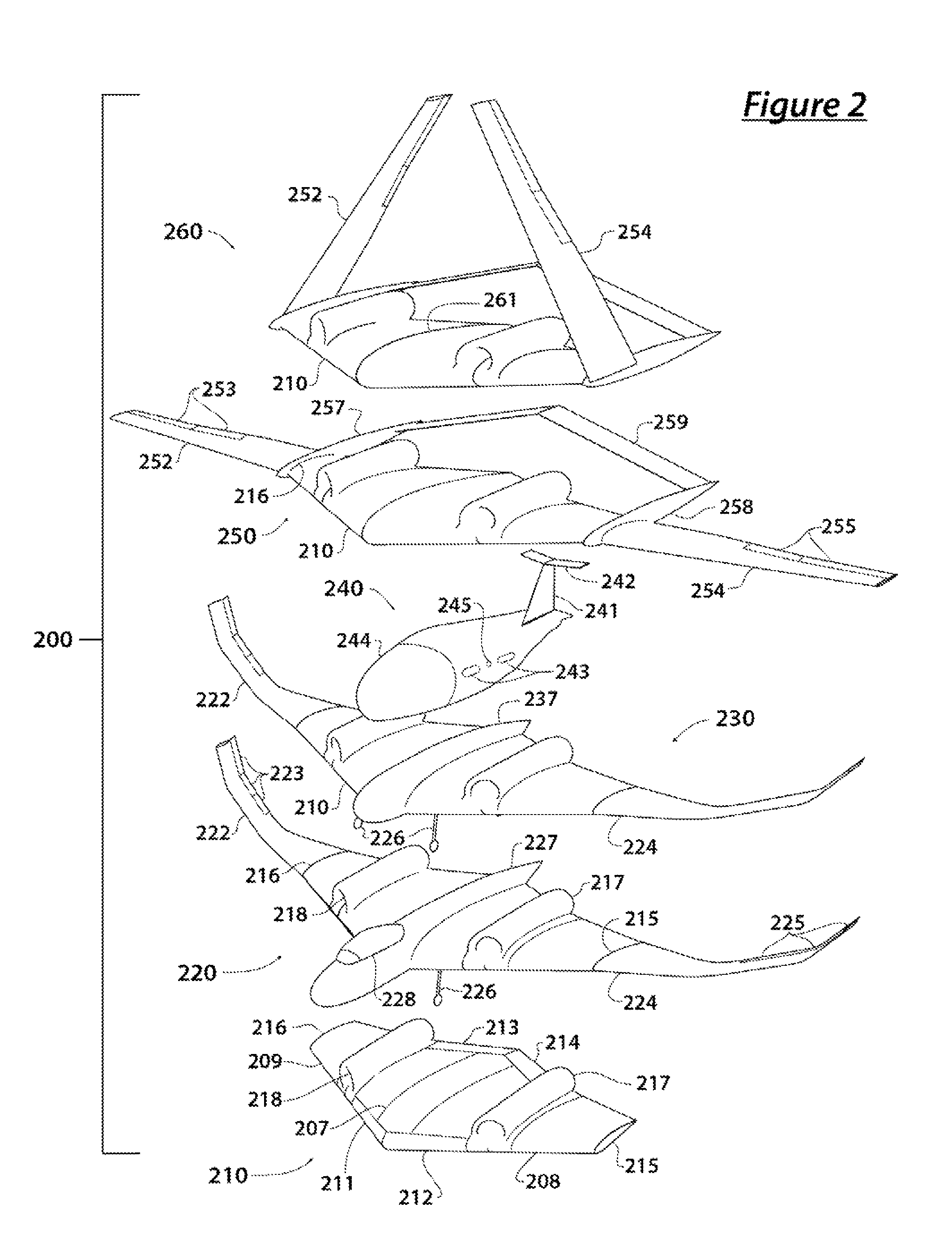

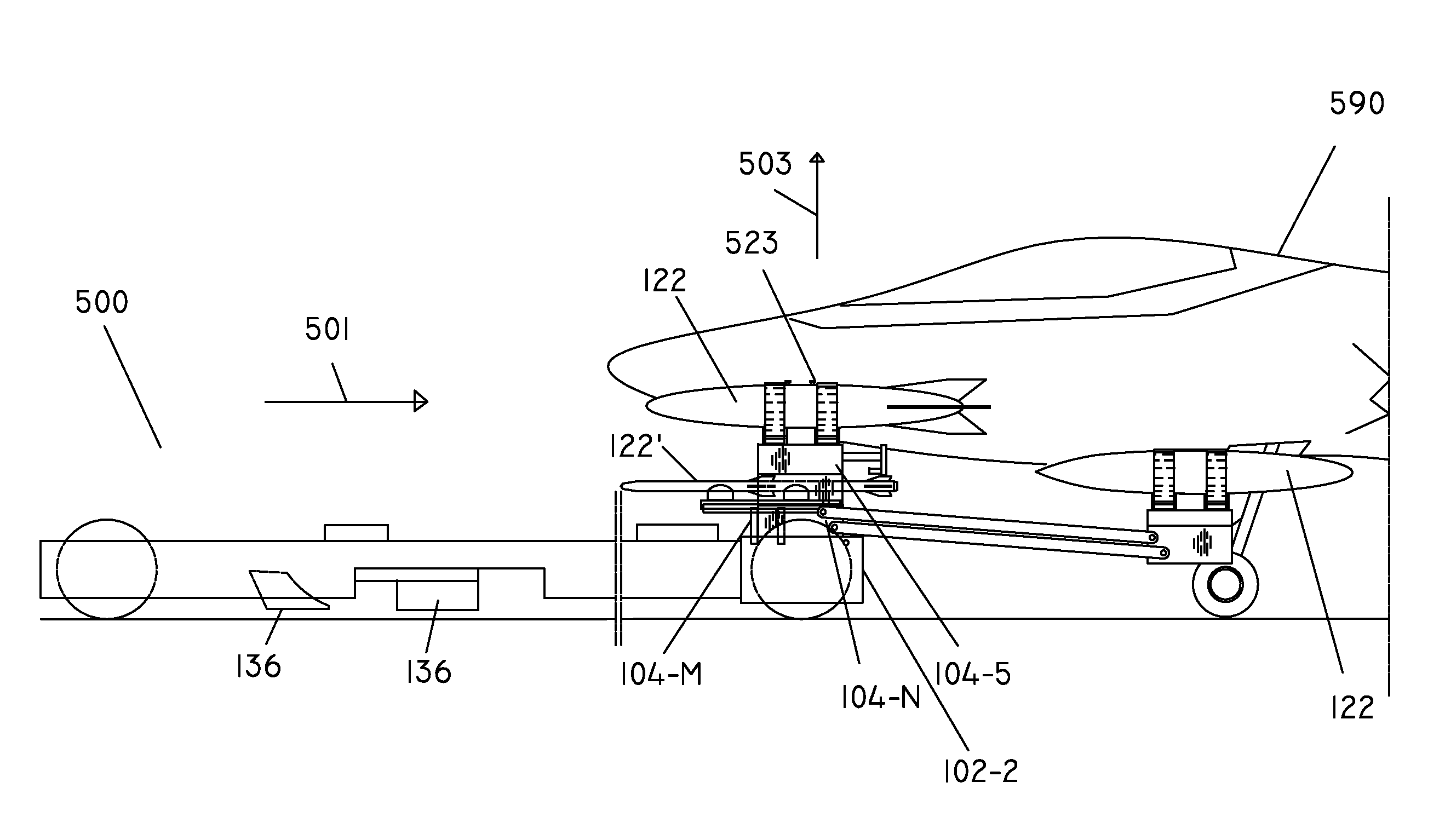

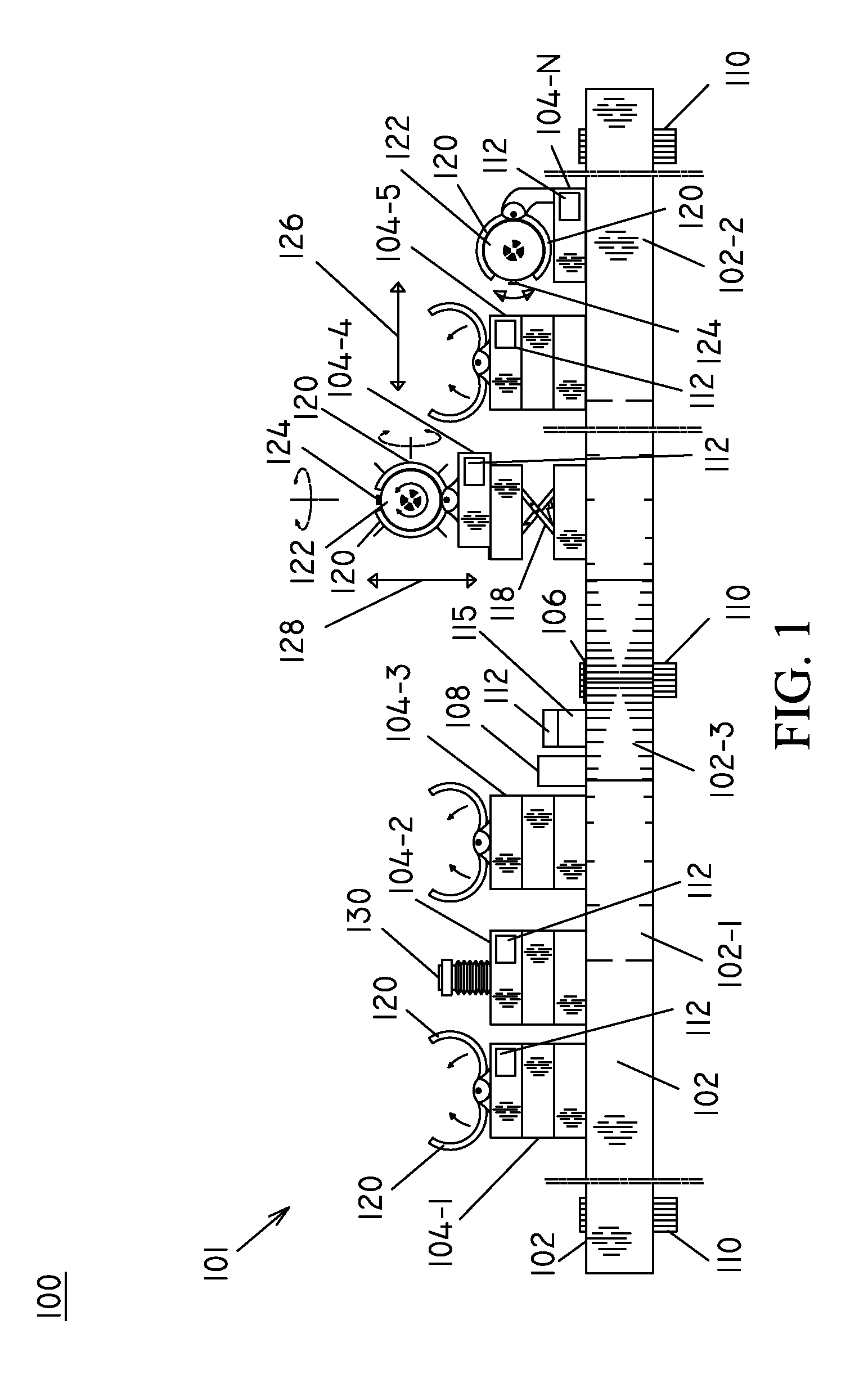

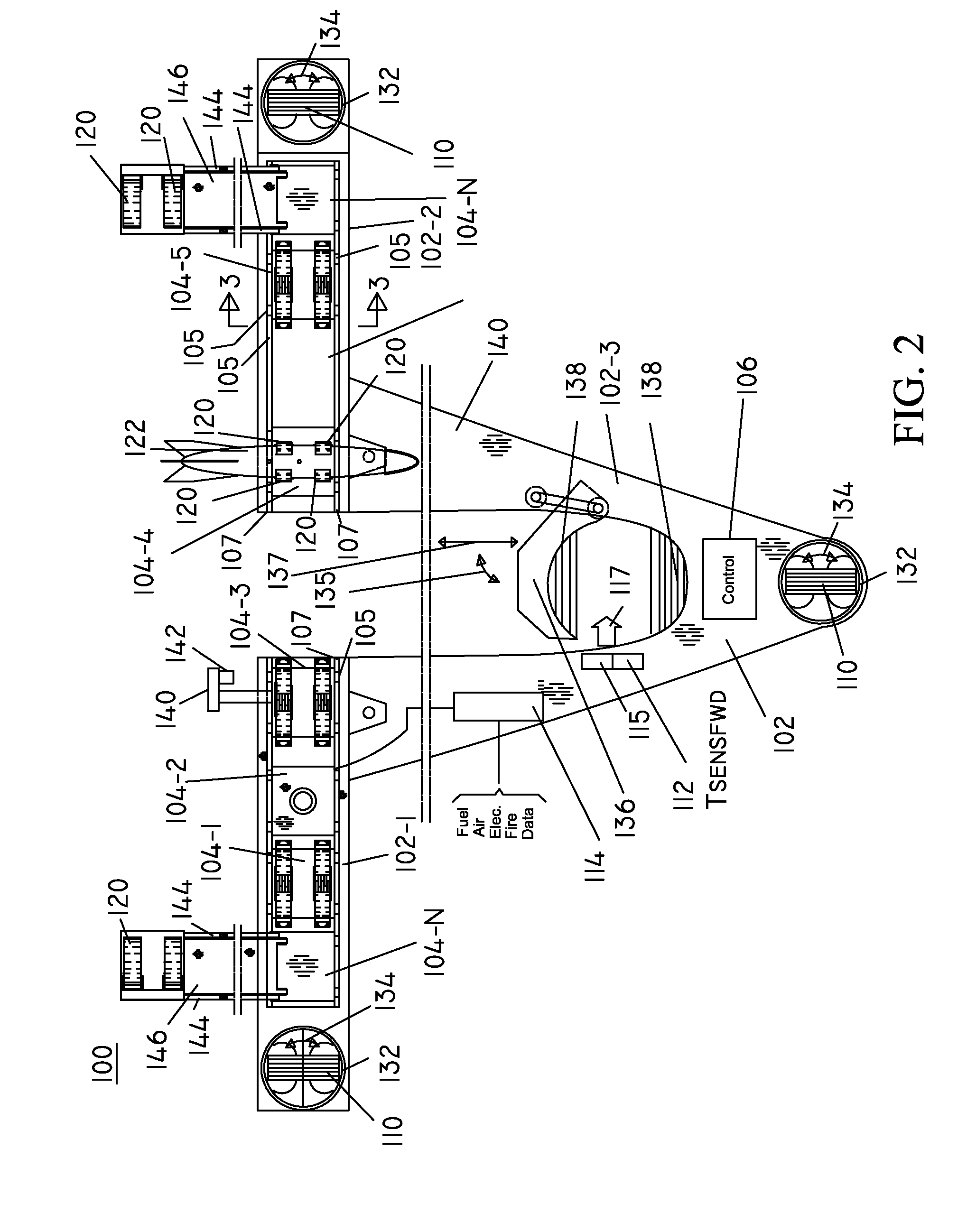

Multi-Role Aircraft with Interchangeable Mission Modules

A flight-operable, truly modular aircraft has an aircraft core to which one or more of outer wings members, fuselage, cockpit, leading and trailing edge couplings, and empennage and tail sections can be removably coupled and / or replaced during the operating life span of the aircraft. In preferred embodiments the aircraft core houses the propulsive engines, avionics, at least 80% of the fuel, and all of the landing gear. The aircraft core is preferably constructed with curved forward and aft composite spars, that couple to outer wing sections and possibly other sections using hardpoints. The aircraft core preferably has a large central cavity dimensioned to interchangeably carry an ordnance launcher, a surveillance payload, electronic countermeasures, and other types of cargo. Contemplated aircraft can be quite large, for example having a wing span of at least 80 ft.

Owner:KAREM ABE

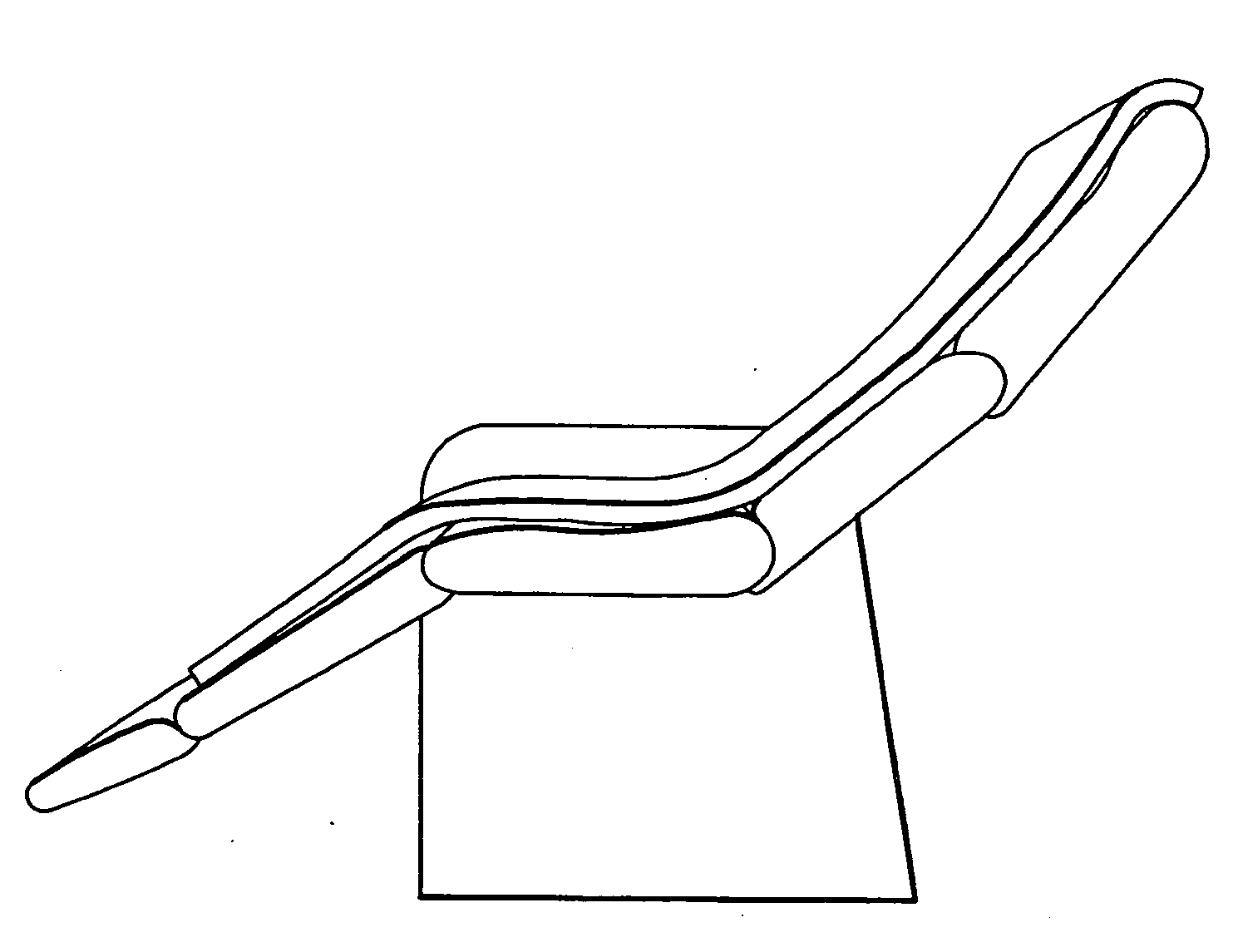

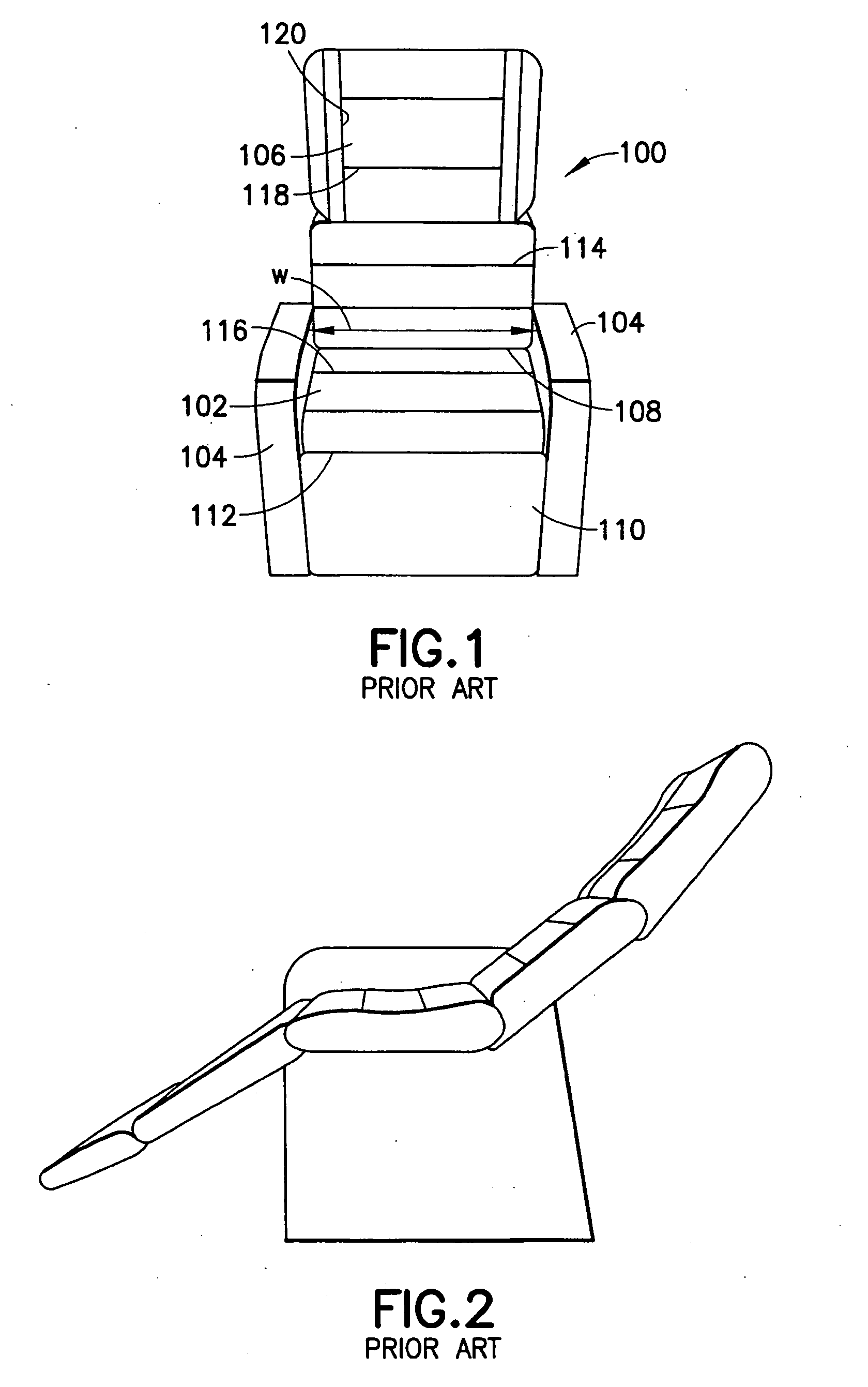

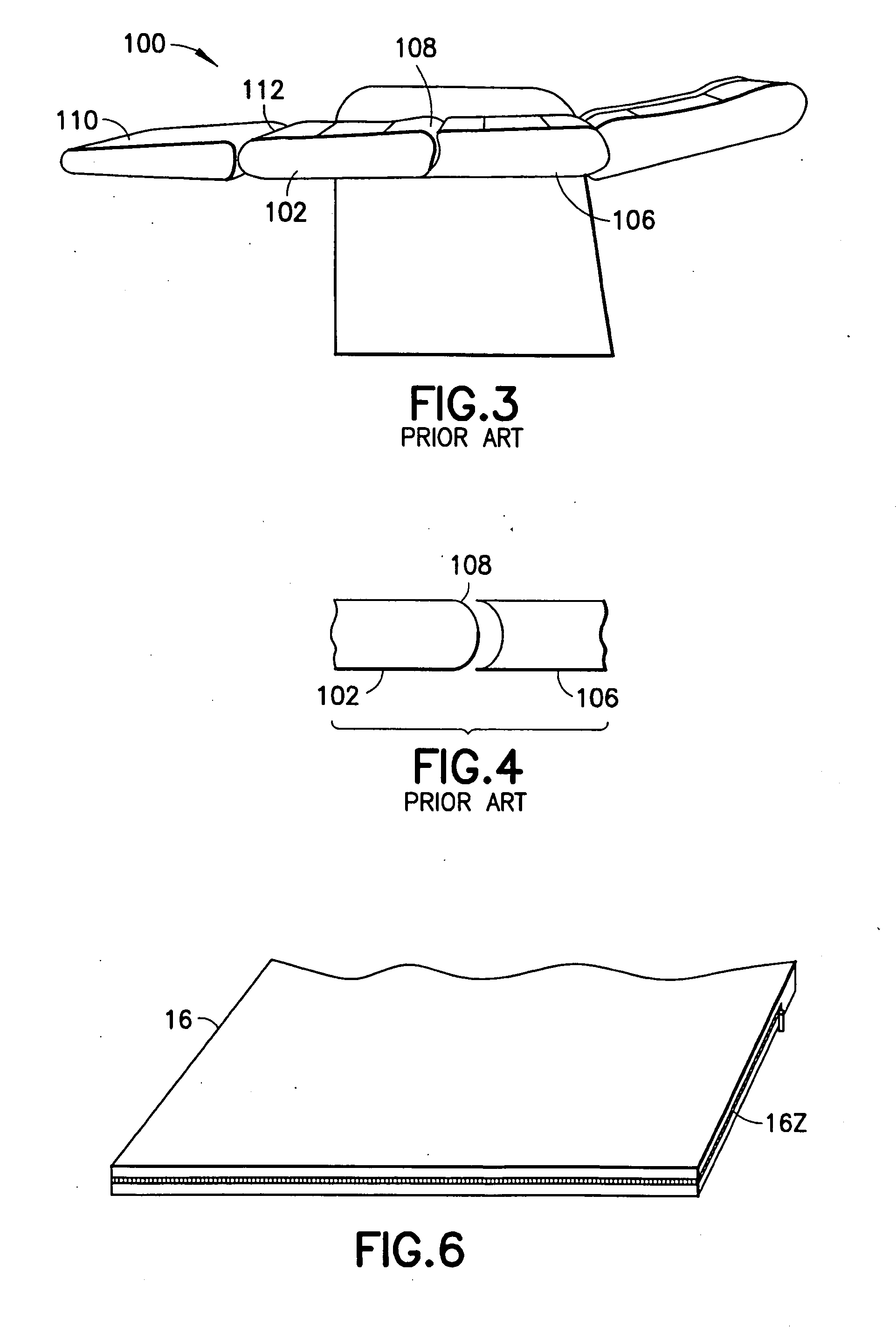

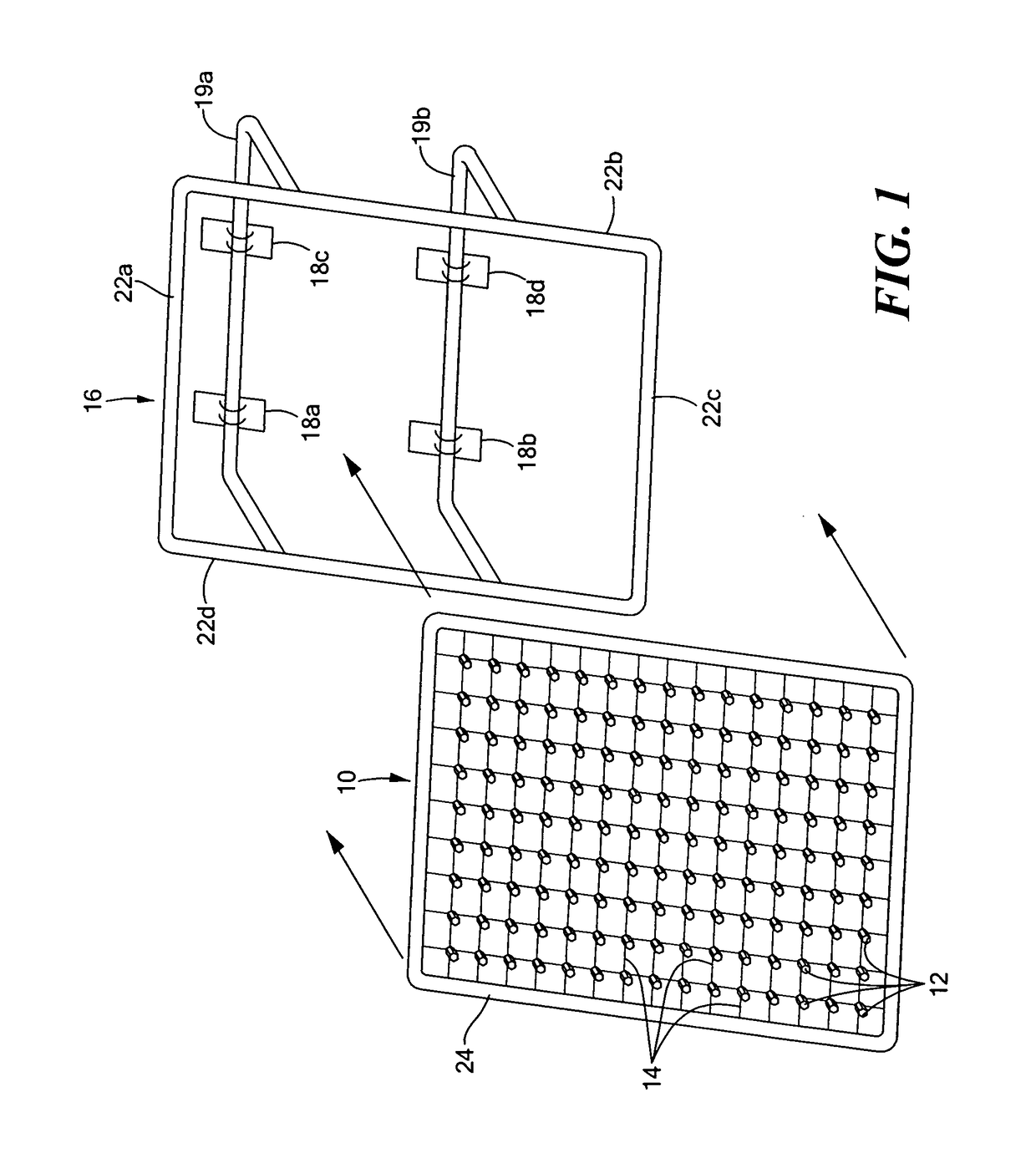

Seating accessory

ActiveUS20070120409A1Avoid permanent damageEasy to storeSeat coveringsTravelling sacksThigh musculatureBack support

A seating pad assembly is provided for use by travelers to increase the comfort for a seat on a public transportation vehicle or at a public transit terminal. The seating pad assembly includes a cushion formed from a viscoelastic foam and having dimensions substantially conforming to the dimensions of at least the hip / thigh support and the back support of the seat. Thus, the viscoelastic foam will bridge hard points and pinch points of the seat and will efficiently support the traveler across the gap. The seating pad assembly further includes a removable cover, straps for holding the pad in a coiled condition and a carrying bag for transporting the pad assembly.

