Automotive front Macpherson suspension and automobile comprising same

A technology of automobile and suspension, which is applied in the direction of suspension, vehicle parts, transportation and packaging, etc. It can solve the problems affecting the driving comfort performance and the driving comfort of the driver, so as to improve the control and comfort, reduce vibration and weaken the The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the following description is only illustrative and exemplary.

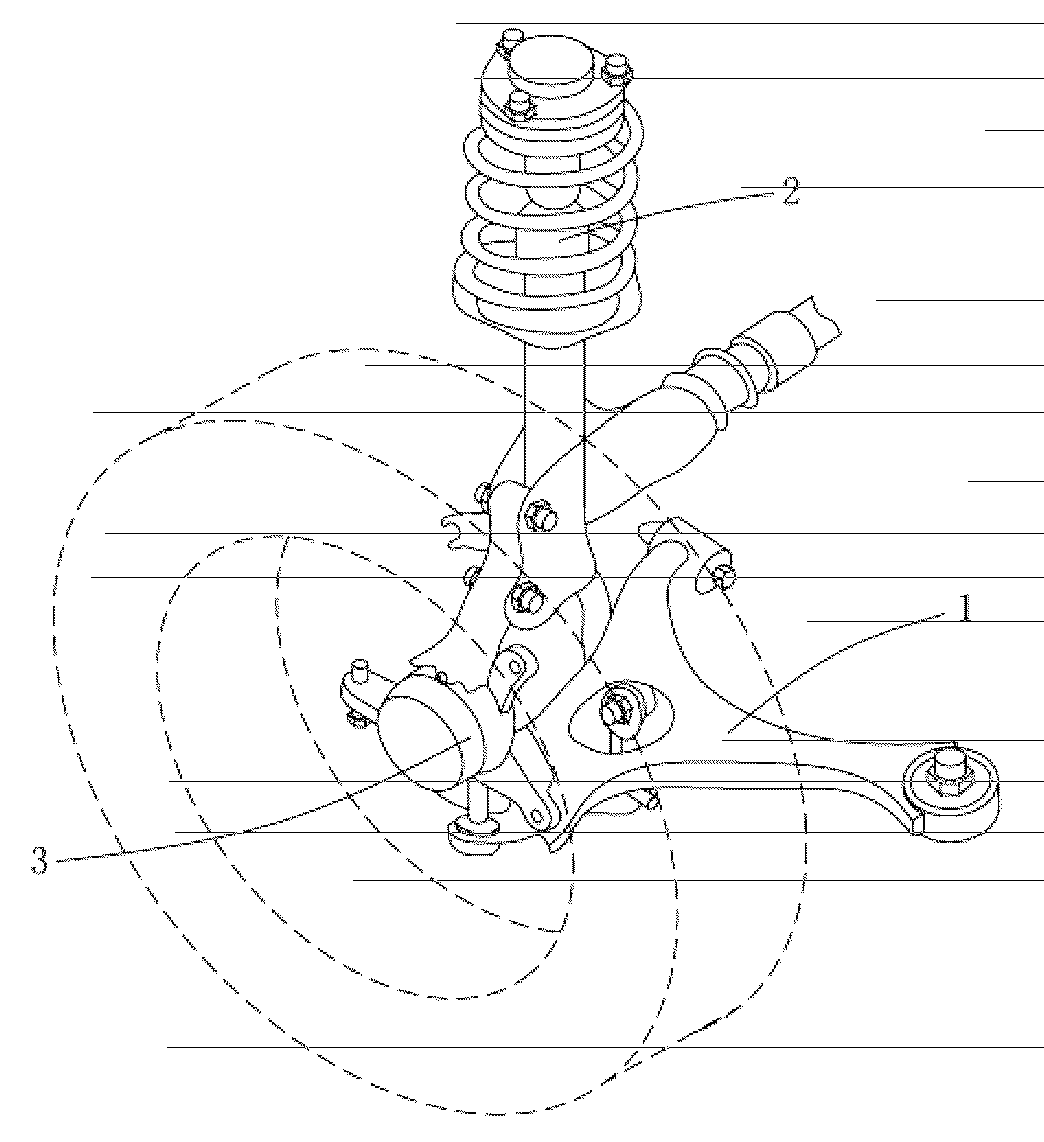

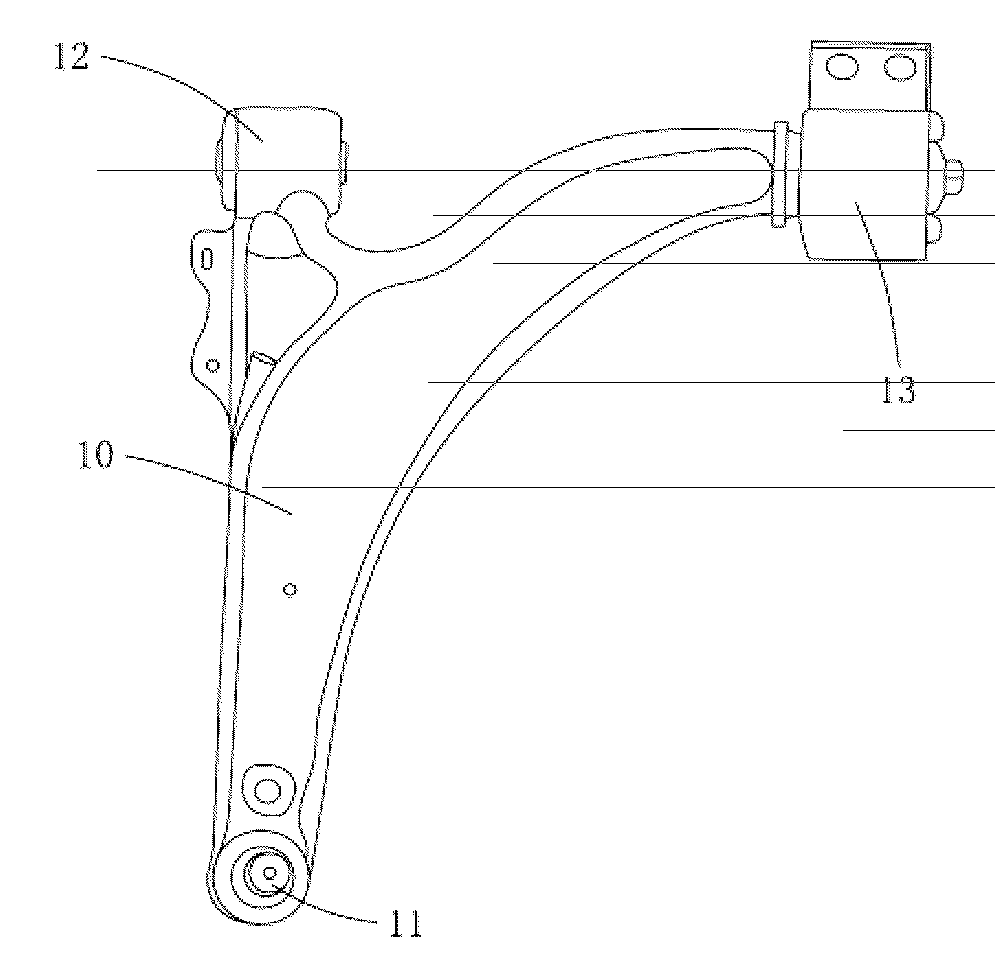

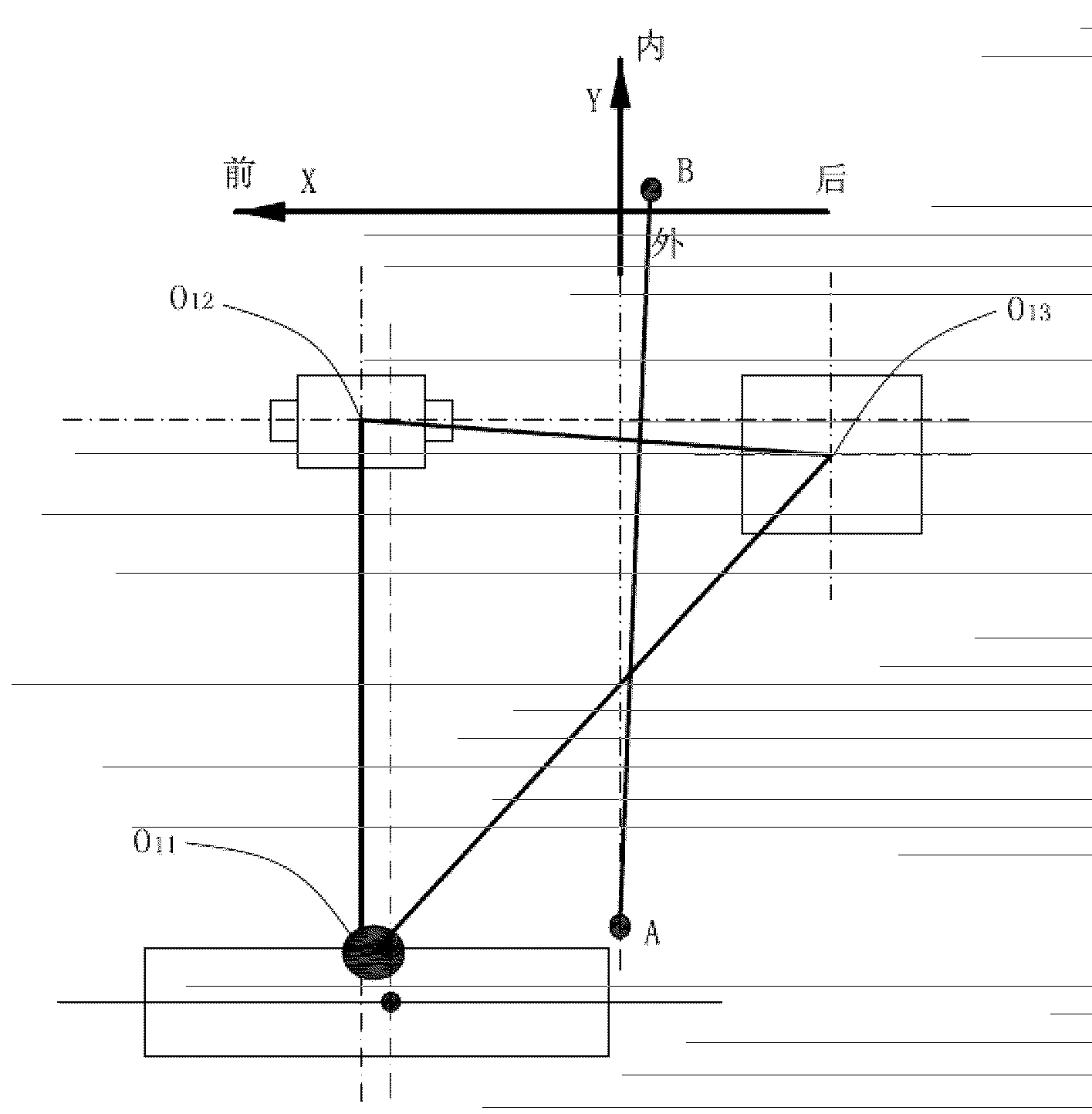

[0032] figure 2 is a schematic diagram of a MacPherson suspension control arm according to one embodiment of the invention. As shown in the figure, the control arm 1 of the front MacPherson suspension of an automobile includes a control arm body 10 , a ball stud 11 , a front frame bushing 12 and a rear frame bushing 13 . A ball stud 11 is located on the control arm body 10 and is used to connect the steering knuckle. Front frame bushings 12 and rear frame bushings 13 are also located on the control arm body 10 and are used to attach to a frame (not shown). Considering that those skilled in the art already have a good understanding of the conventional settings of the MacPherson suspension, the connection relationship between the MacPherson suspension re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com