A method and system for optimizing tolerance of K&C characteristics of automobile suspension

A technology of automobile suspension and optimization method, applied in geometric CAD, special data processing applications, instruments, etc., can solve the problems of development cycle and cost waste, low operability, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

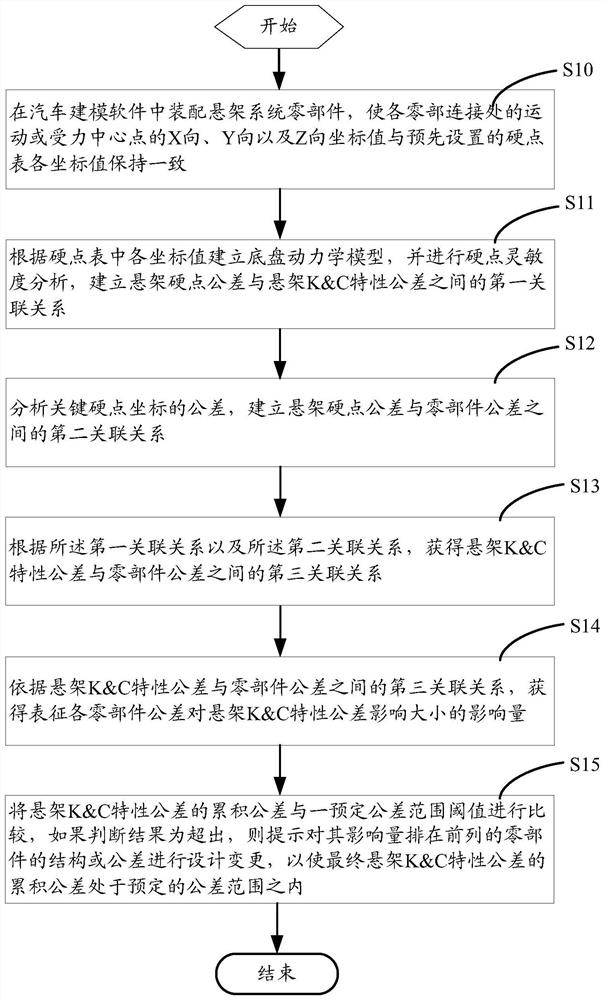

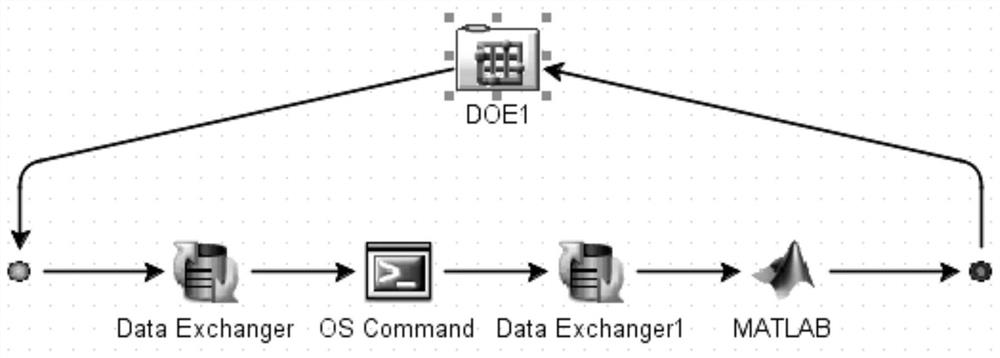

[0086] Please refer to figure 1 As shown, it shows a schematic diagram of a main flow of an automobile suspension K&C characteristic tolerance optimization method provided by the present invention, and please combine it together Figure 2 to Figure 7 Shown, in this embodiment, this method comprises the steps:

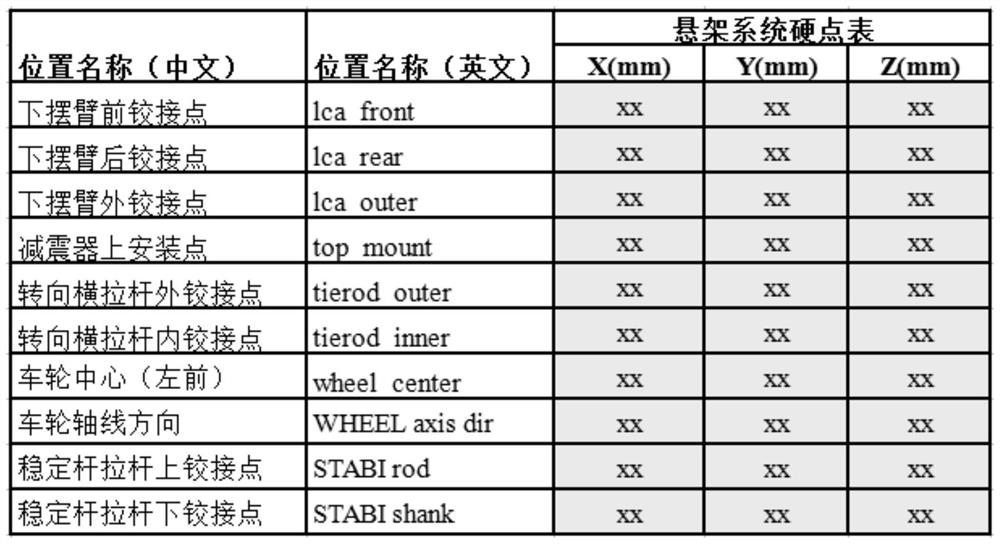

[0087] Step S10, assemble the suspension system components in the vehicle modeling software, make the X-direction, Y-direction and Z-direction coordinate values of the joints of the parts or the center point of the force be the same as the coordinate values of the preset hard point table be consistent;

[0088] In one embodiment, the step S10 specifically includes:

[0089] In CATIA software (an automobile modeling software), correctly assemble the data of the suspension system components, and measure the X-direction, Y-direction and Z-dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com