Supporting beam assembling equipment high in clamping precision

An assembly equipment, high-precision technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment and other directions, can solve the problems of affecting the processing quality of workpieces, many rework phenomena, and large volume of wind power support beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

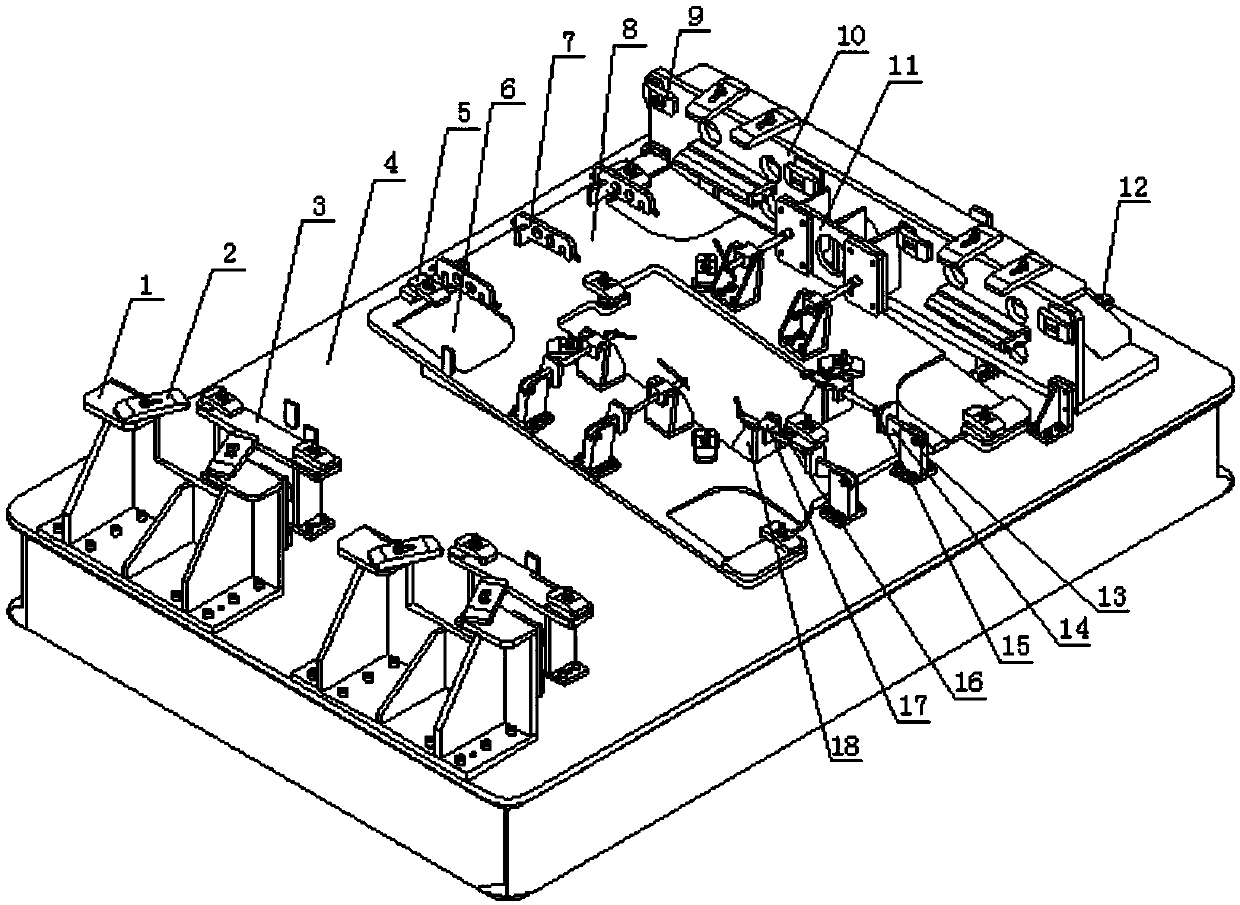