Owner:NIGHTGEAR LLC

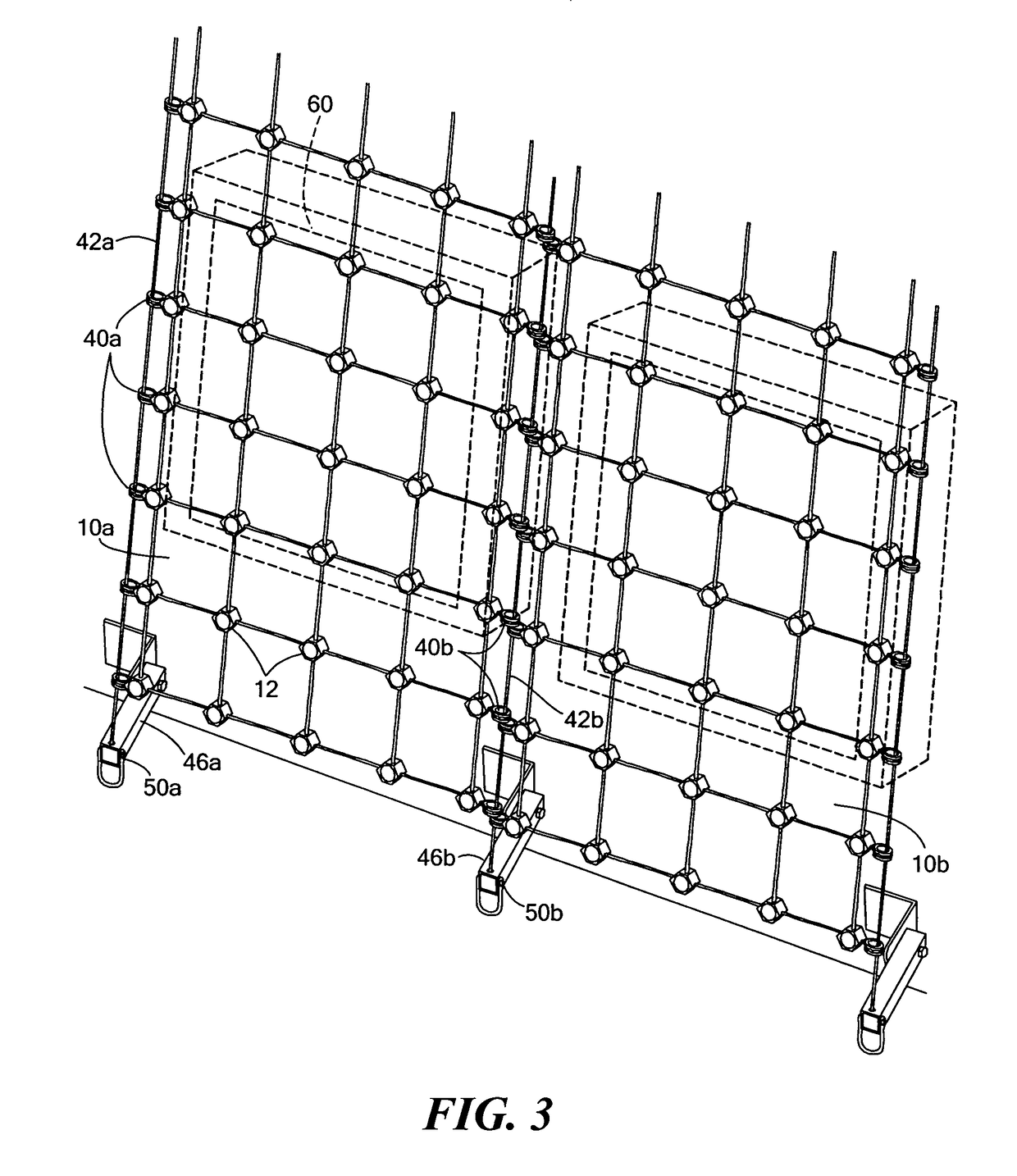

Vehicle and structure shield with a cable frame

Owner:FOSTER-MILLER

Multi-role aircraft with interchangeable mission modules

Owner:KAREM ABE

Method for constructing model base based on reverse engineering

InactiveCN106169006AReduce workloadGeometric CADSpecial data processing applicationsMechanical modelsWorkload

The invention discloses a method for constructing a model base based on reverse engineering. The method comprises the steps of using an ADAMS to establish a dynamical model of a mechanical structure, and obtaining an ADAMS hardpoint file; reading coordinate values of each hardpoint in the ADAMS hardpoint file, and forming a revisable hardpoint table; according to the hardpoint table, establishing a hardpoint mechanical structure model; according to the hardpoint mechanical structure model, establishing a mechanical structure point and line model of each component of the mechanical structure; designing detailed digital analogy of the component according to the mechanical structure point and line model of the component; optimizing the detailed digital analogy; establishing a mechanical structure point and line DMU model, decorating the optimized detailed digital analogy of each component to a corresponding point and line component, and obtaining a parameterized DMU model of the mechanical structure. According to the method, through the use of the reverse engineering, the workload needed for design alternation in the mechanical structure design process can be reduced, and an optimized mechanical model is obtained.

Owner:西安明德理工学院

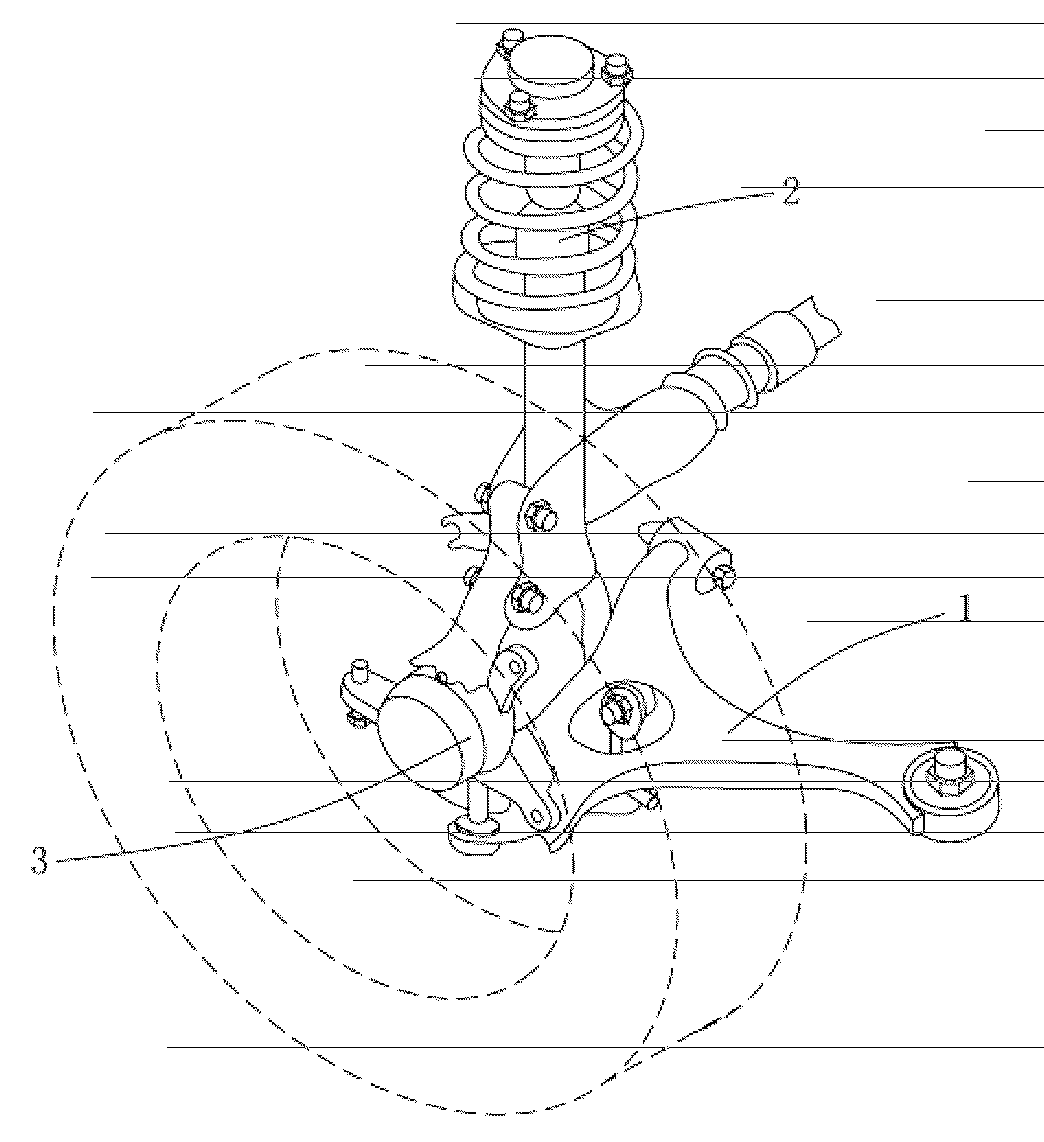

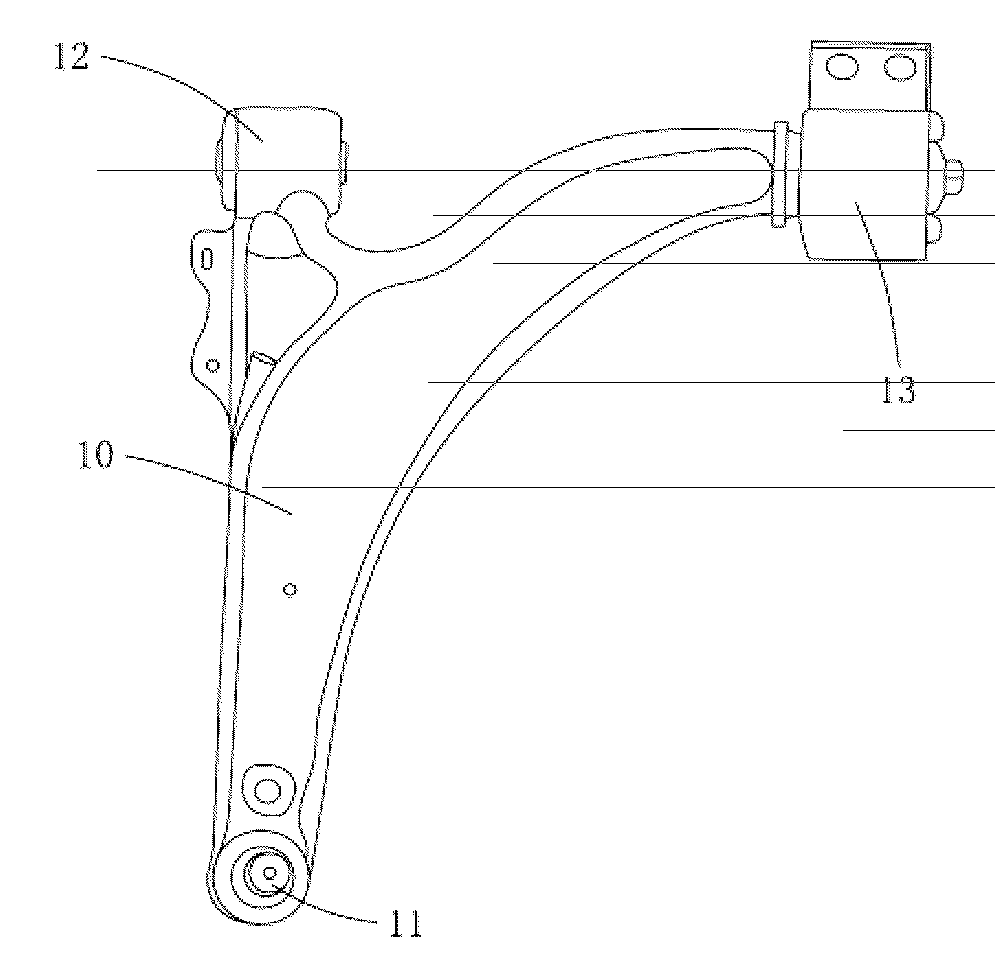

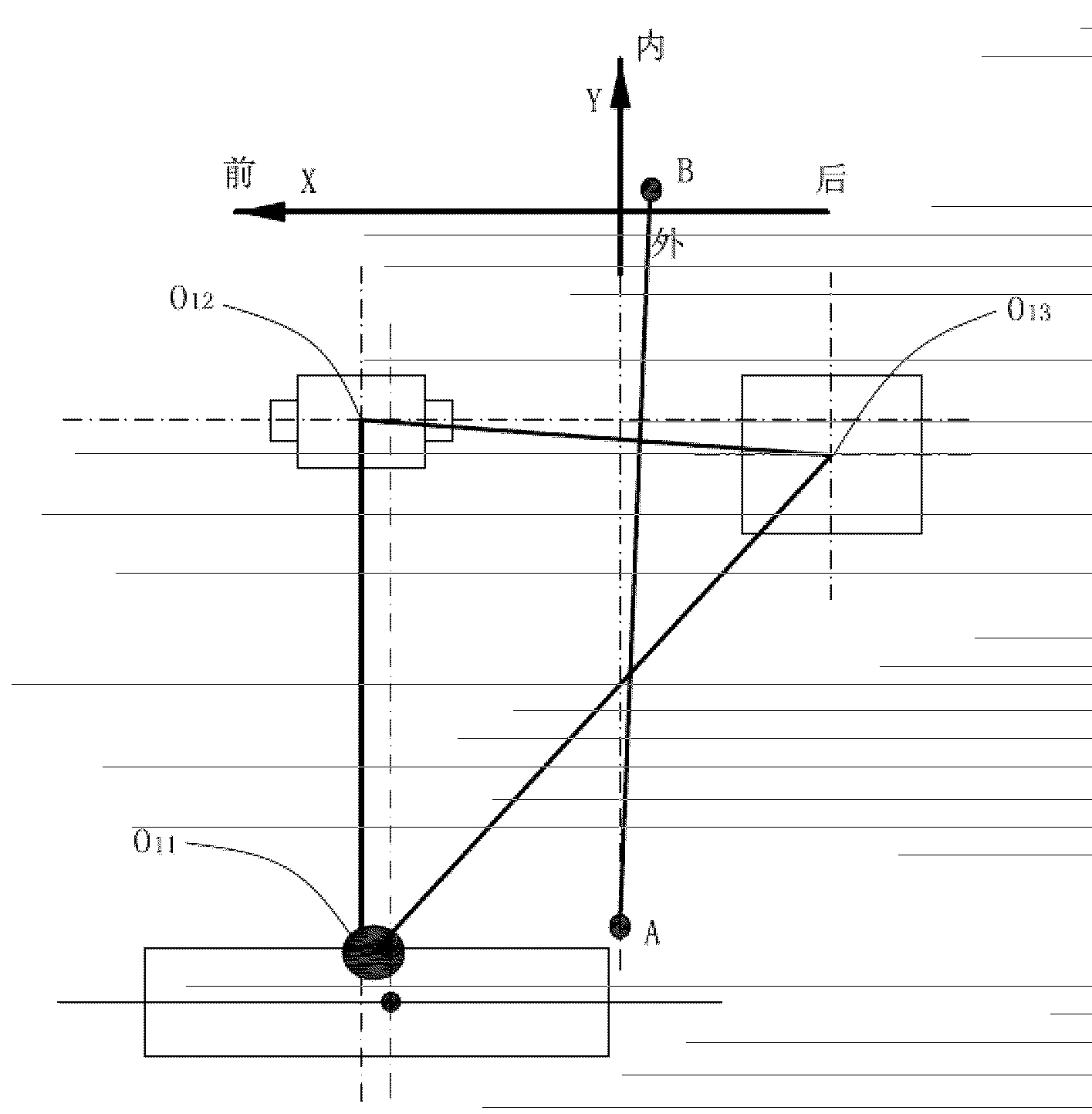

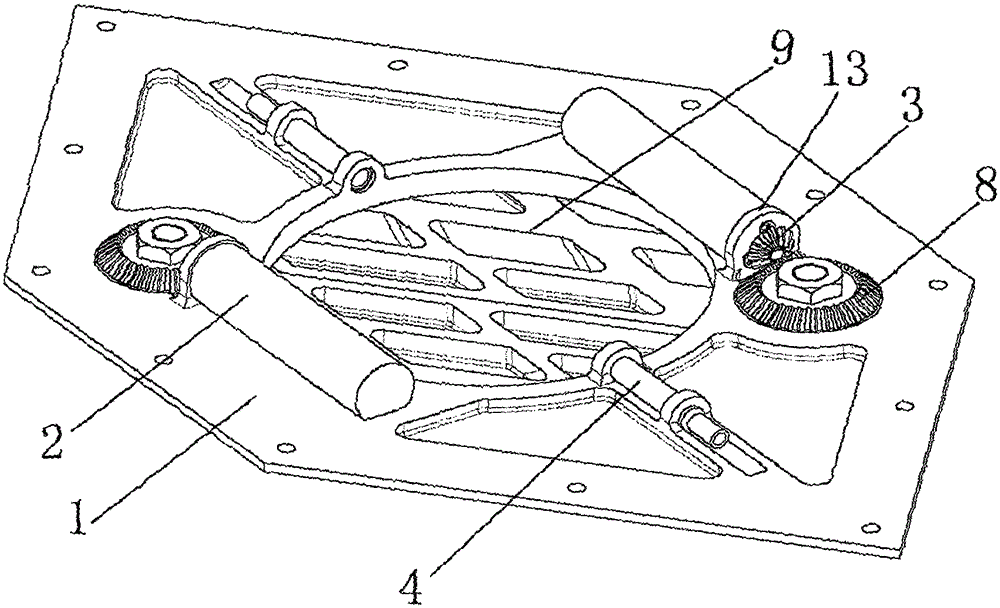

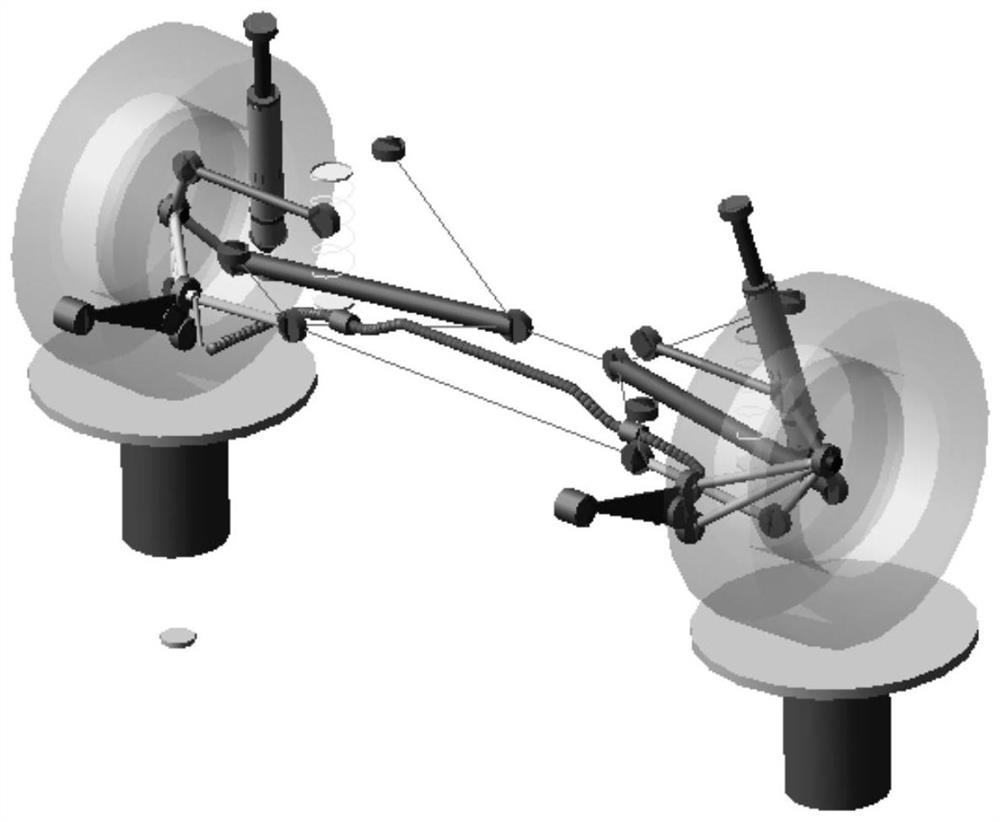

Automotive front Macpherson suspension and automobile comprising same

ActiveCN103465745AReduce vibrationMotor coordinationSteering linkagesPivoted suspension armsRubber materialVehicle frame

The invention relates to an automotive front Macpherson suspension and an automobile comprising the same. A control arm of the automotive front Macpherson suspension comprises a control arm body, a ball pin, a front frame bushing and a rear frame bushing, wherein the ball pin is positioned on the control arm body and is connected with a steering joint; the front frame bushing and the rear frame bushing are positioned on the control arm body and are connected with a frame; at least one of the front frame bushing and the rear frame bushing is made of a rubber material, and the radial rigidity is greater than the axial rigidity. Moreover, the invention also provides an arrangement relationship between key hard points of the control arm. According to the automotive front Macpherson suspension and the corresponding automobile, the rigidity characteristic of front and rear automobile reinforcing bushings on the control arm is perfectly designed, the relationship between the key hard points of the control arm is advantageously designed, the dynamic unbalance of a tire assembly when a vehicle runs at high speed and the vibration transferred to a driver by the frame are reduced, and the driving control and the driving comfort are improved.

