Suspension and plate spring motion analysis method and system

A motion analysis and leaf spring technology, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the inability to guide the design of the front peripheral parts and the difficulty in setting the overall boundary of the dynamic analysis of the suspension system , the combination of the leaf spring and the entire suspension mechanism, etc., to achieve the effect of leaf spring motion simulation, dynamic analysis, and high approximation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

[0055] Refer below Figure 1-Figure 5The suspension and leaf spring motion analysis method and system according to the embodiment of the present invention are described.

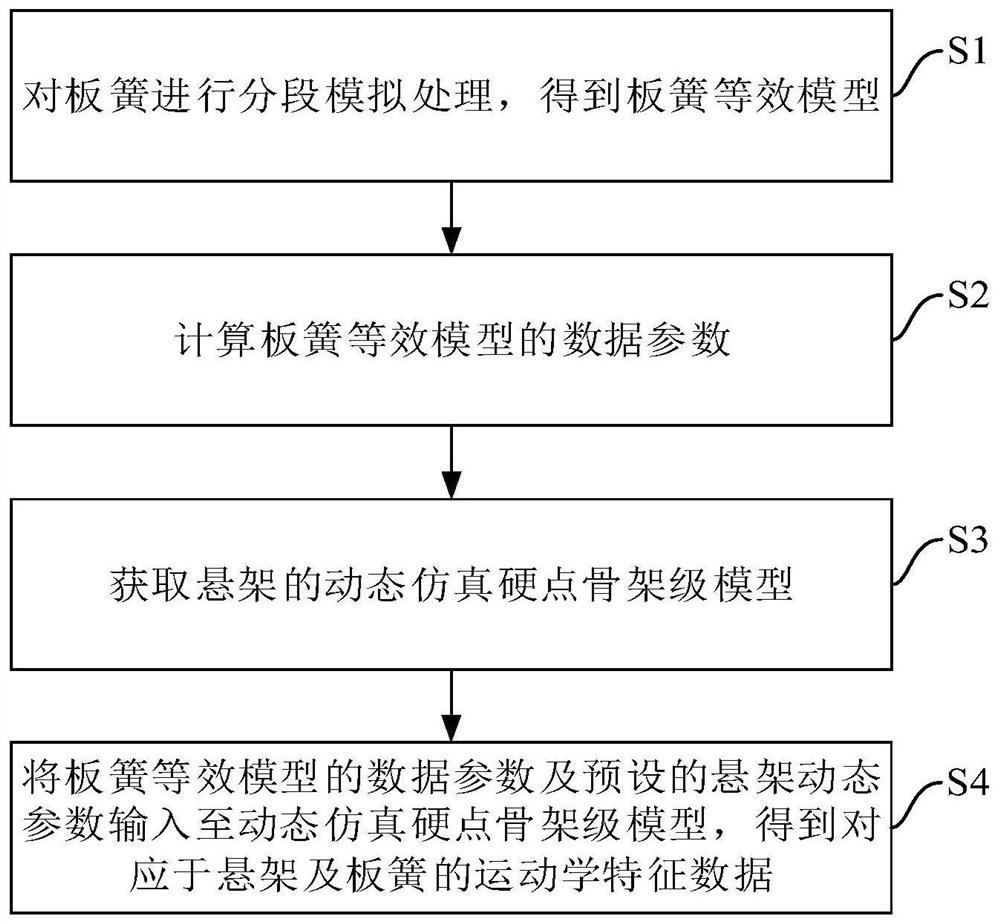

[0056] figure 1 It is a flowchart of a suspension and leaf spring motion analysis method according to an embodiment of the present invention. Such as figure 1 As shown, the suspension and leaf spring motion analysis method includes the following steps:

[0057] Step S1: Carry out segmental simulation processing on the leaf spring to obtain the equivalent model of the leaf spring.

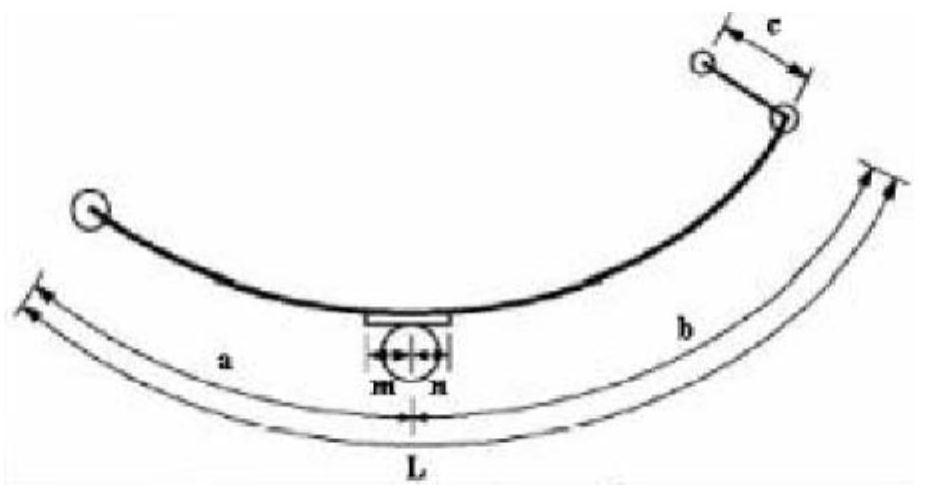

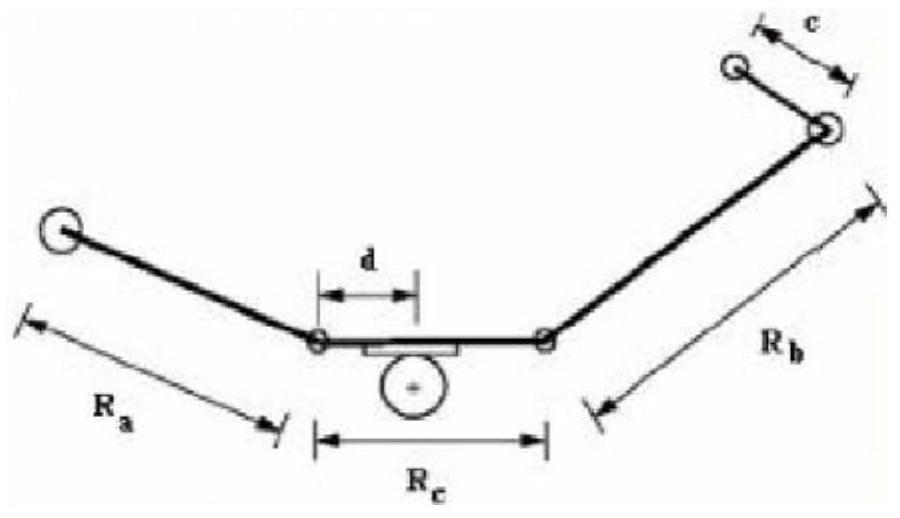

[0058] In one embodiment of the present invention, the leaf spring is simulated in sections to obtain an equivalent model of the leaf spring, including: simplifying the leaf spring to an equivalent model o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com