Demolding and counting machine as well as demolding and arranging device therein

A sorting device and demoulding technology, which is applied to other household appliances, household components, household appliances, etc., can solve the problems that affect the clamping efficiency of the demoulding point machine, cannot put gloves neatly, and speed up quickly, etc. Achieve the effect of improving clamping efficiency, reducing labor intensity and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

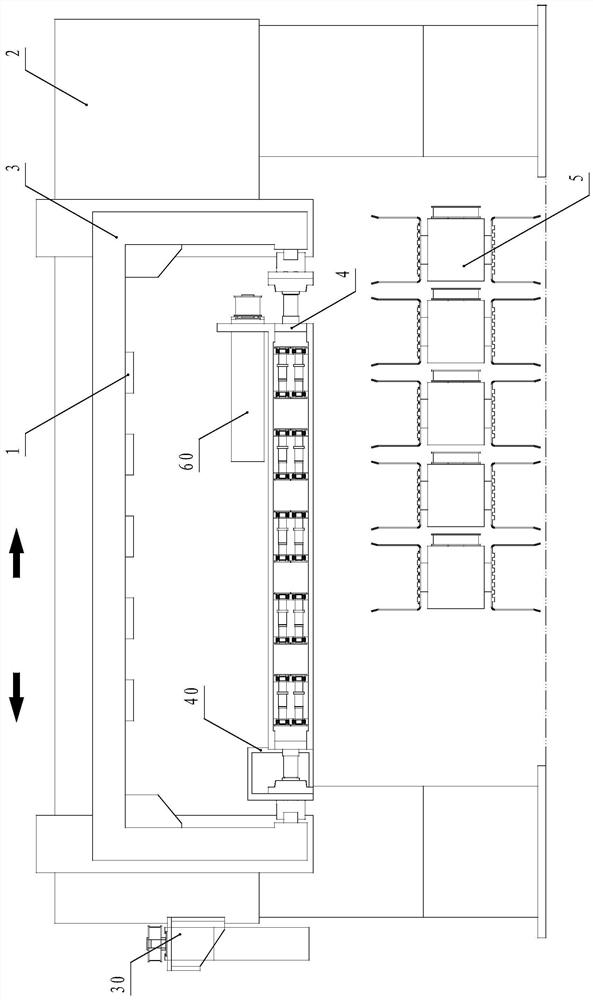

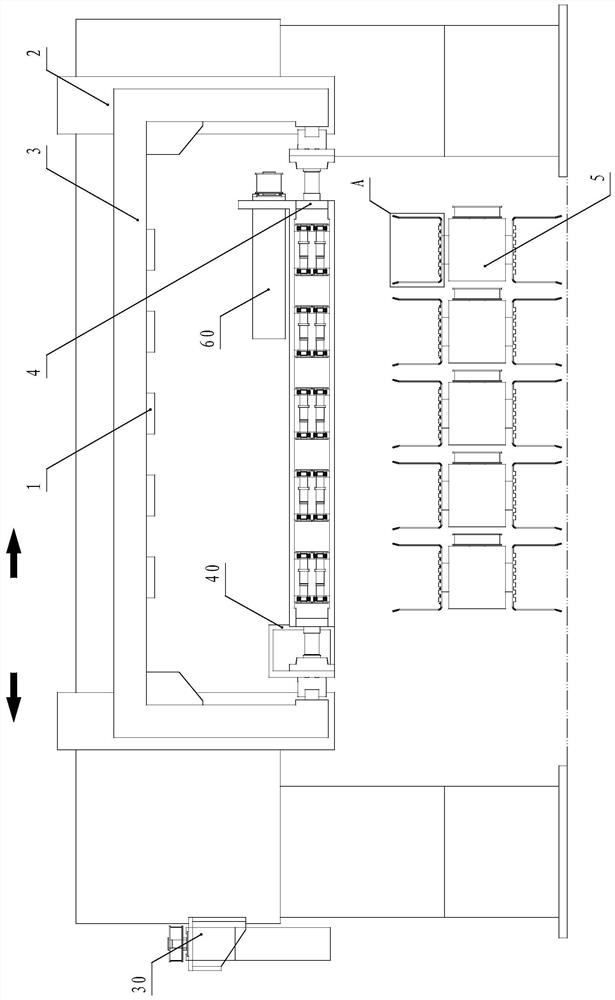

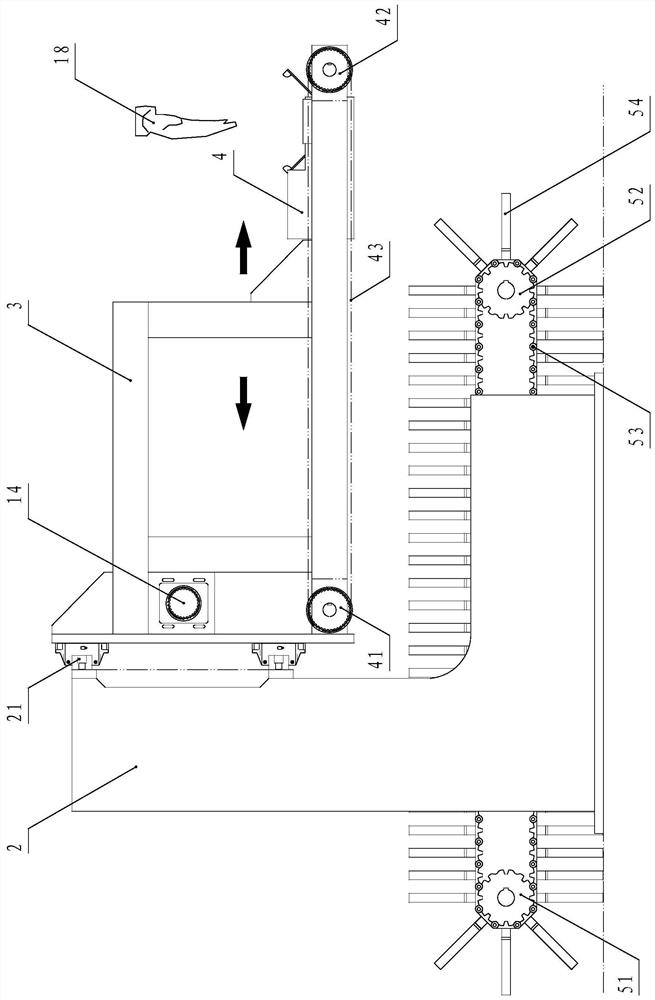

[0030] like Figure 1 to Figure 4 As shown, a kind of demoulding counting machine of the present invention comprises: frame (belonging to the common technology in the art, not shown in the figure) and demoulding finishing device, the specific structure of demoulding finishing device comprises: base 2 , the base 2 is slidably provided with a following mobile frame 3 by a pair of linear guide rails 21, and the base 2 is also provided with a follow-up drive mechanism (belonging to the conventional technology in the art) that is used to drive the follow-up mobile frame 3 to move and includes a follow-up drive motor 30. , no longer described), the following mobile frame 3 is provided with a glove finishing sliding frame 4 that can move along the sliding direction perpendicular to the following moving frame, and a glove finishing sliding drive motor for driving the glove finishing sliding frame 4 to slide 40. A sliding drive mechanism including at least one pair of timing pulleys 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com