Owner:SAIC GENERAL MOTORS +1

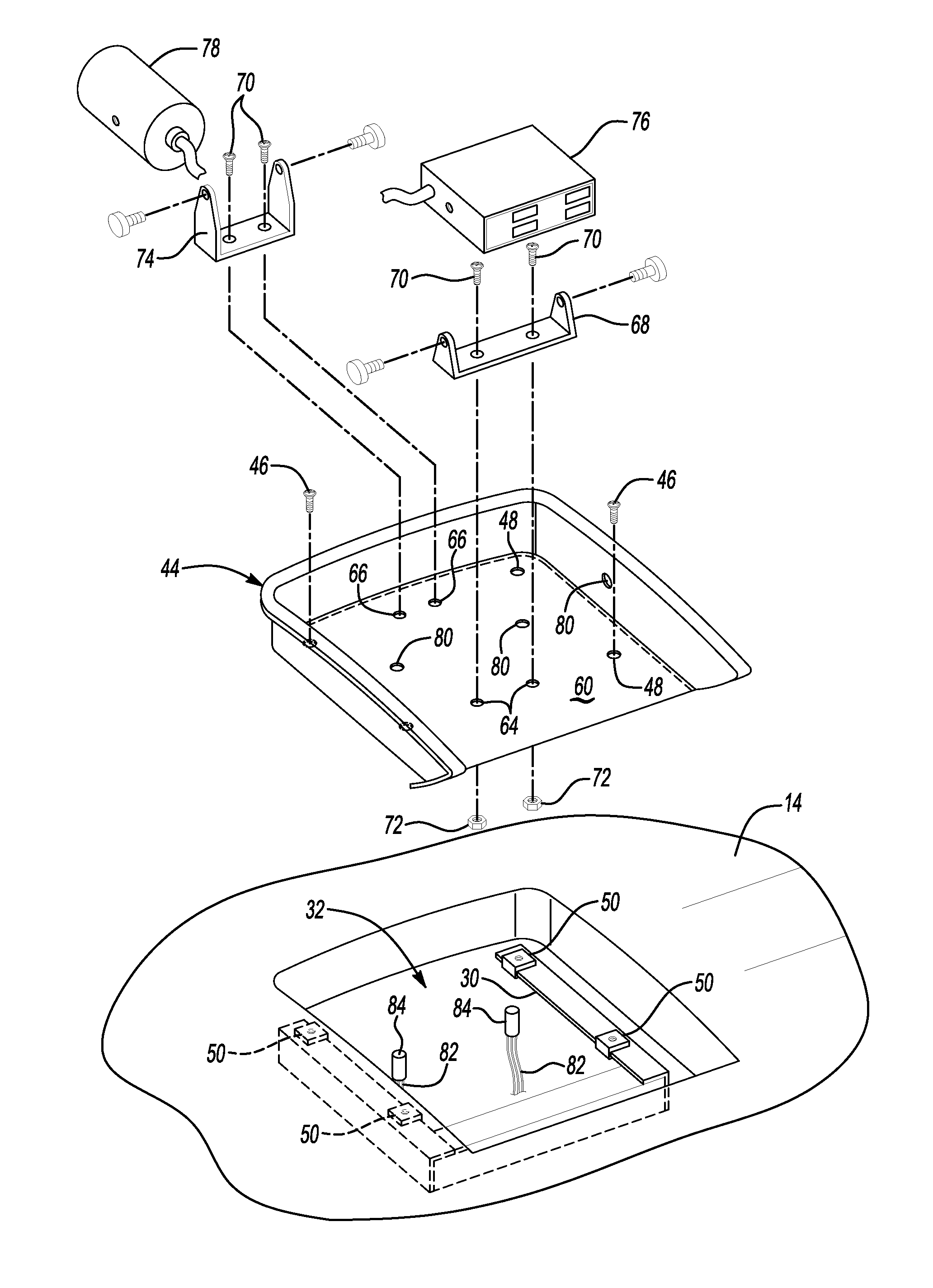

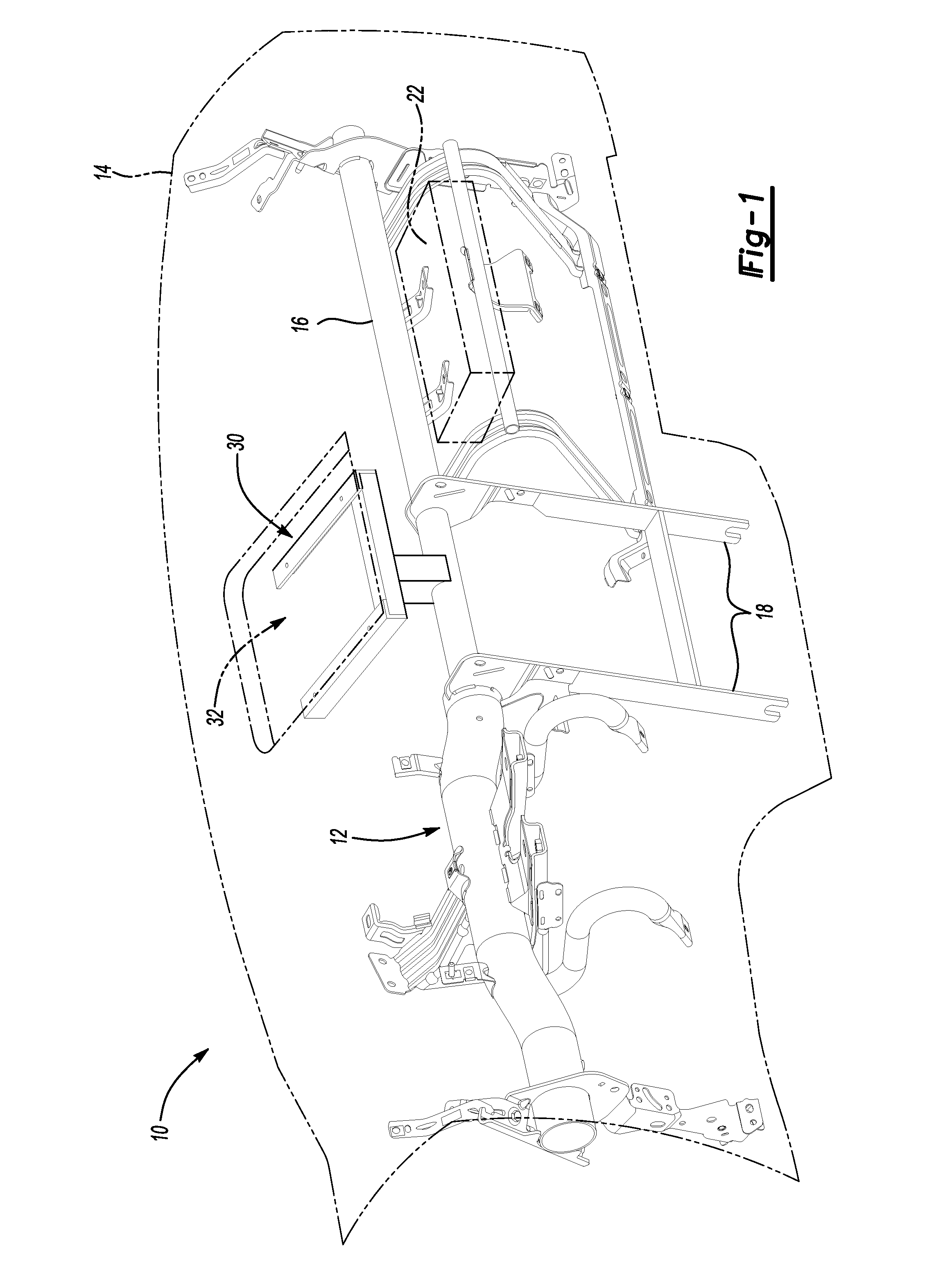

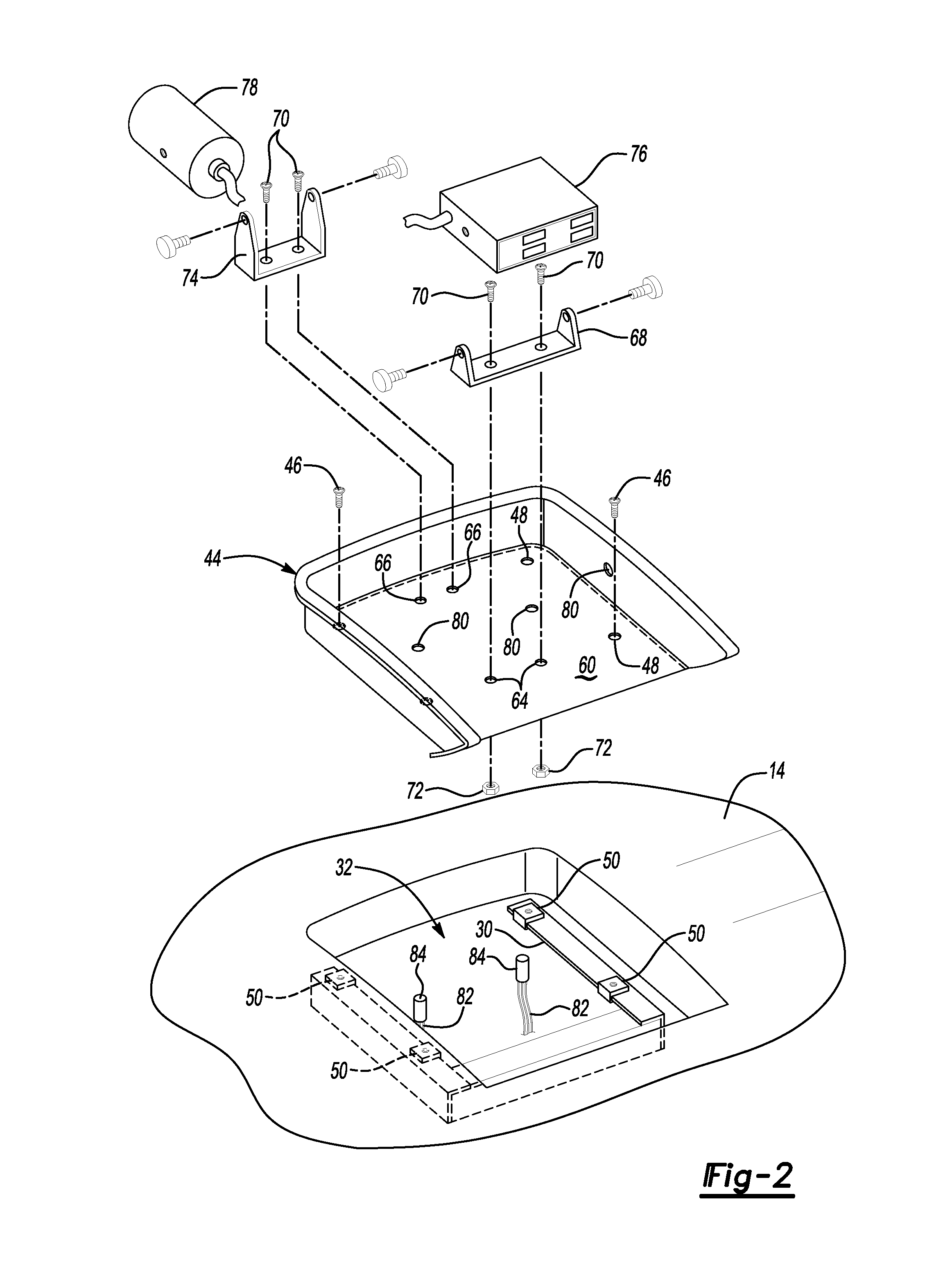

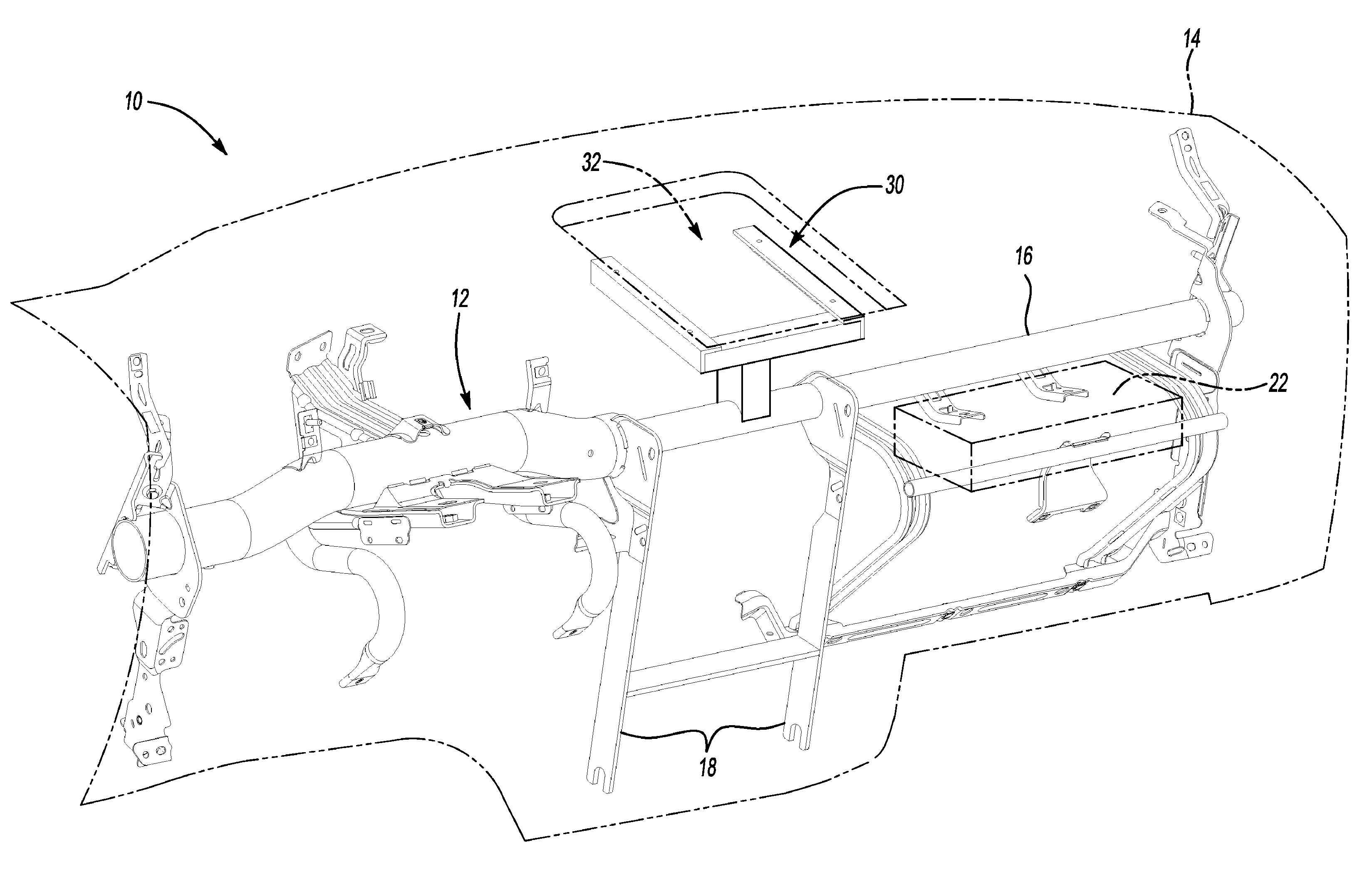

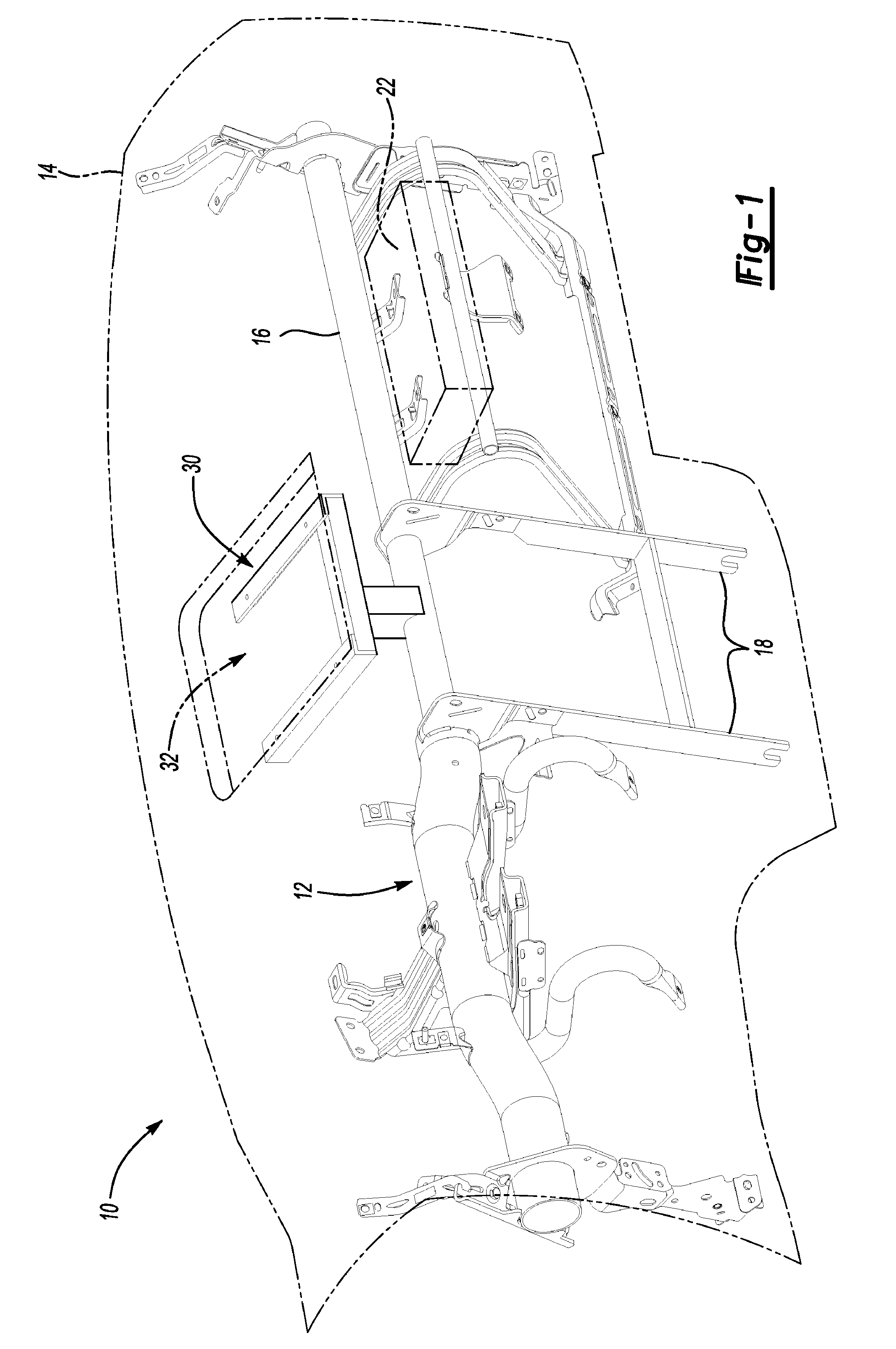

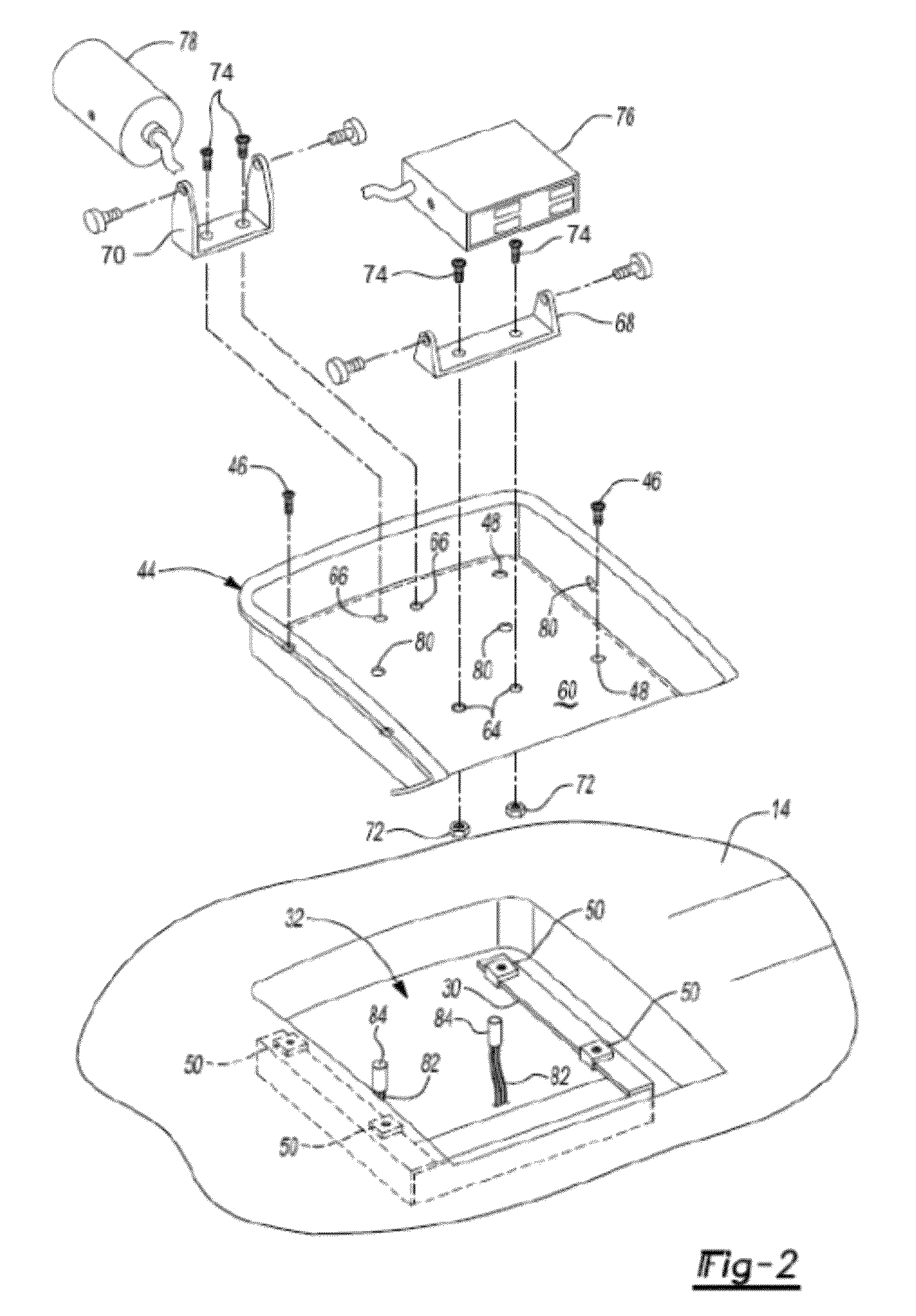

Equipment mounting module for instrument panel

InactiveUS20110221224A1Easy to installCost-effective and efficient customizationSubstation/switching arrangement detailsSuperstructure subunitsRadarComputer module

A mounting bracket is attached to an instrument panel frame, and an aperture is formed in an upper surface of an instrument panel housing in alignment with the bracket to provide a hardpoint for attaching an adapter module. The adapter module is removably secured to the mounting bracket and is provided with component mounting features for securing electrical components such as a radio or radar device. Vehicle electric wiring internal to the instrument panel housing is easily connected with wiring associated with the components. The apparatus allows cost-effective and efficient customization of electrical components mounted to a vehicle instrument panel.

Owner:FORD GLOBAL TECH LLC

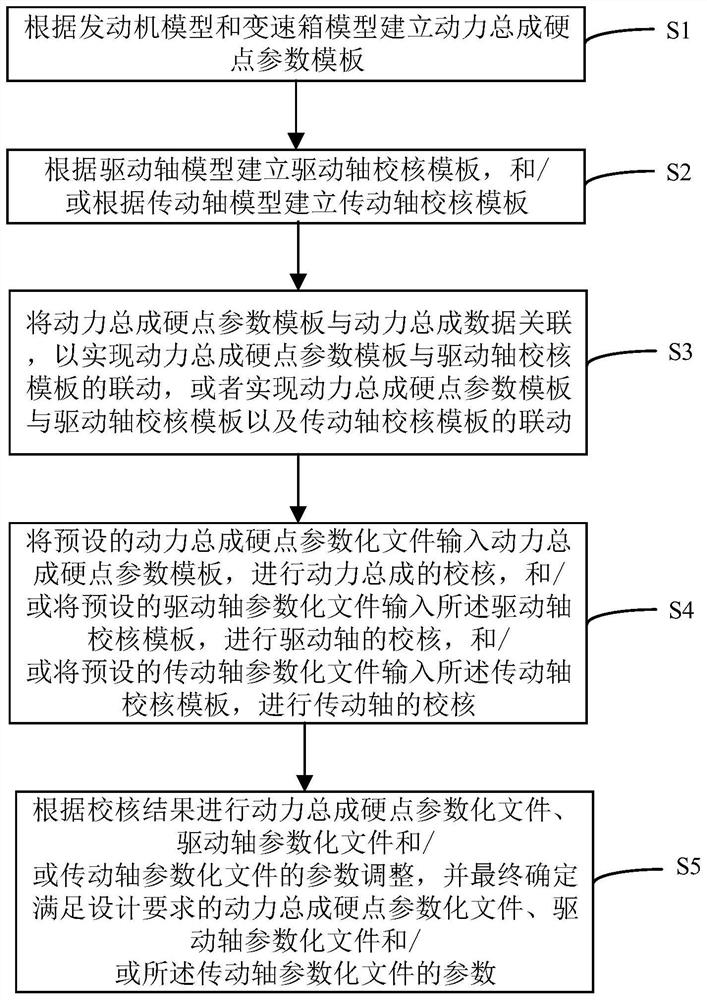

Power assembly positioning method based on CATIA hard point parameters, computer and storage medium

ActiveCN112380620AAchieve positioningImprove positioning efficiencyGeometric CADSustainable transportationDrive shaftControl engineering

The invention belongs to the technical field of platform arrangement design, and discloses a power assembly positioning method based on CATIA hard point parameters, a computer and a storage medium. The method comprises the steps that a power assembly hard point parameter template, a driving shaft checking template and / or a transmission shaft checking template are / is established; inputting a presetpower assembly hard point parameterization file into the power assembly hard point parameter template to check the power assembly, and / or inputting a preset driving shaft parameterization file into the driving shaft check template to check the driving shaft, and / or inputting a preset transmission shaft parameterization file into the transmission shaft check template to check the transmission shaft. Checking the transmission shaft; and adjusting parameters of the power assembly hard point parameterization file, the driving shaft parameterization file and / or the transmission shaft parameterization file according to a checking result. According to the power assembly positioning device, positioning of power assemblies of different vehicle types can be achieved, the power assembly positioningefficiency and the power assembly arrangement accuracy are improved, and the power assembly positioning work difficulty is lowered.

Owner:CHINA FIRST AUTOMOBILE

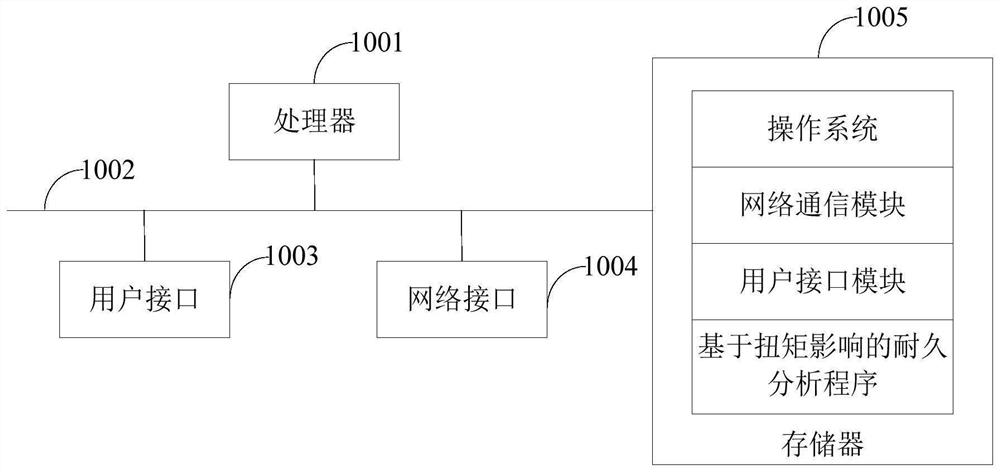

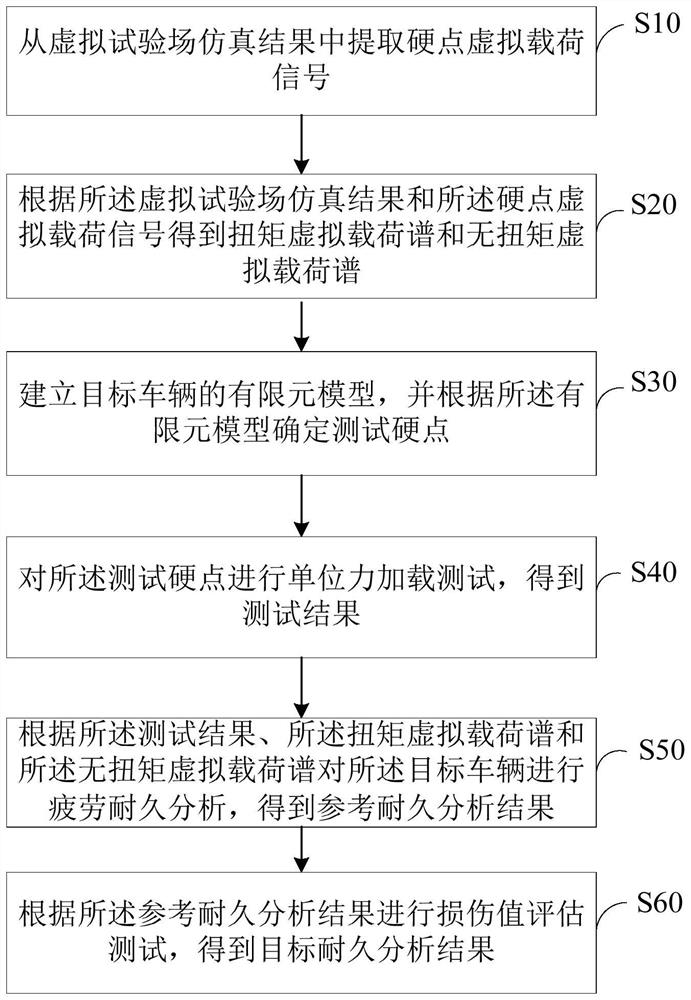

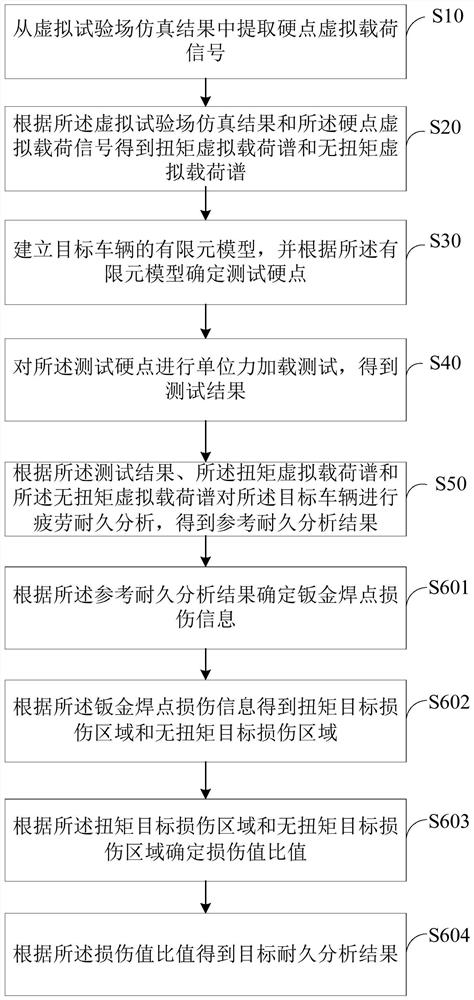

Durability analysis method, device and equipment based on torque influence and storage medium

PendingCN114692445AShorten the development cycleEffective assessmentGeometric CADDesign optimisation/simulationElement modelRoad surface

The invention belongs to the technical field of vehicle evaluation, and discloses a durability analysis method and device based on torque influence, equipment and a storage medium. The method comprises the following steps: extracting a hard point virtual load signal from a virtual test field simulation result; obtaining a torque virtual load spectrum and a torque-free virtual load spectrum according to the virtual test field simulation result and the hard point virtual load signal; establishing a finite element model of the target vehicle, and determining a test hard point according to the finite element model; carrying out a unit force loading test on the test hard point to obtain a test result; performing fatigue durability analysis on the target vehicle according to the test result, the torque virtual load spectrum and the torque-free virtual load spectrum to obtain a reference durability analysis result; and performing damage value evaluation test according to the durability analysis result to obtain a target durability analysis result. Under the condition of no physical sample vehicle and no actual road surface collection road spectrum, the influence of the torque on the whole vehicle fatigue durability simulation analysis result is evaluated, the vehicle development period is shortened, and the cost is saved.

