Gantry type double-blade multi-axis numerical control cutting-carving all-in-one machine

A gantry type, all-in-one machine technology, applied in the field of gantry type double-knife multi-axis CNC cutting and engraving all-in-one machine, can solve the problems of low production efficiency, many auxiliary man-hours, single function, etc., to save auxiliary man-hours, improve work efficiency, reduce The effect of loading errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

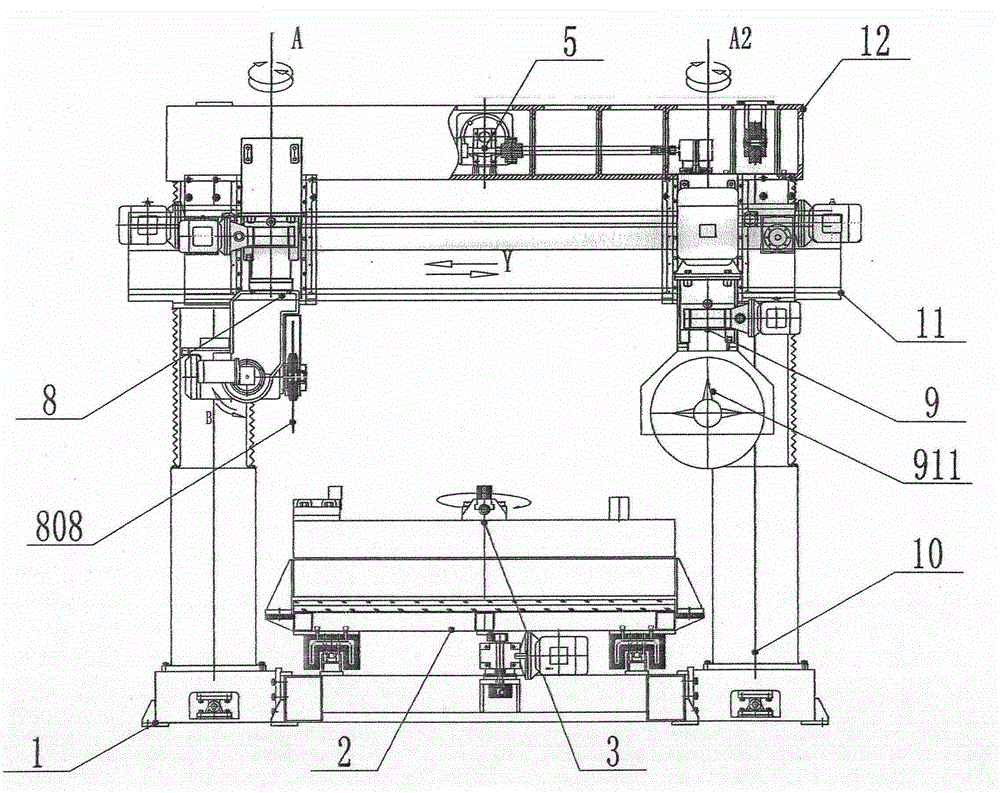

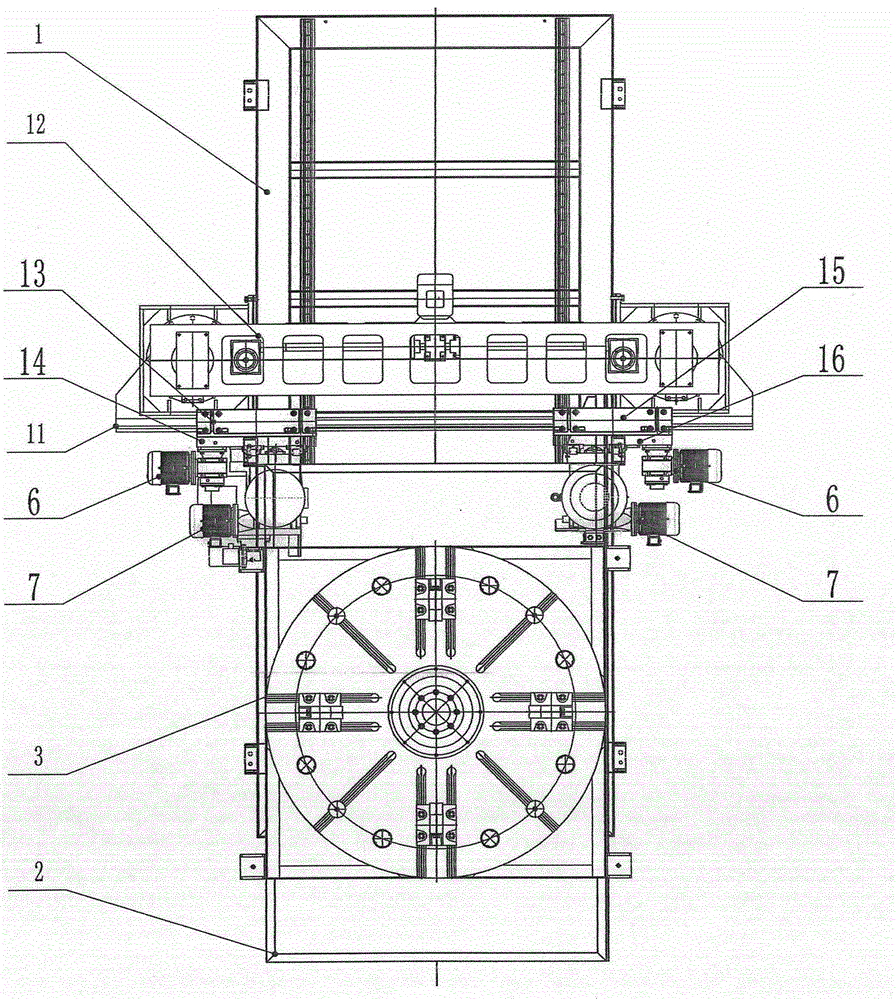

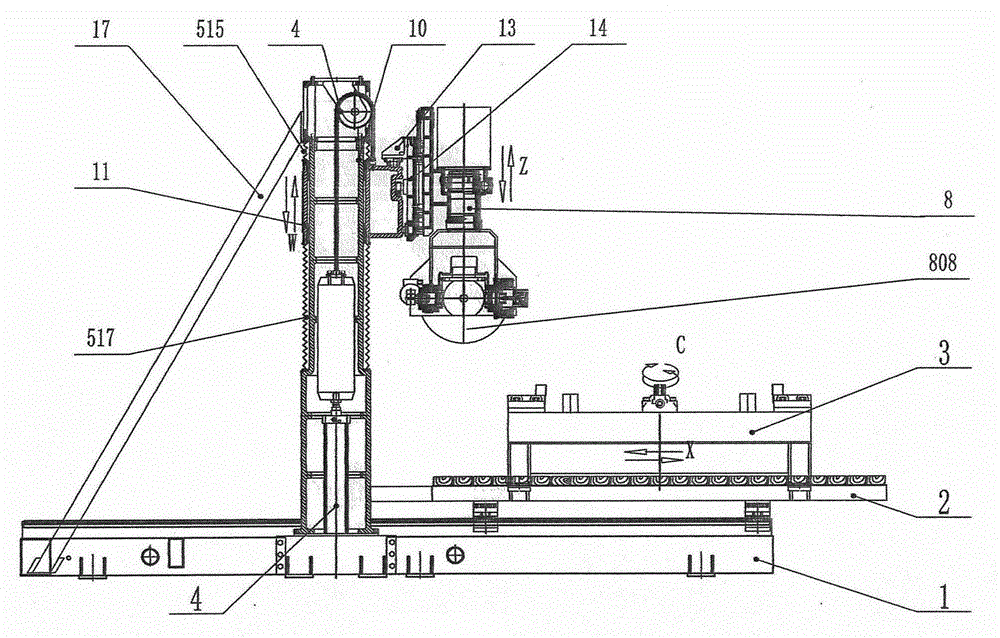

[0147] A gantry-type double-knife multi-axis CNC cutting and carving machine, according to Figure 1-3 As shown, it includes: the main base 1, the column 10 and the top beam 12 are fixed as a gantry structure, the beam 11, the translation workbench 2, and the power head assembly, and the power head assembly is two: the first power head assembly 8 and the second power head assembly 9, the first power head assembly 8 and the second power head assembly 9 are rotated through two identical worm gear rotary actuators 7 respectively, and are passed through two identical linear guide rail pairs 825 and The linear guide pair 932 is respectively connected to the left cross slide 14 and the right cross slide 16, and is respectively driven by the first hydraulic mechanism 822 and the second hydraulic mechanism 930 along the two same linear guide pairs 825 and 932, that is, the Z axis. Sliding fit, the left cross slide 14 and the right cross slide 16 are arranged on the left and right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com