Loading method and loading device for fatigue test

A technology for fatigue testing and loading equipment, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc. It can solve the problems of large loading load error, small fatigue test load, and inability to fix, and achieve reduction Load error, high reliability, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

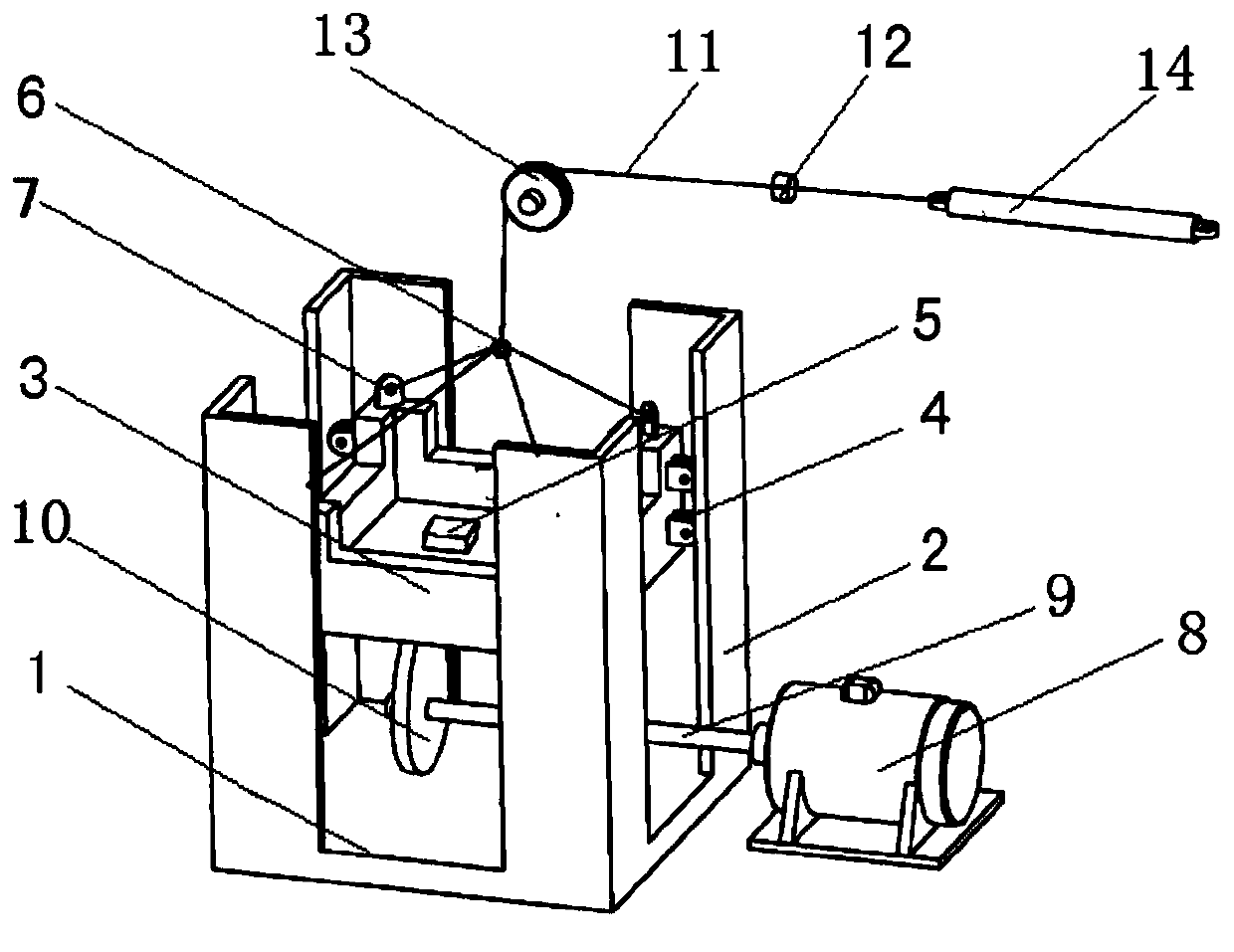

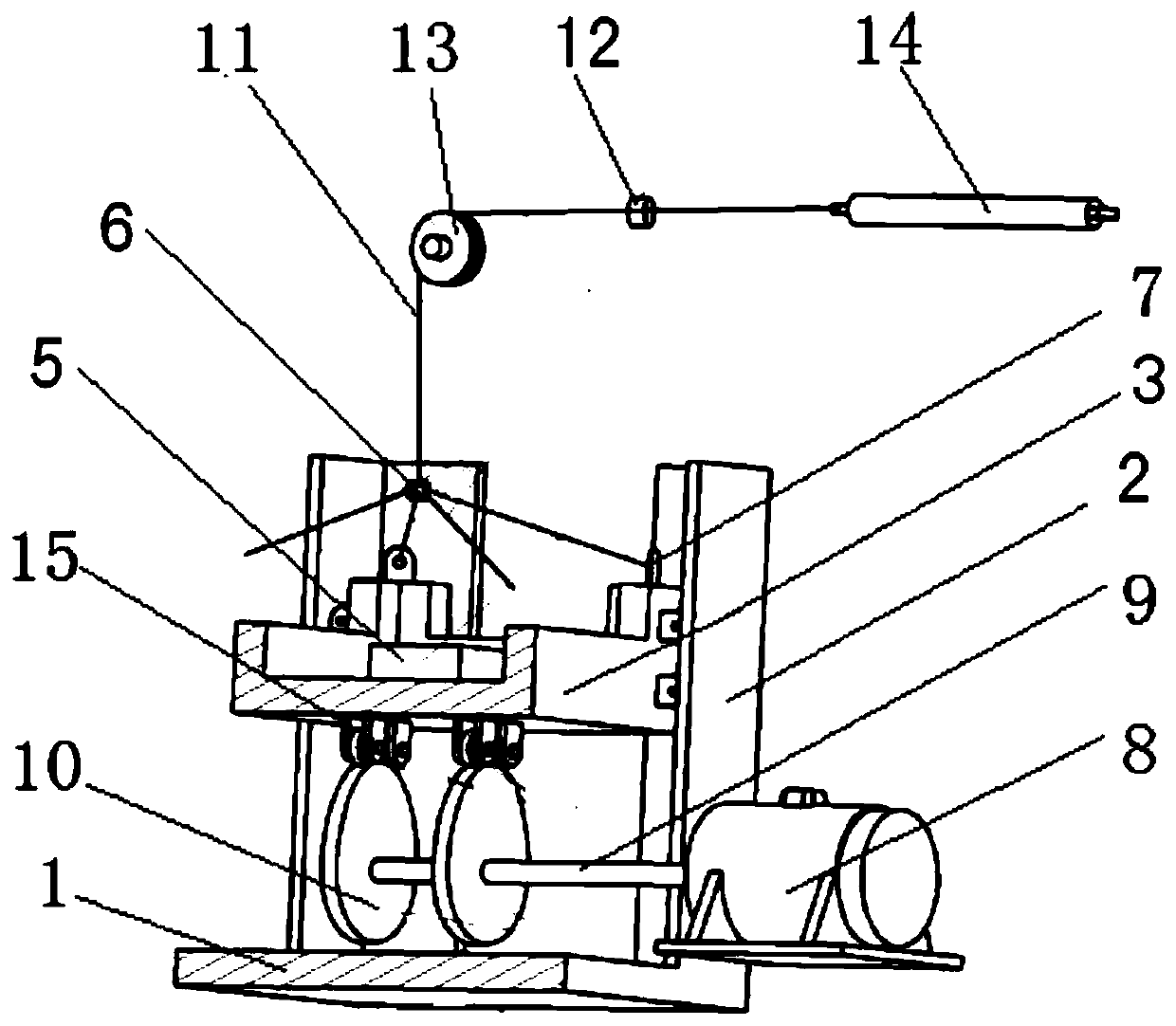

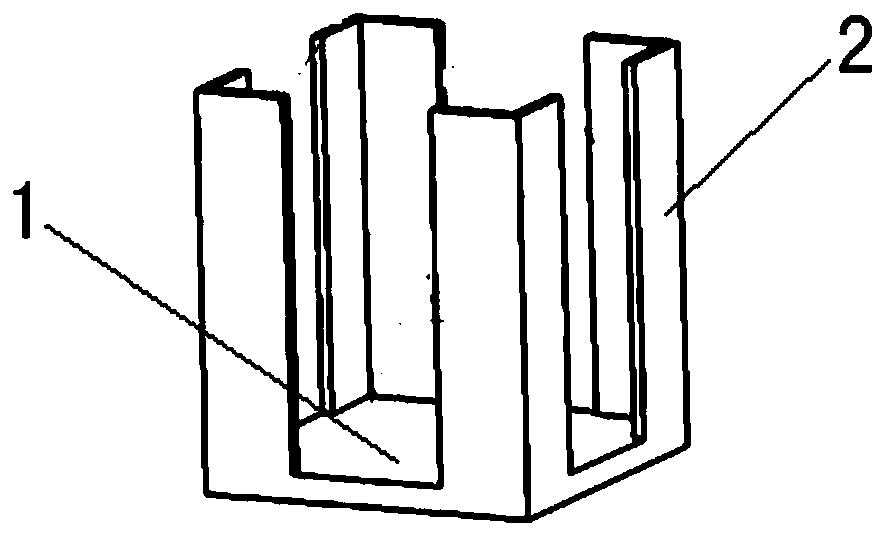

[0017] Referring to the accompanying drawings, the loading equipment for the fatigue test provided by the application contains a loading device and a power unit, and the loading device contains a displacement limiting base 1, a loading platform 3, and a loading mass 5, and the displacement limiting The base 1 contains a plurality of parallel vertical slide rails 2, and the loading platform 3 is provided with a plurality of displacement pulleys 4, which are matched with the vertical slide rails 2 on the displacement limiting base 1, so that the loading platform 3 can slide vertically The rail 2 moves up and down, the bottom of the loading platform 3 is provided with a transmission pulley 15, and the upper end of the loading platform 3 is provided with a traction point 6. The loading mass 5 can be placed on the loading platform 3, and the power device includes a motor 8 And cam 10, cam 10 is positioned on the transmission shaft 9 of motor 8, and cam 10 matches with the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com