Owner:DONGFENG LIUZHOU MOTOR

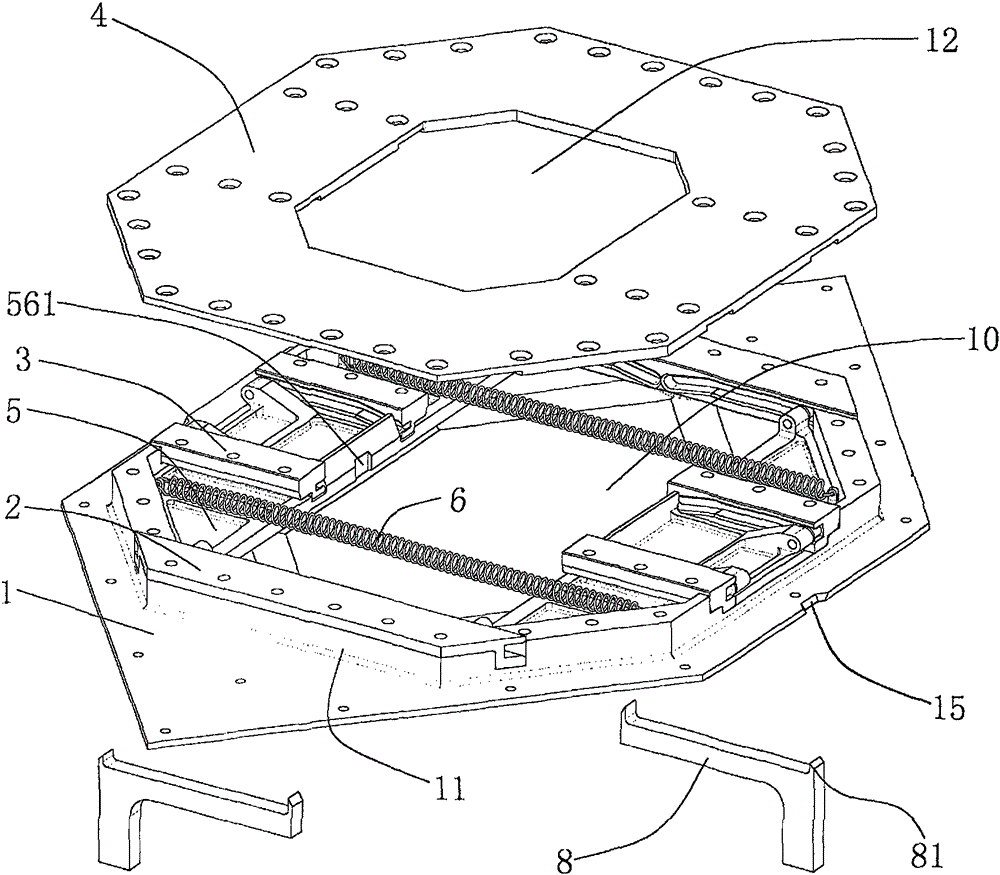

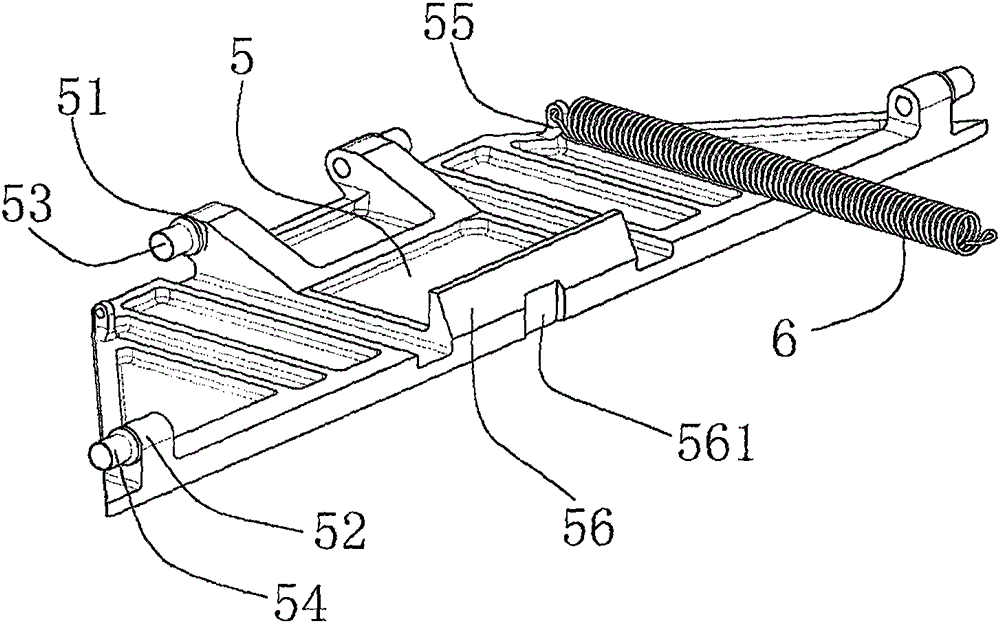

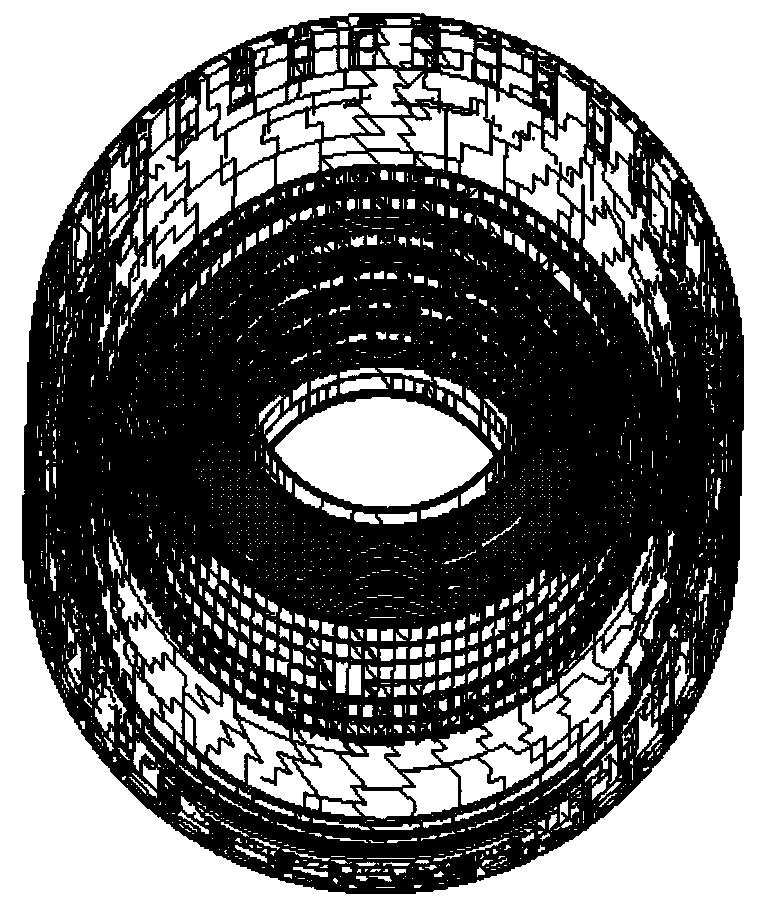

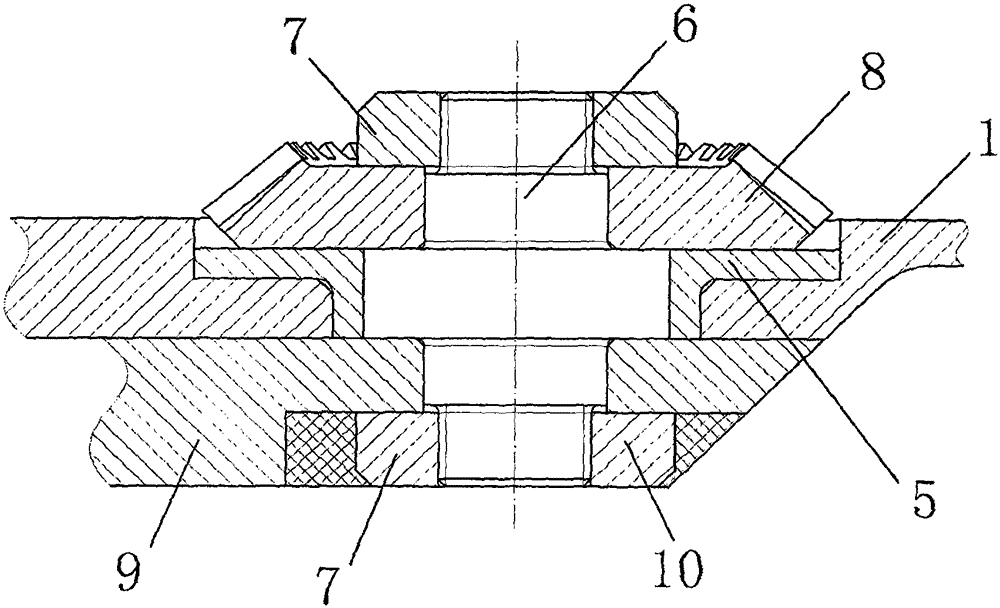

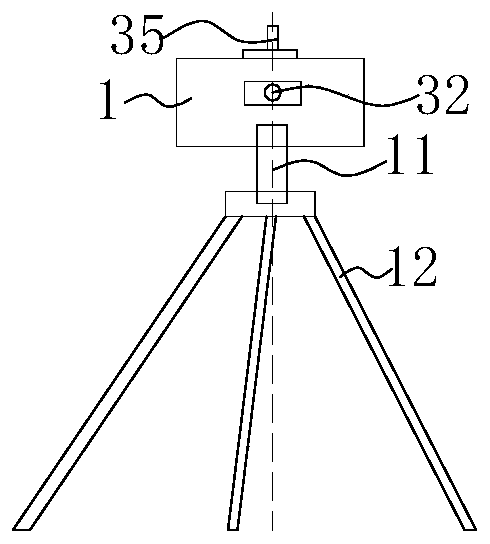

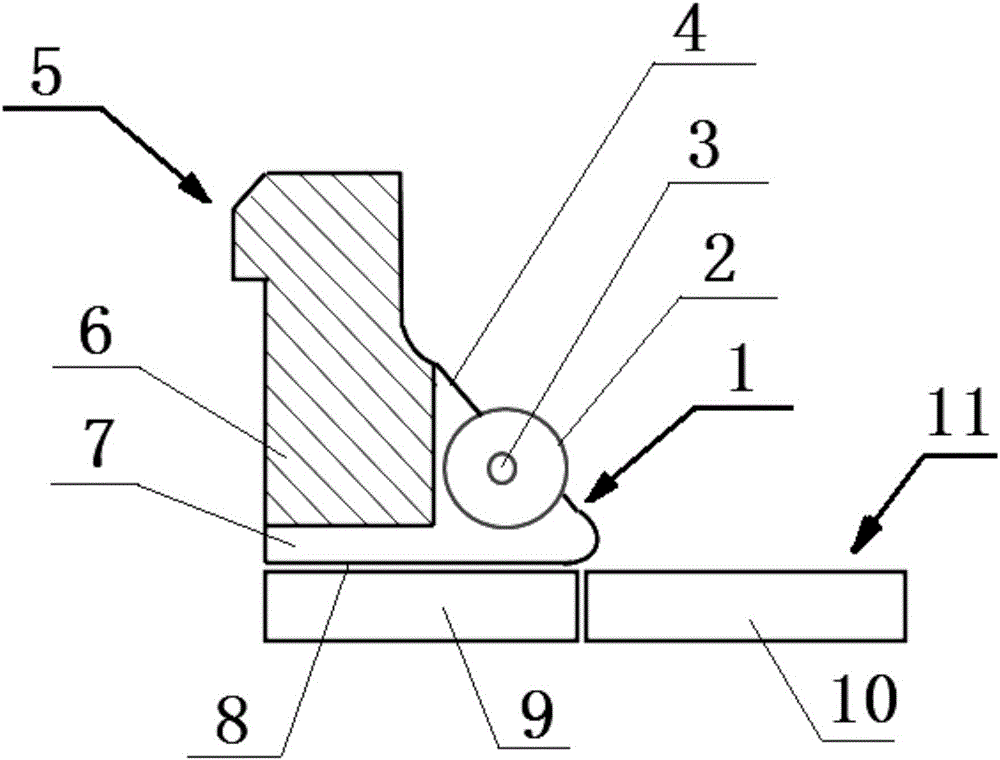

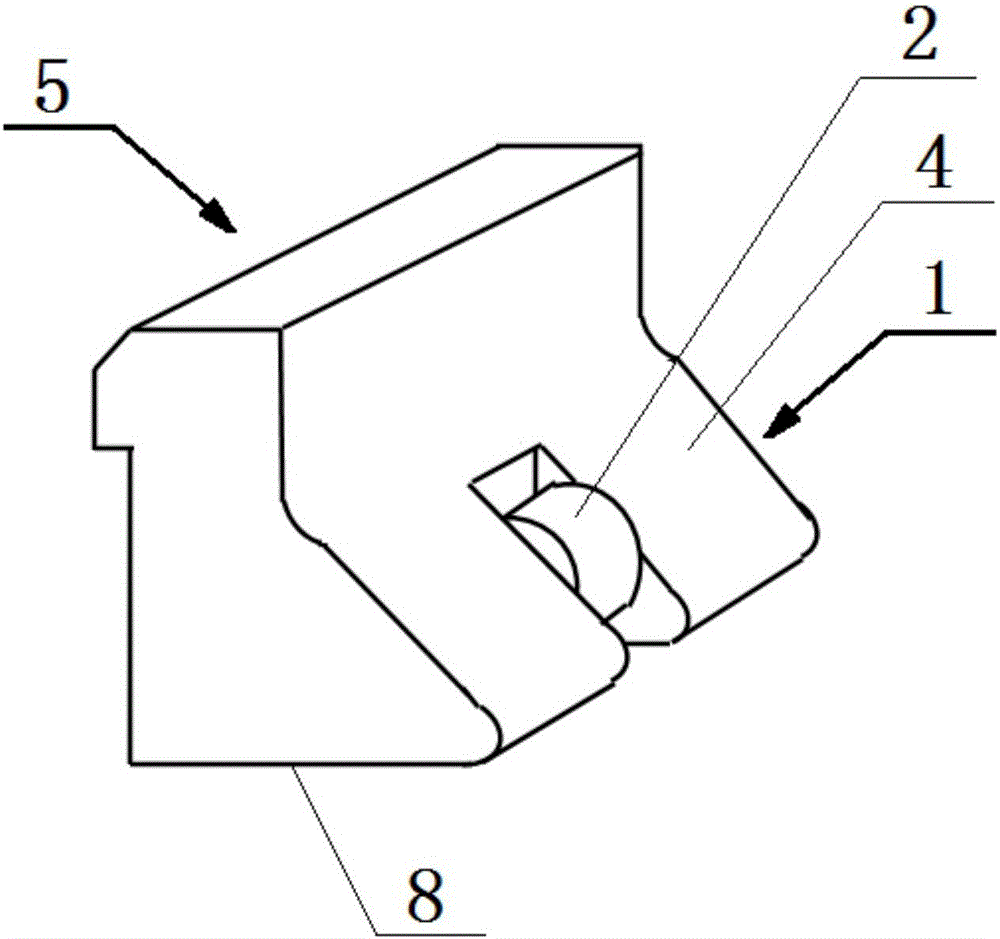

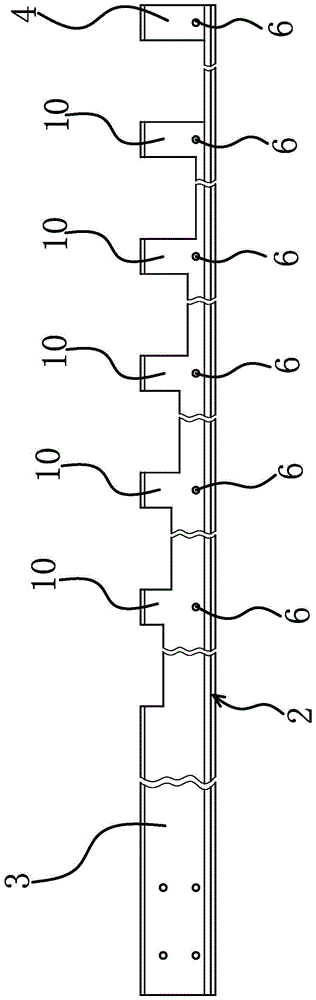

Aircraft hardpoint sealing mechanism driven by springs

InactiveCN105109662ADoes not affect aerodynamic performanceSimple structureAircraft accessoriesEngineeringMechanical engineering

The invention discloses an aircraft hardpoint sealing mechanism driven by springs. The aircraft hardpoint sealing mechanism comprises a casing (1), wherein a positioning ring (11) vertically extends upwards from the upper top surface of the casing (1), two sealing plates (5) which can be mutually connected in an abutting manner, springs (6) for driving the sealing plates (5) to close and handles (8) through which the sealing plates (5) can be opened are arranged in the positioning ring (11), and a lower hole (10) corresponding to the sealing plates (5) is formed in the middle part of the casing (1); a cover plate (4) is fixed on the positioning ring (11), and an upper hole (12) corresponding to the lower hole (10) is formed in the cover plate (4). The aircraft hardpoint sealing mechanism disclosed by the invention is simple in structure andconvenient to use, after the aircraft hardpoint sealing mechanism is closed, the casing and the sealing plates are completely flush with the outer surface of an aircraft and not protruded out of the surface of the aircraft completely, and aerodynamic performances of the aircraft are not influenced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

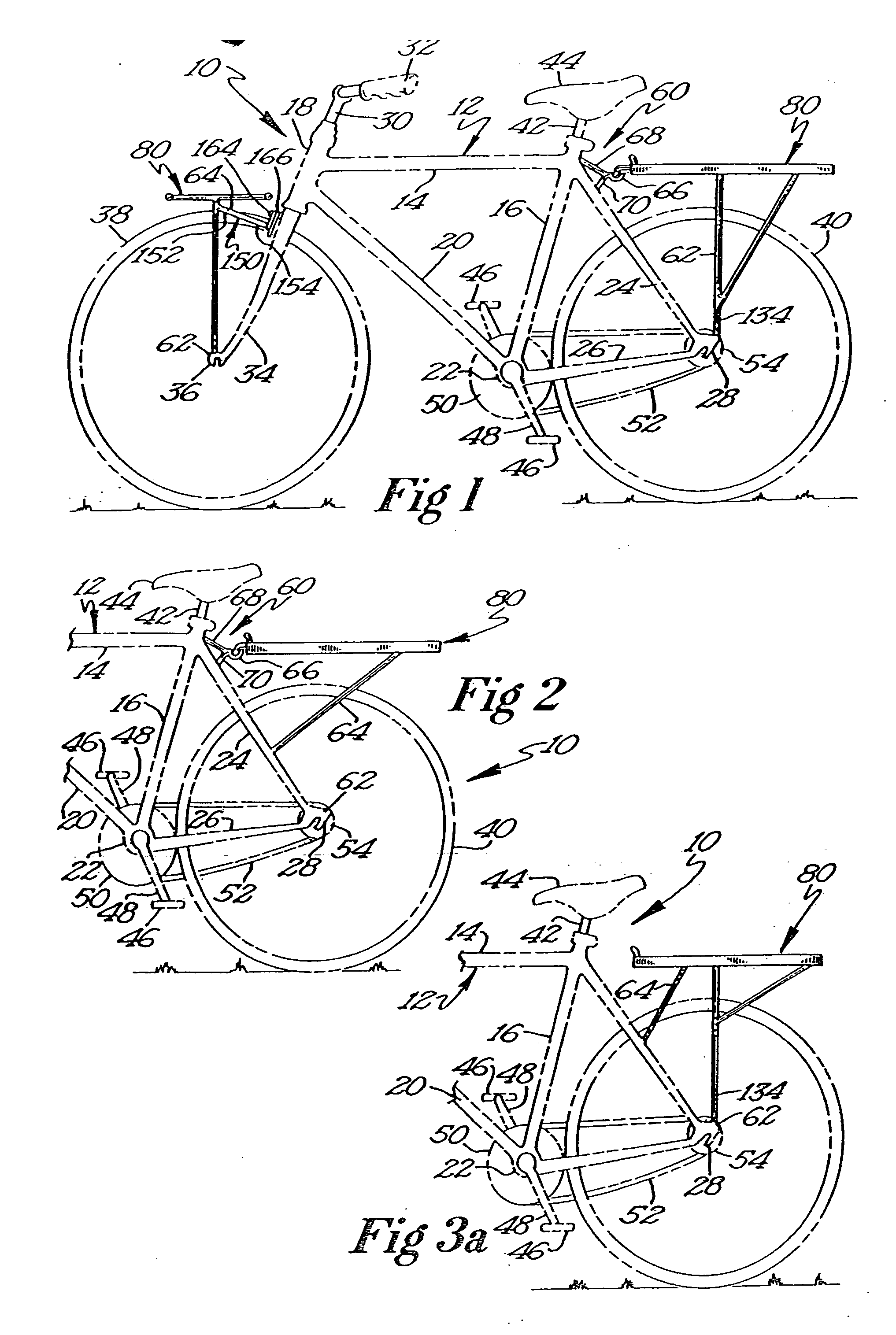

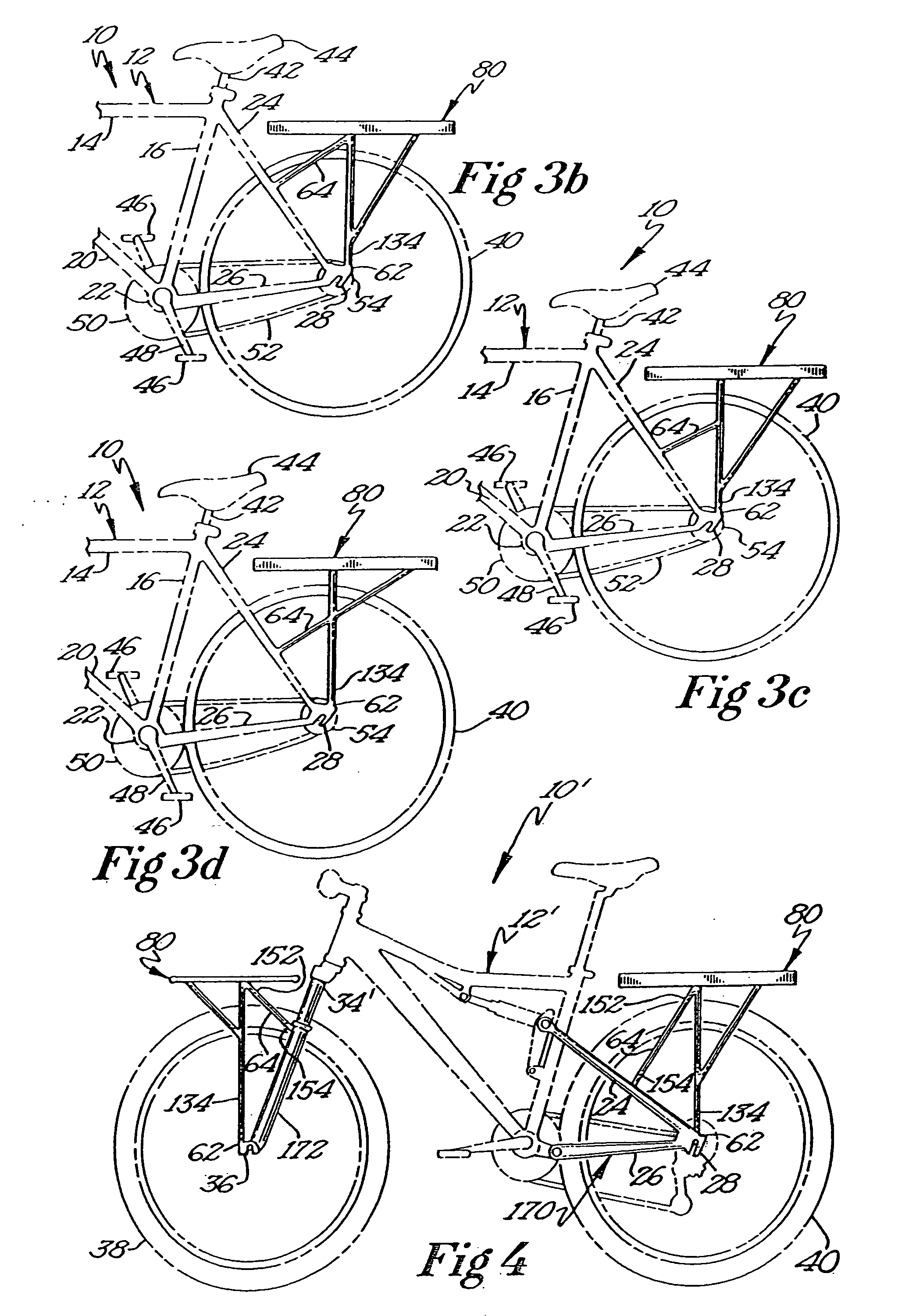

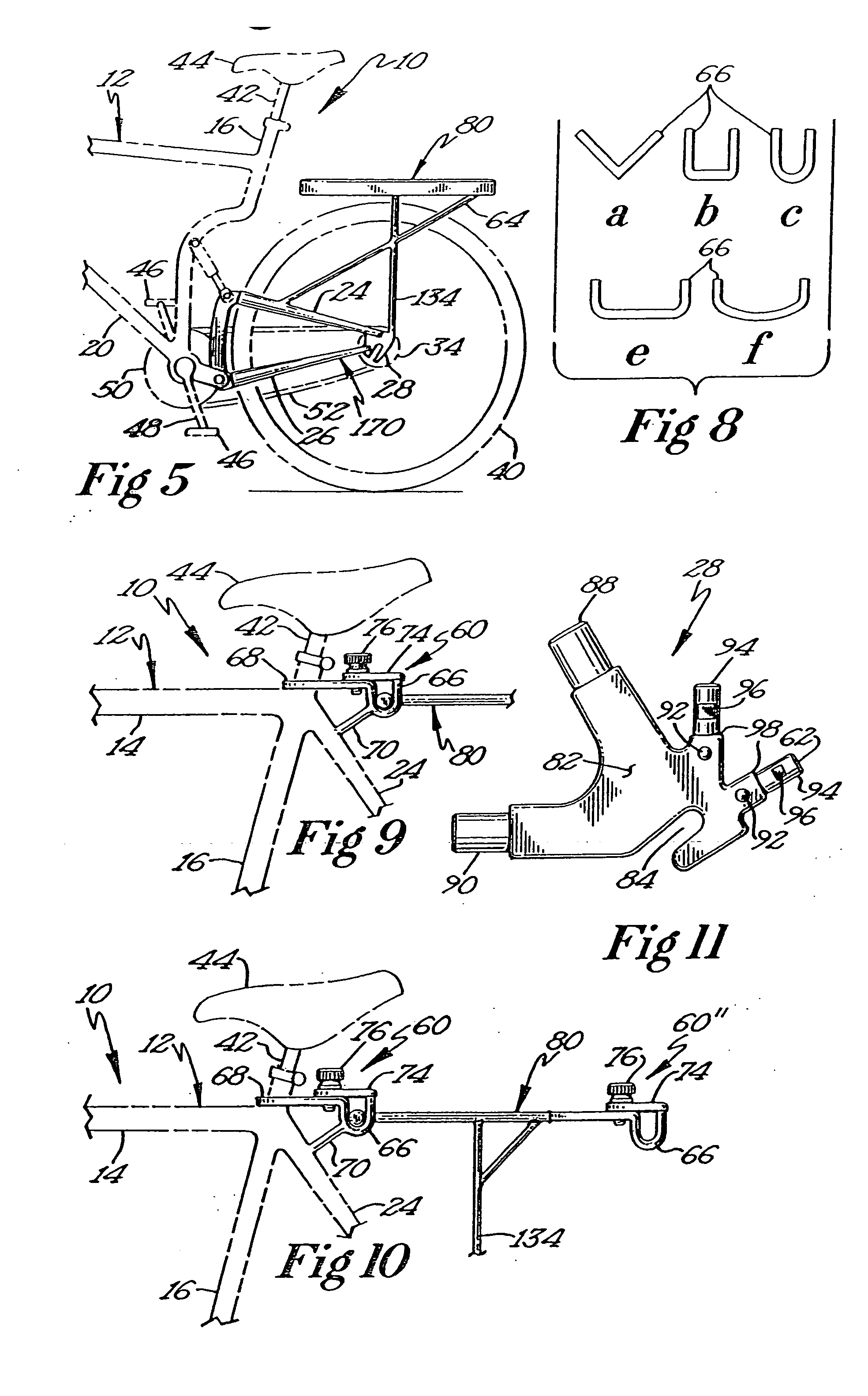

Attachment system for bicycle accessories

InactiveUS20050058727A1Increase flexibilityHigh strengthBiocideLuggage carriersVehicle frameEngineering

A system for attaching bicycle accessories to the frame of a bicycle is disclosed. The system includes a channel mount secured to the frame of the bicycle adjacent the junction of the seat post and seat stay of a bicycle frame. The channel mount forms a hard point attachment for a portion of the bicycle accessory. Alternatively, a mounting mechanism is provided that is operatively configured to be secured to a bicycle dropout frame member. The mounting mechanism includes a post extending away from the bicycle dropout that is shorter than an outer radius of a wheel mounted in the bicycle dropout frame member. In addition, a system for attaching an accessory to a front fork of a bicycle frame is provided. The system includes a lower mount secured to a front bicycle dropout and a rigid support secured proximate to the front fork.

Owner:TRANSBIKE SYST

Equipment mounting module for instrument panel

InactiveUS8272675B2Easy to installCost-effective and efficient customizationSubstation/switching arrangement detailsSuperstructure subunitsRadarComputer module

A mounting bracket is attached to an instrument panel frame, and an aperture is formed in an upper surface of an instrument panel housing in alignment with the bracket to provide a hardpoint for attaching an adapter module. The adapter module is removably secured to the mounting bracket and is provided with component mounting features for securing electrical components such as a radio or radar device. Vehicle electric wiring internal to the instrument panel housing is easily connected with wiring associated with the components. The apparatus allows cost-effective and efficient customization of electrical components mounted to a vehicle instrument panel.

Owner:FORD GLOBAL TECH LLC

Rapid store load system for aircraft and method of operation thereof

ActiveUS9108730B2Shorten the timeLiquid handling installationsPower plant fuel tanksOperational approachAirplane

Owner:GROSSMAN VICTOR A

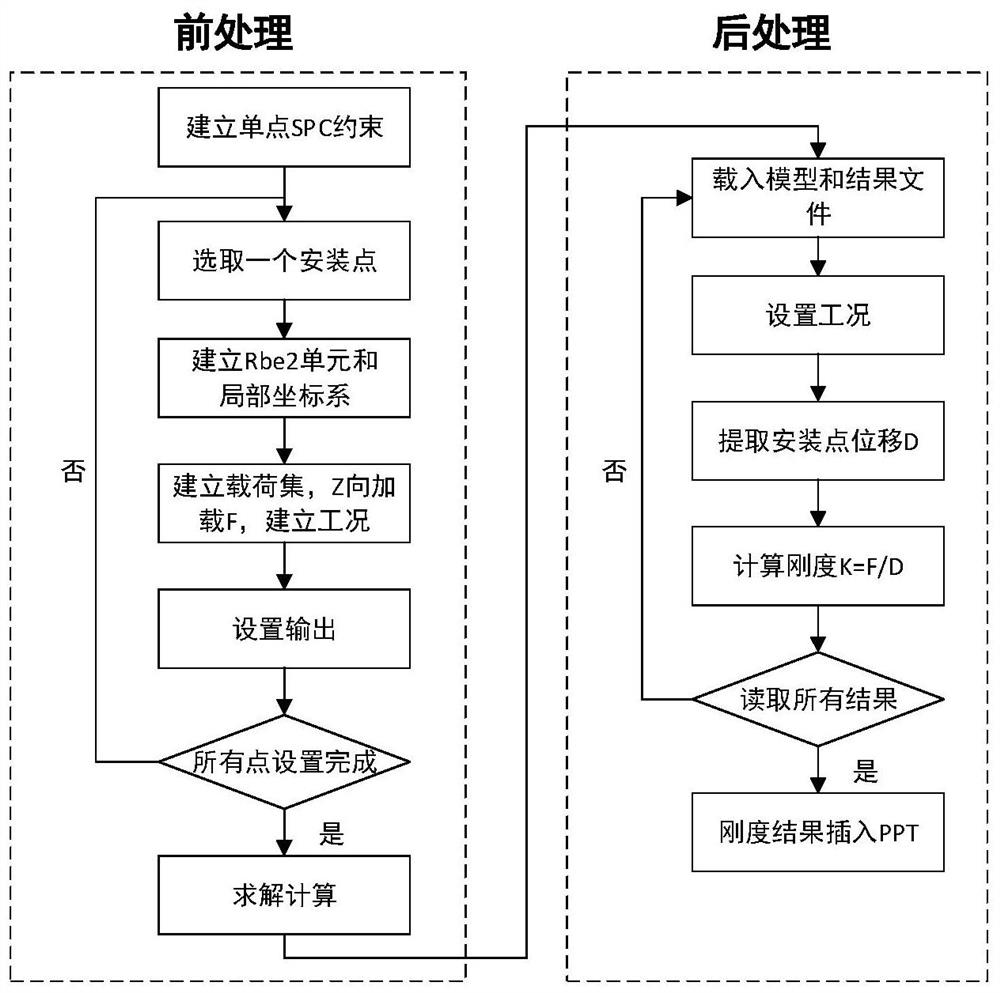

Vehicle body attachment point rigidity result extraction method and electronic equipment

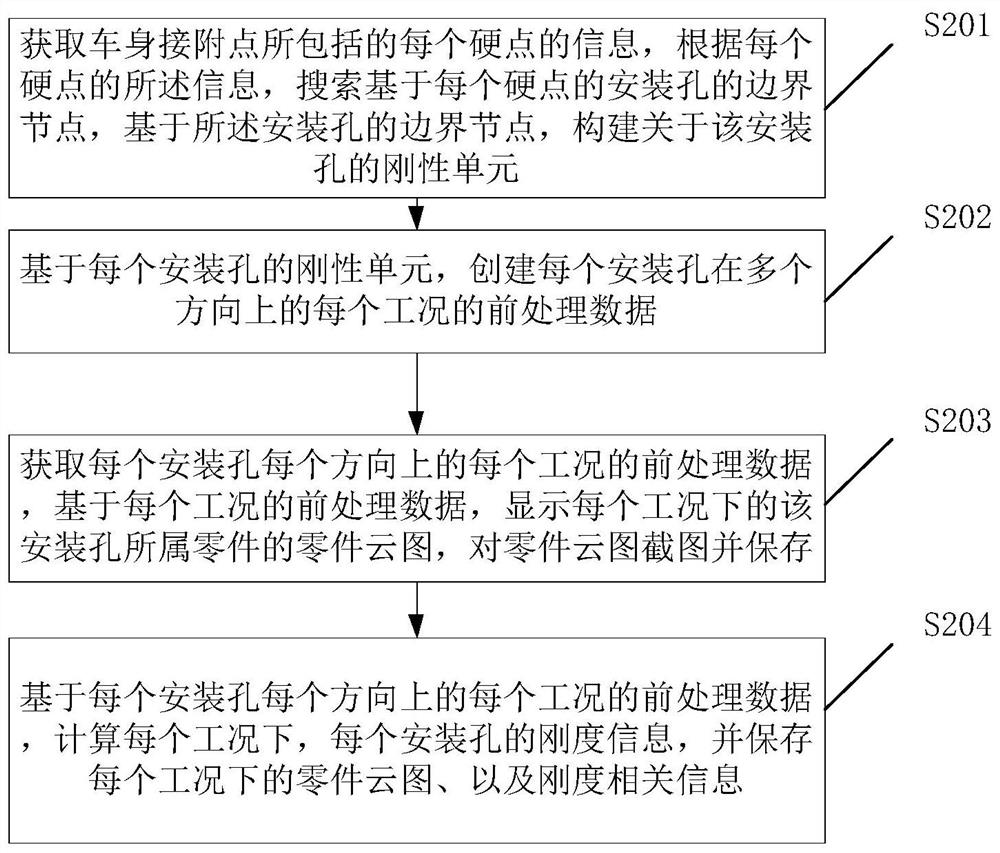

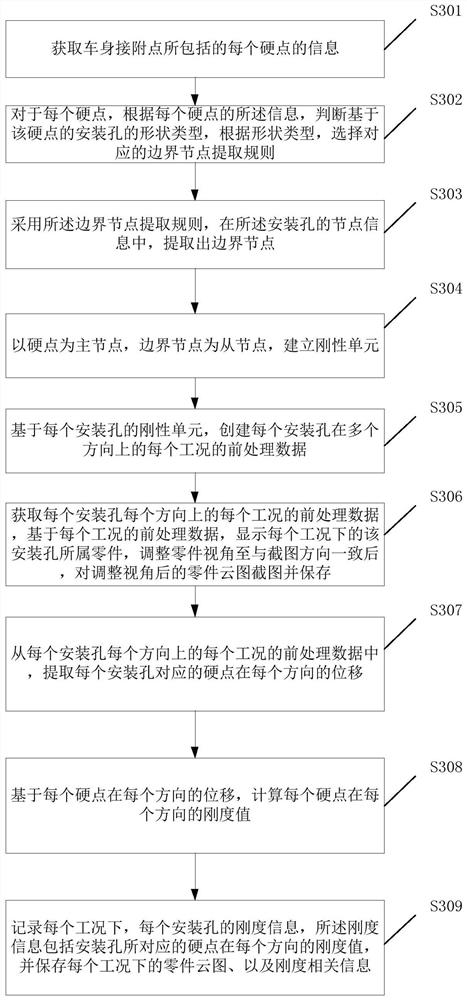

PendingCN111814376AImprove pretreatment efficiencyImprove processing efficiencyGeometric CADDesign optimisation/simulationStructural engineeringInformation searching

The invention discloses a vehicle body attachment point rigidity result extraction method, electronic equipment and a storage medium. The method comprises the steps: searching a boundary node of an installation hole based on each hard point according to the information of each hard point, and constructing a rigid unit related to the installation hole based on the boundary node of the installationhole; creating preprocessing data of each mounting hole under each working condition in multiple directions; acquiring pretreatment data of each working condition in each direction of each mounting hole, displaying a part cloud picture of the part to which the mounting hole belongs under each working condition based on the pretreatment data of each working condition, and performing screenshot on the part cloud picture and storing; and based on the pre-processing data of each working condition in each direction of each mounting hole, rigidity information of each mounting hole under each workingcondition is calculated and stored. According to the method, the workload of engineers is reduced, all attachment points are selected in a framing mode at a time through the pretreatment part, namely, pretreatment and aftertreatment parts of all attachment points are achieved, and automatic adjustment and screenshot of the cloud picture view angle of each part are achieved.

