Fixing device for machining end face position holes of supporting frame

A technology of fixing equipment and support frame, which is applied in metal processing equipment, positioning devices, metal processing mechanical parts, etc., can solve the problems of time-consuming and laborious, long time for disassembling and assembling workpieces, and reducing workpiece processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

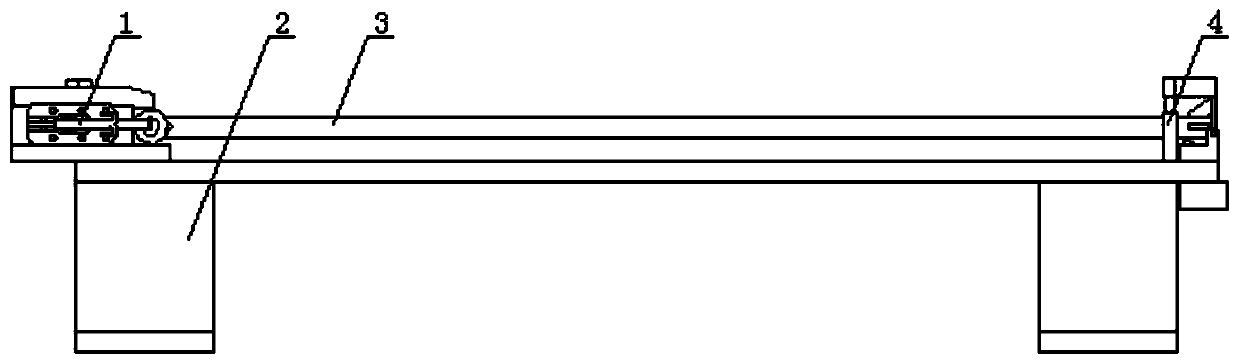

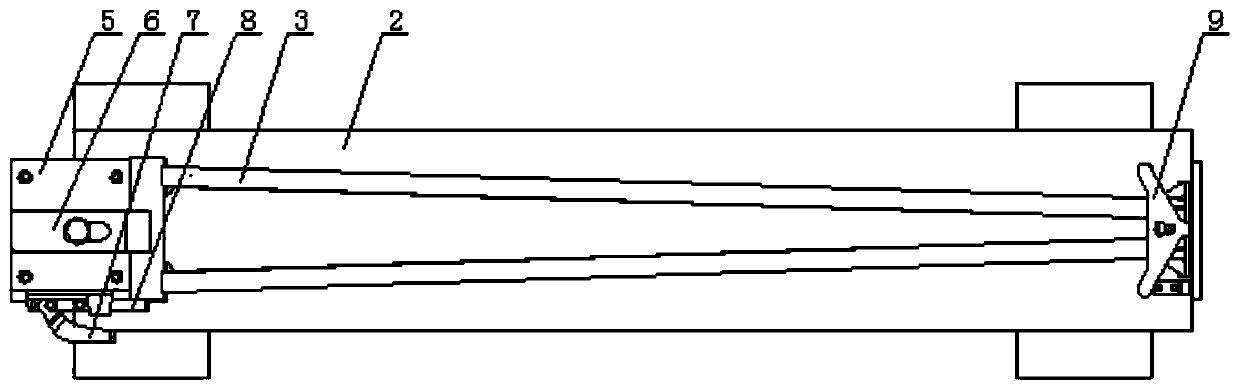

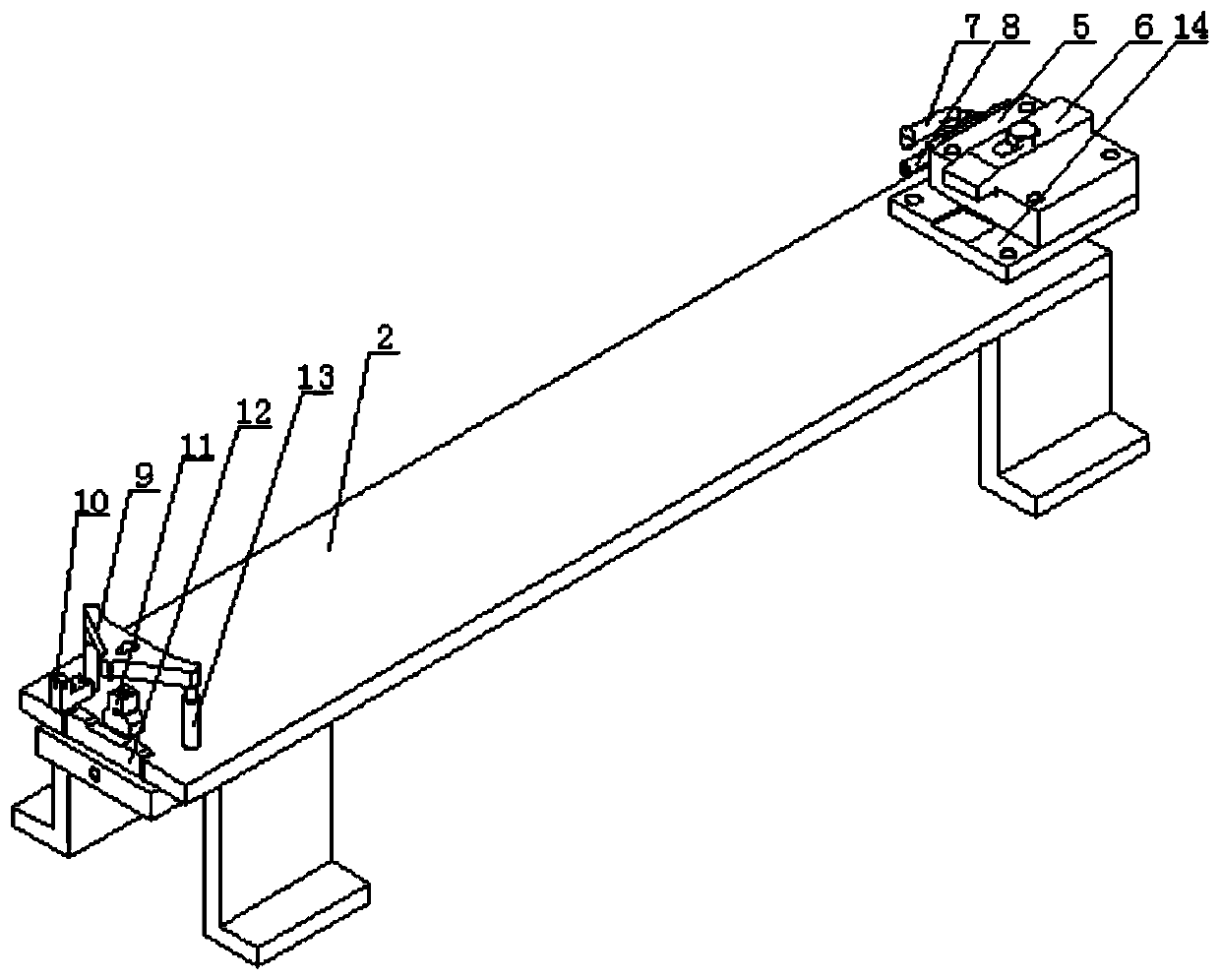

[0019] A fixing device for machining end face position holes of a support frame, comprising a base 2 , a left positioning mechanism 1 and a right positioning mechanism 4 .

[0020] The left positioning mechanism includes a fixed block 5, an upper pressure plate 6, a quick-press wrench 7 and a positioning bar 8. The left side of the upper surface of the base is equipped with a fixed block, and the right side of the fixed block forms a positioning bar for placing workpieces. Slot 14. An upper pressing plate is installed on the upper surface of the fixed block, and a long hole is made on the upper pressing plate, and a top wire is installed in the long hole. above the slot. A quick-press wrench is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com