Equipment used positioning and mounting right bracket of hoisting beam

A technology for positioning installation and hoisting beams, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve problems such as slow production speed, unsatisfactory processing quality, difficult handling or rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

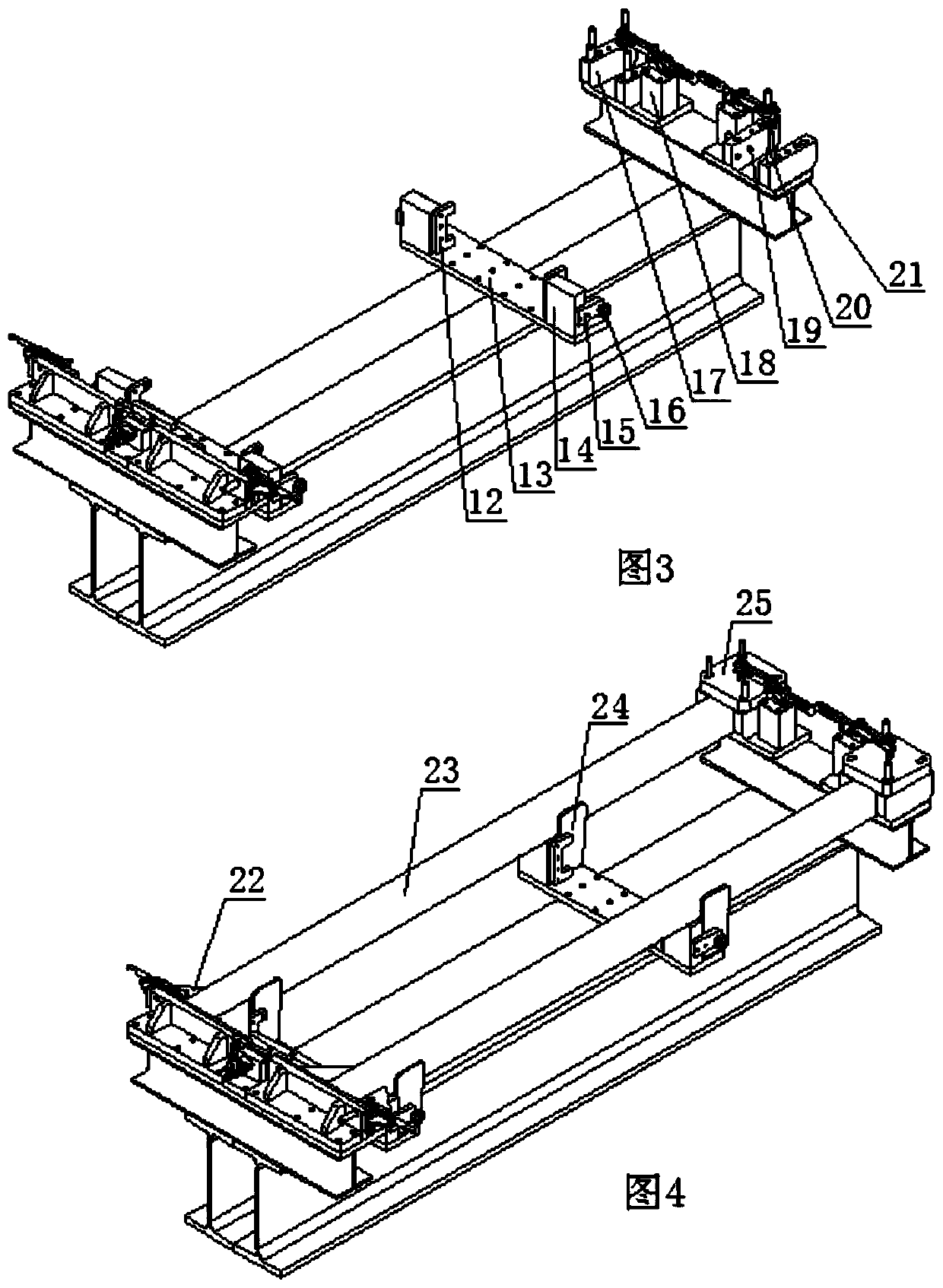

[0019] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings; it should be noted that this embodiment is narrative and not restrictive, and the protection scope of the present invention cannot be limited by this.

