Equipment for fixedly installing and positioning wind power hoisting beam

A technology for hoisting beams and equipment, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve problems such as slow production speed, difficult handling or rotation, and unsatisfactory processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

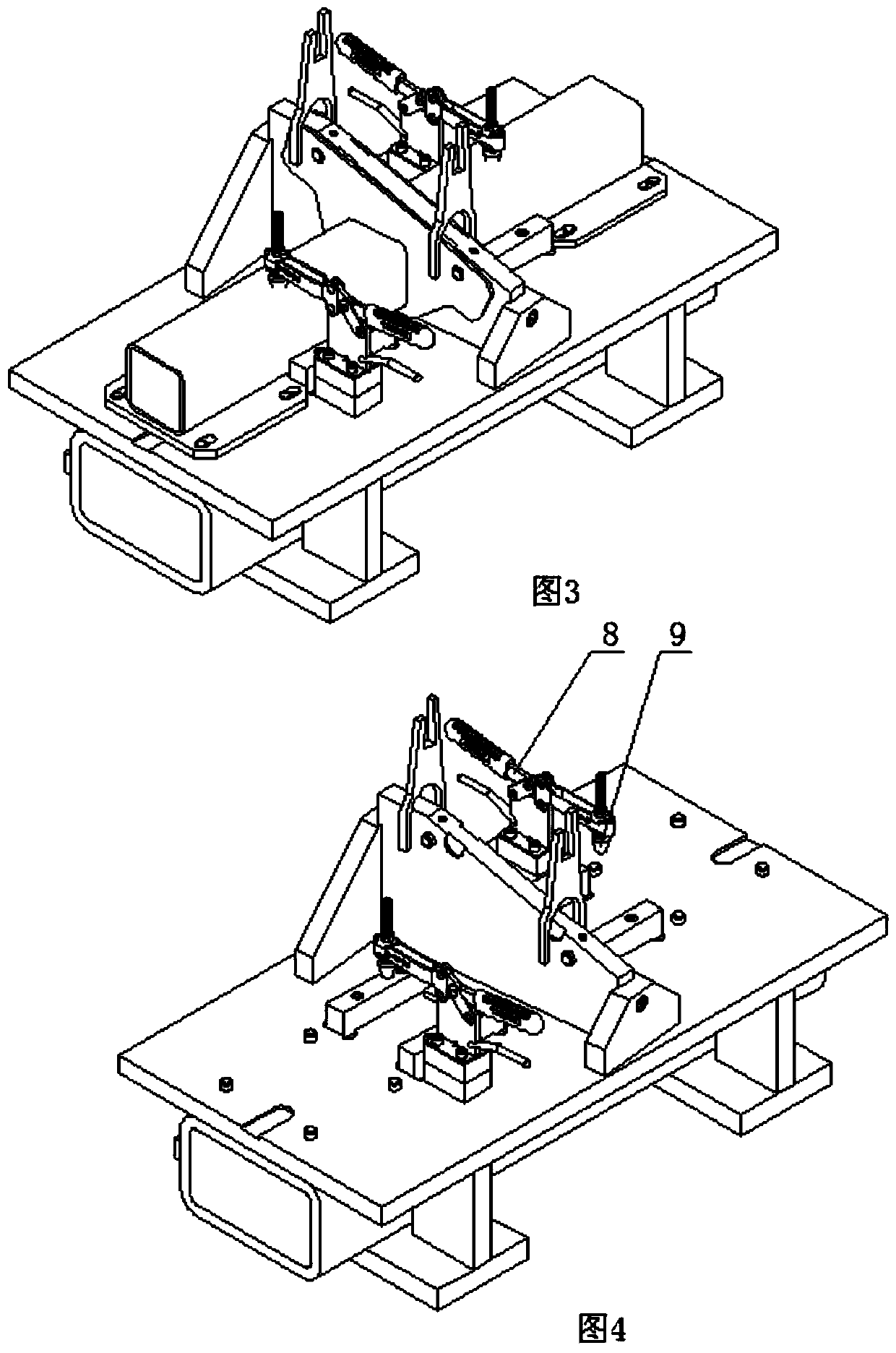

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