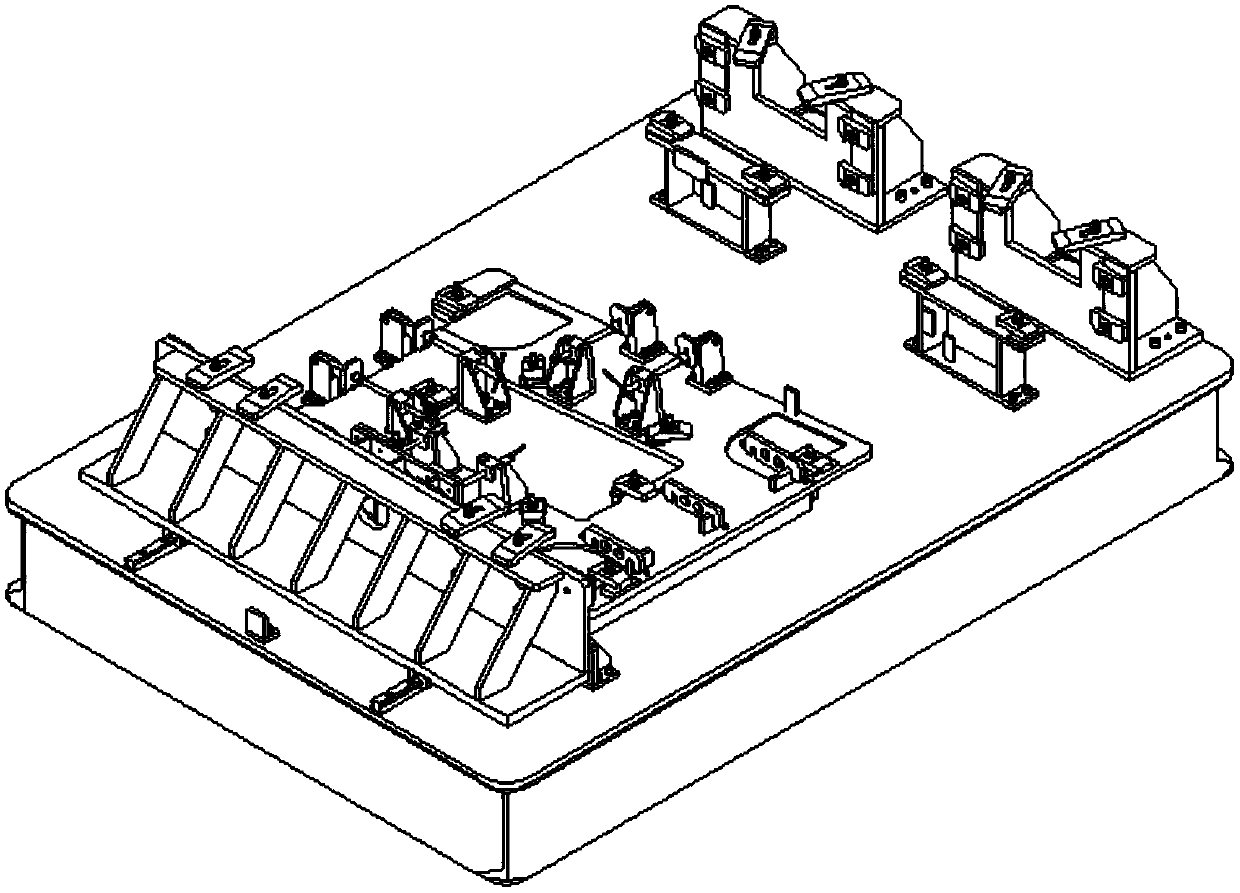

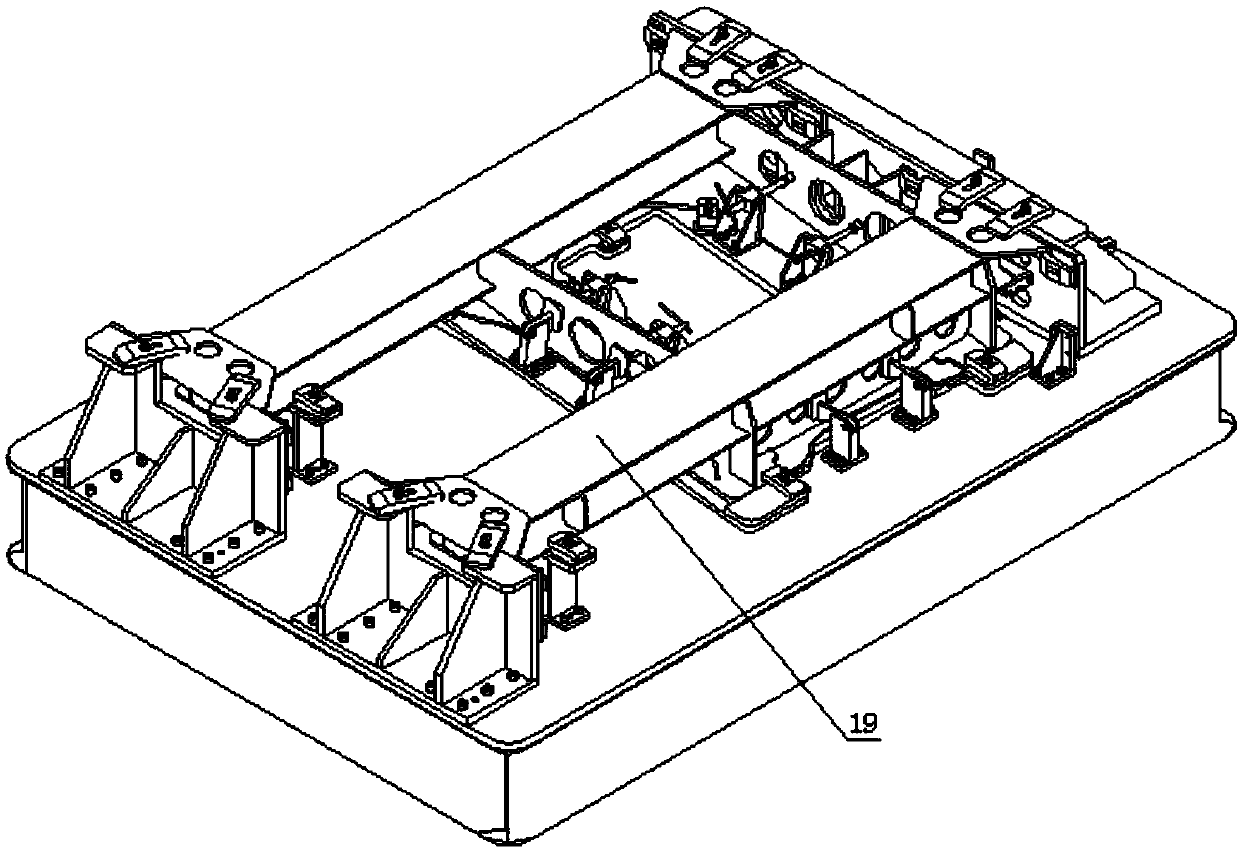

[0021] A support beam assembly device with high clamping precision, comprising a base 4, a workbench 8, a lower pressure plate 5, an upper pressure plate 2, a side pressure plate 9, a side positioning mechanism, a side tightening mechanism, a sliding end positioning mechanism and a fixed type end positioning mechanism. The lower pressing plate, the upper pressing plate and the side pressing plate are all made with long holes, and the top wires are worn in the long holes.

[0022] A workbench is installed on the upper surface of the base, and positioning grooves 6 are respectively made in the middle part and four corners of the workbench, and a lower pressing plate is all installed on the workbench on each positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com