Automatic feeding equipment

A technology of equipment and materials, applied in the field of automatic feeding equipment, can solve problems such as easy confusion, increased labor intensity of workers, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

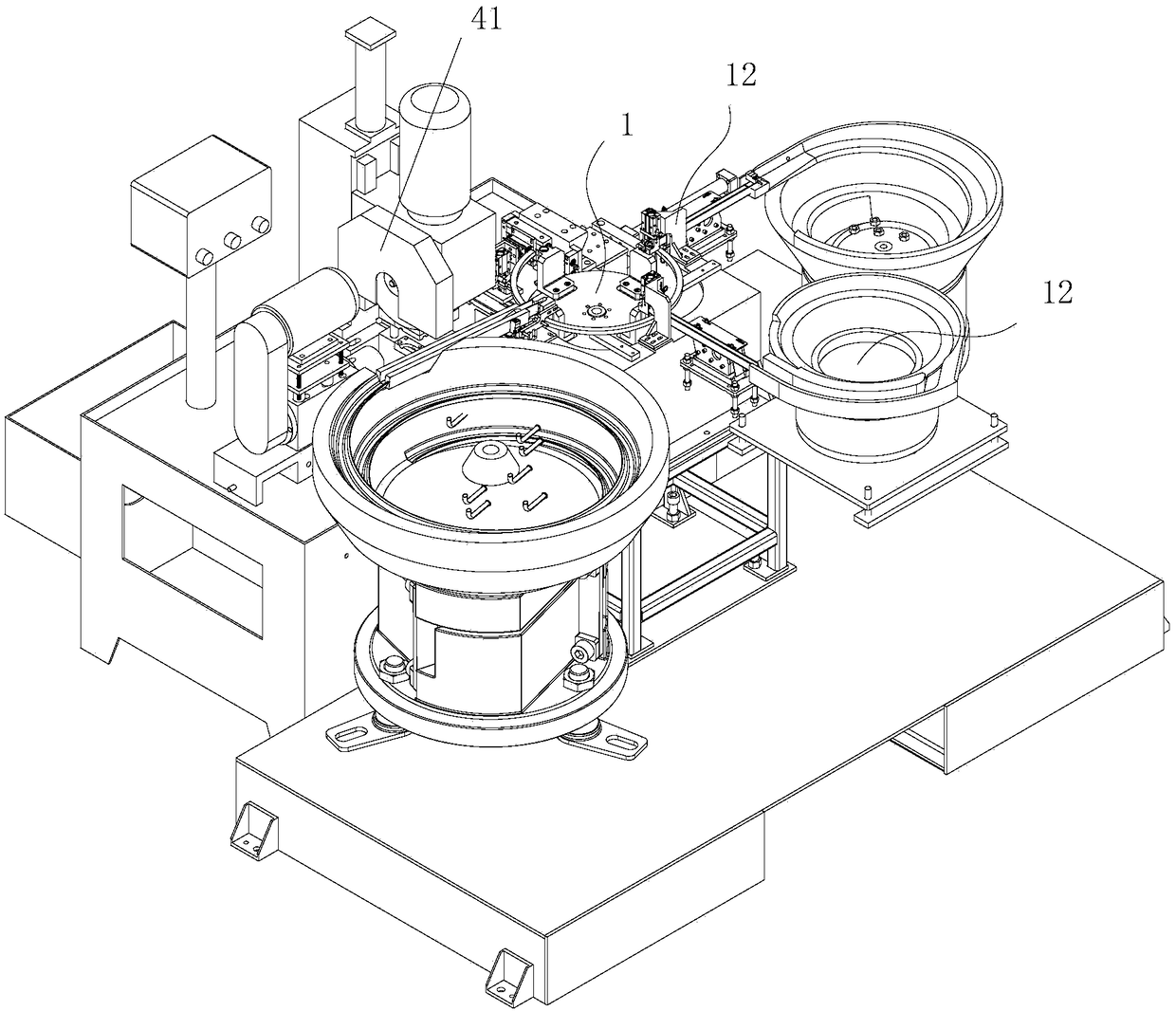

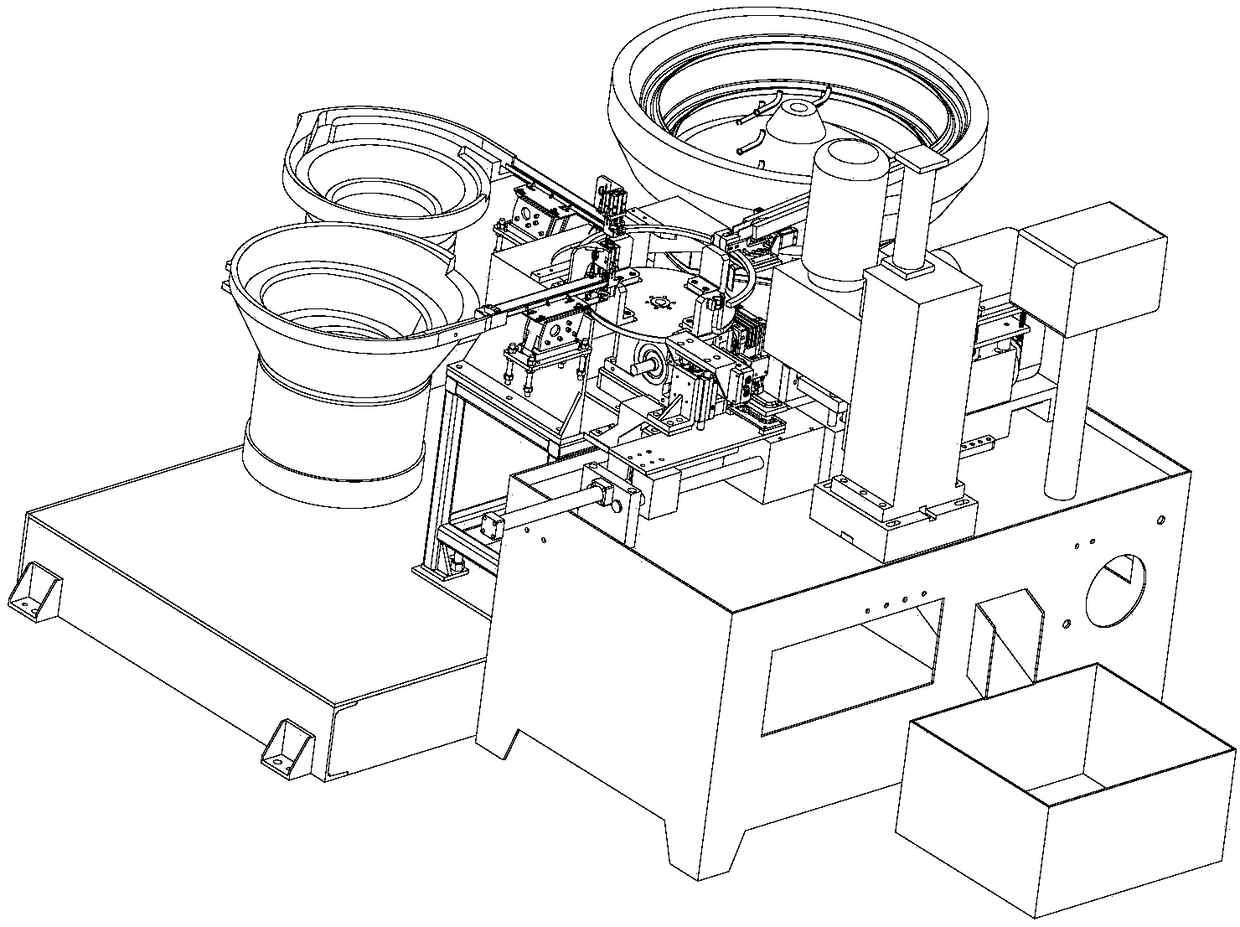

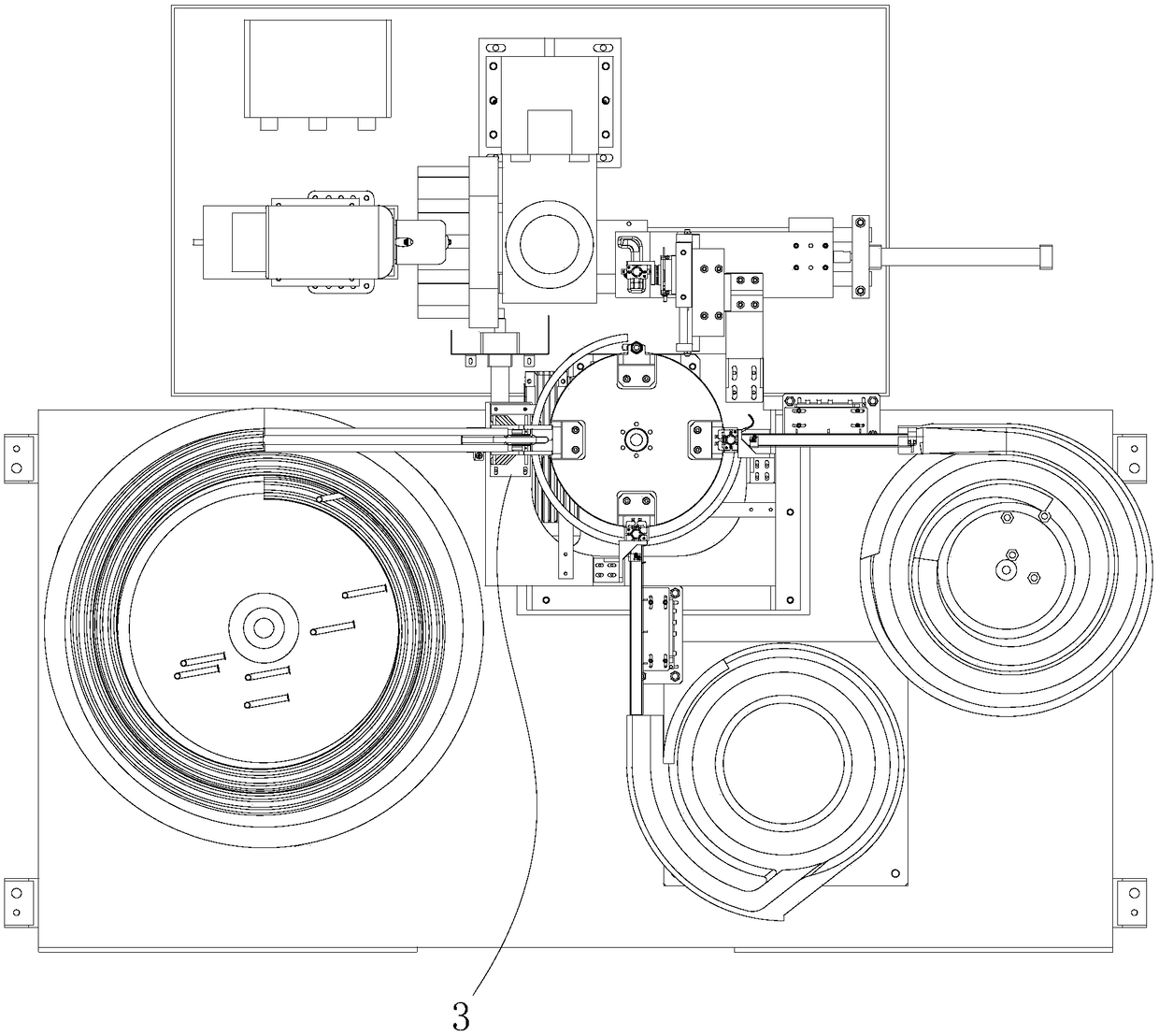

[0076] Such as Figure 1 to Figure 3 , Figure 20 As shown, this embodiment discloses an automatic feeding device, which mainly includes a feeding frame 13, a driving device 1 mounted on the feeding frame 13 for driving material rotation, placing the first and second The positioning and discharging device 12 for the second material, the positioning and turning device 3 for placing the third material, and the clamping and feeding device 43 for clamping the serially connected materials. The loading frame 13 is arranged on the front side of the processing equipment 41 . The driving device 1 is installed in the middle of the feeding frame 13, and adopts a four-station rotation design. The positioning and discharging device 12 is set as two groups. Two groups of the positioning and discharging device 12, the positioning and turning device 3, and the clamping and feeding device 43 are arranged around the driving device 1 at equal intervals in the circumferential direction. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com