Owner:EVERGRANDE NEW ENERGY AUTOMOTIVE INVESTMENT HLDG GRP CO LTD

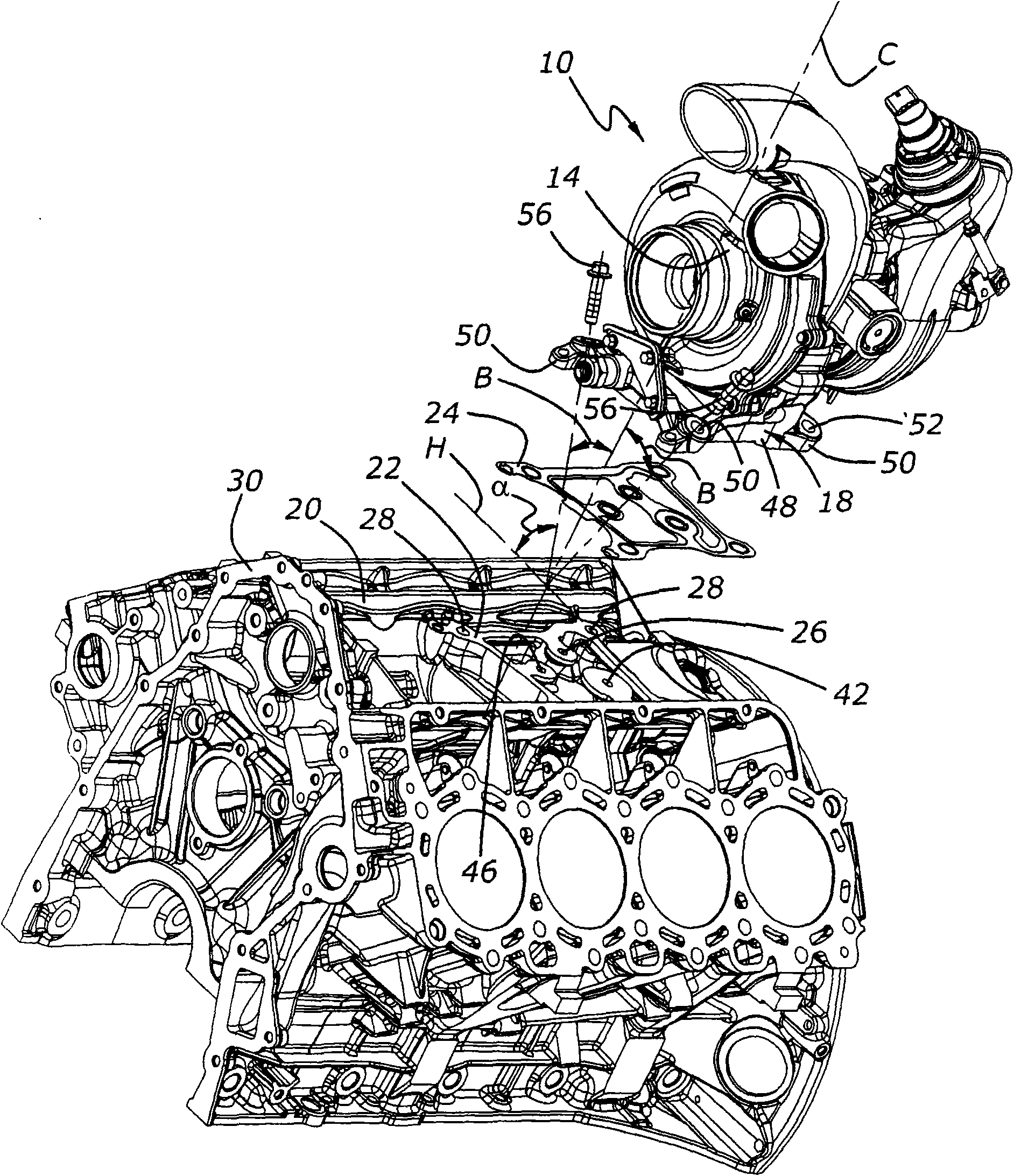

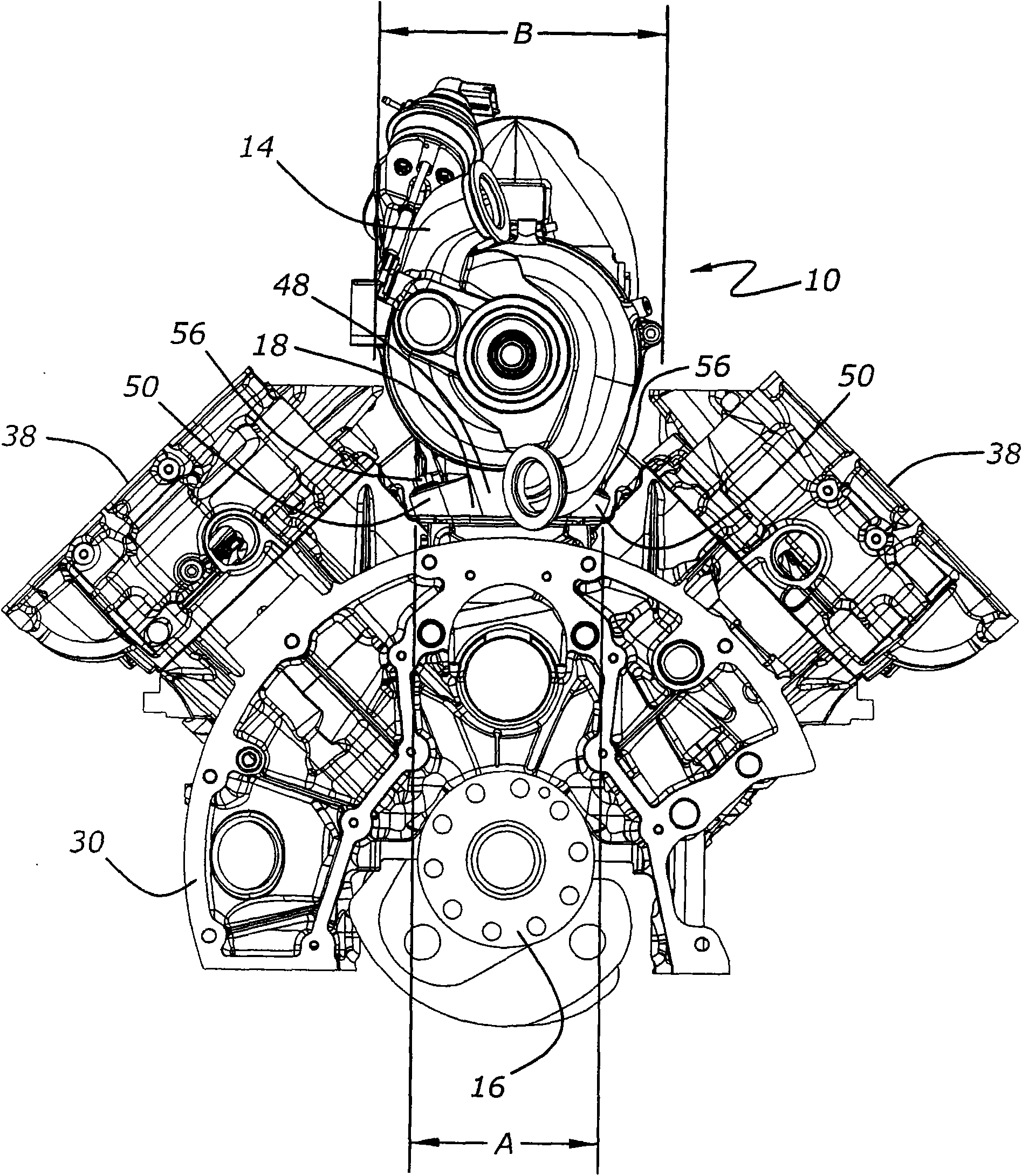

Turbocharger system with internally isolated turbocharger oil drainback passage

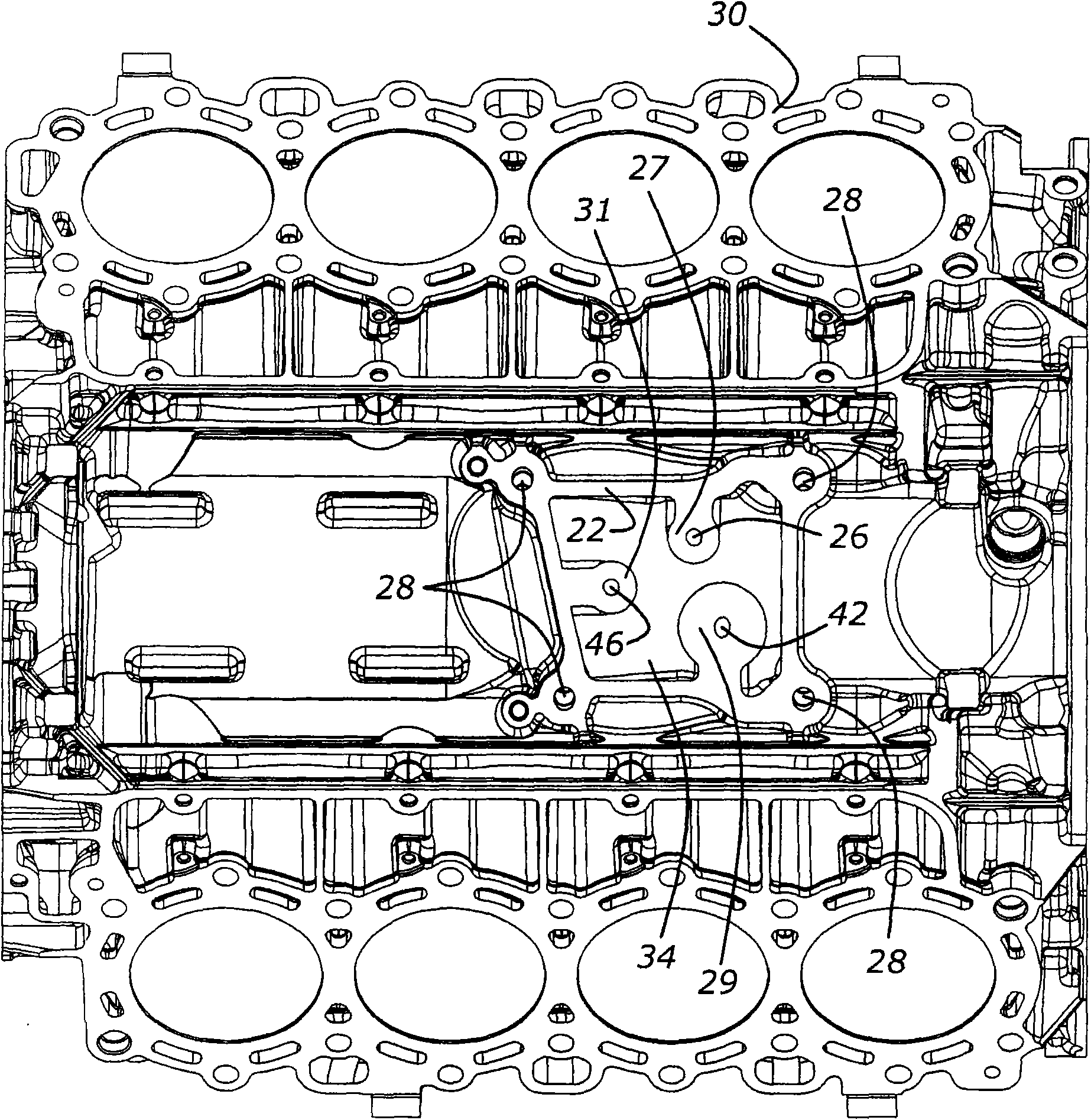

ActiveCN101614152AAvoid damageContact minimizationLiquid coolingCombustion enginesTurbochargerCrankcase

The invention relates to a turbocharger system with internally isolated turbocharger oil drainback passage. The invention provides a turbocharger system of an internal combustion engine. The system comprises a turbocharger system with a practical pedestal, wherein the practical pedestal extends between the turbocharger and a hard point associated with the cylinder body. The practical pedestal comprises a mounting pad which connects the combined turbocharger and pedestal assembly to the engine, an inner lubricating oil supply passage and a coolant supply passage which supply the pressurized lubricating oil and coolant to the turbocharger. The turbocharger system with internally isolated turbocharger oil drainback passage conveys waste oil from the turbocharger to a crankcase sump without permitting the waste oil to contact moving parts of the engine.

Owner:FORD GLOBAL TECH LLC

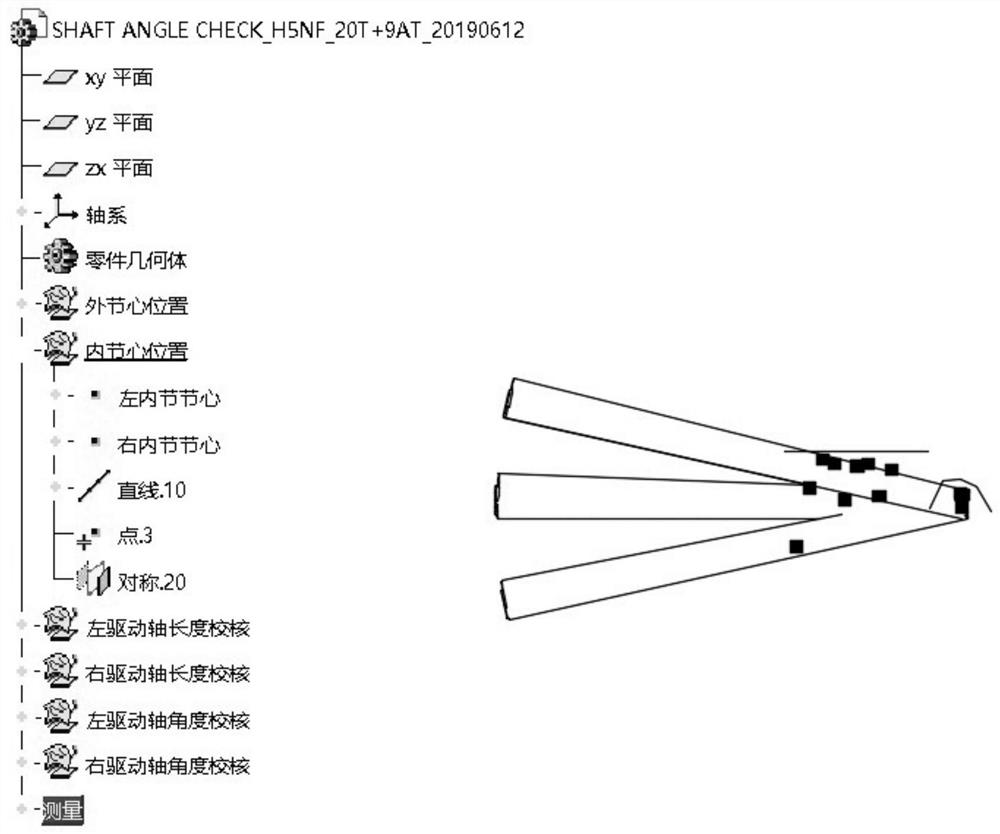

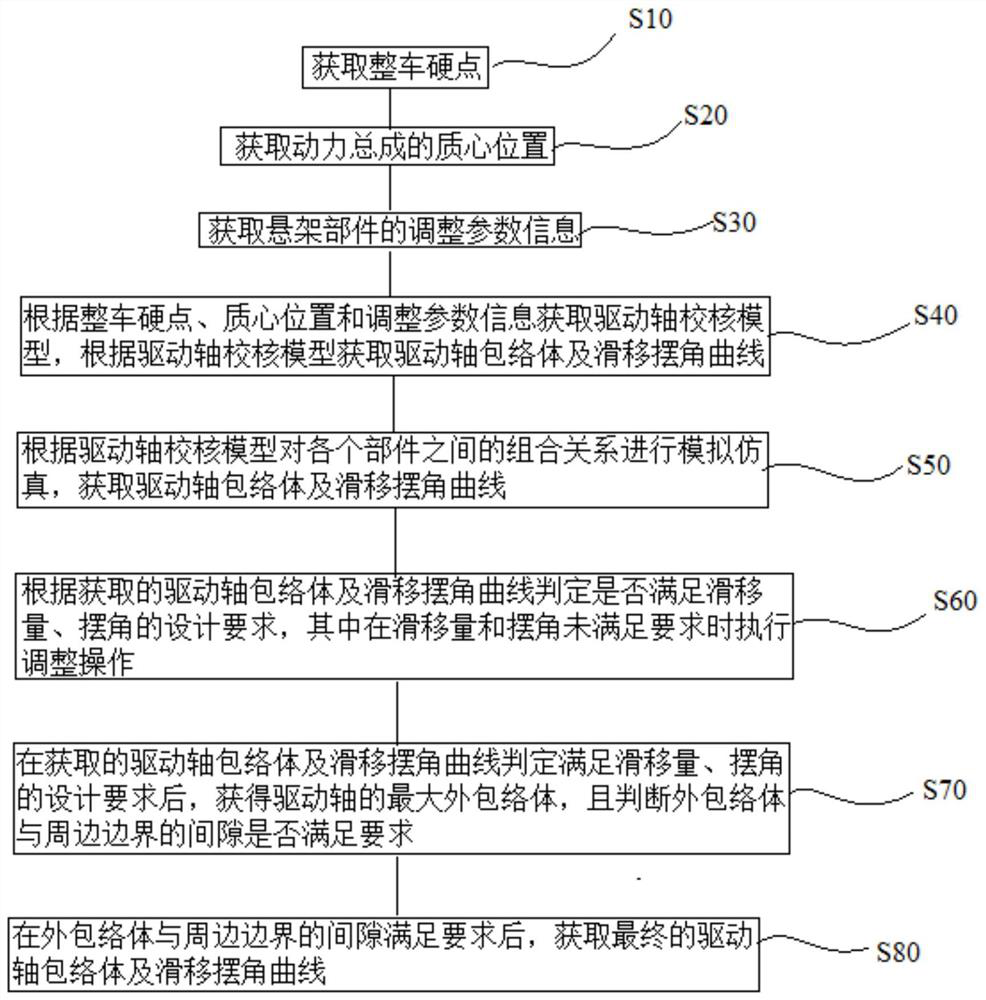

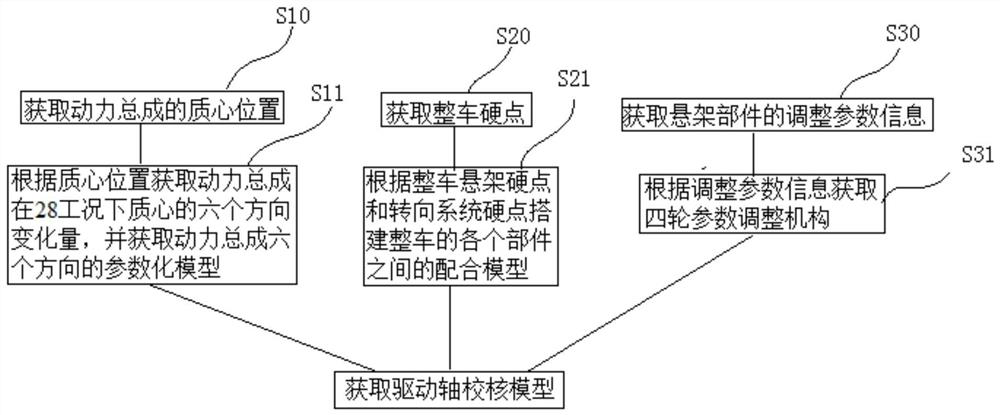

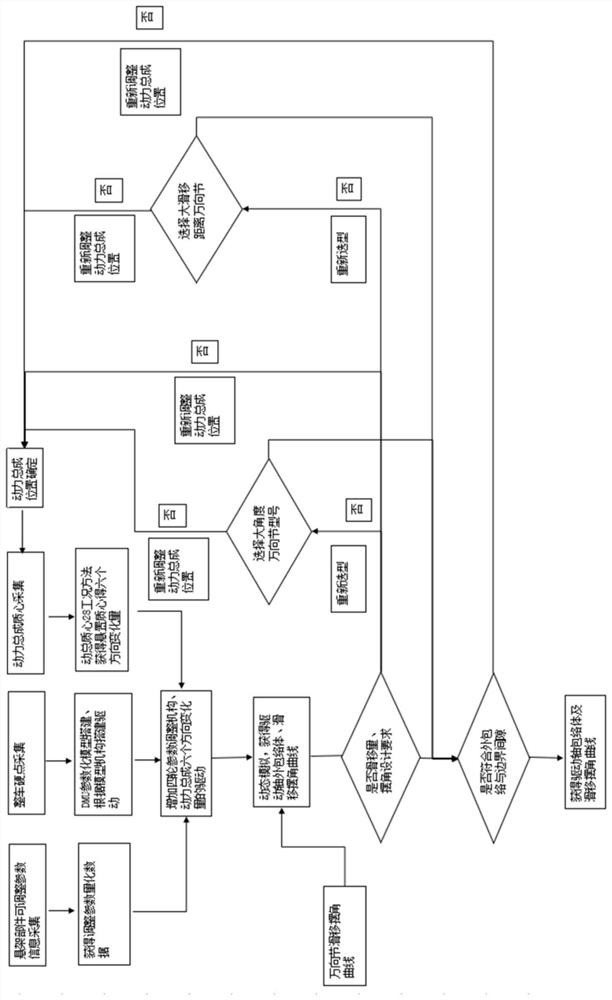

Driving shaft slip deflection angle checking method and driving shaft slip deflection angle checking system

The invention discloses a method and a system for checking a slip deflection angle of a driving shaft. The method comprises the following steps of acquiring a hard point of a whole vehicle; obtainingthe mass center position of the power assembly; obtaining adjustment parameter information of the suspension component; and obtaining a driving shaft checking model according to the whole vehicle hardpoint, the mass center position and the adjustment parameter information, and obtaining a driving shaft envelope body and a slip swing angle curve according to the driving shaft checking model. The method for checking the slip deflection angle of the driving shaft is advantaged in that influence parameters such as the displacement of a power assembly and the adjustment amount of four-wheel parameters are constructed on a driving shaft checking model, the contribution and the influence degree of each parameter variable on the slip amount, the swing angle and the envelope of the driving shaft can be effectively analyzed, and meanwhile, specific analysis and checking can be carried out in combination with actual vehicle arrangement and parameters, so a problem of insufficient design or excessive design caused by design and checking of all vehicle types only depending on empirical values is avoided, and the obtained drive shaft envelope body and slip swing angle curve are more accurate.

Owner:BEIJING ELECTRIC VEHICLE

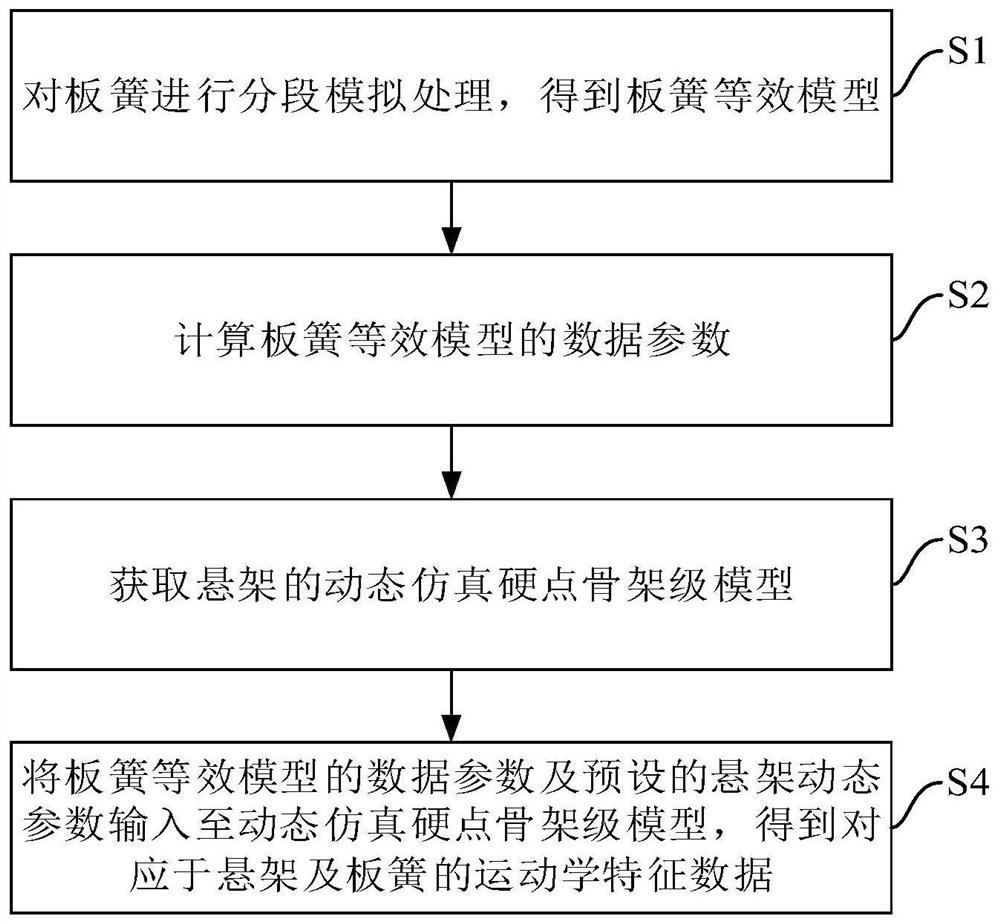

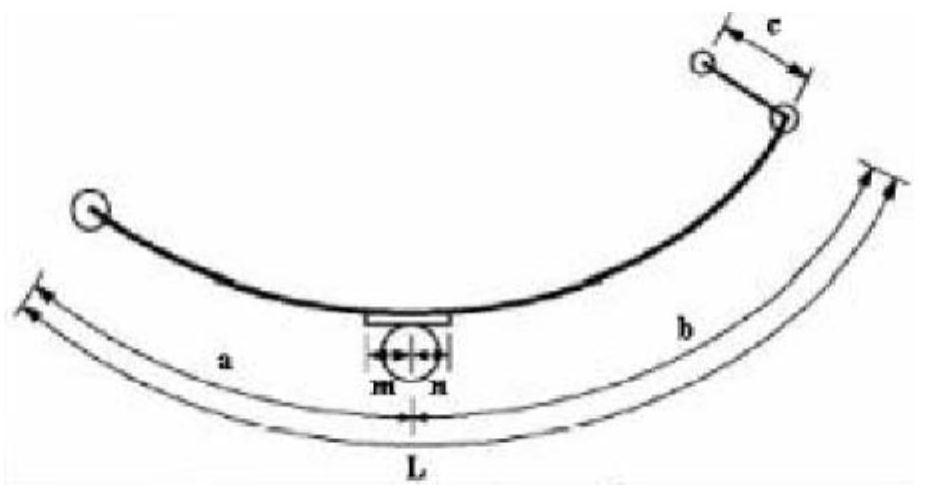

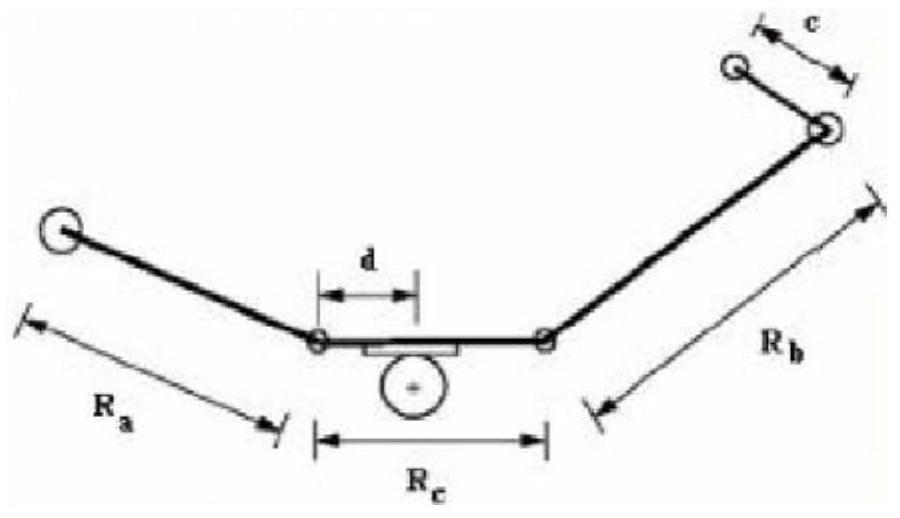

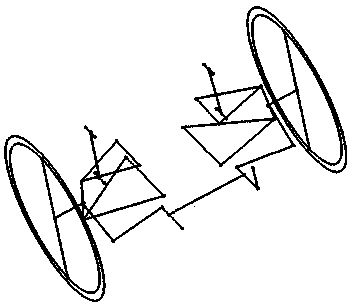

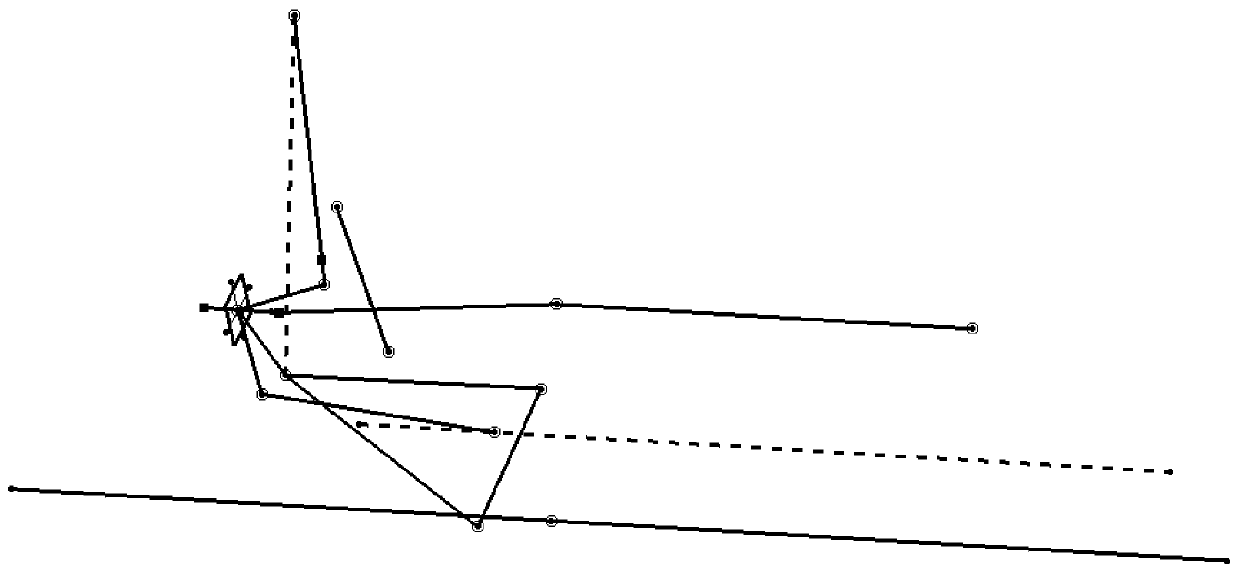

Suspension and plate spring motion analysis method and system

PendingCN112131717AMotion analysis benefitsMotion Analysis Facilitates ImplementationGeometric CADDesign optimisation/simulationClassical mechanicsEngineering

The invention discloses a suspension and plate spring motion analysis method and system, and the method comprises the following steps: carrying out the segmented simulation of a plate spring, and obtaining a plate spring equivalent model; calculating data parameters of the plate spring equivalent model; obtaining a dynamic simulation hard point skeleton-level model of the suspension; and inputtingthe data parameters of the plate spring equivalent model and preset suspension dynamic parameters into the dynamic simulation hard point skeleton-level model to obtain kinematic characteristic data corresponding to the suspension and the plate spring. According to the method and system, the plate spring can be simplified into the plate spring equivalent model, so that the plate spring is combinedwith the whole suspension mechanism, dynamic simulation of a whole suspension system is achieved, high-similarity plate spring motion simulation is achieved, dynamic analysis of suspension inclination bounce can be achieved, and a guiding effect on design of peripheral parts of the front portion is achieved.