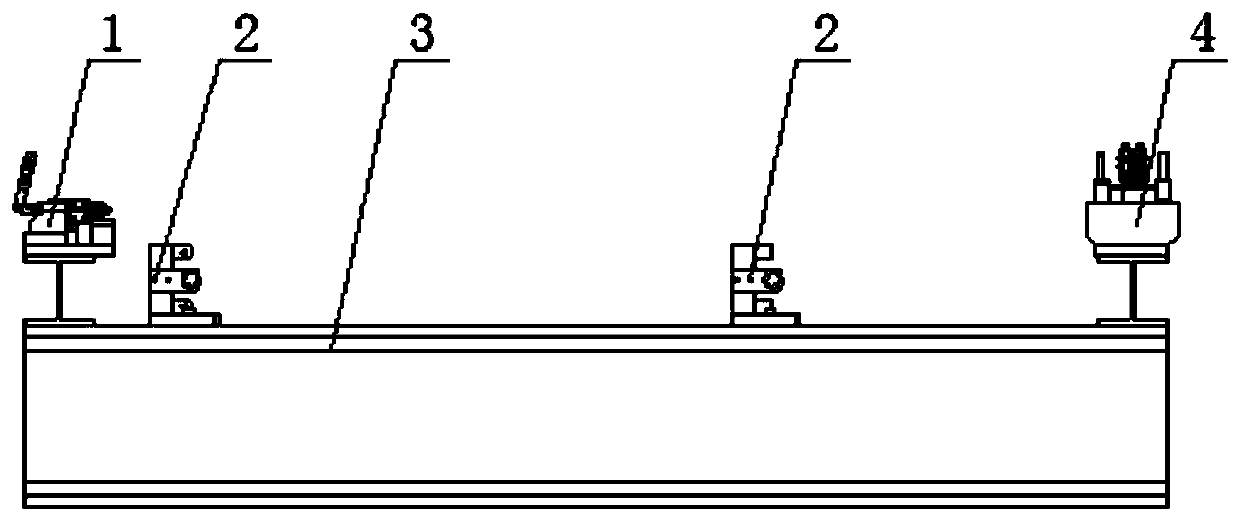

[0020] A device for positioning and installing the right support of a hoisting beam includes a workbench 3, a left end fixing mechanism 1, a side plate fixing mechanism 2 and a right end fixing mechanism 4.

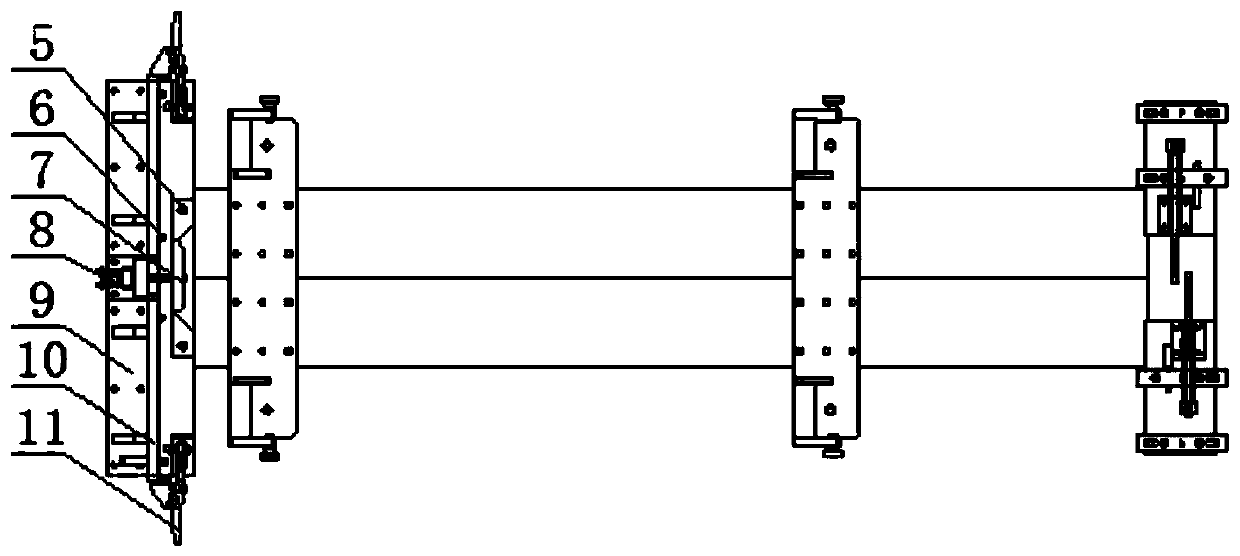

[0021] A left end fixing mechanism is installed on the left side of the upper surface of the workbench. The left end fixing mechanism includes a left base 9, a vertical plate 10, a central pressing plate 7, a horizontal top column 6, a lower positioning block 5 and a quick compression locking assembly 11. The left base A vertical vertical plate is installed on the upper surface of the vertical plate, and a quick pressure wrench 8 is installed in the middle of the vertical plate. The end of the quick pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com