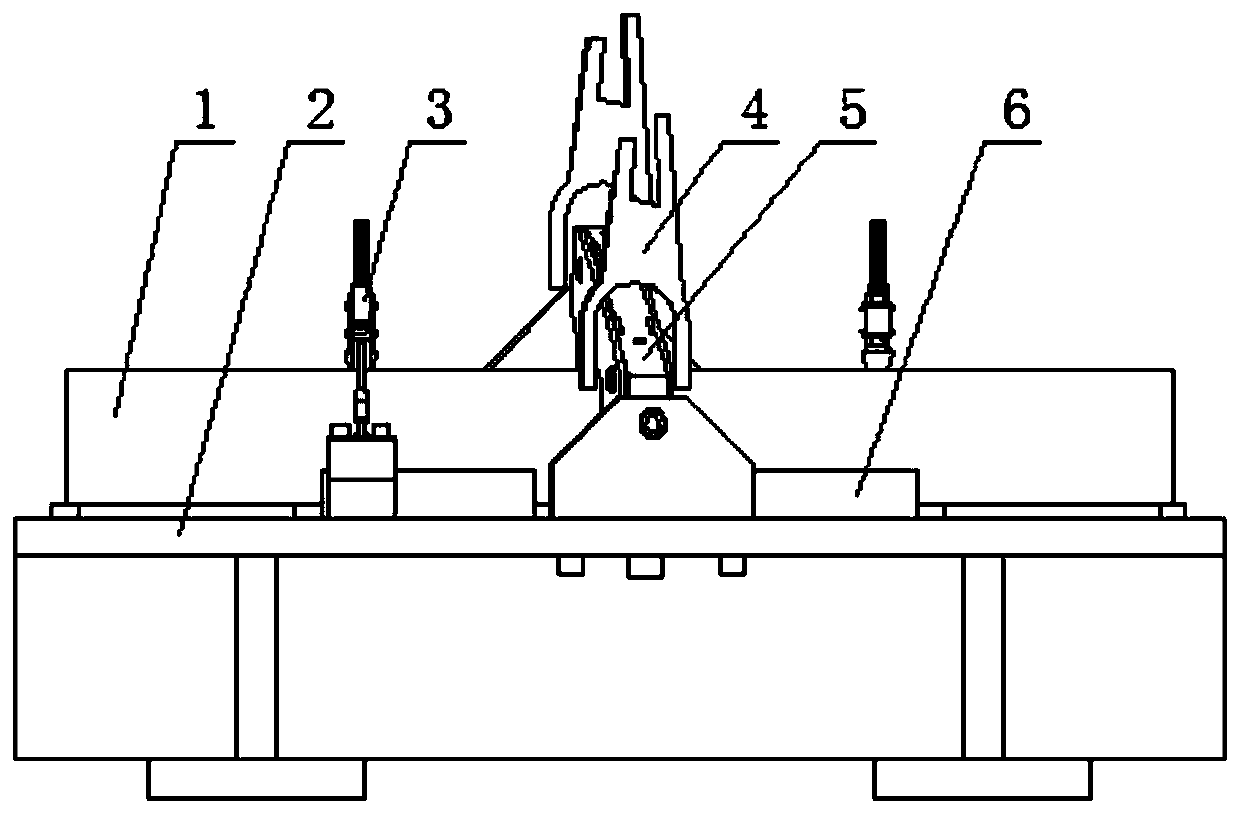

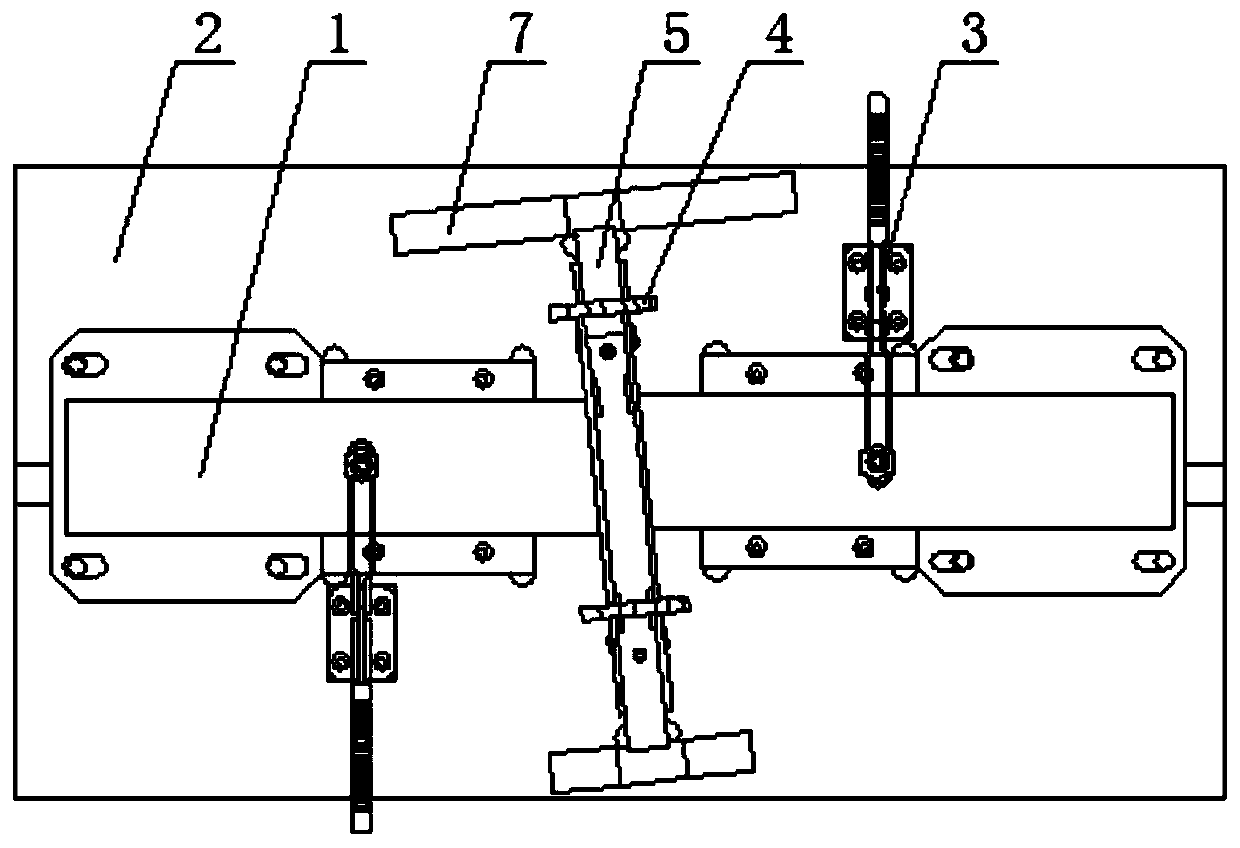

[0019] A device for fixing and positioning a wind power hoisting beam, including a workbench 2, a central positioning mechanism, a lower fixing block 6, a side plate clamping mechanism 4 and a beam fast pressing mechanism 3, and the central positioning mechanism is installed on the upper surface of the workbench The center of the center, and the center positioning mechanism is set obliquely, which divides the upper surface of the workbench into two symmetrical stations. The center positioning mechanism includes a side plate 7 and a central dividing plate 5, and there are two side plates, which are installed on the front and the rear of the upper surface of the workbench respectively, and a central dividing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com