Owner:BEIJING FOTONDAIMLER AUTOMOTIVE

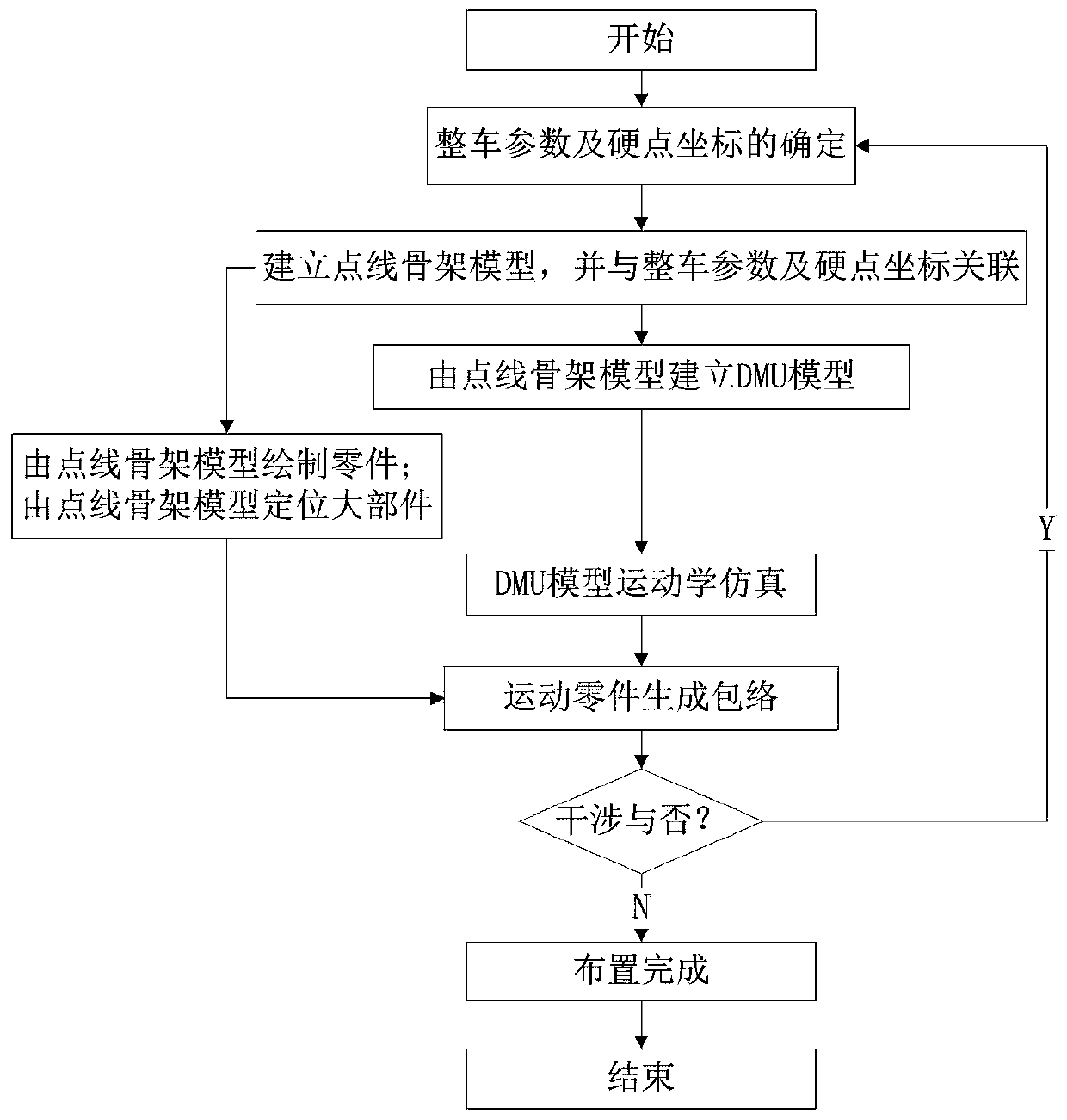

Heavy truck general arrangement method

PendingCN109800471AEliminate interferenceReduce production quantitySpecial data processing applicationsStructural engineeringTruck

The invention belongs to the technical field of vehicle total arrangement, and particularly relates to a top-down heavy truck total arrangement method based on a parameterized skeleton model. According to the method, complete forward design from top to bottom is adopted, and top layer planning is established and serves as a design criterion to be transmitted downwards step by step; The modification is very convenient, only corresponding parameters or hard point coordinates need to be modified, the point-line skeleton model, the part model and the large part are positioned, the point-line DMU model can be automatically modified, and the part motion envelope can be automatically generated; The method is suitable for a series of vehicle types of the same platform, and the requirements can bemet only by establishing one-time vehicle parameters and hard point coordinates, a one-time point line skeleton model and a one-time point line DMU model and simply modifying other vehicle types. Theworkload is greatly reduced, the sample production quantity is reduced, the product development cost is reduced, and the product development period is shortened.

Owner:BEIBEN TRUCKS GRP

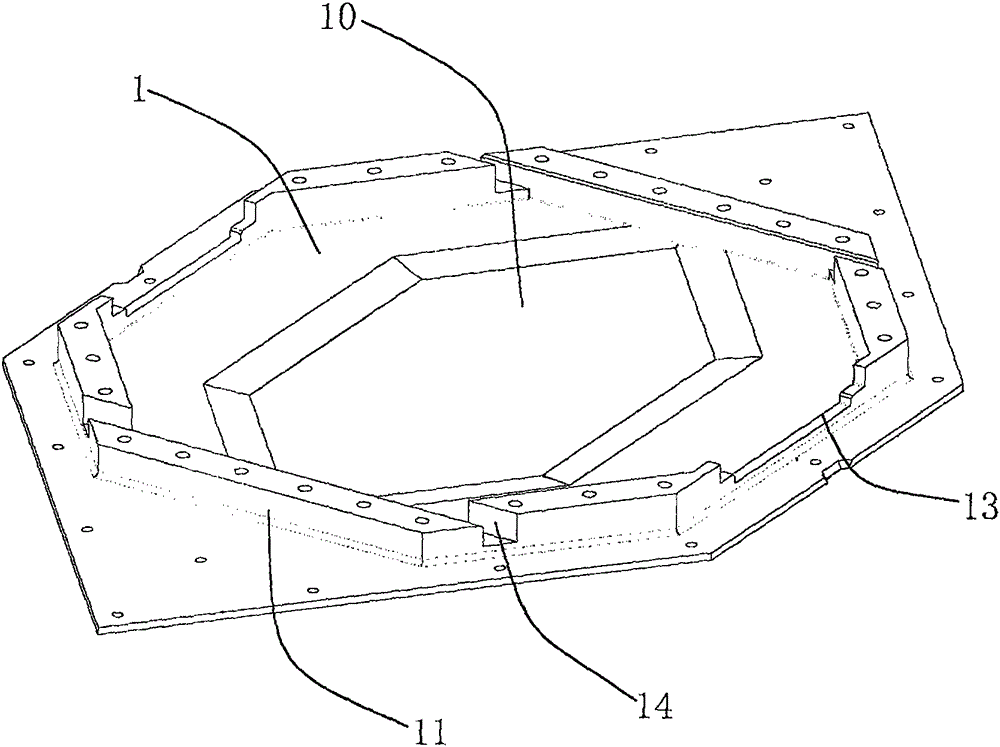

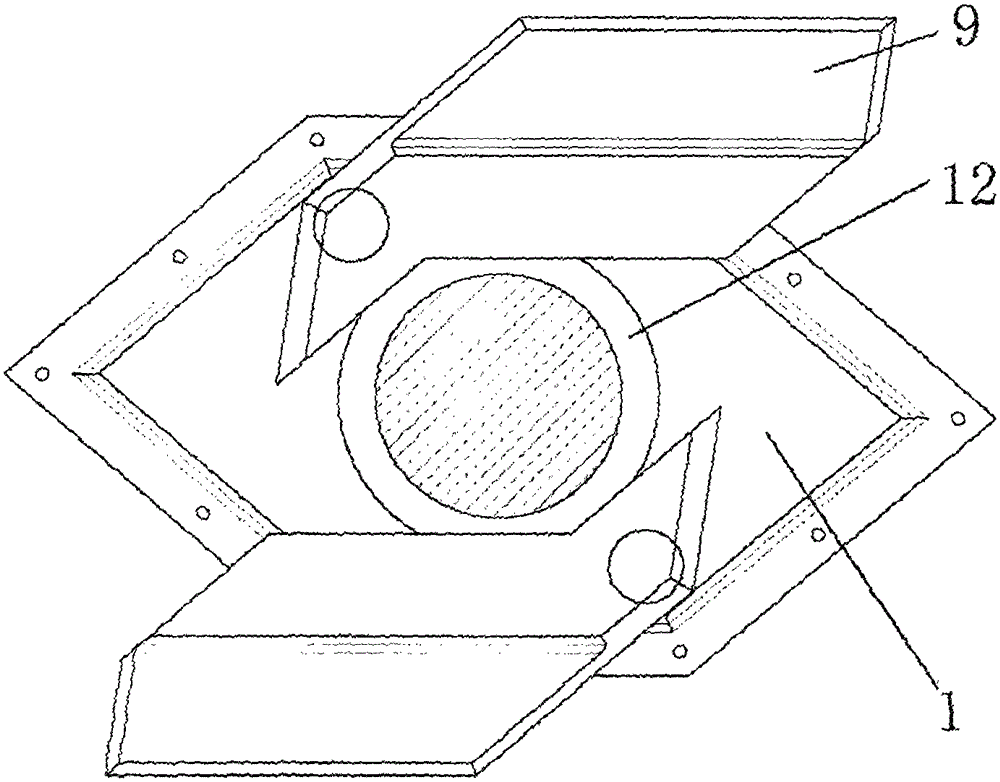

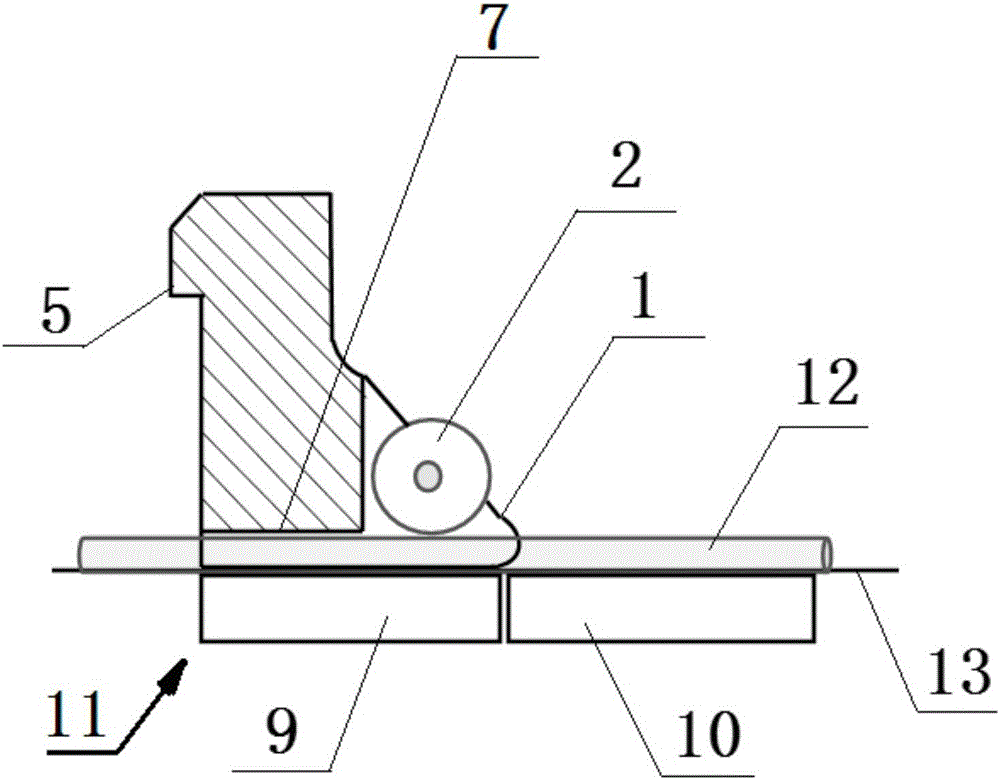

Aircraft hardpoint sealing mechanism driven by motors

The invention discloses an aircraft hardpoint sealing mechanism driven by motors. The aircraft hardpoint sealing mechanism comprises a casing (1), wherein a hanging frame hole (12) is formed in the casing (1), and two sealing plates (9) matched with the casing (1) in a rotating manner are mounted on the bottom surface of the outer sides of the casing (1) respectively and positioned on two sides of the hanging frame hole (12) respectively; a step motor (2) driving the sealing plates (9) to rotate and two opposite-transmitting type infrared sensors (4) positioned on two sides of the hanging frame hole (12) respectively are mounted on the inner side surface of the casing (1). The aircraft hardpoint sealing mechanism disclosed by the invention is simple in structure and convenient to use, when a hanging frame is mounted, the sealing plates are opened through a switch by ground staff, then the sealing plates are held in an open state, and when the hanging frame is released, the sealing mechanism is automatically closed, so that the aircraft hardpoint sealing mechanism is relatively convenient to use; because space for the sealing plates does not need to be reserved in the inner part of the casing, and plan view sizes of the sealing mechanism and a corresponding skin opening are small and slightly greater than sizes of the hanging frame, so that influence on the structural strength of the aircraft is small.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

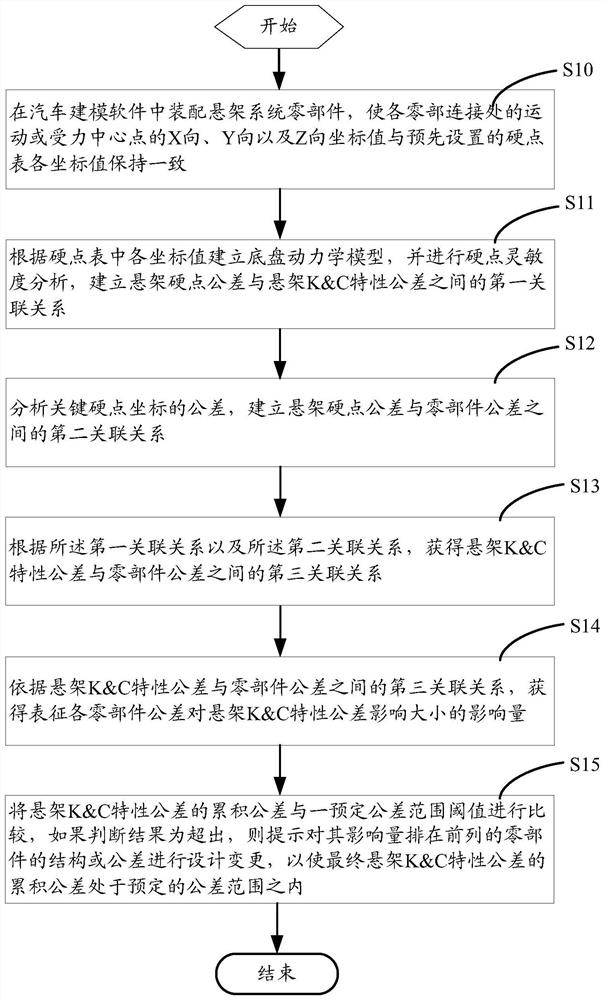

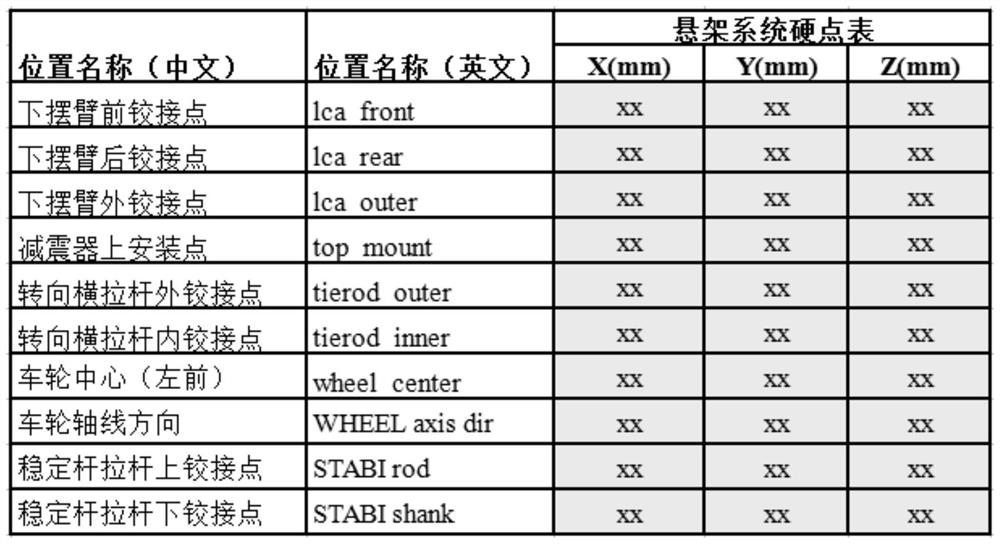

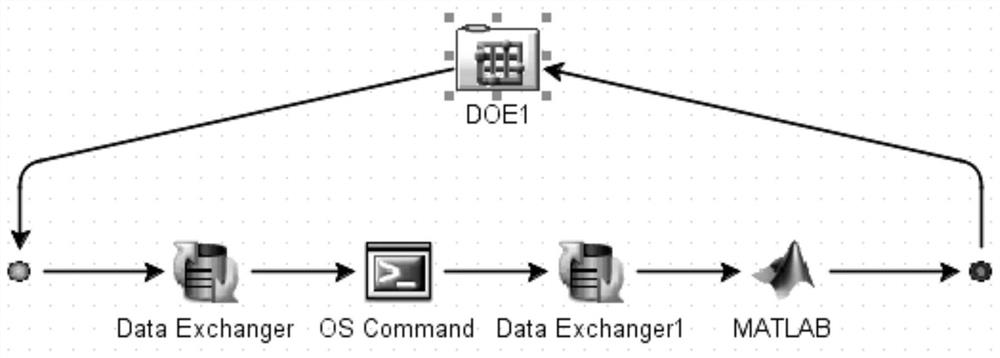

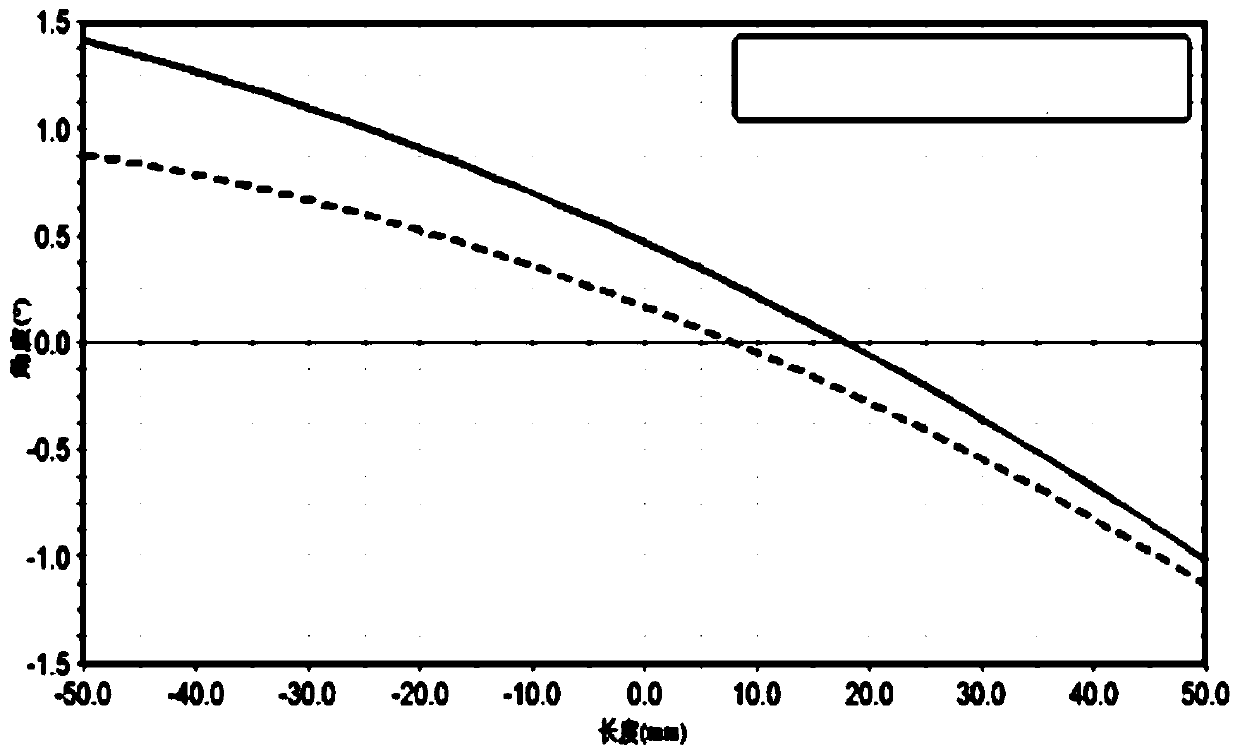

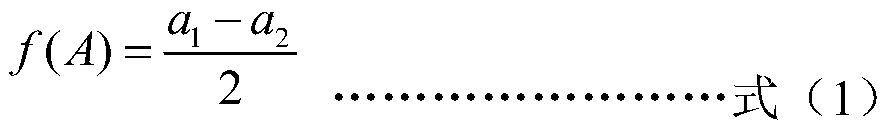

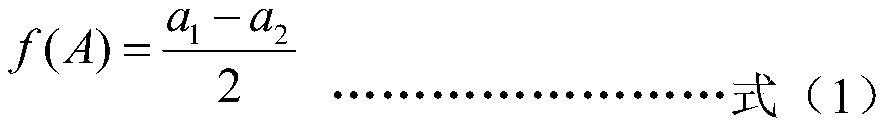

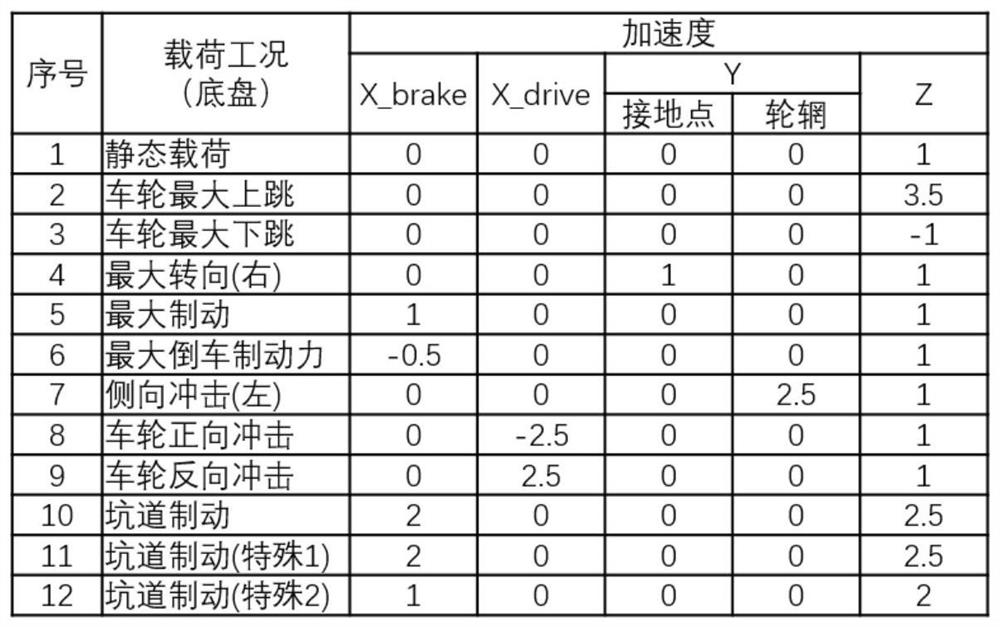

A method and system for optimizing tolerance of K&C characteristics of automobile suspension

ActiveCN107247830BShorten development timeLow costGeometric CADSpecial data processing applicationsKinetic modelRolling chassis

The invention provides an automobile suspension K&C characteristic tolerance optimization method. The method includes: building a chassis kinetic model according to each coordinate in a hard spot table, and building a first correlation between suspension hard spot tolerance and suspension K&C characteristic tolerance; analyzing the tolerance of the coordinates of key hard spots, and building a second correlation between the suspension hard spot tolerance and part tolerance; according to the first correlation and the second correlation, acquiring the third correlation between the suspension K&C characteristic tolerance and the part tolerance, and acquiring the influence quantity representing the influence of each part tolerance on the suspension K&C characteristic tolerance; when the accumulated tolerance of the suspension K&C characteristic tolerance exceeds a preset tolerance range threshold, prompting that design alteration needs to be performed on part structures or tolerance with high influence quantity so as to allow the final accumulated tolerance to be located within the preset tolerance range threshold. The invention further provides a corresponding system. By the automobile suspension K&C characteristic tolerance optimization method, development time can be shortened evidently, and cost can be saved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

