Loading system of packaging unit in civil cabin

A loading system and technology in the engine room, applied in the direction of cooperative devices, computer components, instruments, etc., can solve the problems of lack of automatic verification means and methods, increase verification and guarantee links, and reduce the cost of wrongly loaded container units Probability, the effect of improving aircraft safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution provided by the present invention will be explained in detail below in conjunction with the accompanying drawings.

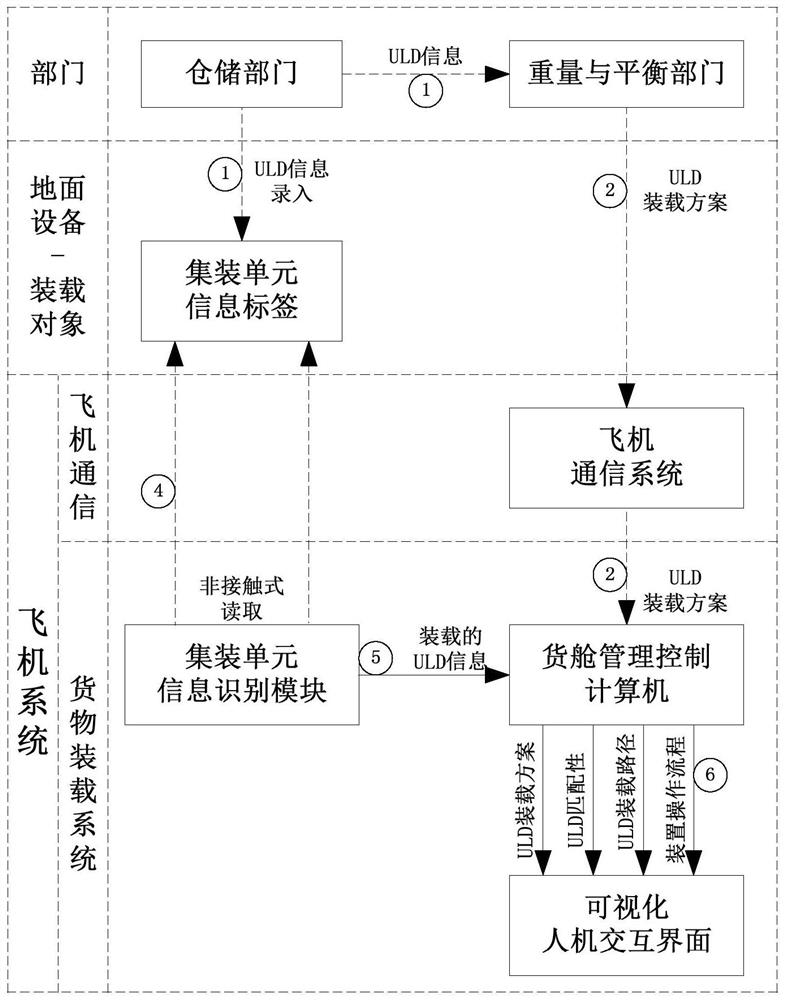

[0024] figure 1 It is a schematic diagram of the information transmission process of the loading system of the containerized unit in the civil aircraft cabin provided by the present invention, as shown in figure 1 As shown, the present invention proposes a position monitoring and loading method in the container unit of civil aircraft, which can realize the monitoring of the final position of the container unit in the cargo compartment and reduce the skill requirements for operators.

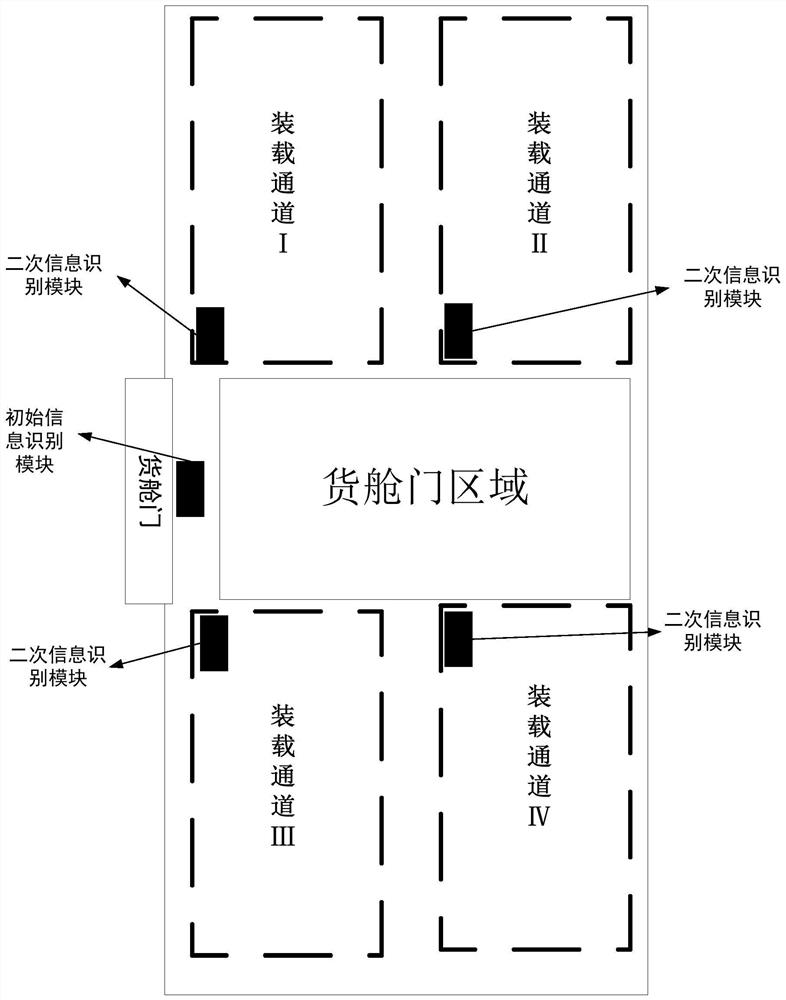

[0025] The present invention is based on the current airport logistics system and the typical architecture of the civil aircraft cargo loading system, adopts non-contact information identification technology (such as two-dimensional code technology, RFID technology, NFC technology, etc.), and cooperates with ground information management and editing eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com