Special positioning and clamping equipment for assembling wind power boundary beam

A side beam and clamping technology, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of low workpiece positioning accuracy, slow workpiece disassembly speed, and affecting workpiece processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

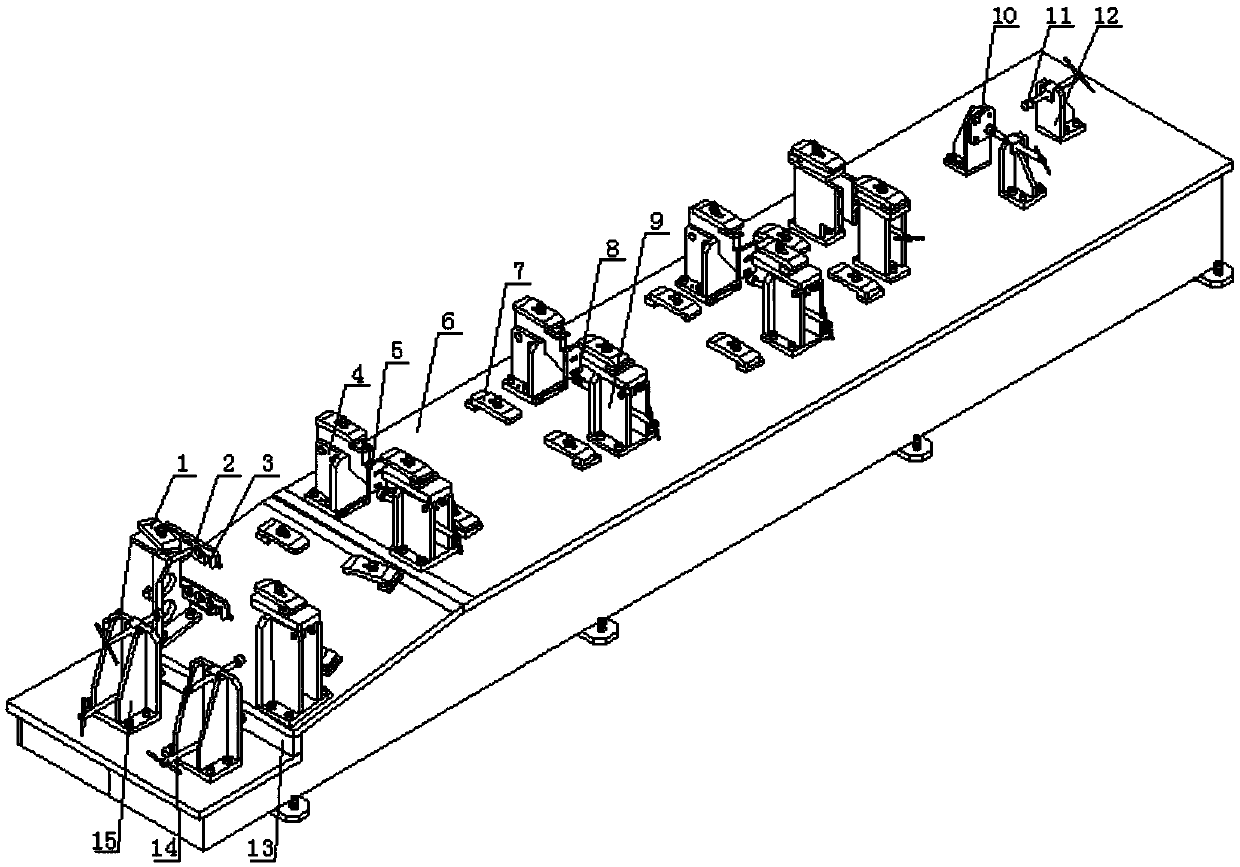

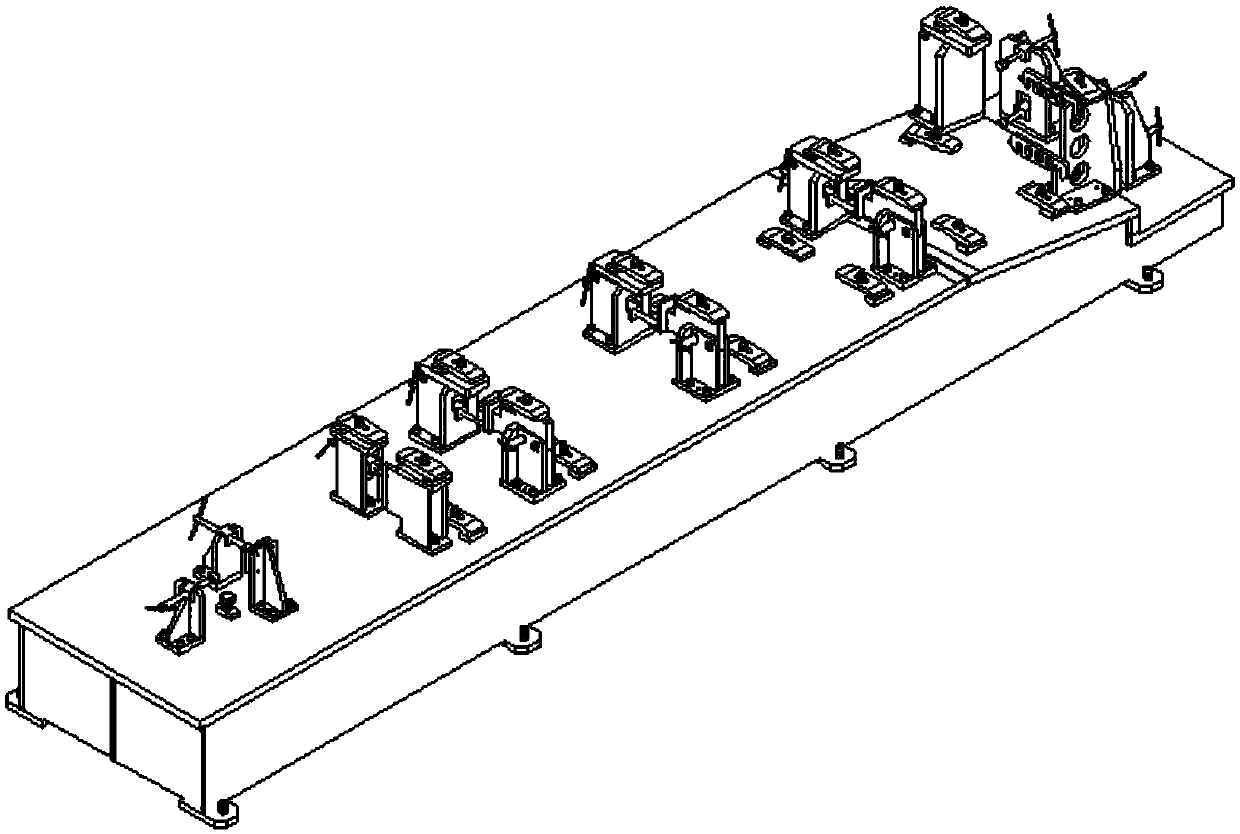

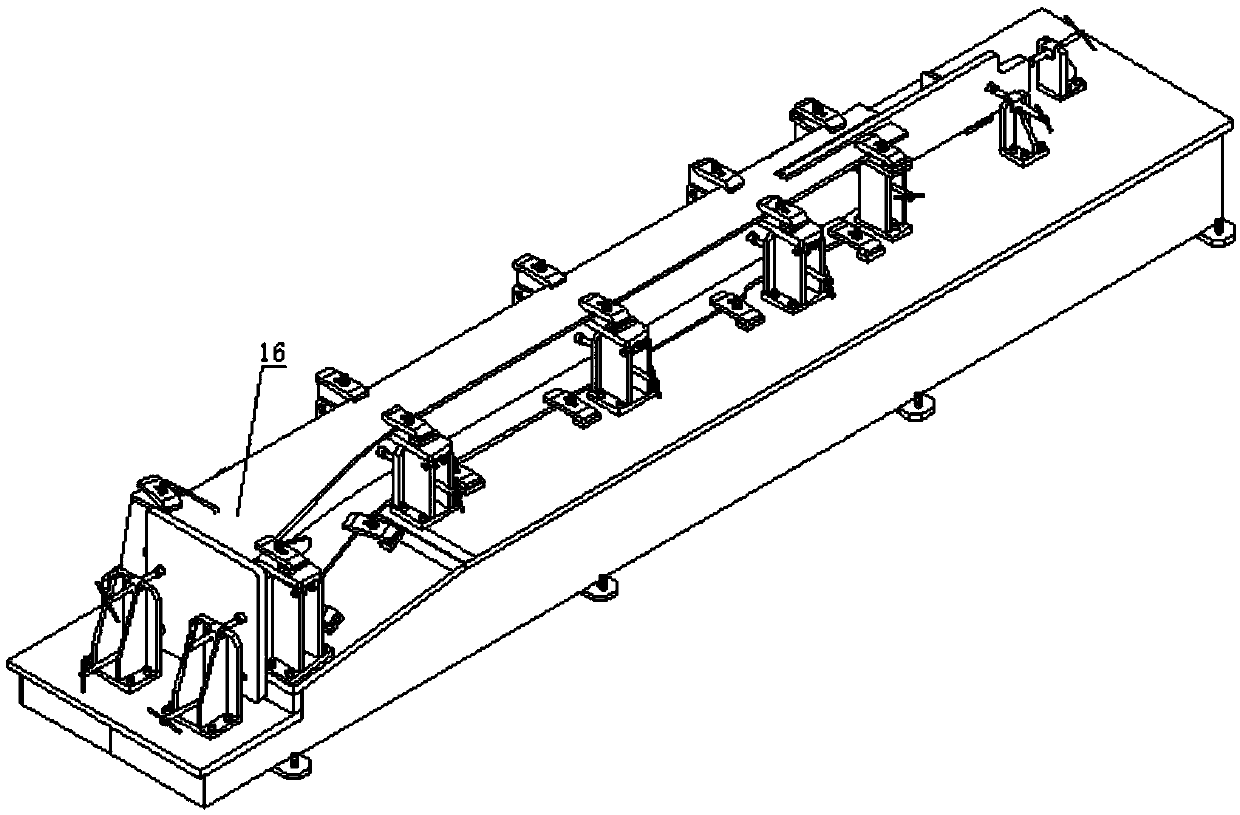

[0019] A positioning clamping device specially used for wind power side beam assembly, including a workbench 6, a left end plate tightening mechanism, a lower pressure plate 7, a vertical plate positioning mechanism, a vertical plate tensioning mechanism, an upper pressure plate 1 and a rear fork plate positioning and tightening mechanism.

[0020] A vertical positioning surface 13 is made on the left side of the workbench upper surface, and the left end plate jacking mechanism is installed on the workbench upper surface on the left side of the positioning surface. The left end plate tightening mechanism is two symmetrically arranged, and each left end plate tightening mechanism includes a support 15 and a top c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com