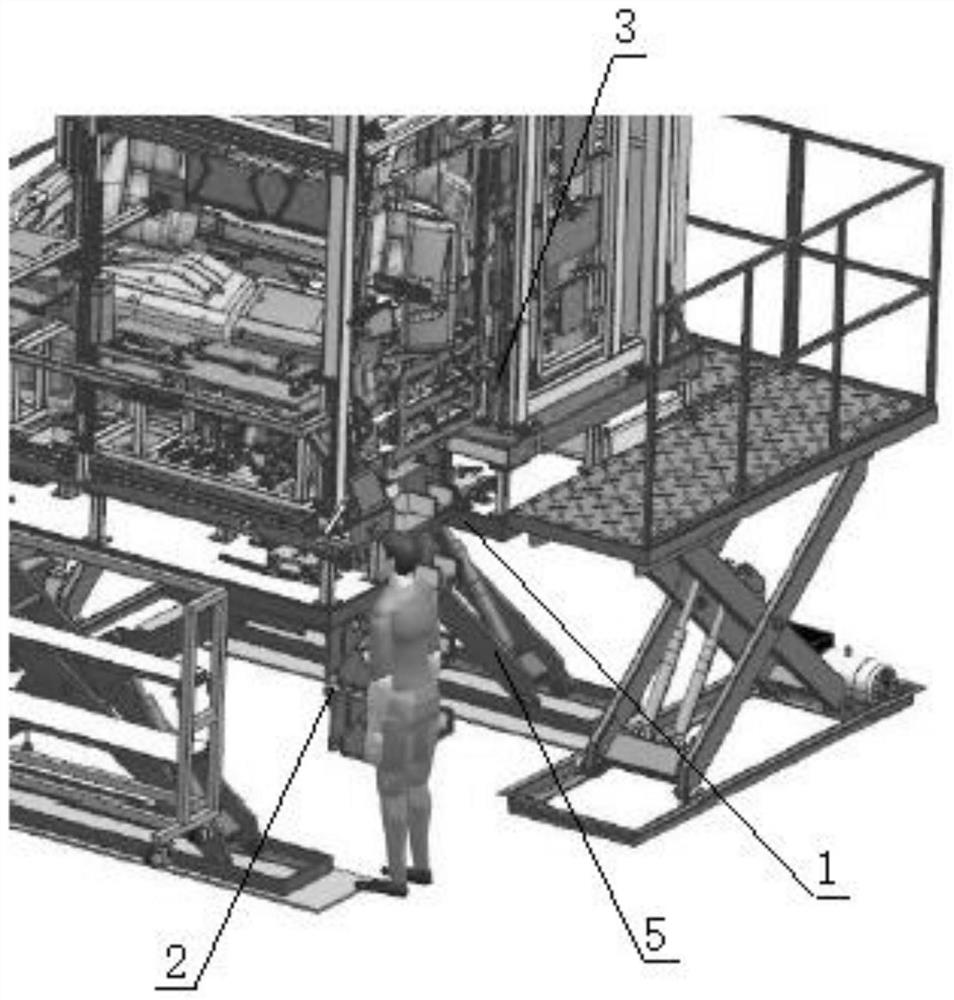

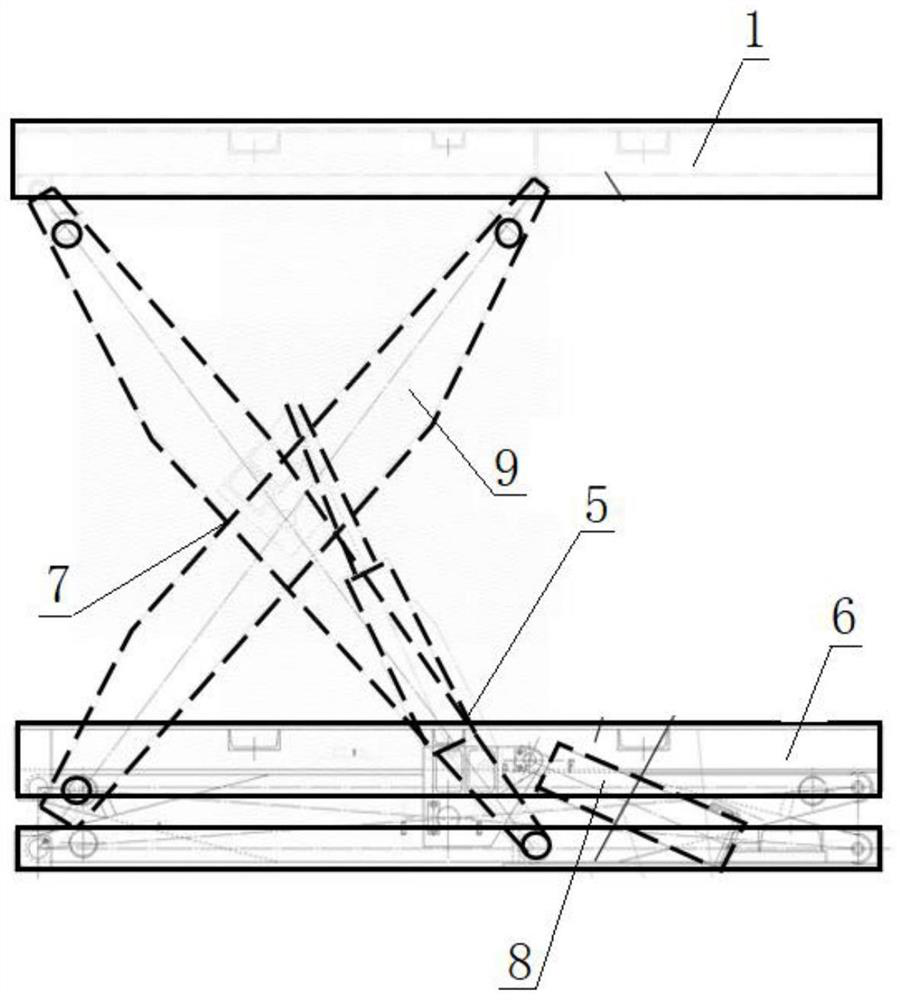

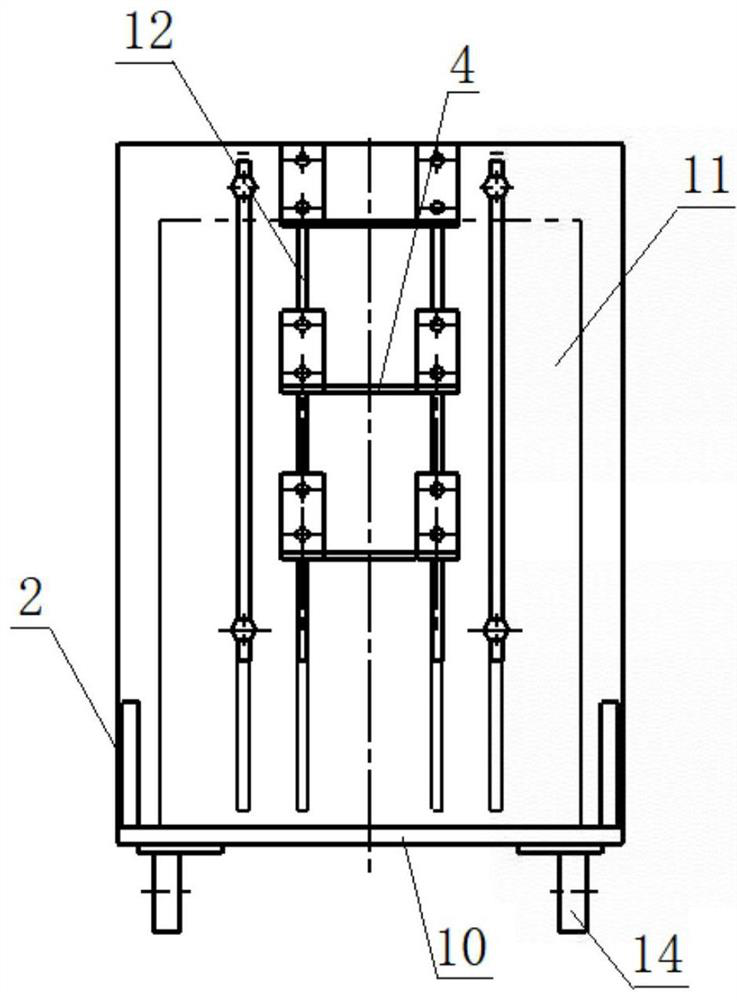

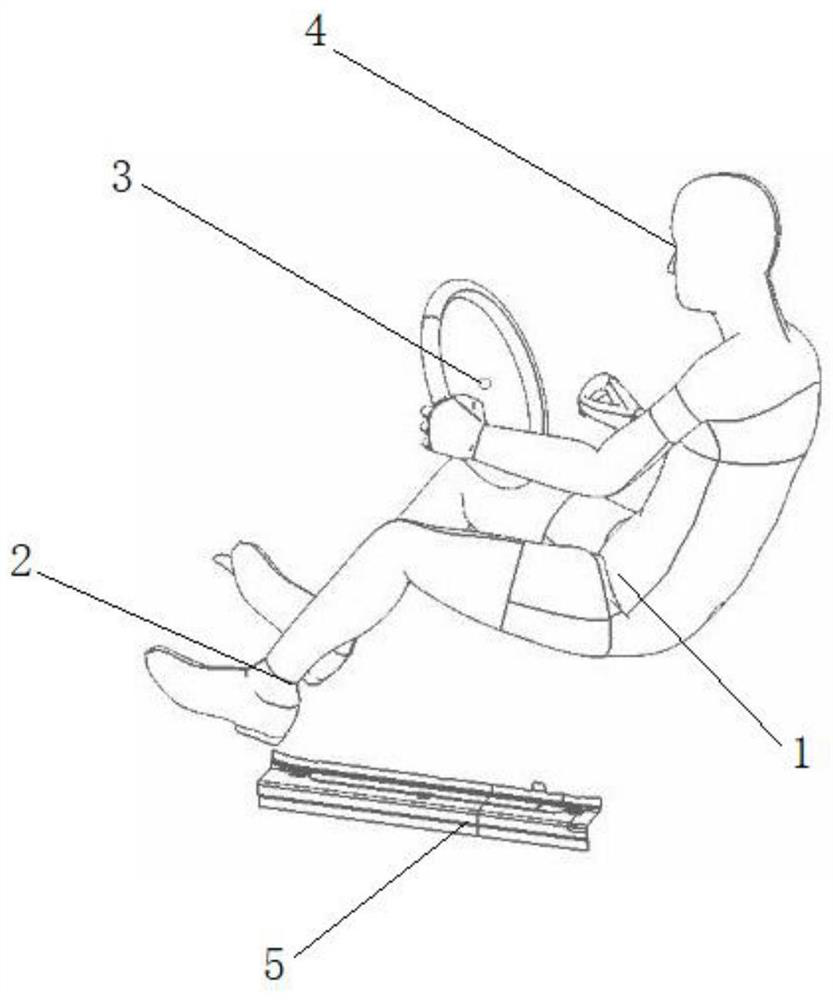

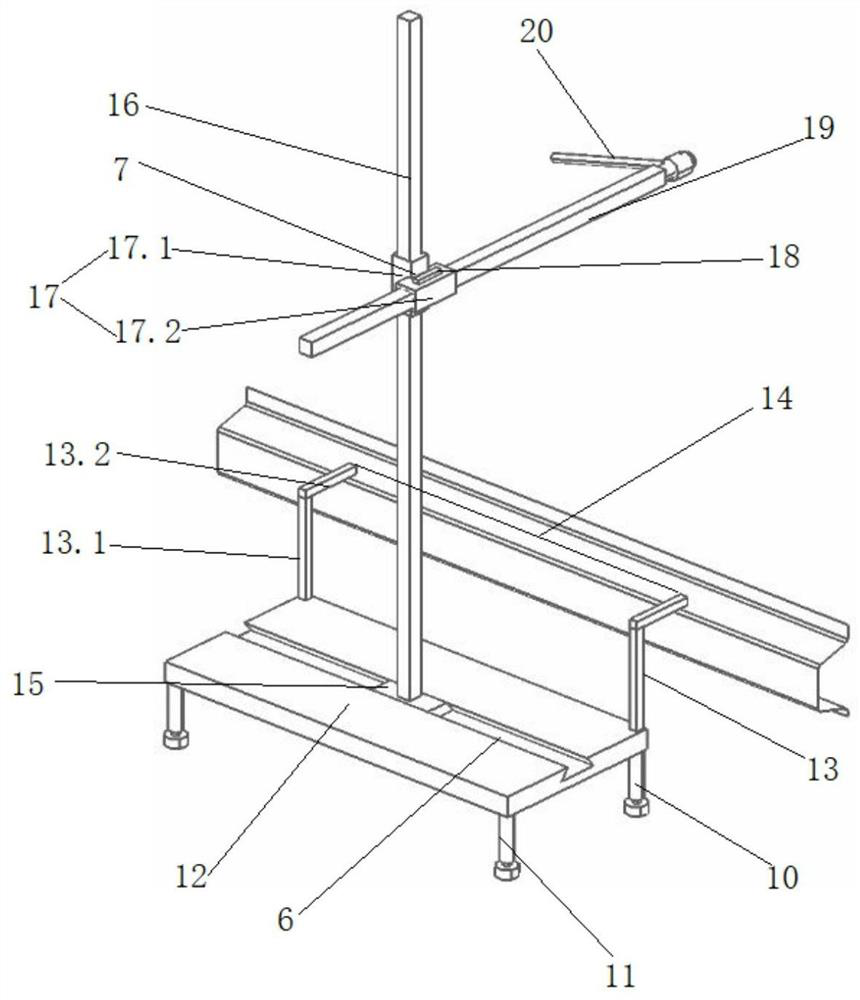

Truck getting-on and getting-off convenience verification device

PendingCN112179678AShorten the development cycleReduce development costsVehicle testingDriver/operatorTransportation technology

The invention relates to the technical field of mechanical devices and transportation, and discloses a truck getting-on and getting-off convenience verification device which comprises a liftable platform simulating a cab floor, a stepping mechanism and a handrail mechanism, and is characterized in that the height of the liftable platform is adjustable and is matched with the height of the cab floor, and the stepping mechanism is matched with the liftable platform; a plurality of stages of brackets are arranged on the stepping mechanism, a driver enters the lifting platform through the brackets, and the handrail mechanism is installed on the lifting platform. According to the truck getting-on and getting-off convenience verification device, cab engineering designers can carry out physical verification on arrangement hard points in the conceptual design stage, discover arrangement problems as soon as possible, carry out optimization and improvement in time, shorten the development periodand reduce the cost.

Owner:DONGFENG COMML VEHICLE CO LTD

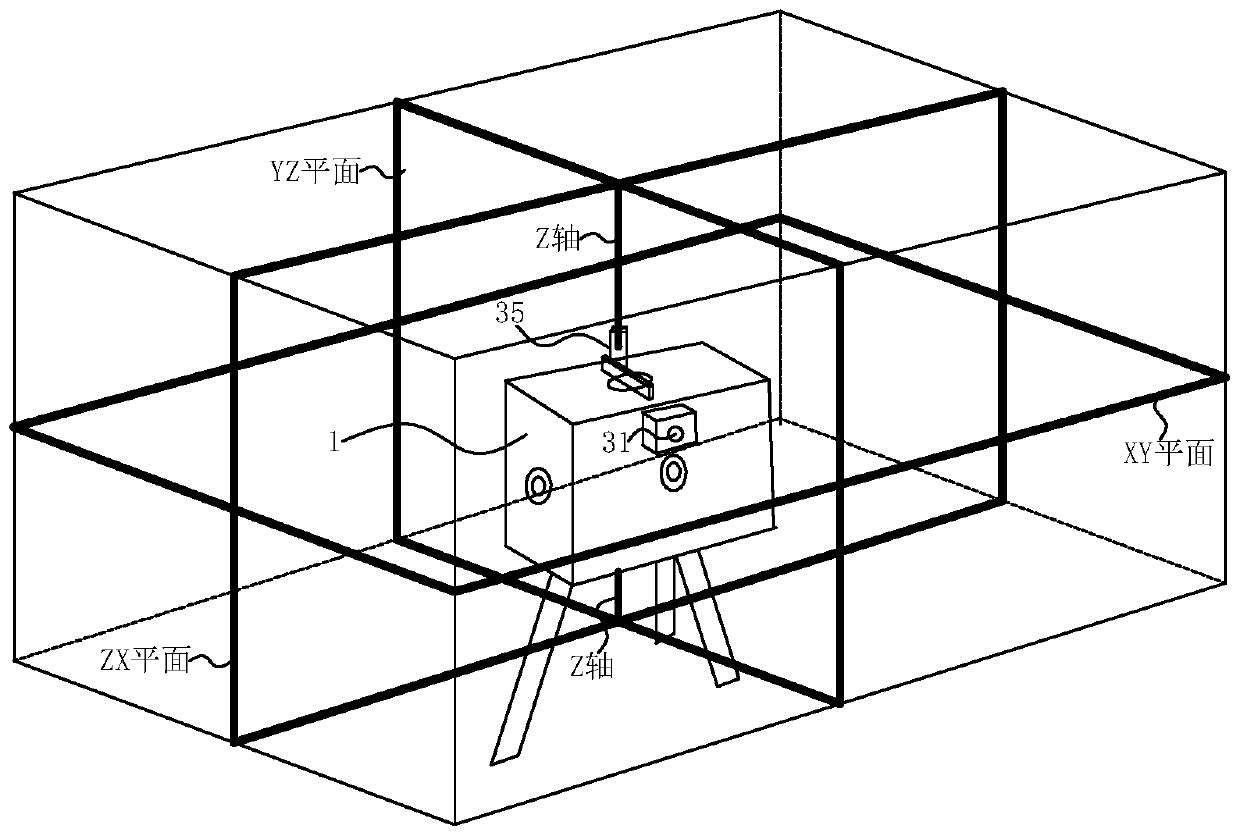

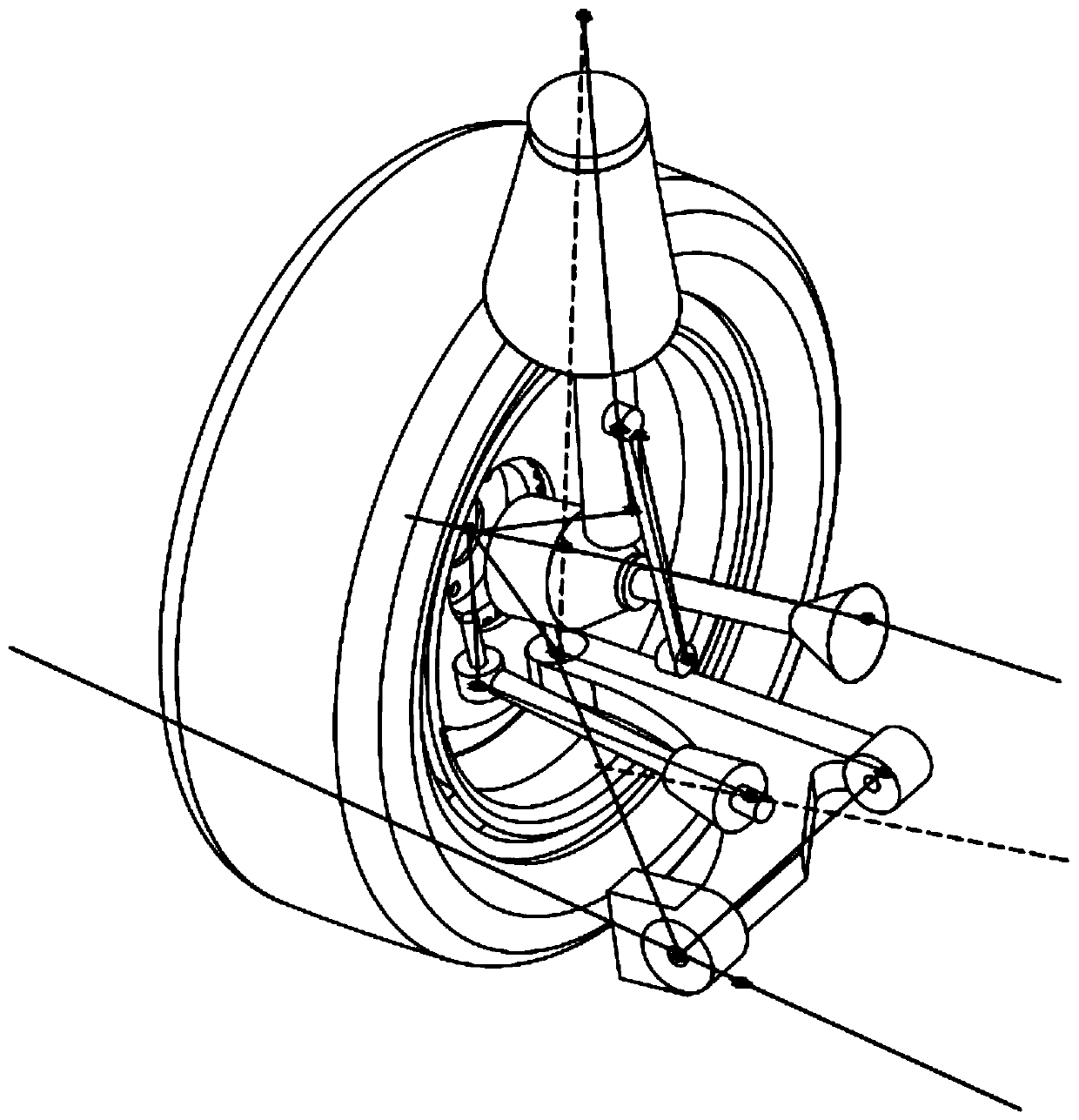

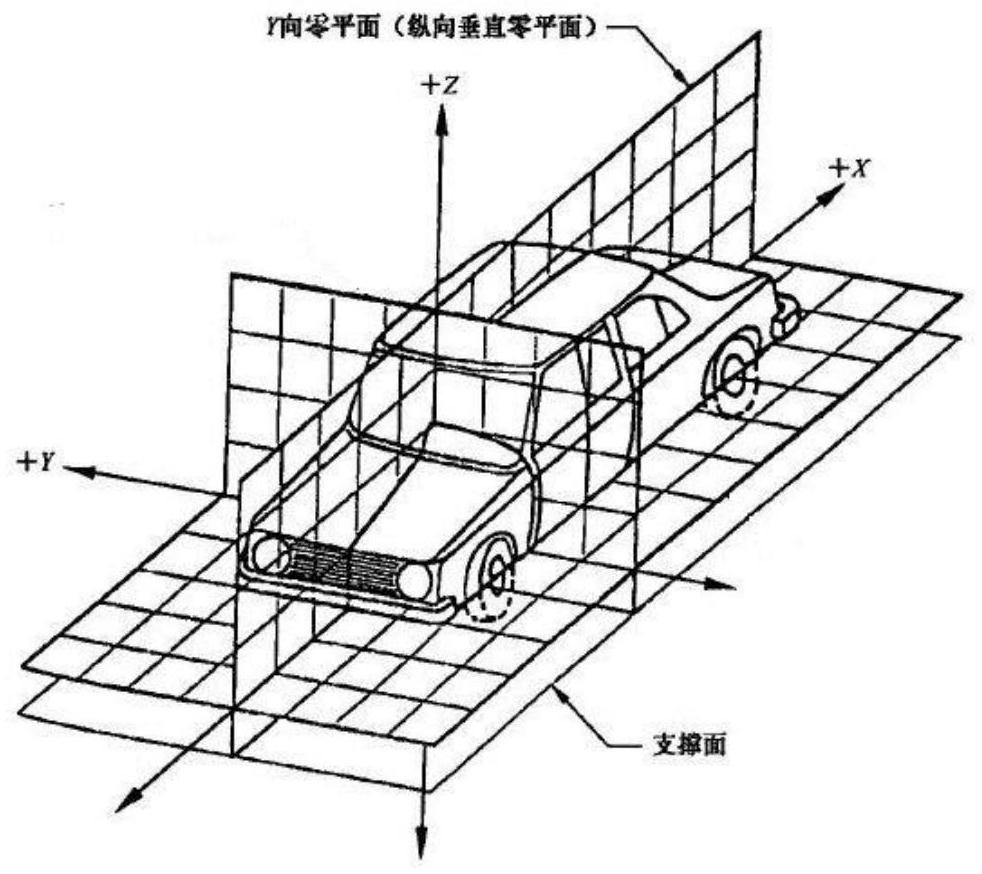

Special equipment for measuring size of hard point of chassis of accident vehicle and measuring method

ActiveCN110926344AHigh measurement accuracyNo influence on measurement accuracyUsing optical meansReference line/planes/sectorsLaser transmitterAccidents vehicle

The invention discloses special equipment for measuring the size of a hard point of a chassis of an accident vehicle and a measuring method. The special equipment comprises two laser level gauges, andan auxiliary level gauge; a main laser transmitting tube and a laser receiving tube are horizontally arranged on the side surfaces of the level gauges and the auxiliary level gauge; a control line ofthe main laser transmitting tube is connected with a signal output end of the single-chip microcomputer. When special equipment is used for measuring hard points of a chassis of a vehicle body, a traditional direct measurement mode is changed into classified measurement, and when no shielding object exists below a measured point, the center position of the measured point is determined through thetwo level gauges, the distance of the measured point is measured through the laser transmitter, the laser receiver and the single-chip microcomputer, the measurement precision is not affected by theheight of the measured point, the measurement speed is high, and the measurement precision is high. When the lower part of one measured point is shielded, equivalent measurement is realized by addingan auxiliary level gauge and utilizing a rectangular principle, and other parts on the vehicle body do not need to be dismounted, so that the measurement speed and precision are effectively improved.

Owner:XIHUA UNIV

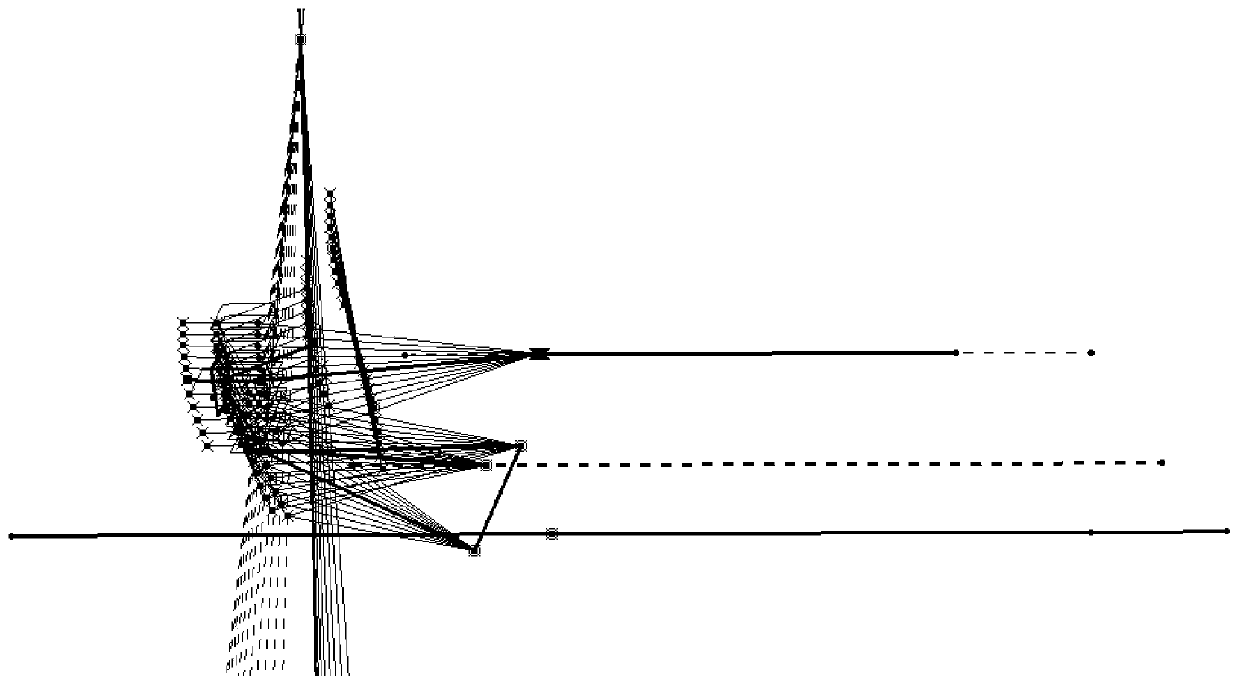

Structure design-oriented suspension hard spot optimization method

ActiveCN110727990AEasy to balance K characteristicsGeometric CADSustainable transportationEngineeringMechanical engineering

The invention relates to the technical field of automobile suspension structure design, and discloses a structure design-oriented suspension hard spot optimization method, which comprises the following steps: drawing a suspension design load position hard spot in CATIA software; drawing a plurality of groups of parameter-free hard spots, constraining the internal relative position of each group ofparameter-free hard spots according to the size relationship of the hard spots at the designed load position of the suspension, driving each group of parameter-free hard spots by setting a fixed spotand a wheel heartbeat height, and driving each group of parameter-free hard spots to different up-and-down jumping states by the wheel heartbeat height; drawing a to-be-optimized suspension K characteristic curve according to the suspension motion trail, and drawing the target suspension K characteristic curve and the to-be-optimized suspension K characteristic curve in the same table; and adjusting the suspension design load position hard spot to optimize the suspension K characteristic curve. When the suspension design load position hard spot is adjusted, simulation analysis does not need to be operated, and the suspension K characteristic curve can be automatically updated, so that all parameters of the K characteristic curve can be displayed in one interface, and various properties ofthe K characteristic can be conveniently balanced.

Owner:CHINA FIRST AUTOMOBILE

Method for optimizing suspension positioning parameters

The invention discloses a method for optimizing suspension positioning parameters, which is characterized by comprising the following steps of: P1, establishing an automobile double-wishbone suspension system model based on ADAMS / Car, and obtaining related hard point coordinates; p2, performing simulation analysis on the model to obtain a positioning parameter change curve, and judging whether optimization is needed or not according to a parameter change range; p3, optimizing the positioning parameters which need to be optimized; and P4, optimization verification: importing the adjusted hard point coordinates into a previously established model, and judging the rationality of the positioning parameters. According to the method for optimizing the suspension positioning parameters, the problems that an existing suspension design model is simple, the control effect is poor, and parameter optimization cannot be conducted on suspension positioning can be effectively solved, then the automobile running stability can be accurately and effectively adjusted, the driving comfort degree is improved, and the optimization method is simple in design and easy to implement.

Owner:开沃新能源汽车集团股份有限公司

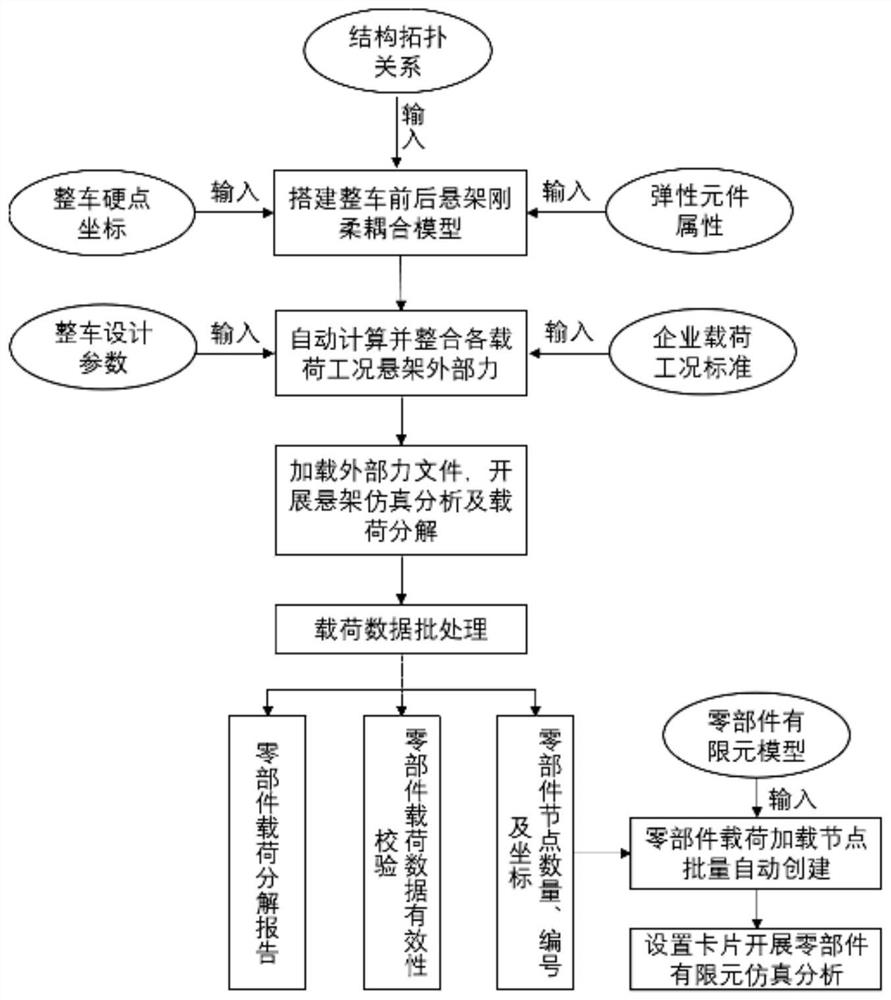

Suspension load decomposition, data processing and finite element load loading method

PendingCN113821959AReduce inputSave time at workGeometric CADText processingElement modelBatch processing

The invention discloses a suspension load decomposition, data processing and finite element load loading method, which comprises the following steps of: inputting a whole vehicle hard point coordinate, an elastic element attribute parameter and a structure topological relation, and establishing a whole vehicle front and rear suspension rigid-flexible coupled multi-body dynamic model; inputting vehicle design parameters and enterprise load working condition standards, and automatically calculating and integrating the external force of the suspension under each load working condition; loading an external force file; carrying out suspension simulation analysis and load analysis; carrying out batch processing on load data; generating a part load decomposition report; verifying the validity of the part load data; exporting the node number, the number and the coordinate of the part; inputting a finite element model of the part; automatically creating part load loading nodes in batches; arranging a card, and performing finite element simulation analysis of the parts. In the process of the method, synchronous processing of all data is carried out at the same time, so that the working time is greatly saved, the efficiency is improved, and the correctness of load data provided for CAE engineers is ensured.

Owner:YIBIN COWIN AUTO CO LTD

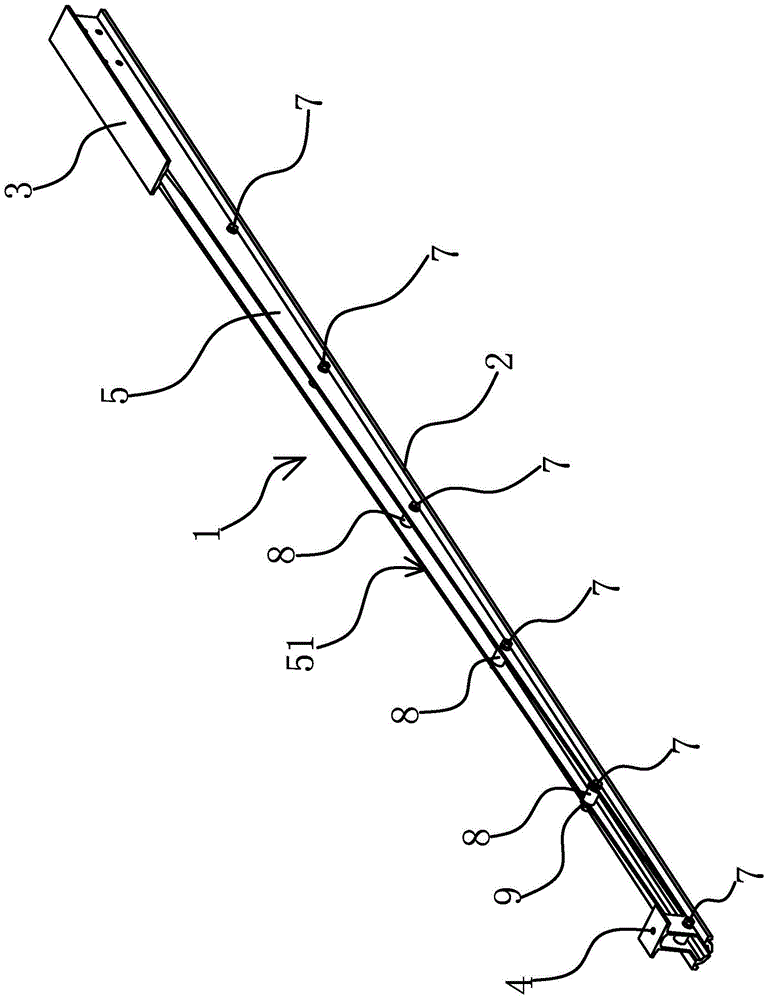

Driver man-machine hard point coordinate acquisition device and method

ActiveCN112050766AVerify design rationalityImprove driving experienceGeometric CADMeasurement devicesDriver/operatorMan machine

The invention relates to a driver man-machine hard point coordinate acquisition device and method. Two positioning supports of a collecting device are oppositely arranged on a first side of a bottom plate in the length direction of the bottom plate, and the bottom end of a first supporting rod which is vertically arranged is arranged in the middle of the bottom plate in a sliding mode in the length direction of the bottom plate; a second supporting rod arranged in the width direction of the bottom plate is perpendicularly connected to the first supporting rod through a connecting piece, the second supporting rod can slide on the first supporting rod and can move relative to the connecting piece in the direction parallel to the width direction of the bottom plate, and an angle measuring rodis rotatably connected to the end, away from the bottom plate, of the second supporting rod. According to the invention, the three-dimensional coordinates of the man-machine hard point of a Chinese driver can be rapidly collected by combining a real vehicle, so that the design rationality of the vehicle model is verified, the product development is ensured to truly face Chinese users, and the driving experience and the product quality are improved.

Owner:DONGFENG MOTOR CORP HUBEI

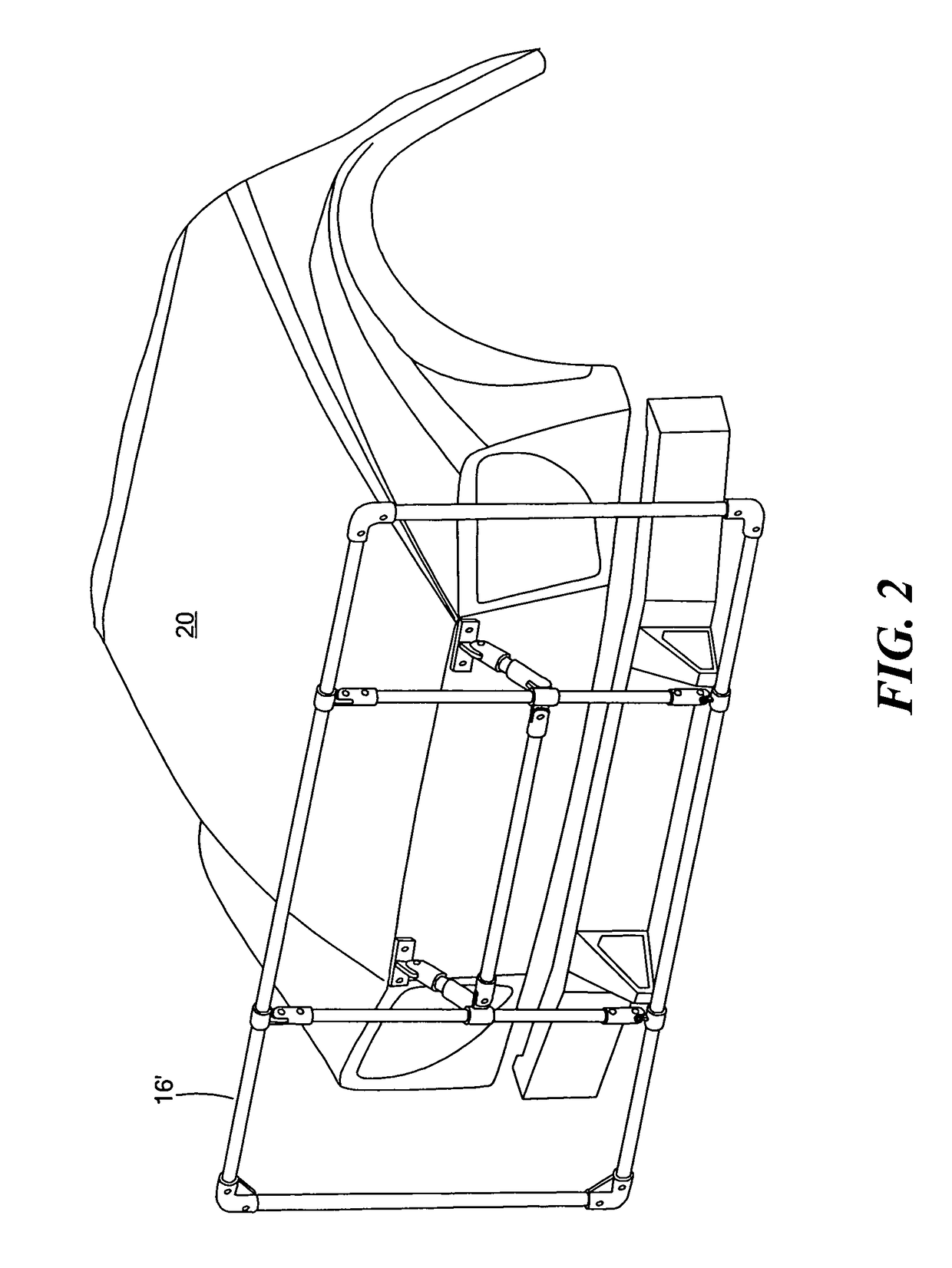

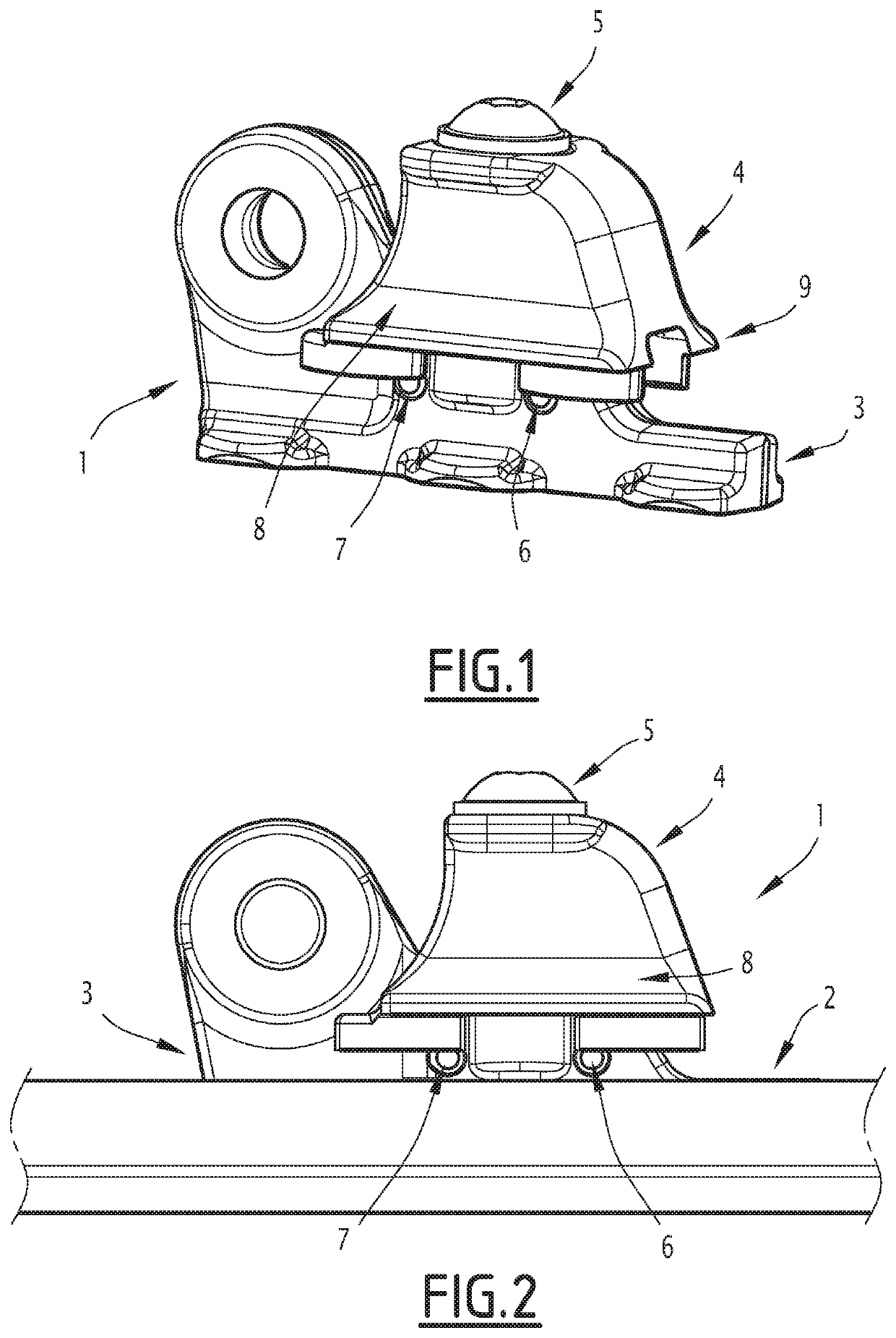

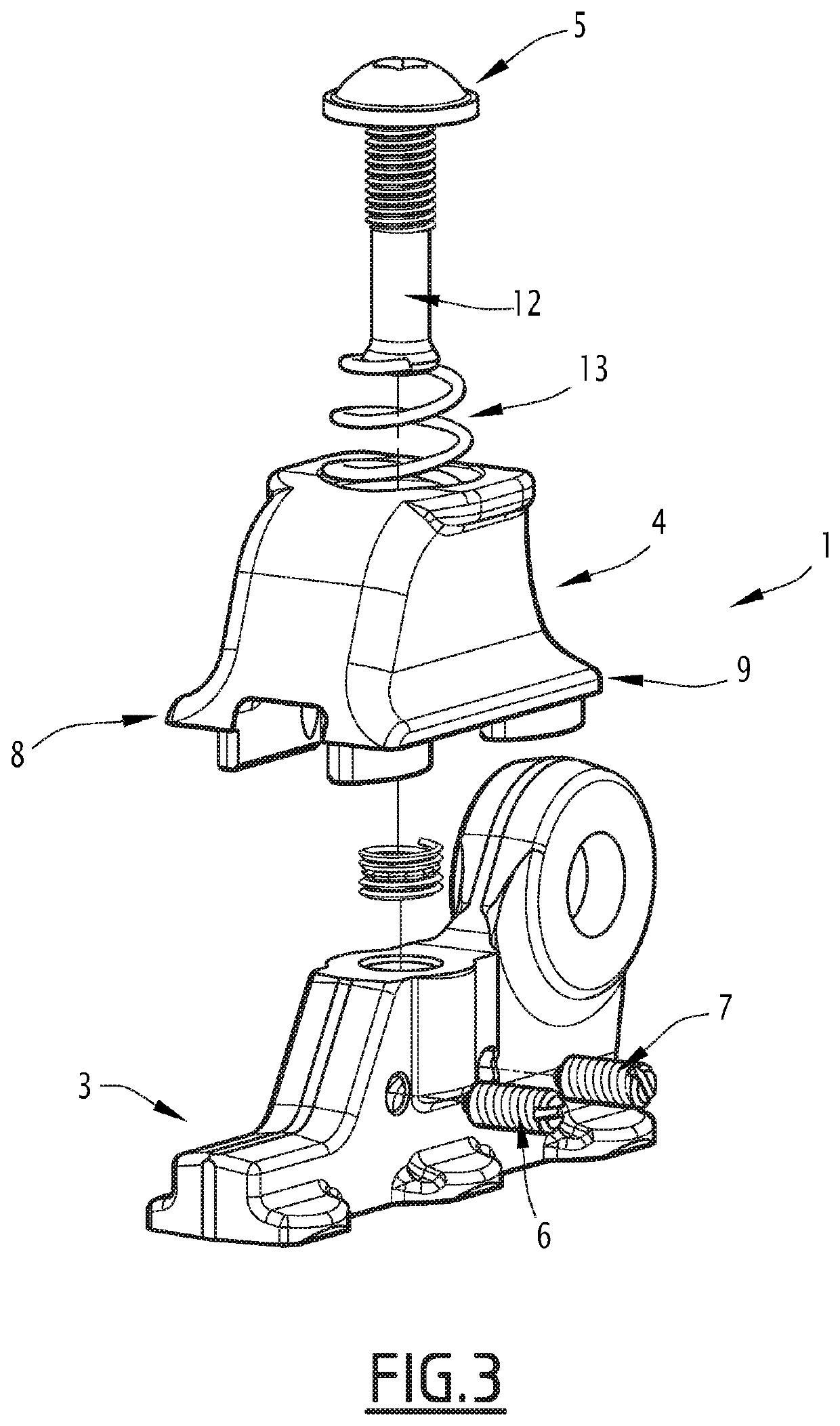

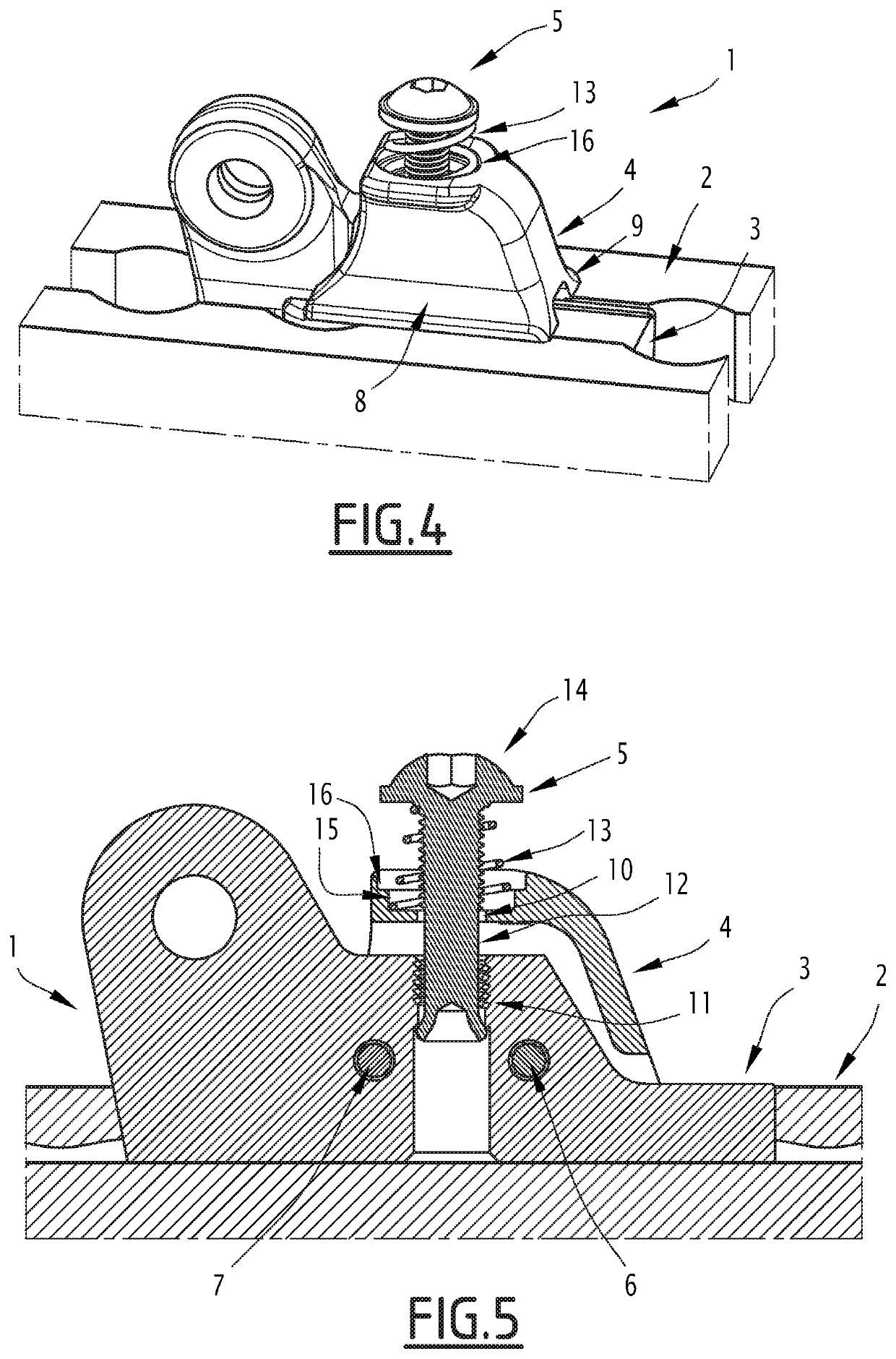

System for securing a seat notably for aircraft and seat comprising such a system

A system for securing a seat, in particular in an aircraft, in a rail, in particular a rail of the aircraft, the system including a base, and clamping and locking jaws for clamping and locking the system into position in the rail, by gripping the rail between the base and the clamping and locking jaws, the clamping and locking jaws being movable relative to the base between a first drawn-apart position for mounting / dismounting of the system in / from the rail and a second drawn-together position for locking the system, by clamping around the rail, by use of an actuator that is operable by a mounting / dismounting operator between an unlocking position and a locking position of the system, wherein hard spot crossing is provided between the base and the clamping and locking jaws, the hard spot crossing maintaining the clamping and locking jaws in their first drawn-apart position for mounting / dismounting the system.

Owner:TECH INDS

Flexible bending die with wheel preventing deformation

InactiveCN104998974AAvoid hard pointsAvoid the defects of bending and deformationShaping toolsEngineeringMechanical engineering

The invention discloses a flexible bending die with a wheel preventing deformation and belongs to the technical field of metal bending dies. The flexible bending die solves the problems that when an existing outer refrigerator plate is in bent production, a condensing pipe is liable to be bent, shrunken and deformed. The flexible bending die with the wheel preventing deformation comprises an upper die and a lower die. The lower die comprises a lower die base. A rotating arm is hinged to the front end of the lower die base. The upper die comprises an upper die base located above the lower die base. A through groove which is through in a front-and-back mode is formed in the center of the upper die base. Male dies are arranged at the front ends of the parts, located on the two sides of the through groove, of the upper die base respectively. A rotating shaft is installed between the male dies. The wheel is arranged on the rotating shaft. According to the flexible bending die with the wheel preventing deformation, due to the fact that the wheel is arranged between the male dies, in the bending process, the deforming position of the condensing pipe floats along with the cylindrical wheel, the damp generated in deformation is eliminated, and the defect that when the existing outer refrigerator plate is in bending production, hard spots are generated on the condensing pipe or bending, shrinking and deforming are generated on the condensing pipe is overcome.

Owner:SHANGHAI SHARP ELECTRONICS

A Rigid-Flexible Transitional Busbar

The invention provides a rigid-flexible transition busbar, which belongs to the technical field of electrified railway and urban rail transit overhead catenary. It solves the problems of transitional hardness and high cost in the existing rigid-flexible transition busbar. The rigid-flexible transitional bus bar includes a bus bar body. The two ends of the bus bar body are respectively a rigid connection end and a flexible connection end. The lower part of the bus bar body has a clamping jaw. The rigid-flexible transition part whose body rigidity gradually decreases, the upper surface of the rigid-flexible transition part is a continuous transition slope; the bus bar body is distributed along the length direction with several connecting through holes passing through the bus bar body, and locks are respectively installed in the connecting through holes. Each locking bolt is covered with a positioning sleeve, and the two end surfaces of the positioning sleeve respectively abut against the inner surface of the main body of the bus bar. The rigid-flexible transitional busbar adopts a continuous transition slope for transition, eliminating hard points in the rigid-flexible transitional busbar.

Owner:浙江旺隆轨道交通设备有限公司

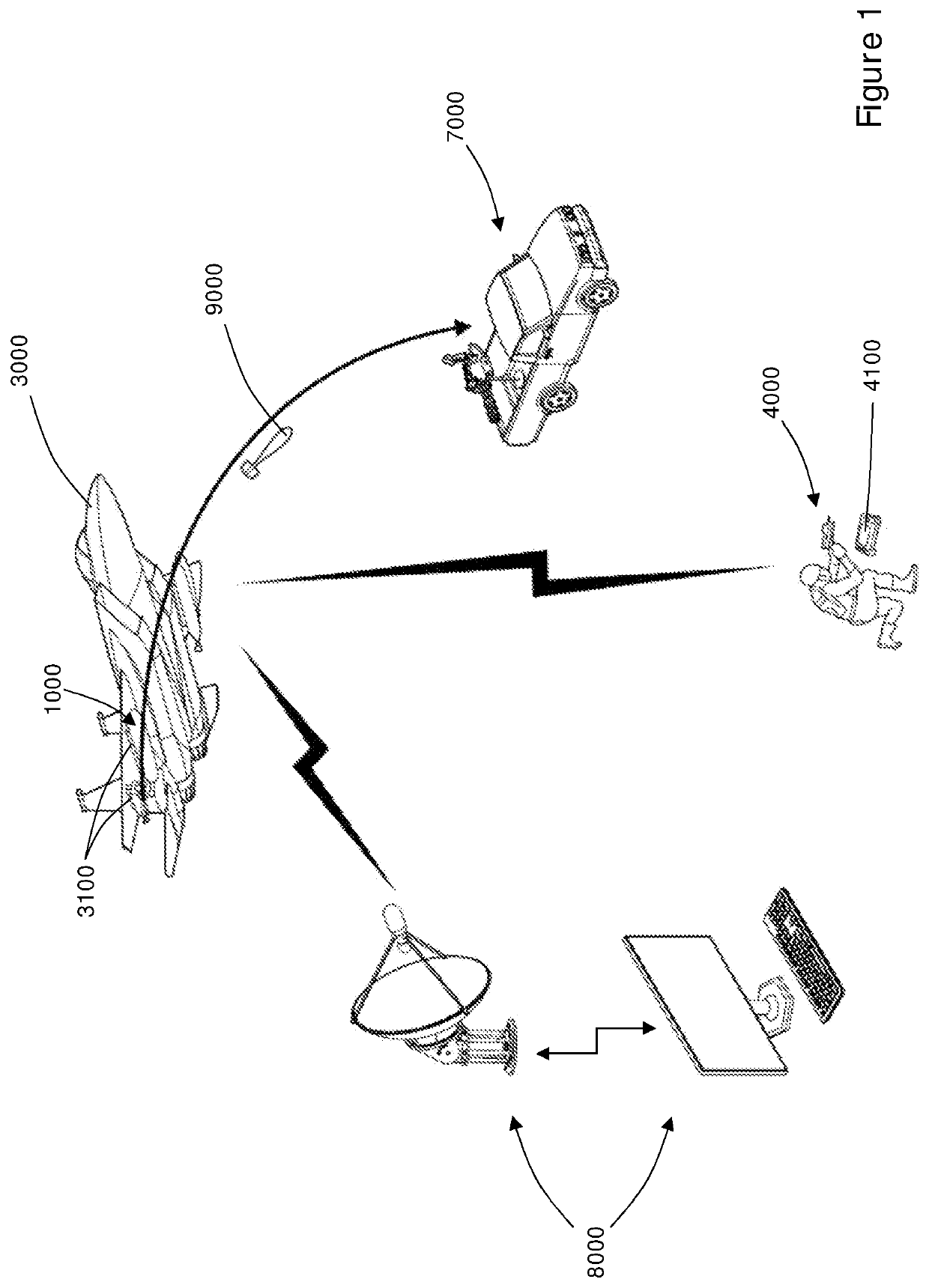

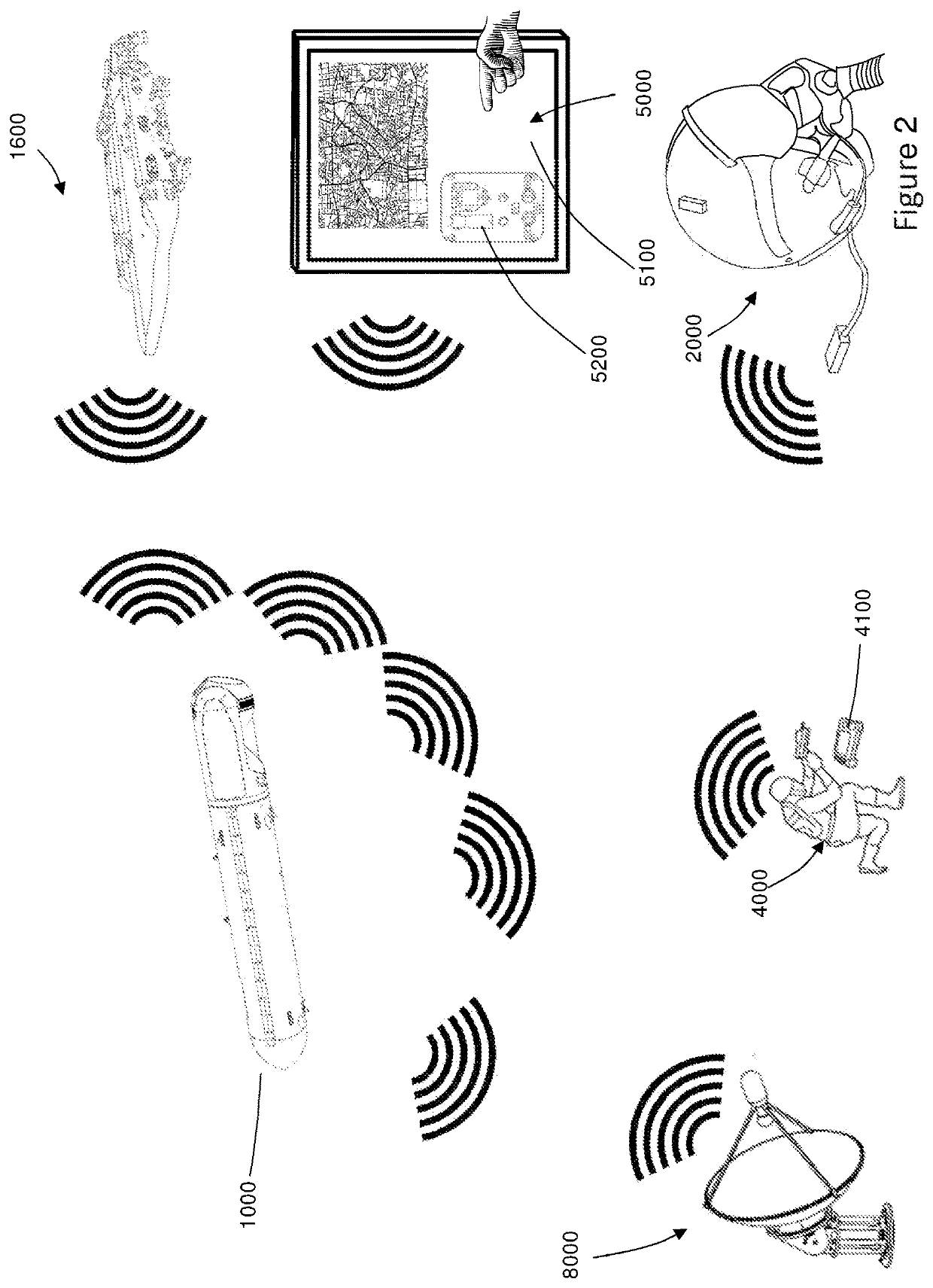

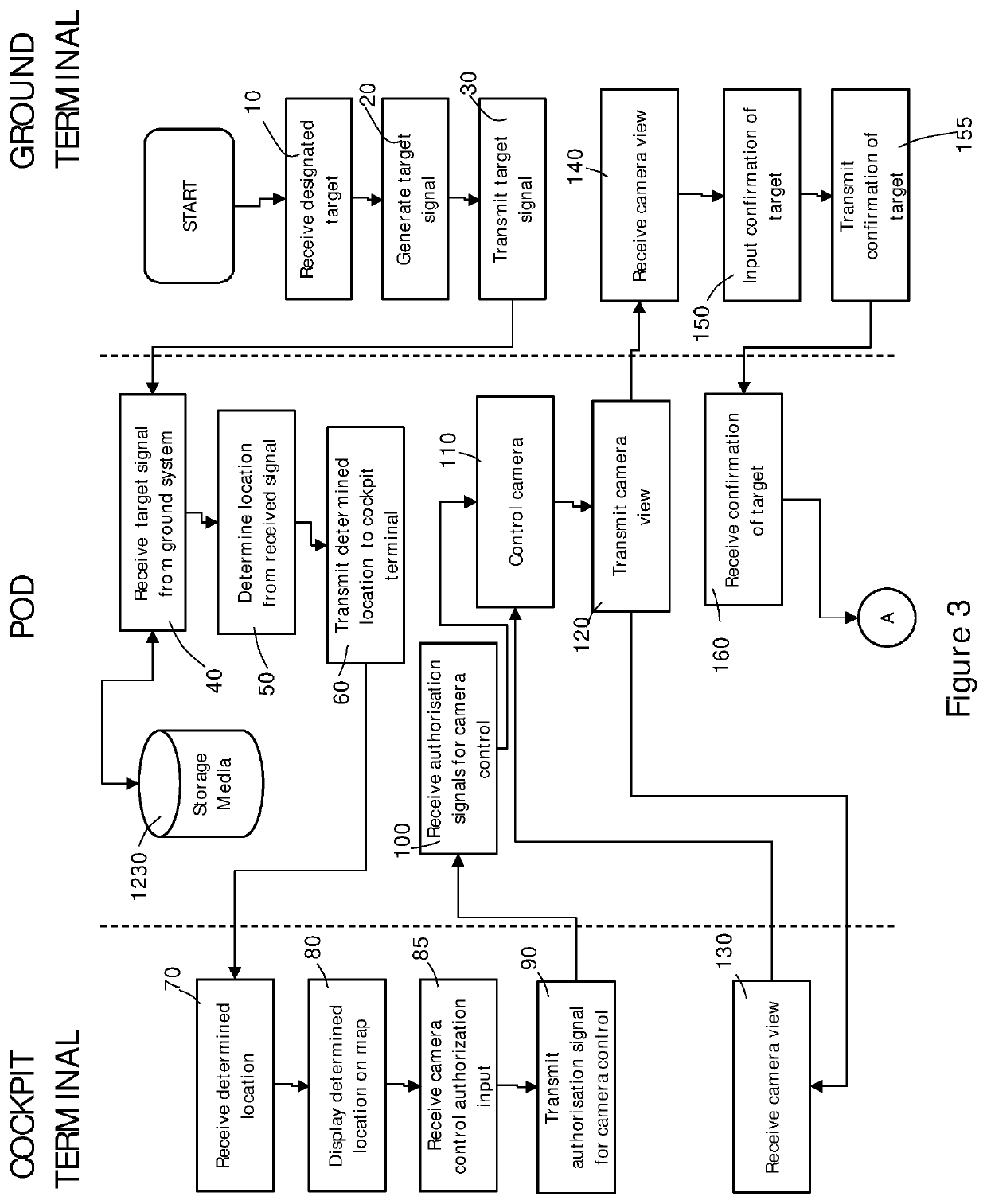

Weapon targeting training system and method therefor

PendingUS20220114906A1Good senseCosmonautic condition simulationsDirection controllersAirplaneReal-time computing

The present invention relates to a training system for training of a forward controller. The training system utilises a pod housing that can be attached to a hardpoint under an aircraft wing. The pod is configured to receive communications from the forward controller on the ground (or in another aircraft) and communicate wirelessly with an HMD and / or electronic device in the cockpit of the aircraft. This allows cheaper, less expensive aircraft to be used for training purposes.

Owner:SINAB TECH PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com